Special molding process of finished lacquered wood veneer, lacquer and preparation method

A molding process and wood veneer technology, applied in the field of special-shaped molding of finished wood veneer paint panels, can solve the problems of high energy consumption, high cost, low efficiency, etc., and achieve the effects of low cost, reduced pollution, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

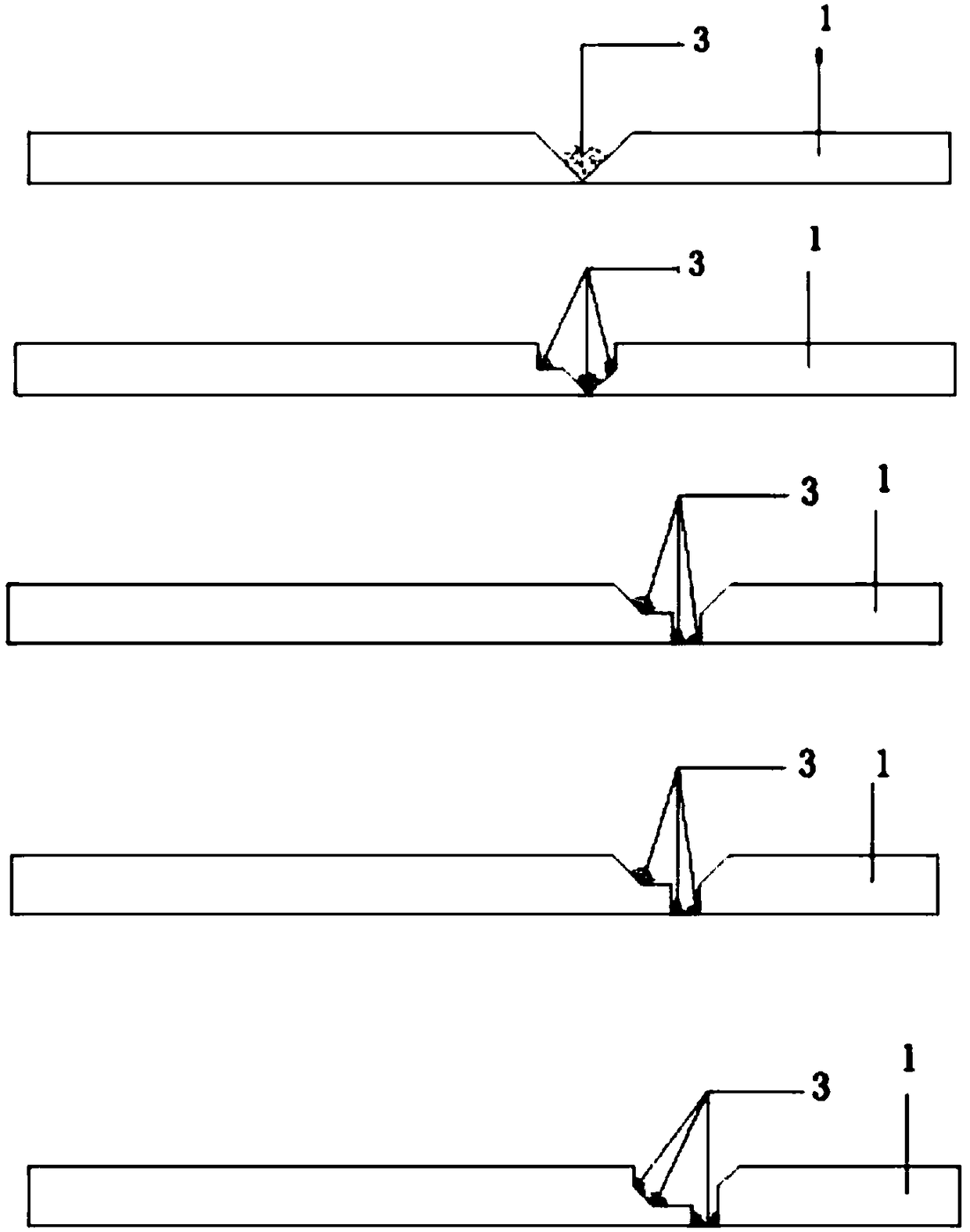

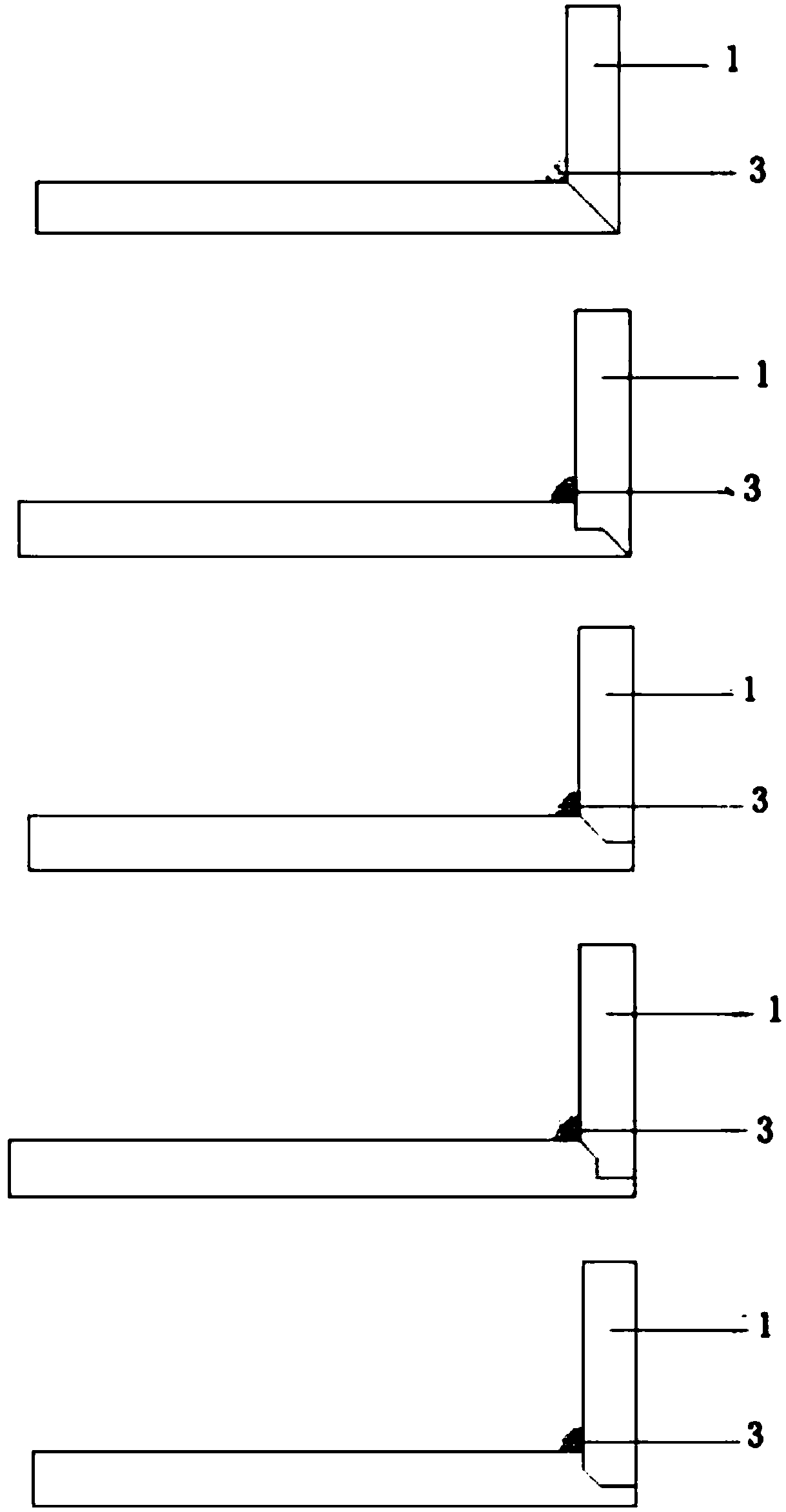

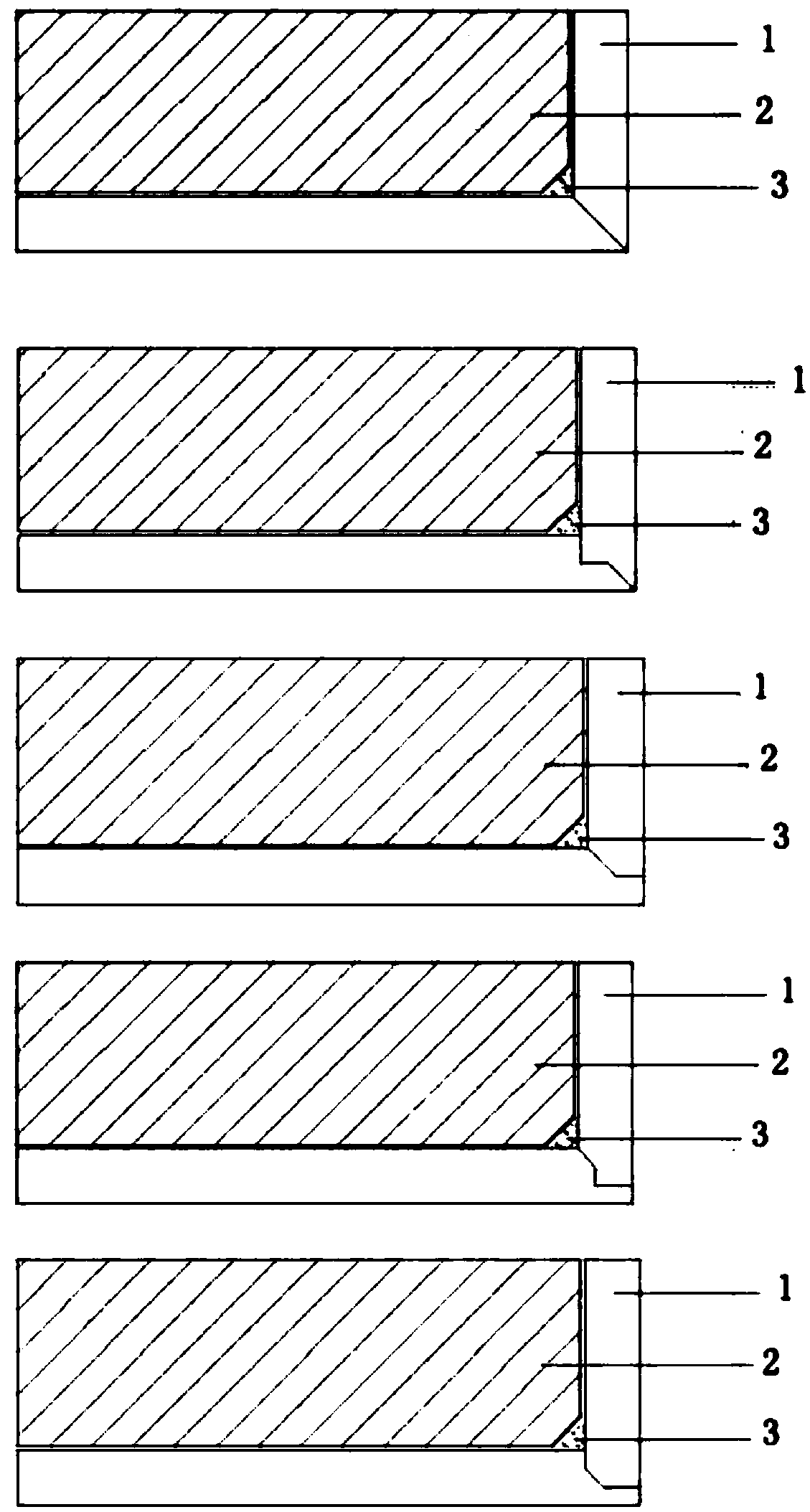

[0058] An automatic special-shaped molding process for wood veneer finished paint boards, comprising the following steps:

[0059] a. The preparation steps of finished paint boards with wooden veneers that have not been profiled and are planar: place the prepared paint agent 5 between the double stick coating wheels 4, turn on the conveyor belt 8, and set the speed of the conveyor belt to 8-10 m / min, the planar wood veneer 6 without special-shaped molding is transported to the double-stick coating wheel 4 through the conveyor belt 8 for paint brushing, and the wood veneer is dried after the paint is finished, to obtain The wood veneer finished paint board;

