Multi-story building construction using long strand timber panels

a technology of long strand timber panels and multi-story buildings, which is applied in the direction of walls, constructions, building components, etc., can solve the problems of limiting the amount of consistent board product that can be obtained and made into clt products, affecting the construction efficiency of buildings, so as to achieve more cost-effective manufacturing, increase the load bearing capacity, and improve the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

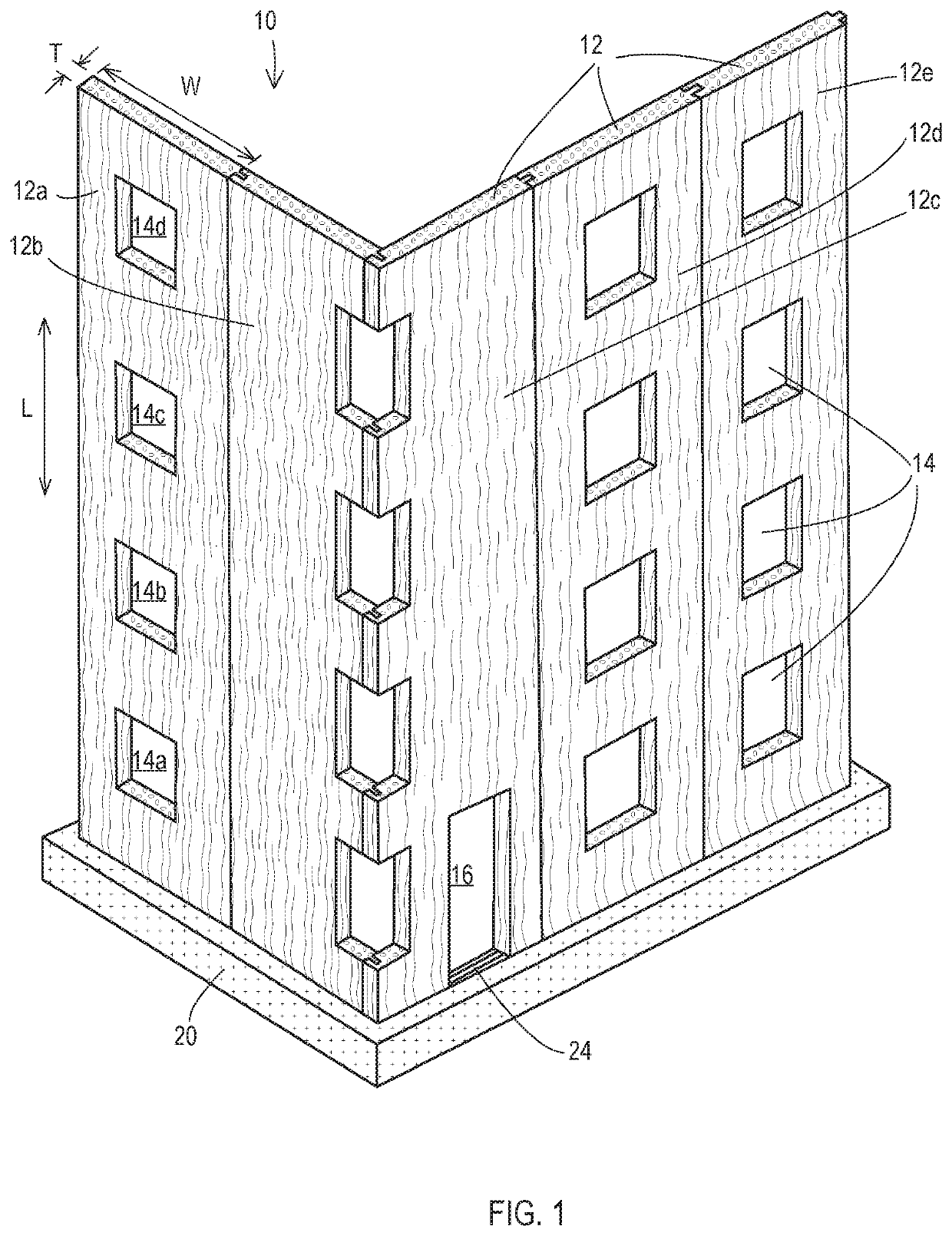

