Polymer alloy bar forming treatment system

A polymer alloy and processing system technology, applied in the field of polymer alloy bar forming processing system, can solve the problems of grinding processing impact, low work efficiency, misaligned butt joint, etc., to increase the grinding area, improve processing quality, and reduce complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention may be implemented in many different ways as predetermined and covered by the claims.

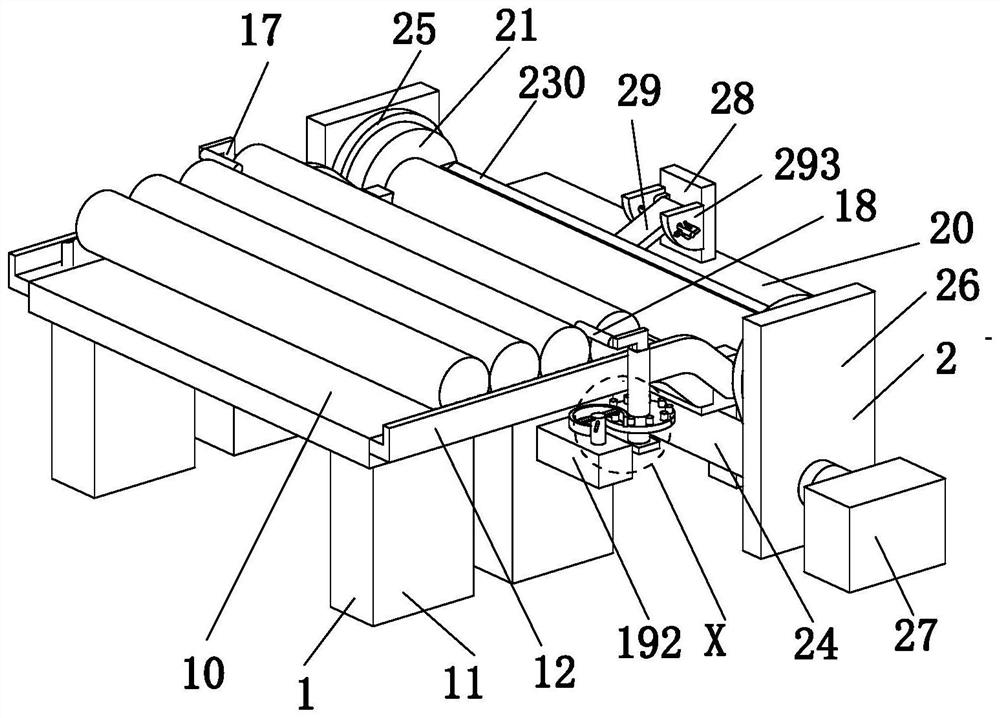

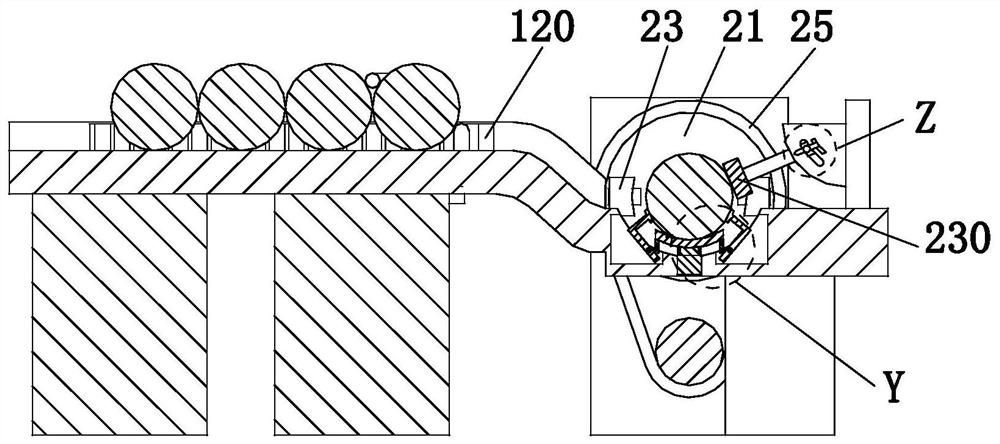

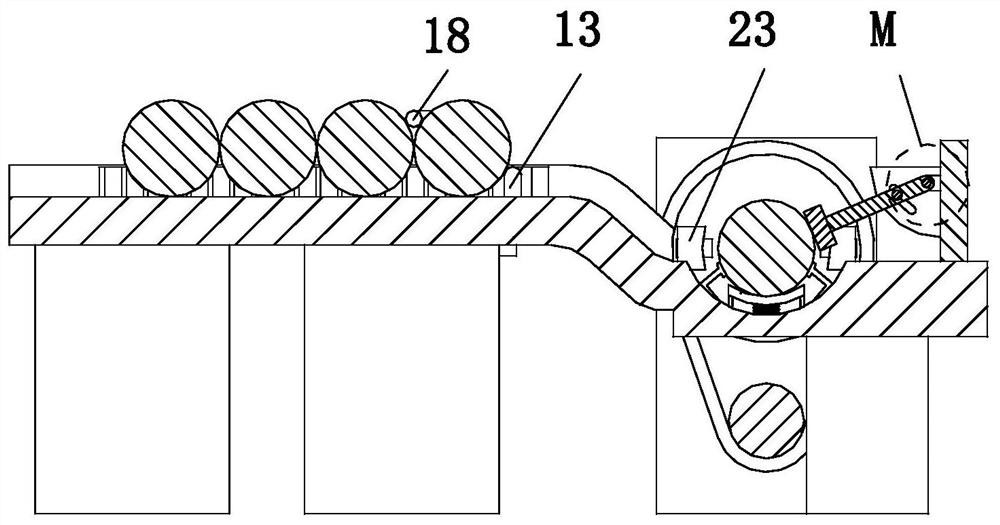

[0032] like Figure 1 to Figure 9 As shown, a polymer alloy bar forming processing system includes a feeding mechanism 1 and a grinding mechanism 2. The lower end of the feeding mechanism 1 is installed on the existing working ground, and the right end of the feeding mechanism 1 is connected with a Grinding mechanism 2, the lower end of the grinding mechanism 2 is installed on the existing working ground.

[0033] The feeding mechanism 1 includes a feeding table 10, a pedestal 11, a baffle plate 12, a limit block 13, a compression spring 14, a bottom plate 15, a rotating shaft 16, a connecting plate 17, a push rod 18, a disc 19, a cylinder 190 and The transmission unit 191, the lower end surface of the feeding table 10 is symmetrically ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com