Prefinished and prefabricated corner for single step attachment in millwork applications

a millwork and prefabricated technology, applied in the field of building products, can solve the problems of time-consuming process and associated cost, affecting the appearance of finished products, and gaps becoming more obvious to the eye, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which the invention belongs.

[0030]Although any methods and materials similar or equivalent to those described herein can be used in the practice or testing of the present invention, the preferred methods and materials are now described.

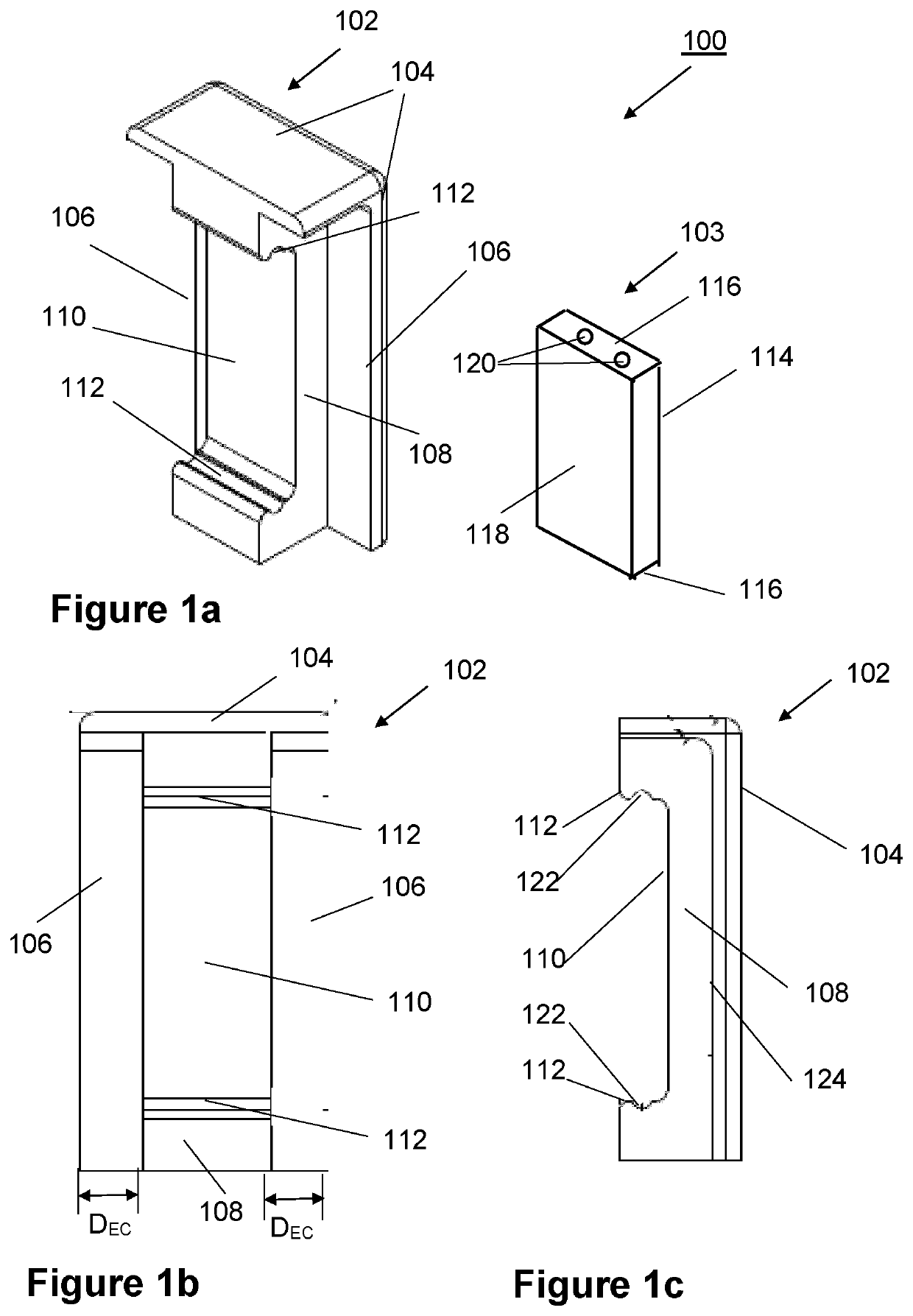

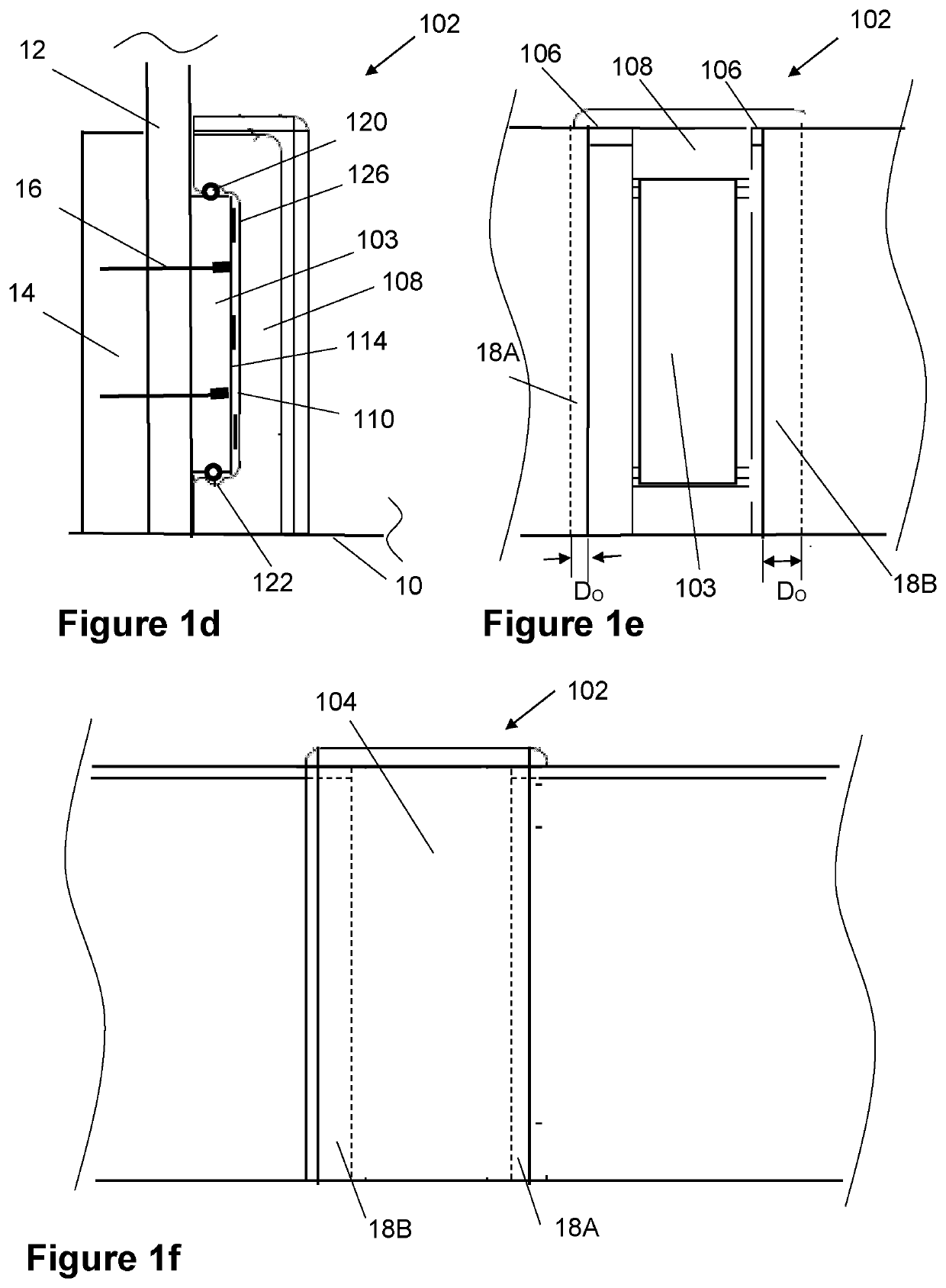

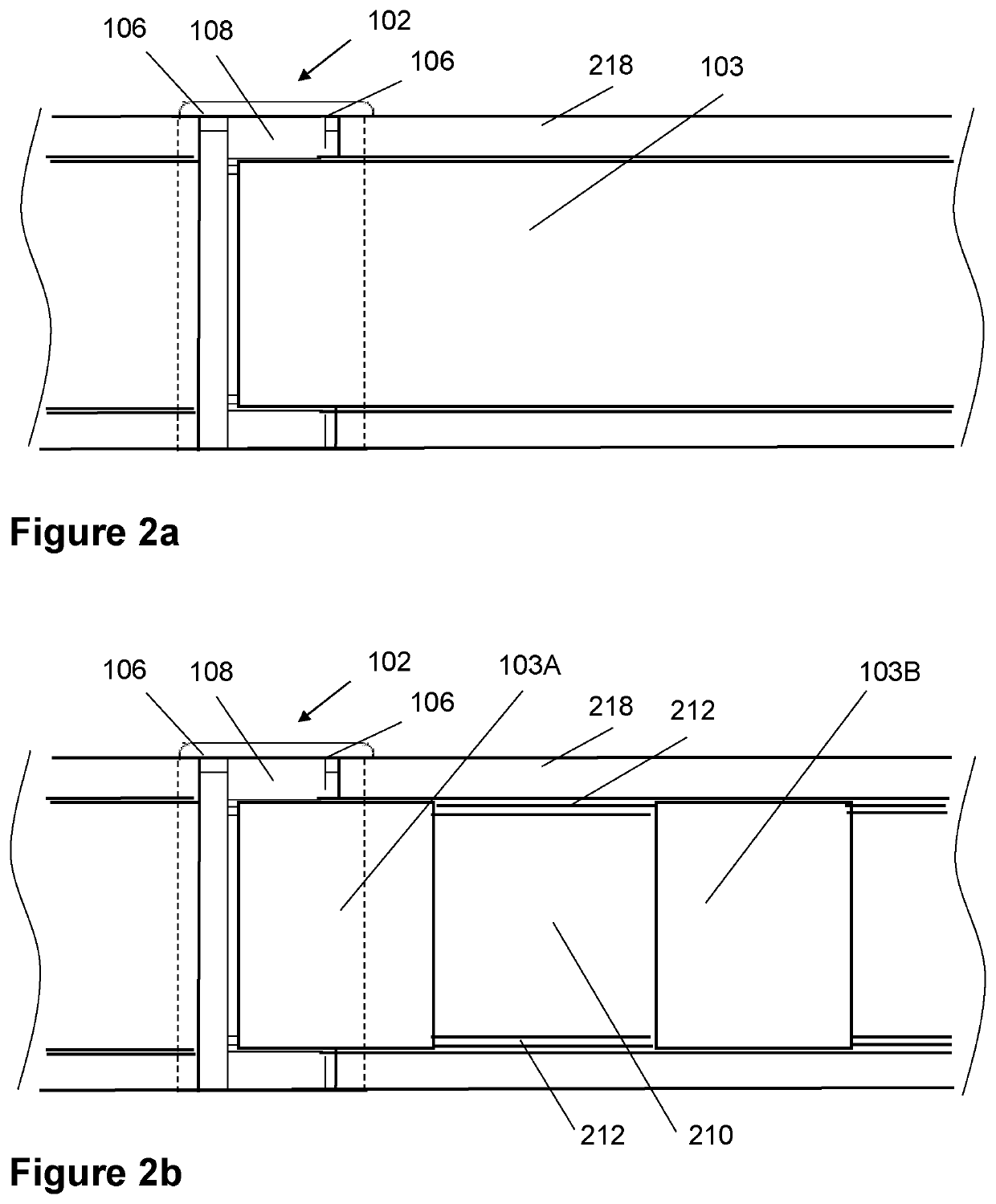

[0031]Referring to FIGS. 1a to 1f, a finishing trim piece end cover system 100 according to a preferred embodiment of the invention is provided. The finishing trim piece end cover system 100 comprises at least a mounting element 103 and a finishing trim piece end cover element 102. The mounting element 103 comprises inner surface 114, inner side surfaces 116, and outer surface 118. The outer surface 118 of the mounting element 103 is configured to be secured to a building structure. The mounting element 103 is easily installed in any location of the building structure such as a bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com