Pretreatment distillation device and method for continuous regeneration of waste lubricating oil

A technology of waste lubricating oil and distillation equipment, which is applied in the direction of vacuum distillation, separation method, lubricating composition, etc., can solve the problems of the reduction of continuous operation efficiency of distillation equipment and the decrease of fraction effect, and achieve the improvement of continuous operation efficiency, increase of fraction effect, The effect of improving distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

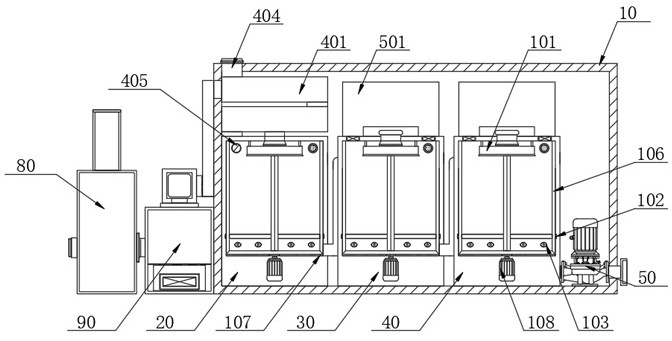

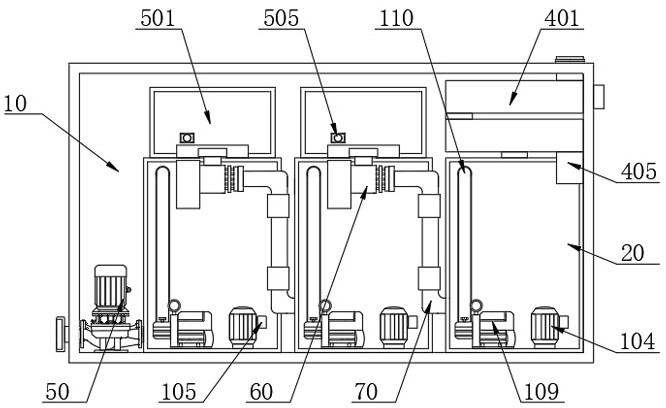

[0040] see Figure 1-2 As shown, a pretreatment distillation device for continuous regeneration of waste lubricating oil includes a cabinet 10, and a first-stage distillation tank 20, a second-stage distillation tank 30 and a third-stage distillation tank 40 are arranged side by side inside the cabinet 10. The right side inside the cabinet 10 A first suction pump 50 is provided, and the feed end of the first suction pump 50 is communicated with the interior of the three-stage distillation tank 40, and the back of the two-stage distillation tank 30 and the third-stage distillation tank 40 is provided with a second pumping material. pump 60, and both ends of the two second suction pumps 60 are connected with oil delivery pipes 70, wherein the two oil delivery pipes 70 of one second suction pump 60 are respectively connected with the primary distillation tank 20 and the secondary distillation tank 30. Internal communication, the two oil delivery pipes 70 of the other second sucti...

Embodiment 2

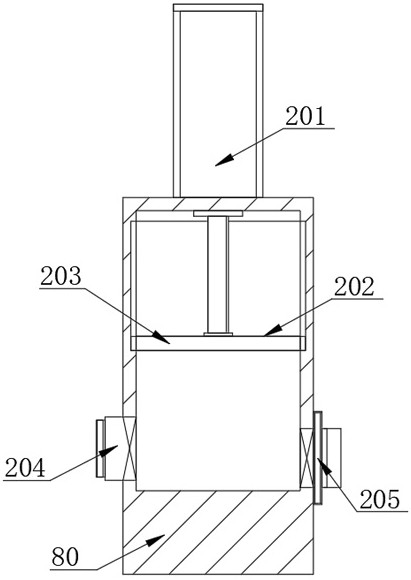

[0043] see Figure 1-3 As shown, in the present invention, one side of the chassis 10 is provided with a material extraction box 80, and the inside of the material extraction box 80 is provided with a material extraction mechanism. The top of the box 80 is fixedly connected, one end of the drive shaft of the servo electric cylinder 201 penetrates the extraction box 80 and extends to the inside of the extraction box 80, and one end of the drive shaft of the servo electric cylinder 201 that extends to the inside of the extraction box 80 is fixedly connected with a movable Plate 202, the surface of the movable plate 202 is covered with a rubber sleeve 203, the surface of the rubber sleeve 203 is slidably connected with the inner wall of the extraction box 80, and the drive shaft of the servo electric cylinder 201 is used to drive the movable plate 202 to slide up and down inside the extraction box 80 According to the sliding stroke of the drive shaft of the servo electric cylinde...

Embodiment 3

[0045] see Figure 1-4 As shown, in the present invention, a separation box 90 is arranged between the chassis 10 and the extraction box 80, and a separation mechanism is arranged inside the separation box 90. The separation mechanism includes a separation frame 301, and the two sides of the separation frame 301 are connected to the separation box 90. The interior of the separation frame 301 is fixedly connected, the separation frame 301 is provided with a separation screen 302, and the top of the separation frame 301 is provided with electric push rods 303 on both sides. To the bottom of the separation frame 301, and the surface of the separation frame 301 is sleeved with a movable frame 304, the two sides of the top of the movable frame 304 are respectively fixedly connected with the bottom ends of the two electric push rods 303 drive shafts, and the interior of the movable frame 304 is arranged There is a sponge block 305, the inner surface of the sponge block 305 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com