Manufacturing method of plant fibre products

A plant fiber and production method technology, which is applied in the field of making plant fibers into fully biodegradable plastic products, can solve the problems of difficulty in producing low-cost and high-quality products, unstable product performance, and large amount of reagents, so as to expand varieties and application scopes. , the effect of expanding production methods and process fields, reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

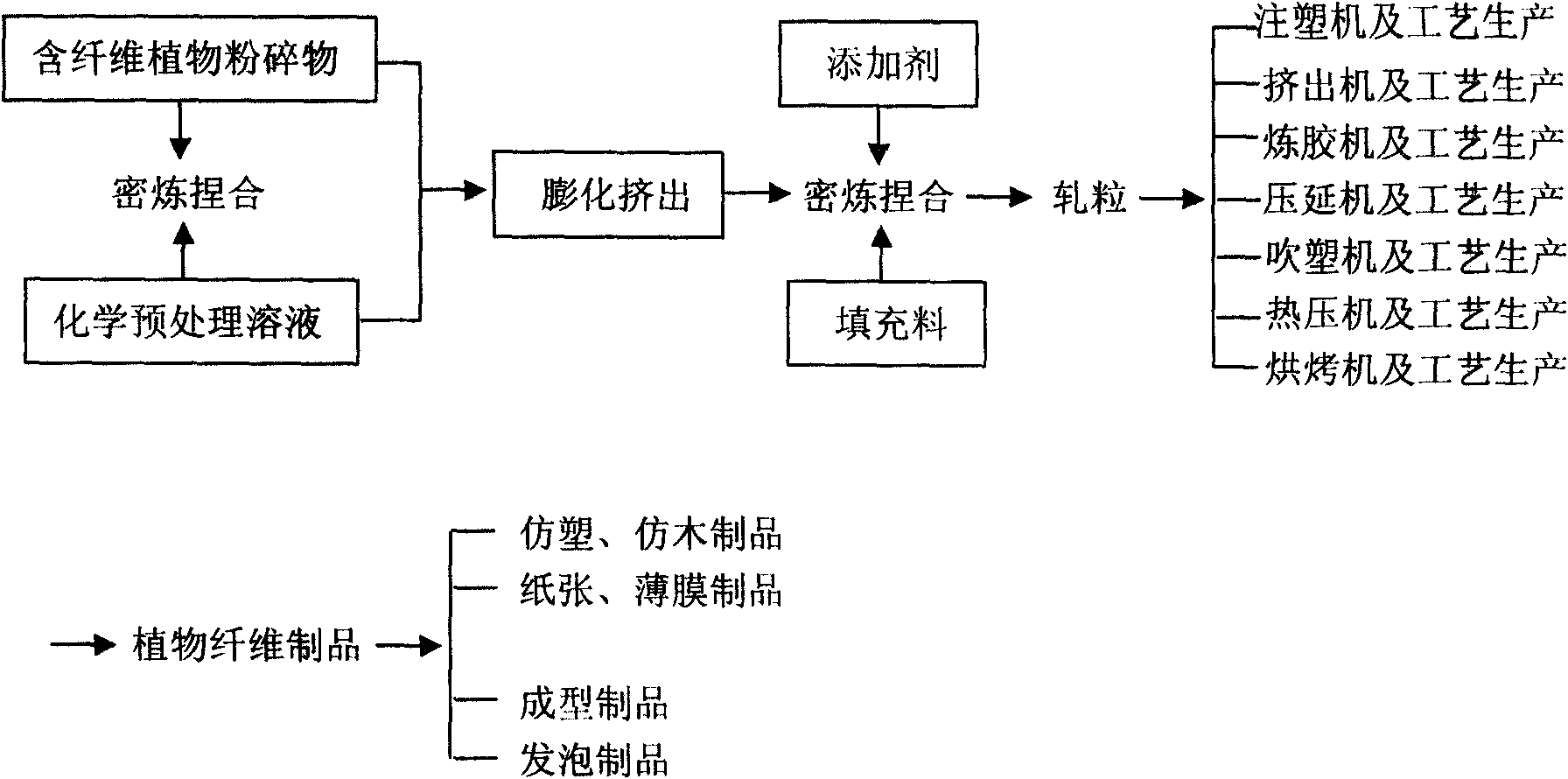

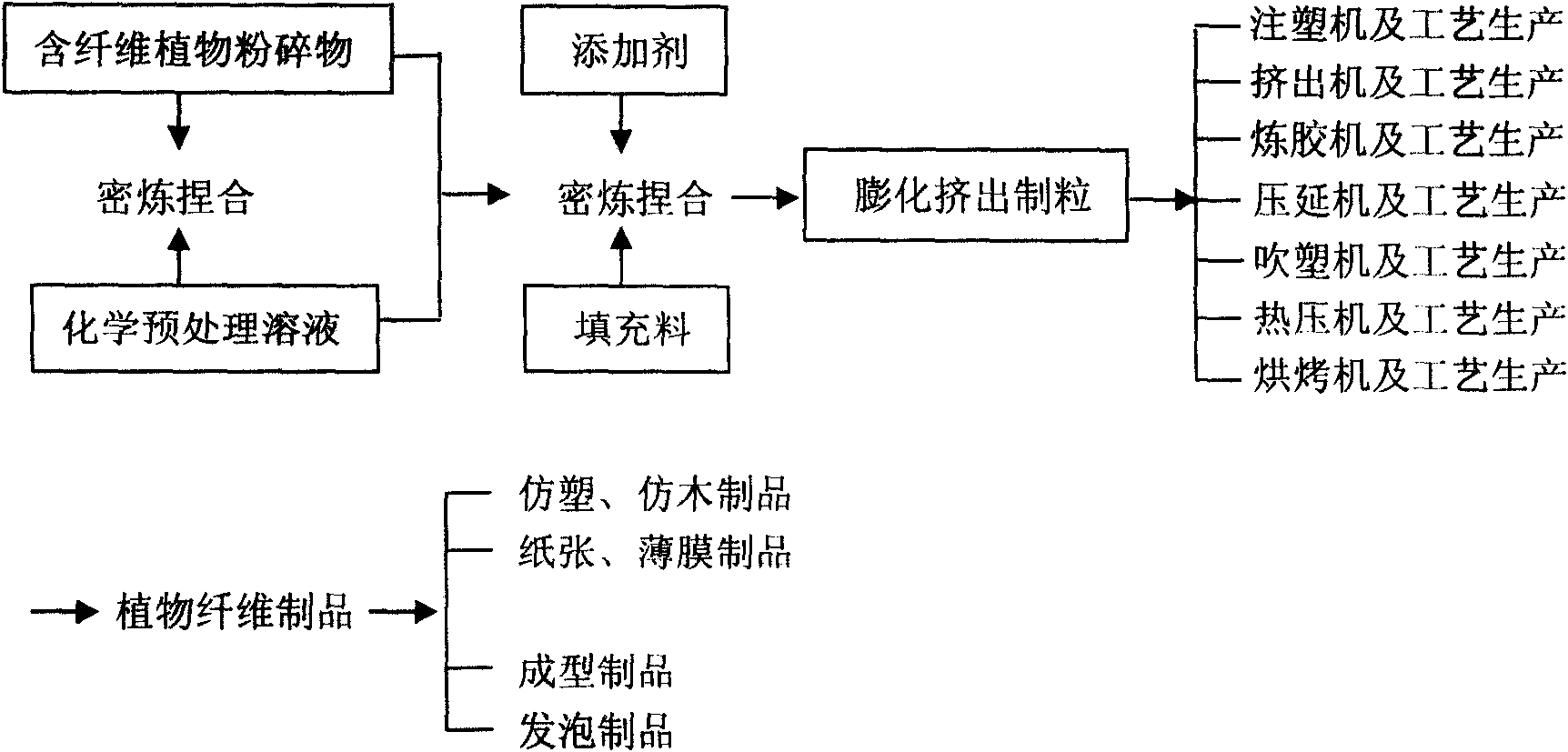

Method used

Image

Examples

Embodiment 1

[0017] (1) Pour 30 kilograms of crushed sawdust into the banburying kneader, start the banbury kneader to work, then add 6% soda ash and 5 kilograms of water of the sawdust raw material and banbury and knead for 6 minutes.

[0018] (2) Pour the above banbury kneading material into the puffing extruder for puffing.

[0019] (3) The puffed extruded material is poured into the banburying kneader again, and 5% calcium stearate, 3% monoglyceride, 12% glycerol, 8% light calcium carbonate, 1 % preservatives, 12% polyvinyl alcohol, 4% whitening agent, 1% sulfur dioxide, banburying and kneading for 3 minutes, adding hydrochloric acid solution (concentration 36% and water 3 kg), banburying and kneading The PH value of the product is adjusted to neutral, and the moisture content is 40%-60%.

[0020] (4) After banburying, pour out and use a granulator to roll and compress into particles, which become plant plastic particle raw materials.

