Method used for detecting resin curing degree of sticky membrane paper laminated woodwork surfaces

A technology of resin curing and detection method, which is applied in the direction of material analysis by chemical reaction of materials, and material analysis by observing the influence of chemical indicators, to achieve the effects of clear characterization, improved production efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

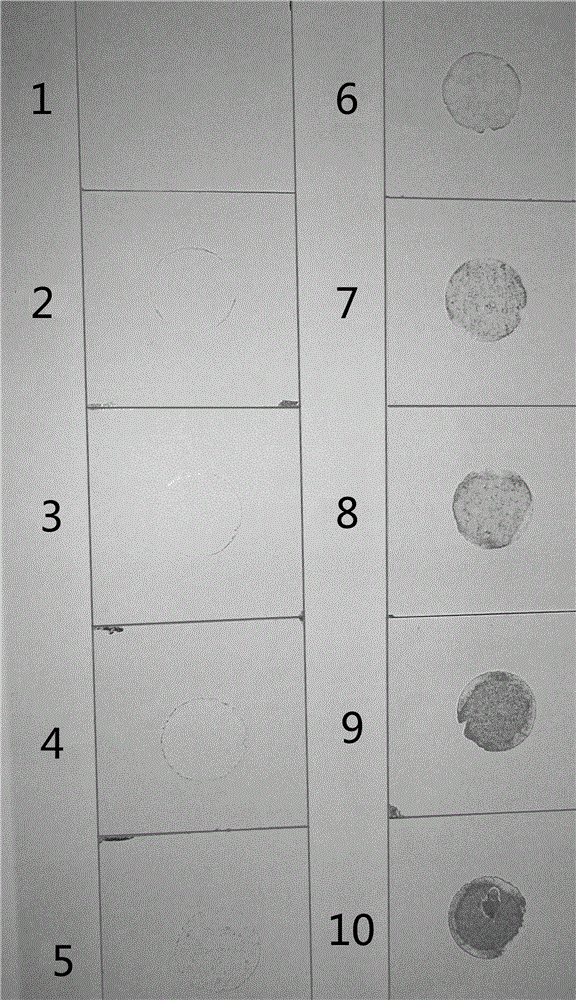

Image

Examples

Embodiment 1

[0027] Prepare 100 mL of nitric acid solution with a mass fraction of 8%, weigh 0.1 g of methyl orange and add it to the nitric acid solution, stir evenly and let stand.

Embodiment 2

[0029] Prepare 100 mL of nitric acid solution with a mass fraction of 10%, weigh 1.0 g of methyl red into the nitric acid solution, stir evenly and let stand.

Embodiment 3

[0031] Prepare 100 mL of nitric acid solution with a mass fraction of 12%, weigh 1.5 g of bromophenol blue B and add it to the nitric acid solution, stir evenly and let stand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com