Waste water treatment equipment

A wastewater treatment and equipment technology, applied in water/sewage treatment equipment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of deteriorating water quality and affecting the survival of fish and other aquatic animals, and achieve convenient operation and equipment The effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

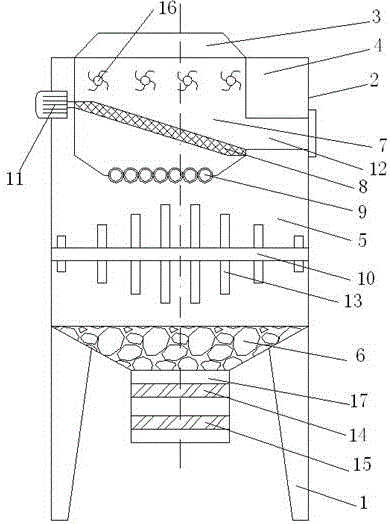

[0015] Such as figure 1 As shown, a kind of waste water treatment equipment of the present invention comprises support 1 and cylinder body 2, and support 1 is provided with cylinder body 2, and cylinder body 2 upper end is provided with feed inlet 3, and cylinder body 2 lower end is provided with discharge port 17 , the cylinder 2 is provided with a separation chamber 4, a stirring chamber 5 and a sedimentation chamber 6 sequentially from top to bottom. The separation chamber 4 includes a separation cylinder 7 and a separation net 8 connected to the separation cylinder 7. The lower end of the separation net 8 is connected to There is a crushing wheel 9, a stirring shaft 10 is arranged in the stirring chamber 5, a separation net 8 is connected to a vibrating motor 11, the separation net 8 is placed obliquely in the separation cylinder 7, and one side of the separation cylinder 7 is provided with a slag outlet 12, and the outlet The entrance of the slag outlet 12 is placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com