[0021] (5) The particles are added to the injec...

Embodiment 2

[0023] (1) 30 kilograms of crushed corn stalk fibers are poured into the started banburying kneader, then add 3% soda ash of corn stalk fiber raw material and 4 kilograms of water banburying and kneading for 4 minutes. Add hydrochloric acid solution, banbury kneading for 2 minutes, and adjust the pH value to 7.

[0024] (2) add 4% calcium stearate, 4% monoglyceride, 10% glycerin, 6% light calcium carbonate, 2% antiseptic, 15% polyvinyl alcohol, 3% whitening agent, banburying and kneading together for 2 minutes, moisture content 30%.

[0025] (3) Put the banburying kneaded material into the puffing extruder to extrude into tablets (the shape of the die head of the extruder changes), and then into the calender to be pressed into paper and film.

Embodiment 3

[0027] (1) 30 kg of crushed wheat straw fiber, 5% hydrogen peroxide, 5% hydrochloric acid and 5 kg of water were kneaded for 6 minutes, then added soda ash solution for 2 minutes, and the pH value was adjusted to neutral.

[0028] (2) Add 4% calcium stearate, 2% monoglyceride, 5% glycerin, 4% cake instant hair oil, 1% 4,4'-oxobisbenzenesulfonyl hydrazide , 1% preservative, and 25% polyvinyl alcohol are banburyed and kneaded together, and mixed with water.

[0029] (3) When the moisture content is 160%, it enters into microwave baking (the baking temperature is controlled at 120° C.), and becomes a foaming and shockproof plant fiber product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com