[0060] b. Attach the polyester film protective film to the front of the finished paint board with wooden veneer that has not been formed in a special shape and is planar in step a, and the finished wood veneer that has not been shaped in a special shape and is in a planar shape is finished by an intelligent feeding device ...

Embodiment 2

[0071] The paint agent used in the process of preparing the planar wood veneer finished paint board without special-shaped molding includes the following components:

[0072] 32 parts of epoxy modified polyester resin

[0073] 28 parts of melamine modified phenolic resin

[0074] Phosphorus bromine synergistic flame retardant 12 parts

[0075] Carbon fiber 8 parts

[0076] Silver vanadate 5 parts

[0077] Nano silicon carbide 5 parts

[0078] Chitin 5 parts

[0080] 25 parts of solvent.

[0081] Described paint agent also comprises following component:

[0082] Leveling agent 6 parts

[0083] Dispersant 5 parts

[0084] Defoamer 5 parts

[0085] Antioxidant 1 part.

[0086] The defoamer is ethylene glycol siloxane, and the leveling agent is butyl cellulose.

[0087] The antioxidant is soybean oil.

[0088] The preparation method of described paint agent comprises the following steps:

[0089] Step A: 32 parts of epoxy modified polyes...

Embodiment 3

[0094] The paint agent used in the process of preparing the planar wood veneer finished paint board without special-shaped molding includes the following components:

[0095] 38 parts of epoxy modified polyester resin

[0096] 31 parts of melamine modified phenolic resin

[0097] Phosphorus bromine synergistic flame retardant 13 parts

[0098] carbon fiber 9 parts

[0099] Silver vanadate 8 parts

[0100] Nano silicon carbide 6 parts

[0101] Chitin 6 parts

[0103] 33 parts of solvent.

[0104] Described paint agent also comprises following component:

[0105] Leveling agent 8 parts

[0106] Dispersant 6 parts

[0107] Defoamer 6 parts

[0108] Antioxidant 2 parts.

[0109] The defoamer is ethylene glycol siloxane, and the leveling agent is butyl cellulose.

[0110] The antioxidant is soybean oil.

[0111] The preparation method of described paint agent comprises the following steps:

[0112] Step A: 38 parts of epoxy modified polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com