Lithium carbon dioxide battery cathode and preparation method thereof

A carbon dioxide, battery cathode technology, applied in the field of electrochemical energy, can solve the problems of poor structural stability of MoC/C nanocomposite materials, poor electrochemical performance of batteries, and inability to industrialize production, etc. Diffusion, good cycle life, improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A method for preparing a positive electrode of a lithium carbon dioxide battery comprises the steps of:

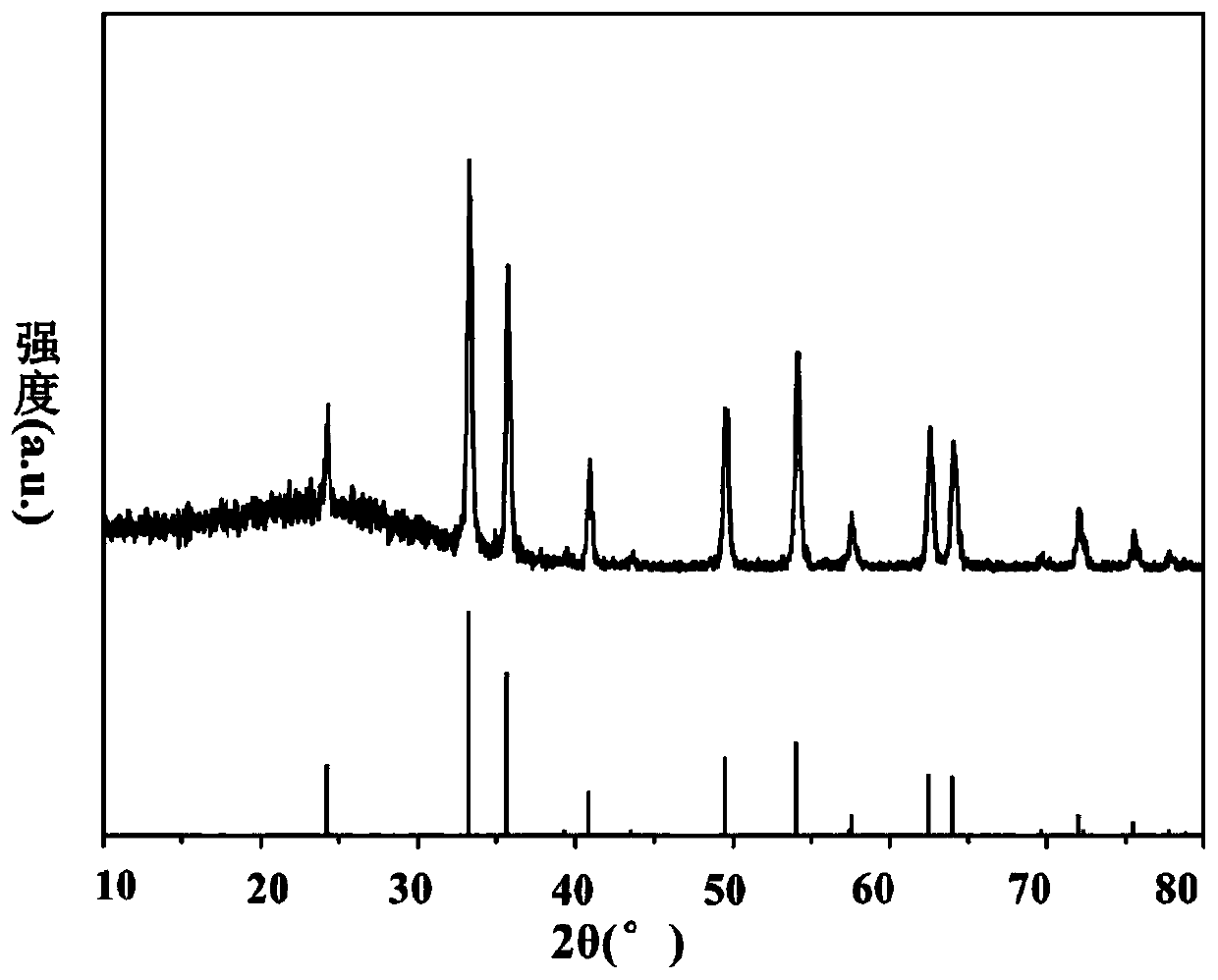

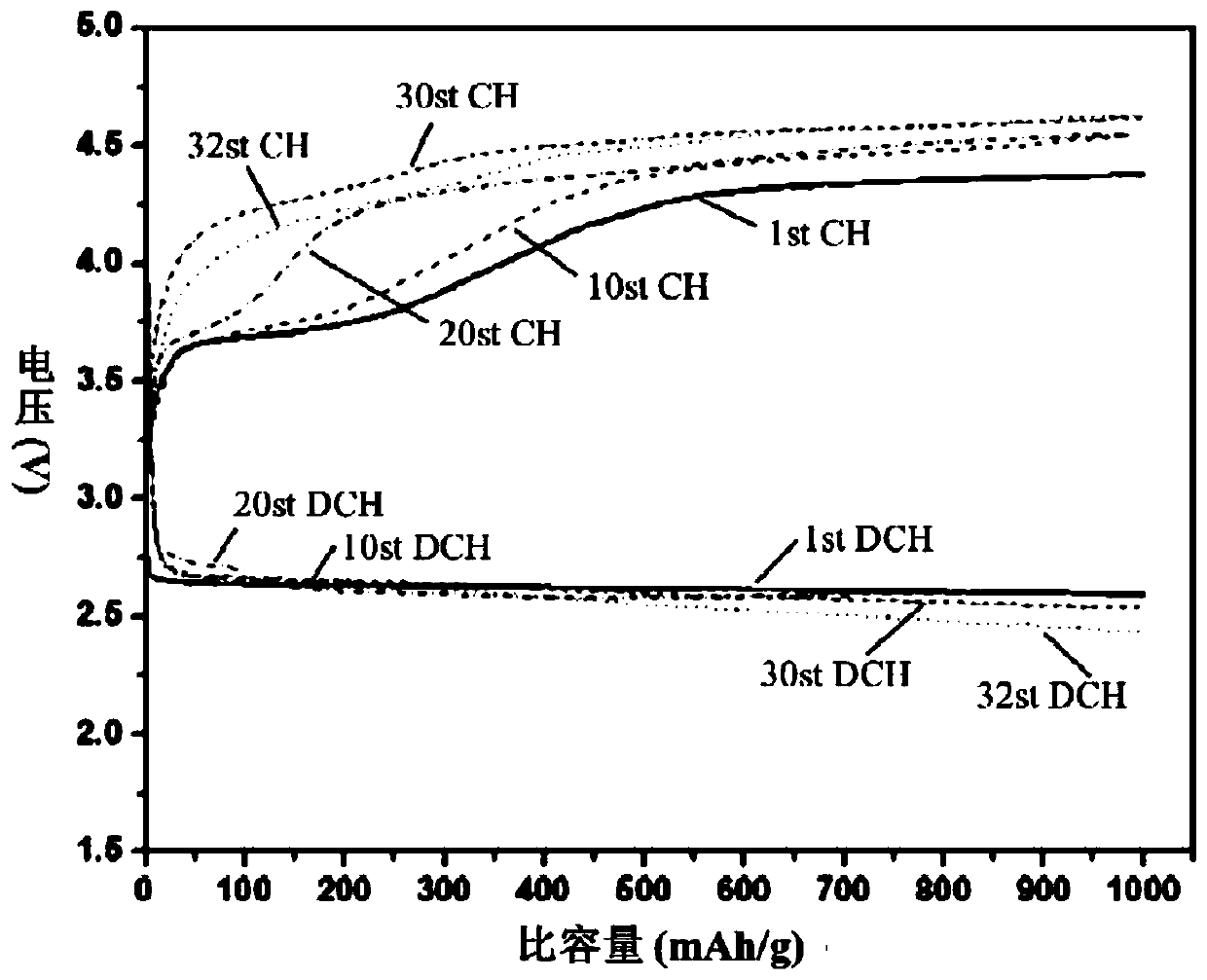

[0069] (1) the polystyrene pellet that particle diameter is 210nm is soaked in the mixed solution of ferric nitrate nonahydrate and ethylene glycol and methanol 8h, and the molar concentration of ferric nitrate nonahydrate is 2mol / L in the described mixed solution, described The volume ratio of ethylene glycol and methanol is 1.5:1, the precursor is obtained by suction filtration, the precursor is dried at 50°C for 26h, and the product obtained by drying is heated to 300°C at a heating rate of 1°C / min and kept for 4h , and then heated to 500°C for 4 hours to obtain a three-dimensional pore structure α-Fe 2 o 3 , the three-dimensional pore structure of α-Fe 2 o 3 The X-ray diffraction pattern of figure 1 As shown, it can be seen from the diffraction peaks in the figure that the obtained product is α-Fe 2 o 3 And the purity is high without impurity peaks, the th...

Embodiment 2

[0072] The difference with Example 1 is that the three-dimensional pore structure α-Fe in step (2) 2 o 3 The mass ratio of conductive carbon black Super P is 0.125:1.

Embodiment 3

[0074] The difference with Example 1 is that the three-dimensional pore structure α-Fe in step (2) 2 o 3 The mass ratio of conductive carbon black Super P is 8.1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com