Smashing and separating device for bagged industrial refuse

A technology of industrial waste and separation device, which is applied in recycling technology, mechanical material recycling, plastic recycling, etc. It can solve the problems of large and complex broken bag processing, human damage, and harmful gas release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

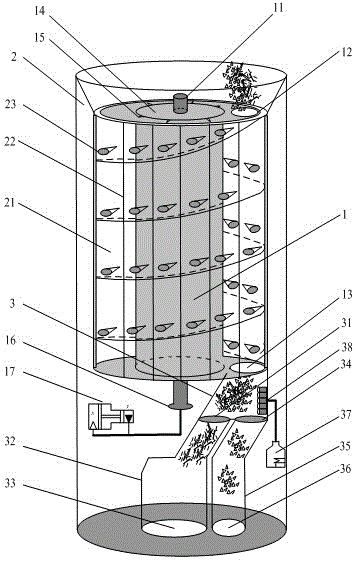

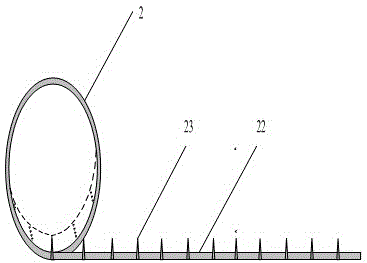

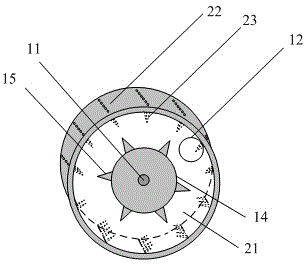

[0027] Taking a fragment separation treatment device for industrial bagged garbage as an example, the device is composed of a rotating rotor assembly 1, a nail cylinder 2 and a separation assembly 3. The rotating rotor assembly 1 includes a rotating shaft 11, a transmission channel inlet 12, a transmission channel outlet 13, a Tube 14, blade 15, motor 17, transmission device 16, nail tube 2 includes transmission channel 21, nail hanger 22, nail 23, separation assembly 3 includes light waste material separation baffle 31, light waste separation Barrel 32, light garbage discharge port 33, general waste subdivision baffle 34, general waste subpackage tube 35, general waste discharge port 36, air blower 37, air outlet 38. The steps to use the device are as follows:

[0028] A garbage load. The broken bag separation device starts, and the engine drives the rotating rotor assembly to rotate through the transmission device 16, and the blower 37 starts simultaneously. Pour the bagge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com