Piston for an internal combustion engine

A technology for internal combustion engines and pistons, applied in the field of internal combustion engine pistons, can solve difficult and impossible problems, and achieve the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

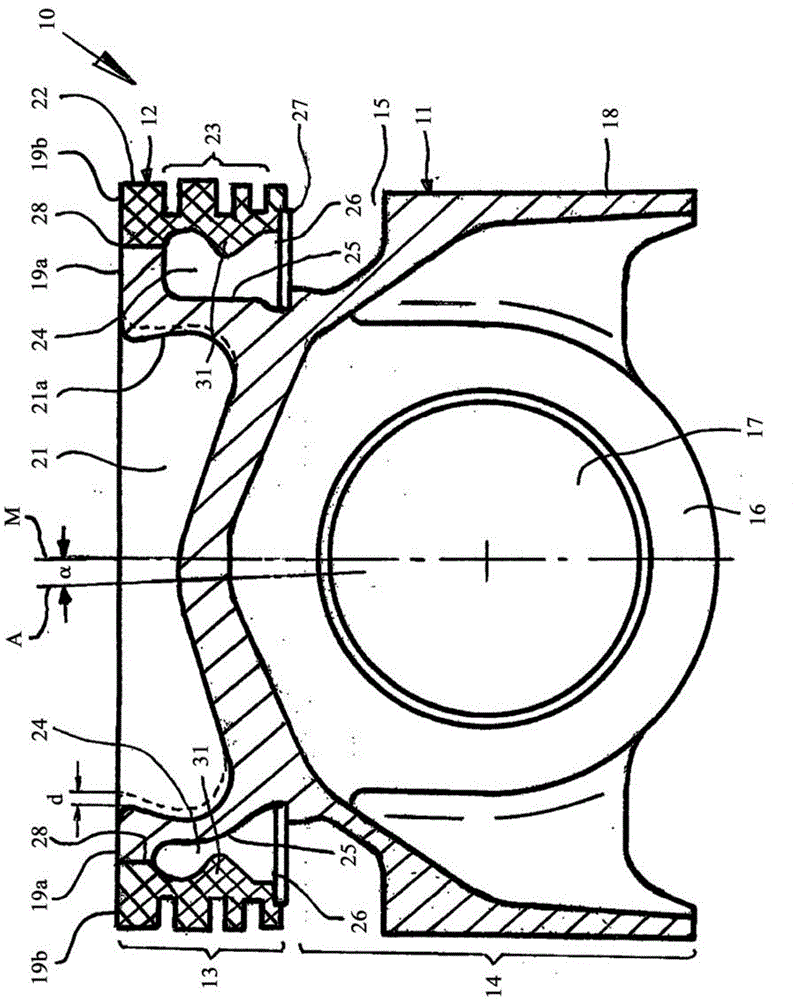

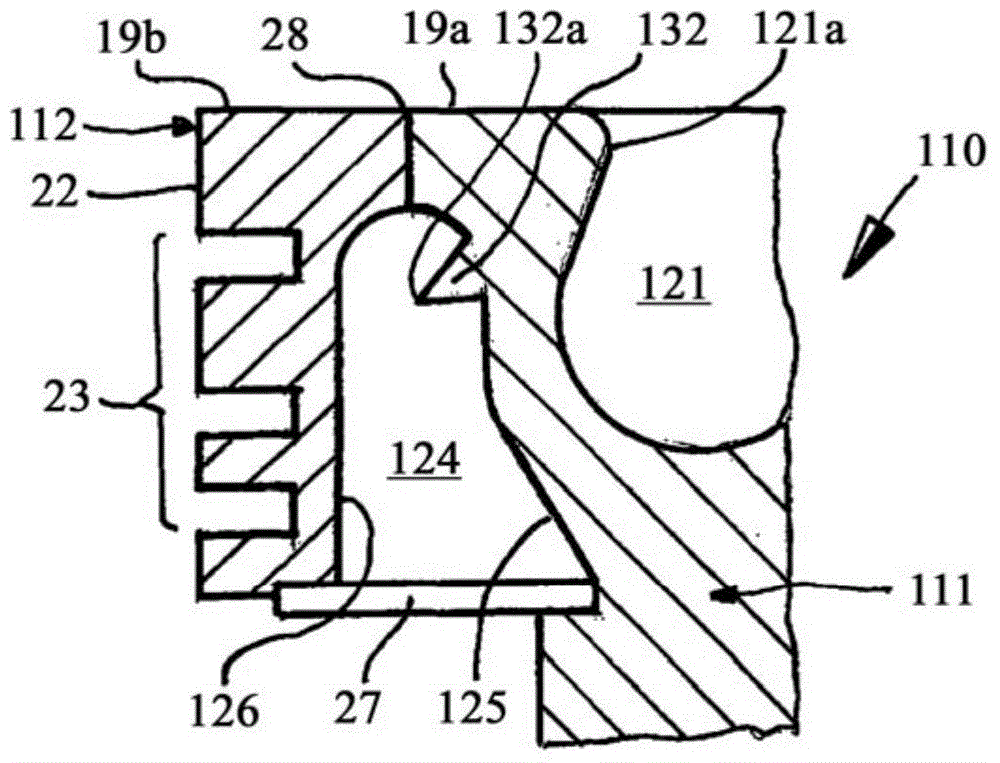

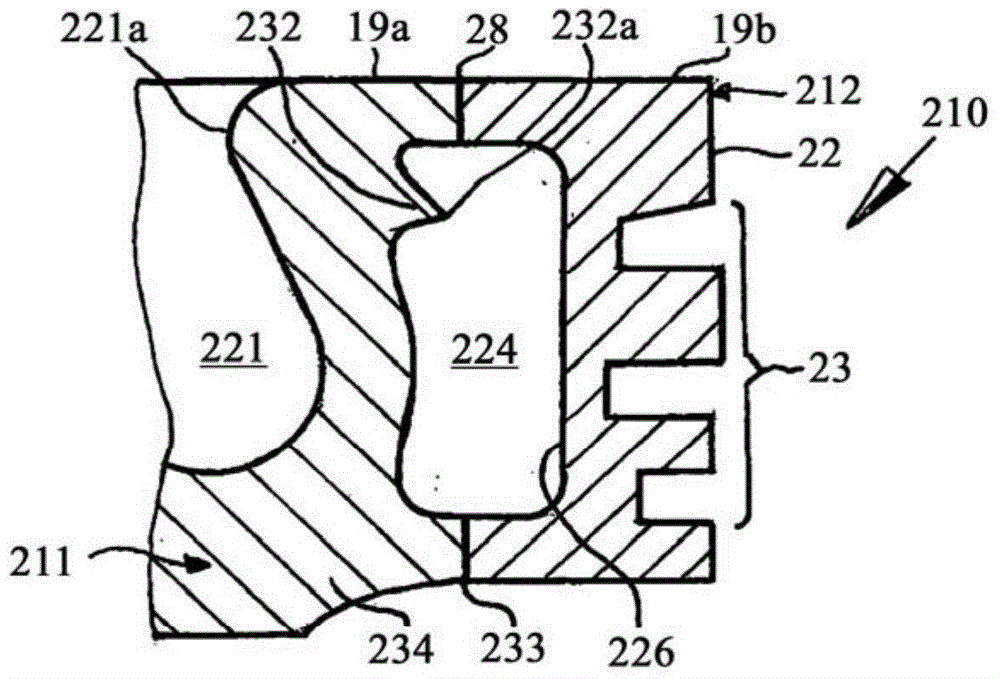

[0023] figure 1 A particularly preferred embodiment of the piston 10 according to the invention is shown. The piston 10 has a piston base body 11 and a piston ring part 12 . The two components may be constructed of any metallic material suitable for component joining. The piston base body 11 and the piston ring part 12 together form a piston crown 13 and a piston skirt 14 of the piston 10 . In the present exemplary embodiment, the piston 10 is a piston with a so-called thermally insulated piston skirt, ie an annular groove 15 is arranged between the piston head 13 and the piston skirt 14 . However, the invention also enables the use of piston skirts (attached image 3 and 4 ).

[0024] The piston skirt 14 has, in a known manner, a hub 16 and a hub bore 17 for receiving a piston pin (not shown), as well as an active surface 18 .

[0025] The piston base body 11 also forms, in the region of the piston head 13 , an inner part 19 a of the piston crown and a piston crown rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com