Rapid dewaxing device for FFPE sample and using method of FFPE rapid dewaxing device

A sample and dewaxing technology, applied in the preparation of test samples, etc., can solve the problems of difficult to automate the dewaxing process, complex dewaxing process, large workload, etc., achieve convenient and rapid separation processing, avoid aerosol pollution, Automate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

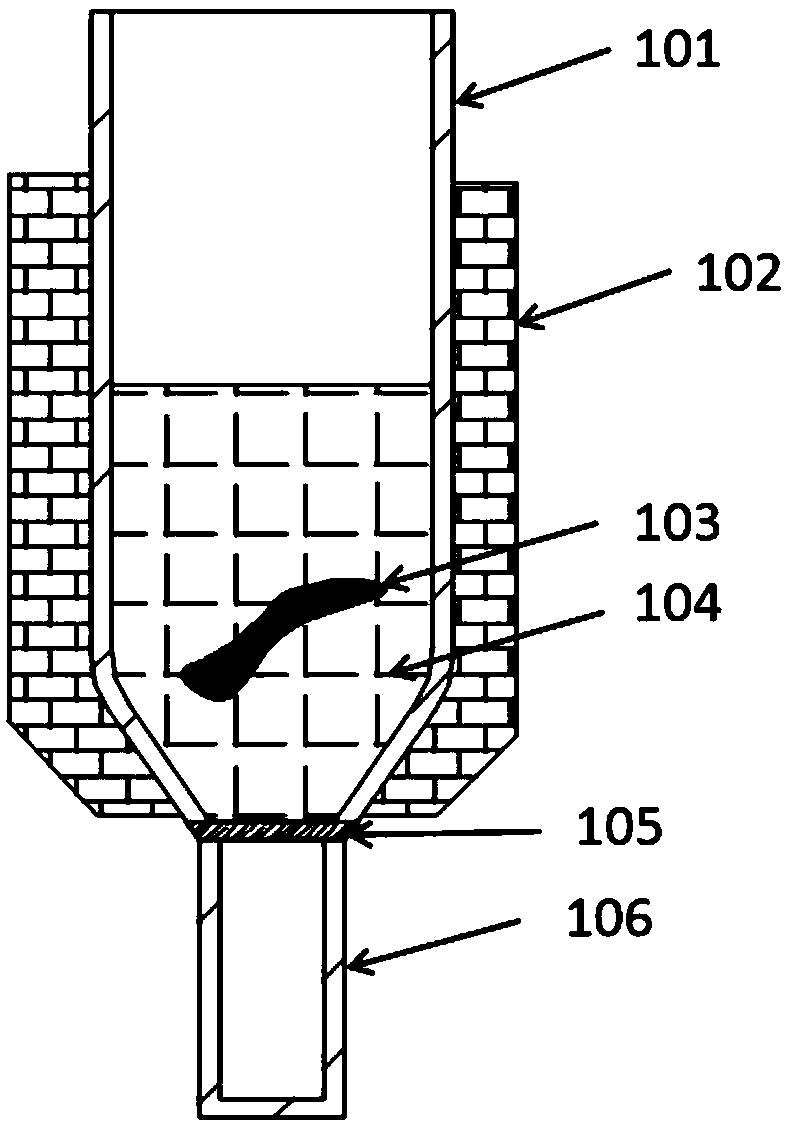

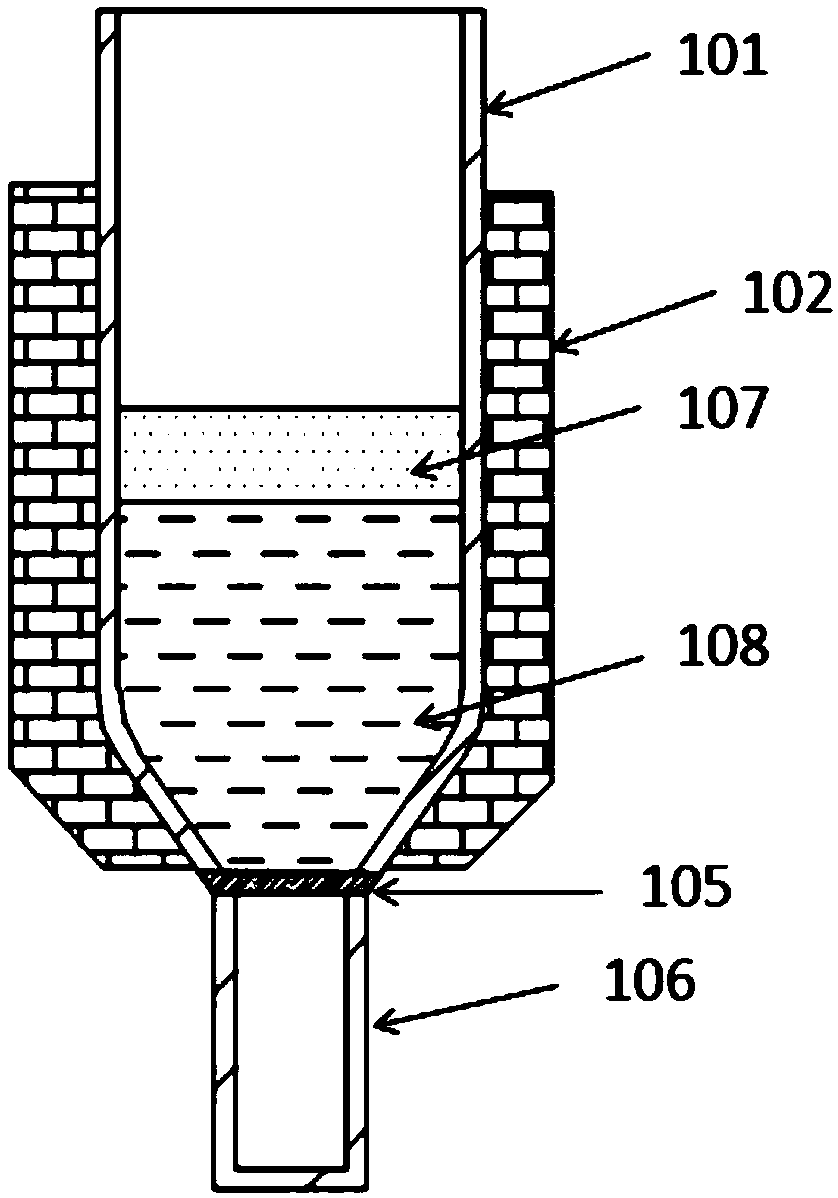

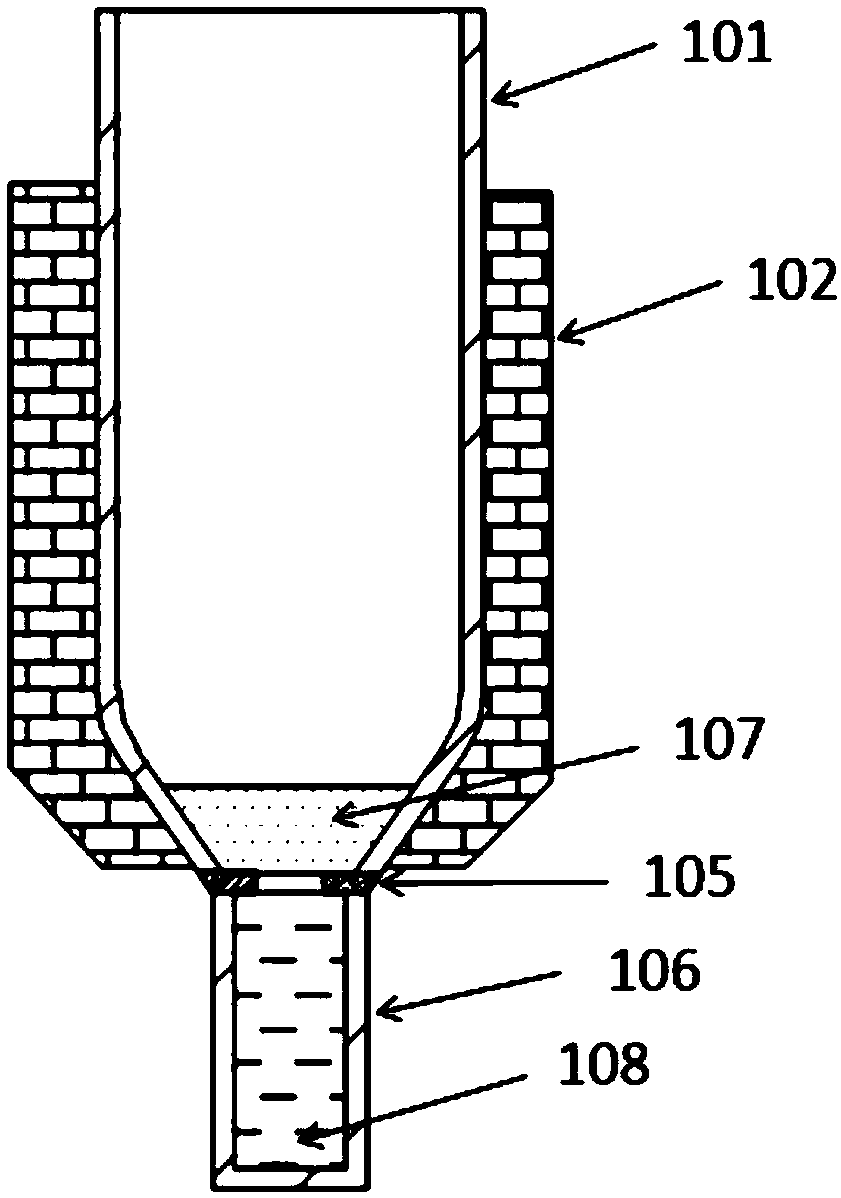

[0034] Manually operated FFPE dewaxing device and process:

[0035] There is a sealing device above the sample incubation chamber 101, and the sample incubation chamber 101 is prepackaged with 200 μL tissue lysate, 20 μL proteinase K and 50 μL oil phase reagents, such as mineral oil, paraffin oil, vegetable oil and silicone oil.

