Grinder for ball head assembly

A grinding machine and ball head technology, which is applied in the direction of grinding machines, seat surface grinders, grinding workpiece supports, etc., can solve the problems affecting the service life of ball head components, etc., and achieve the effect of improving grinding efficiency, improving grinding accuracy, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings and embodiments.

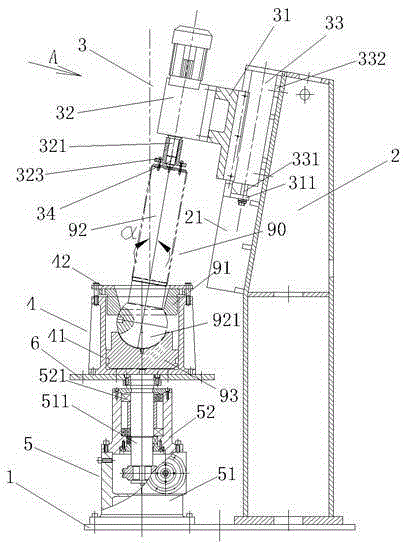

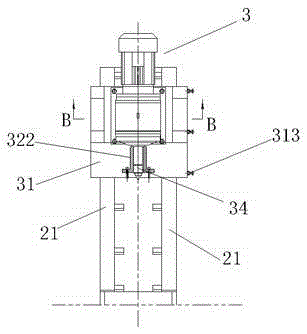

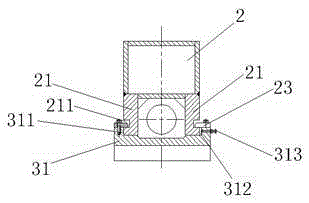

[0016] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a bottom plate 1, a body 2, an upper center rotating device 3, a grinding tool 4, and a grinding tool rotating support device 5. The body 2 of this embodiment is a thick-walled hollow box type welded structure. The bottom of the upright body 2 is vertically fixed on the right end of the bottom plate 1, and the grinding tool rotating support device 5 is vertically fixed on the left end of the bottom plate 1. The upper center rotating device 3 is supported obliquely on the upper side of the fuselage 2 and includes a sliding seat 31, an upper motor-reducer combination 32, a sliding seat moving cylinder 33 and an upper center 34. The angle between the axis of the upper center 34 and the vertical is α =-9°~-11°, this embodiment is -10°, the included angle α simulates the working condition of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com