Log conveying device

A technology for conveying devices and round logs, which is applied in the direction of conveyors, transportation, packaging, packaging, etc., can solve the problems of large-scale machinery such as high energy consumption, high labor intensity, and poor safety, and achieve high energy consumption, strong continuity, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

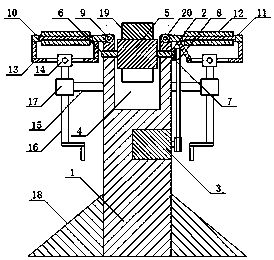

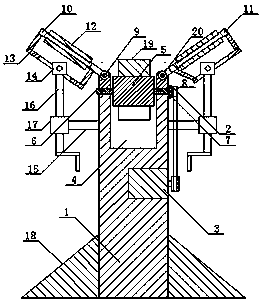

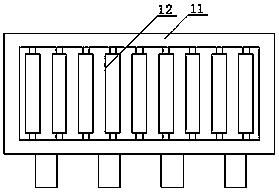

[0015] A log conveying device of the present invention includes a rectangular parallelepiped frame body 1, a transmission chain 2 and a drive motor 3. The top of the rectangular parallelepiped frame body 1 is provided with a longitudinal groove 4, and more than two grooves 4 are arranged in the grooves 4 The rotating roller 5, the shafts 6 at both ends of the rotating roller 5 are all mounted on the side wall of the groove 4 through bearings, and the outer circumference of the rotating roller 5 is fixedly installed with more than one axial blade 19, the rotating roller 5 The extension of the shaft 6 at one end is provided with a transmission wheel 7 and is connected by a transmission chain 2. One of the extensions of the shaft 6 is provided with a driving wheel 8 which is connected to the drive motor 3 fixed on the rectangular parallelepiped frame 1. The left side of the top groove 4 of the body 1 is movably connected to the left frame 10 through a first shaft 9 and the right si...

Embodiment 2

[0017] A log conveying device of the present invention includes a rectangular parallelepiped frame 1, a transmission chain 2 and a drive motor 3. The top of the rectangular parallelepiped frame 1 is provided with a longitudinal groove 4, and more than two grooves 4 are arranged The rotating roller 5, the shafts 6 at both ends of the rotating roller 5 are all mounted on the side wall of the groove 4 through bearings, and the outer circumference of the rotating roller 5 is fixedly installed with more than one axial blade 19, the rotating roller 5 The extension part of the shaft 6 at one end is provided with a transmission wheel 7 and is connected by a transmission chain 2. One of the extension parts of the shaft 6 is provided with a driving wheel 8 which is connected to the drive motor 3 fixed on the cuboid frame 1. The cuboid frame The left side of the top groove 4 of the body 1 is movably connected to the left frame 10 through a first shaft 9 and the right side of the top groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com