Device for wood drying chamber heat energy recovery and VOC treatment

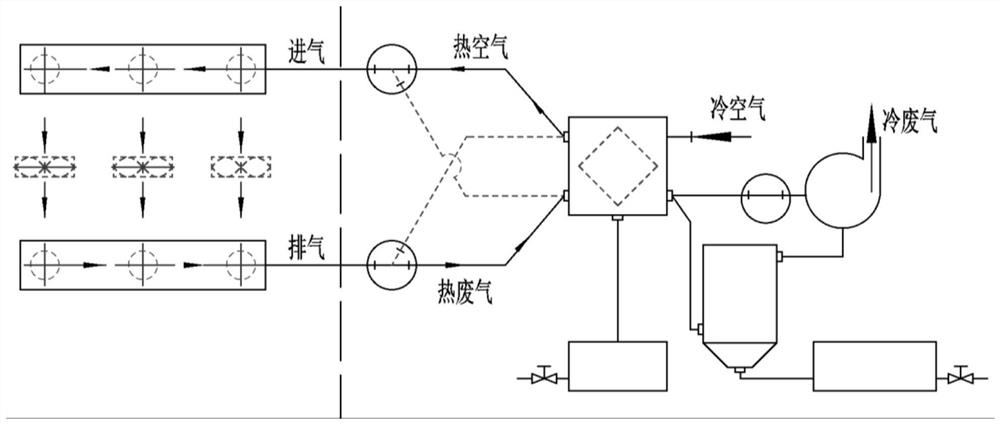

A technology for wood drying and heat energy recovery. It is used in drying gas arrangement, drying solid materials, drying and other directions. It can solve the problems of inability to continuously exhaust and dehumidify, and achieve the effect of simple structure, low installation threshold and high adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

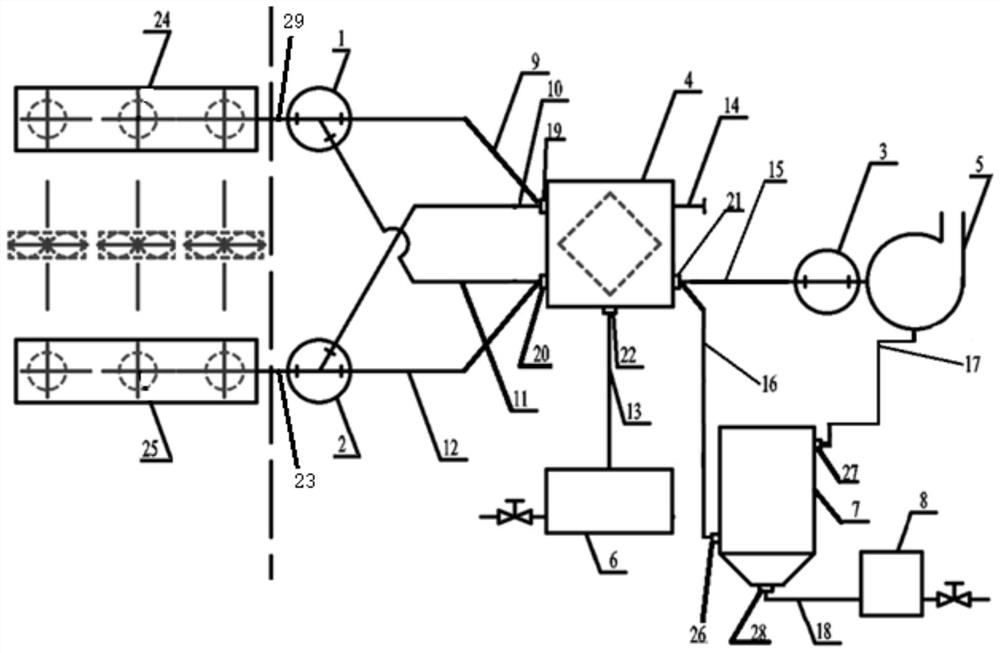

[0121] Taking the existing wood drying room as an example, the drying room heat recovery and VOC treatment device of the present invention is used to renovate the existing drying room for heat recovery and VOC treatment. The drying room of this embodiment is used for drying pine boards, and the device of the present invention is used for heat energy recovery and VOC treatment.

[0122] The first and second air valves of the air intake and exhaust assembly of the device of the present invention are respectively fixedly connected with different air intake and exhaust actuators in the drying chamber, that is, the C valve of the first air valve is always kept in an open state, and it is connected with the drying chamber. The first intake and exhaust actuator 24 is connected; the c valve of the second air valve is always kept open, and is connected with the second intake and exhaust actuator 25 of the drying chamber.

[0123] Drying room capacity is 20m 3 , the size of the pile of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com