Powdery material dryer

A powdery material and drying machine technology, which is applied in the direction of granular material drying, dryer, and preliminary treatment to promote the drying of solid materials. It can solve the problems of low work efficiency, incomplete drying, and influence on the production line, so as to improve work efficiency. , The process is simple, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

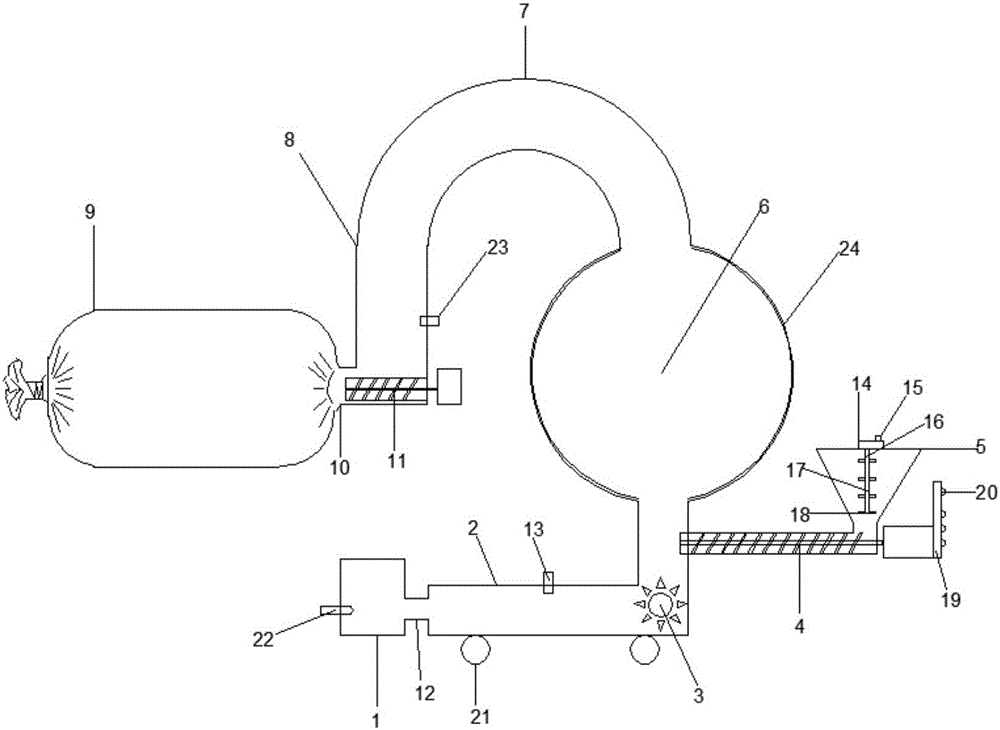

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

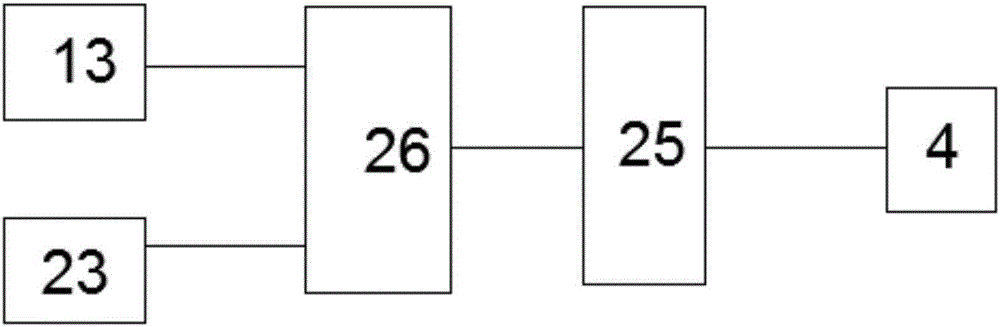

[0020] see Figure 1-2 , a kind of powdery material drier, comprises air induction device, feeding stirring device, temperature control device, drying device and collecting device, and air induction device is made up of induction fan 1, air inlet pipe 2 and connecting hose 12, so The induced draft fan 1 is connected with the air inlet pipe 2 through a connecting hose 12; the feeding stirring device is composed of a screw feeder 4, a feeding funnel 5, a mounting plate 14, a stirring motor 15 and an agitator 16, and the feeding funnel 5. The screw feeder 4 is arranged on the side of the vertical drying pipe. The top of the feed funnel 5 is fixed with a mounting plate 14 by bolts. The mounting plate 14 is fixed with a stirring motor 15. The agitator 16 includes a stirring shaft 17 With stirring tooth 18, stirring shaft 17 is connected with the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com