Gas drainage system for tunnel and tunnel structure

A technology of gas drainage and tunnel structure, which is applied in the direction of gas discharge, drainage, safety devices, etc., to reduce the risk of escape, avoid accumulation, avoid safety hazards and even accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and exemplary embodiments, wherein the same reference numerals in the accompanying drawings all refer to the same components. Also, detailed descriptions of known arts will be omitted if they are unnecessary to illustrate the features of the present invention.

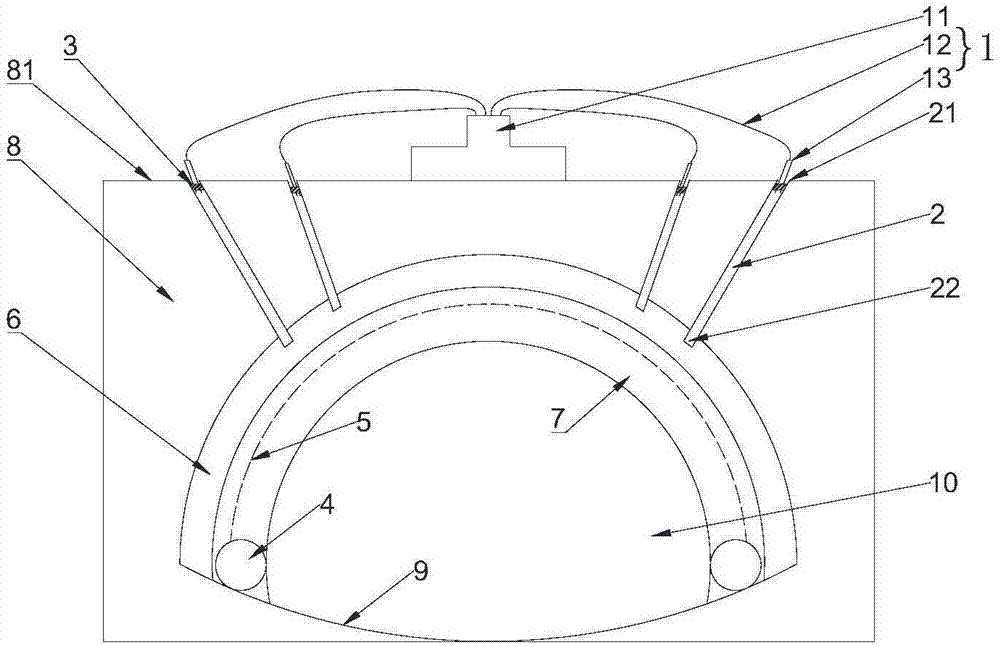

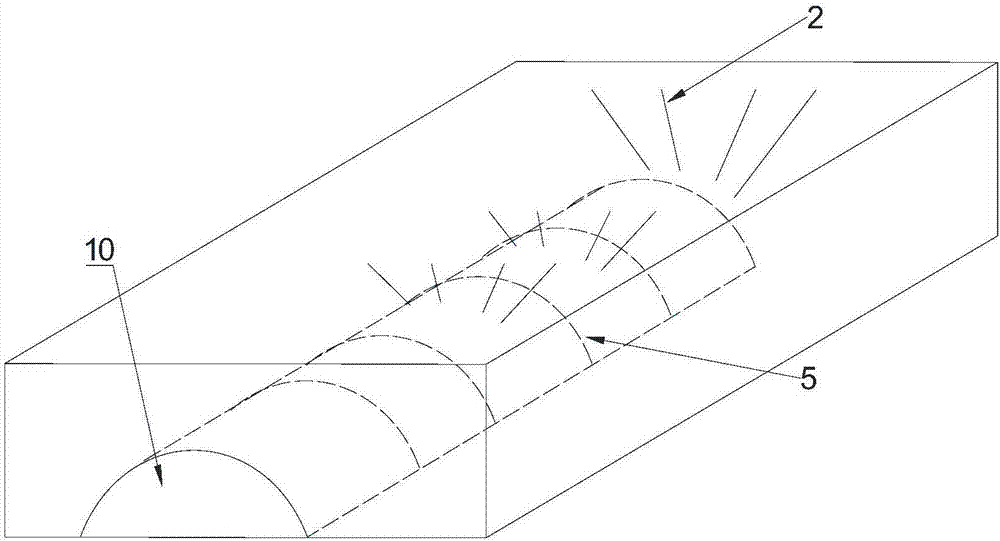

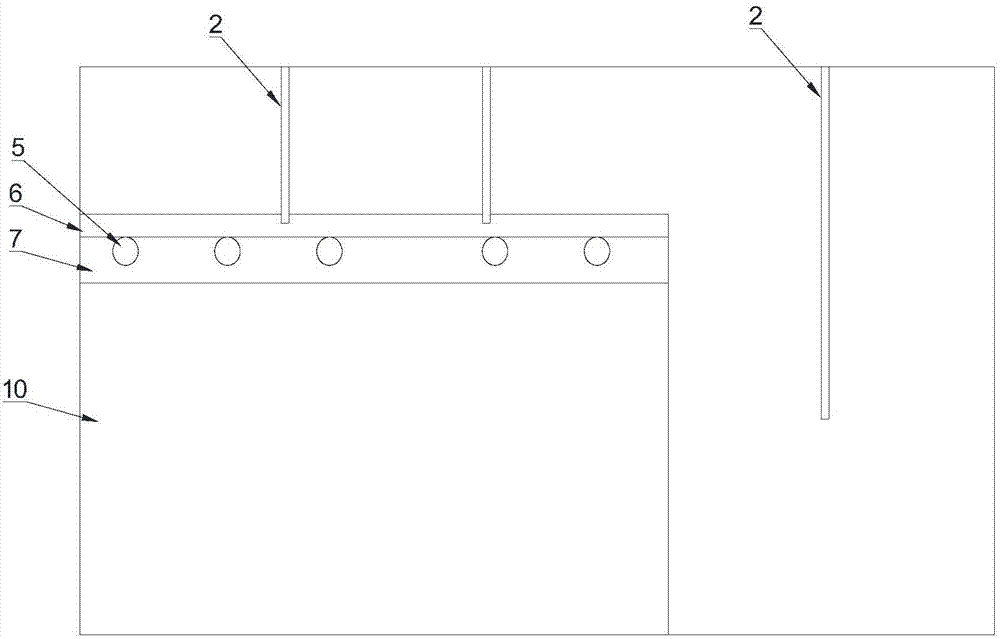

[0031] Such as figure 1 As shown, one of the embodiments of the tunnel structure provided by the present invention includes: gas drainage system, drainage pipe 4, annular blind ditch 5, primary support 6, secondary lining 7, inverted arch 9 and tunnel cavity 10. The gas drainage system includes an air extraction device 1, a gas drainage channel 2 and a sealing device 3; the primary support 6 is a steel frame support located on the outer layer of the tunnel; the secondary lining 7 is airtight permanent concrete pouring, located inside the primary support 6; the inverted arch 9 is arranged opposite to the secondary l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com