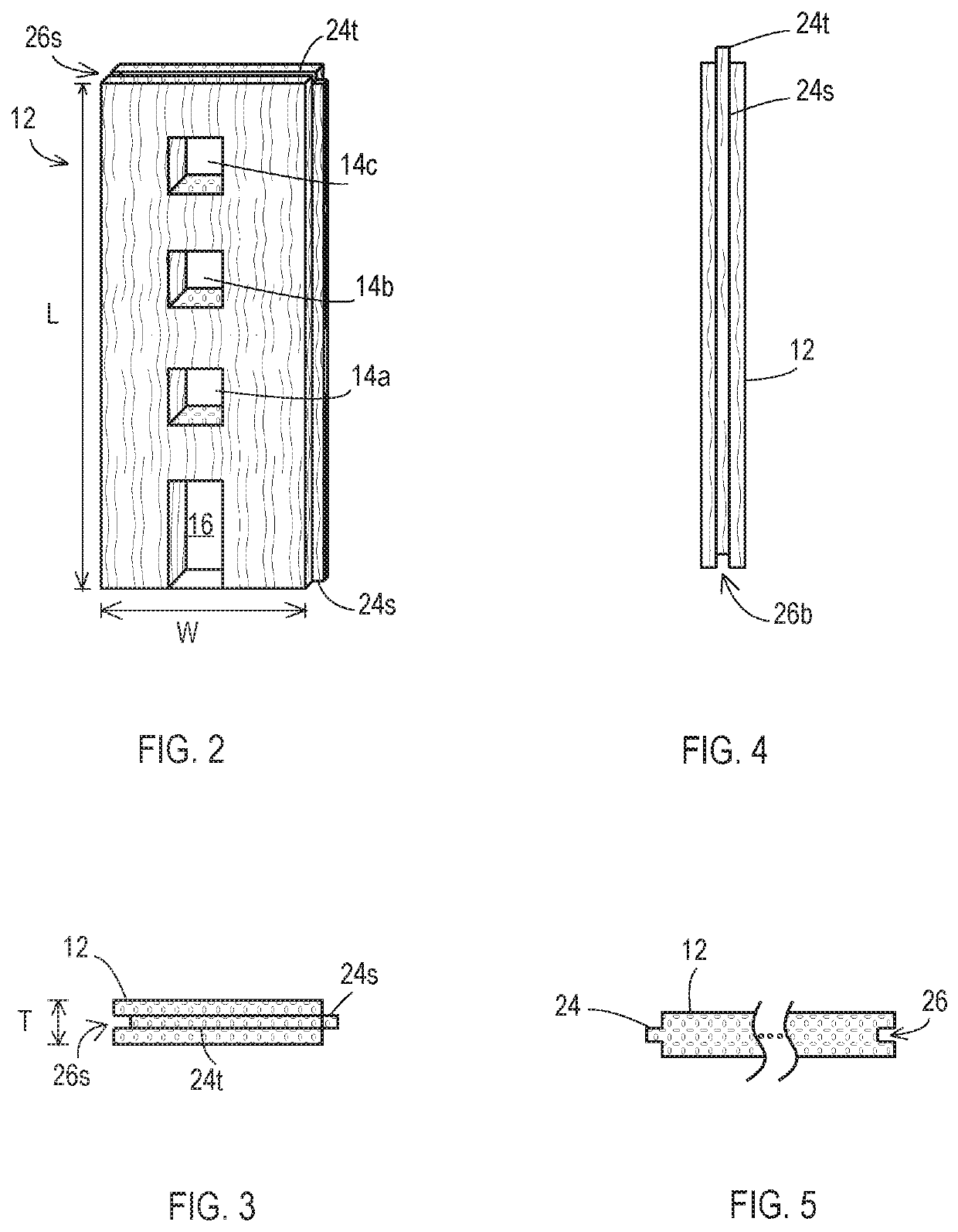

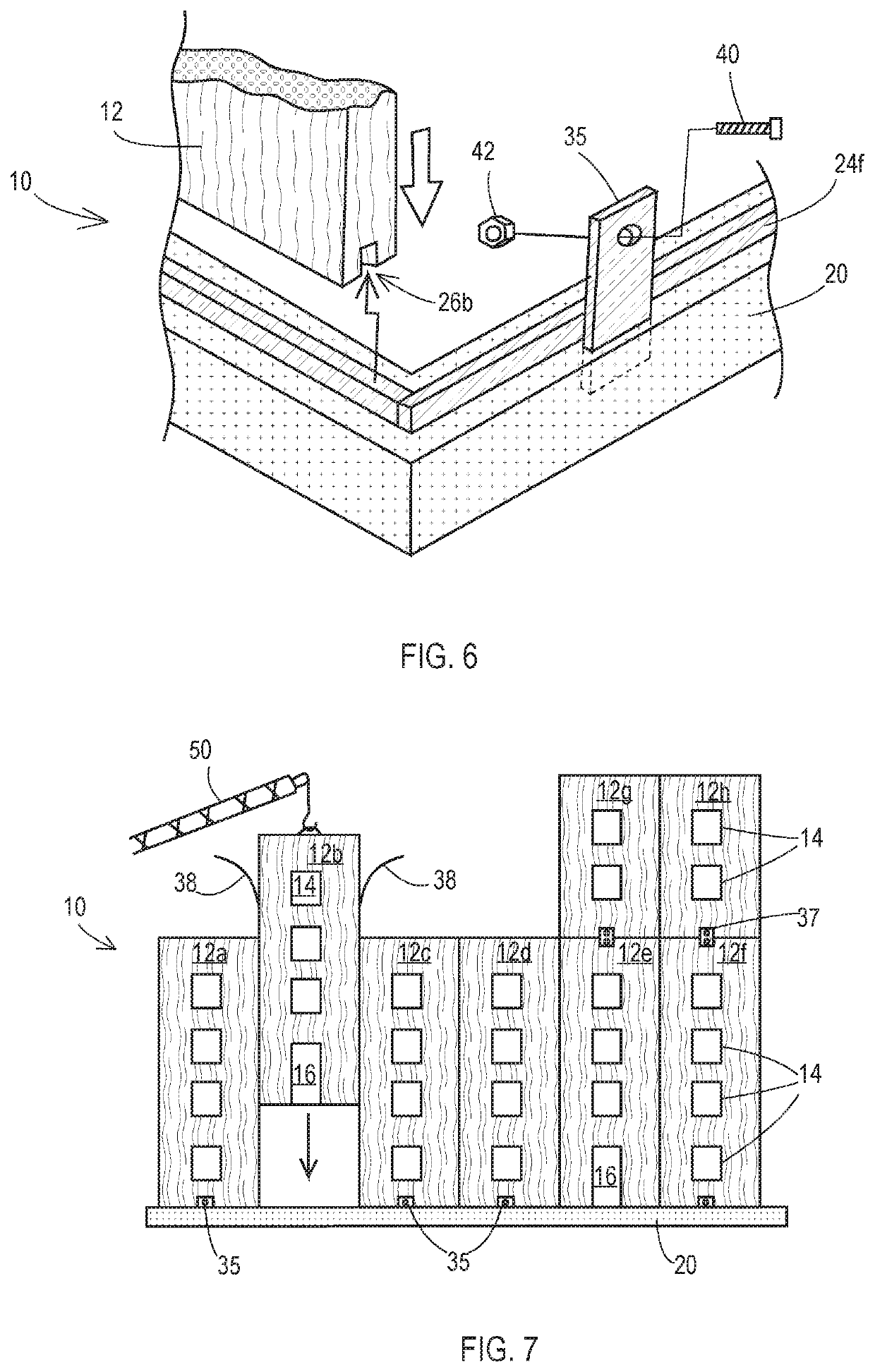

[0068]Turn now to the drawings, which accompany the following detailed description and illustrate various aspects, embodiments, features, and elements of the claimed inventions and the context for the use thereof. While exemplary embodiments and aspects are described herein, it will be understood that various modifications to the methods and devices can be made without departing from the scope of the present invention, which are solely limited by the appended claims. For example, the size, shape, position, materials, and other aspects of the described structural panels may vary from those illustrated in a number of ways. Furthermore, the sequential recitation of steps in any claim is not a requirement that the steps be performed in any particular order, unless otherwise so stated.

[0069]The following is a description of certain non-limiting preferred embodiments and / or aspects of the claimed invention. Those skilled in the art will recognize, or be able to ascertain using no more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com