High-strength hollow fiber membrane module and preparation method thereof

A fiber membrane and high-strength technology, which is applied in the field of high-strength hollow fiber membrane modules and its preparation, can solve the problems that the seals at both ends of the membrane filaments are easy to fall off, the hollow fiber membrane modules are scrapped early, and the hollow fiber membrane filaments are prone to damage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

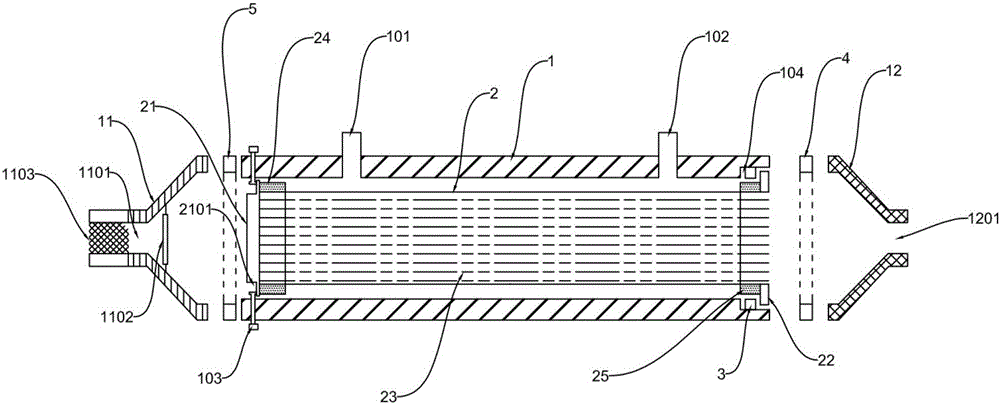

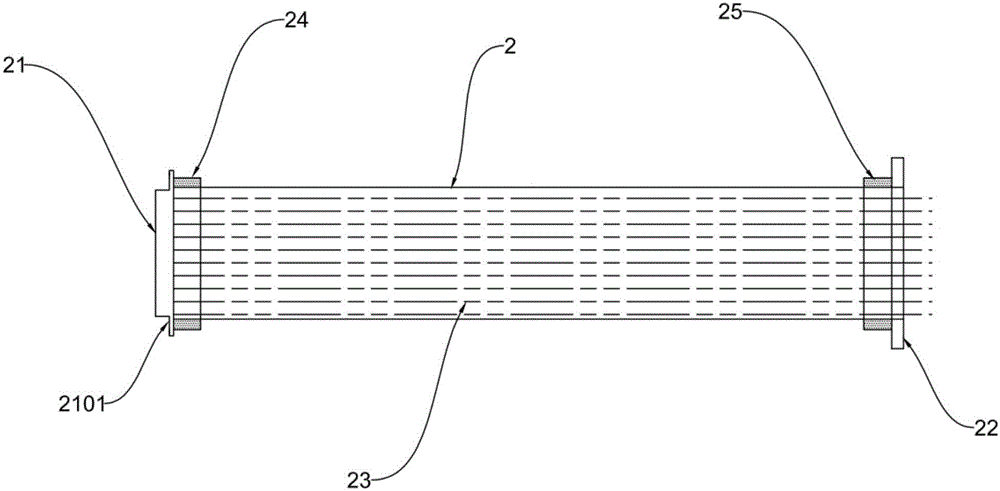

[0049] See attached figure 1 and figure 2 The present invention is further described.

[0050] The invention relates to a high-strength hollow fiber membrane module, which is characterized in that it at least comprises: an adventitia cavity (1) and an inner membrane core (2) assembled inside the adventitia cavity (1), the adventitia cavity (1) ) is set as a stainless steel cylinder, and the inner membrane core (2) is formed by several hollow fiber membrane filaments (23) distributed in bundles;

[0051] One end of the inner film core (2) is an epoxy hard glue sealing end (21), the other end of the inner film core (2) is an epoxy hard glue casting end (22), and the inner film core (2) is located at One side of the epoxy resin hard glue sealing end (21) is blocked inside the epoxy resin hard glue sealing end (21), and the inner film core (2) is located at the side of the epoxy resin hard glue casting end (22) and passes through the epoxy resin hard glue sealing end (21). Res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com