[0036] The FFPE tissue sample is put into the sample incubation chamber 101 after opening the sealing device above the sample incubation chamber 101, and the sealed state is maintained again by closing the lid.

[0037] The volume of the sample storage chamber 106 is 200 μL, and the sample storage chamber 106 can be removed from the whole device and stored with a lid on.

[0038] Tissue lysate, proteinase K and oil phase reagents are all commercially available.

[0039] According to the aforementioned dewaxing process (see schematic Figure 1-3 ), after the sample storage chamber 106 is full, close the valve 105, remove the sample storage chamber 1...

Embodiment 2

[0041] FFPE dewaxing device and process connected to the subsequent automatic nucleic acid extraction device:

Embodiment 3

[0042] The schematic diagram of the device used in embodiment 3 is shown in the schematic Figure 4 .

[0043] The FFPE tissue sample is put into the device through the opening and closing device (not shown here) above the sample incubation chamber 101 .

[0044] The sample incubation chamber 101 includes 500 μL tissue lysate, 10 μL proteinase K and 100 μL oil phase reagent.

[0045] One end of the sample channel 109 is connected to the valve 105, and the other end can be connected to the sample chamber of the subsequent nucleic acid extraction device.

[0046] The driving pump 110 is a schematic liquid driving device, which can pump the liquid in the sample incubation chamber 101 to the subsequent sample chamber through the sample channel 109 .

[0047] The valve 105 contains a filter membrane (not shown here), which can filter unlysed tissue fragments and oil phase liquid in the water phase layer 108 .

[0048] Tissue lysate, proteinase K and oil phase reagents are all co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com