Machining method for external molded part of outer mold of insulator pouring mold

A processing method and technology of insulators, which are applied in the field of processing outer shaped parts, can solve problems such as inability to process outer shaped parts, achieve the effects of reducing processing difficulty and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

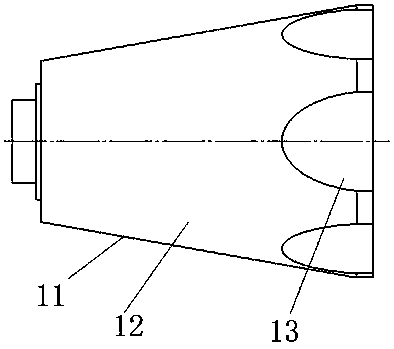

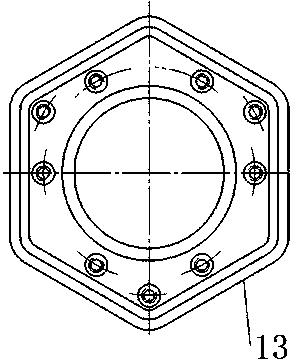

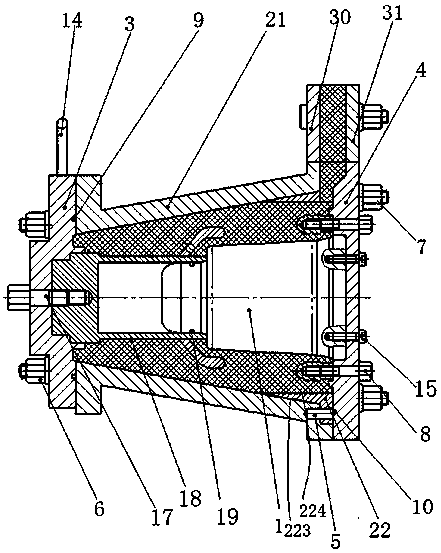

[0025] In the embodiment of the processing method of the outer molding of the insulator casting mold in the present invention, the processing method of the outer molding includes the following steps: the first step is to turn the blank, and process the axis extending along the left and right directions and the outer diameter The conical section that gradually becomes larger from left to right, when turning the conical section, also turns the cylindrical section that is connected to the right end of the conical section and is coaxially arranged with the conical section. The outer diameter of the cylindrical section is larger than that of the conical section. The taper of the conical section matches the taper of the inner hole of the tapered hole section 211 of the corresponding cone forming part 21, and the outer peripheral surface of the cylindrical secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com