Automatic fin feeding device of fin evaporator

A finned evaporator, automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of wrong direction of fins, poor pipe penetration, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

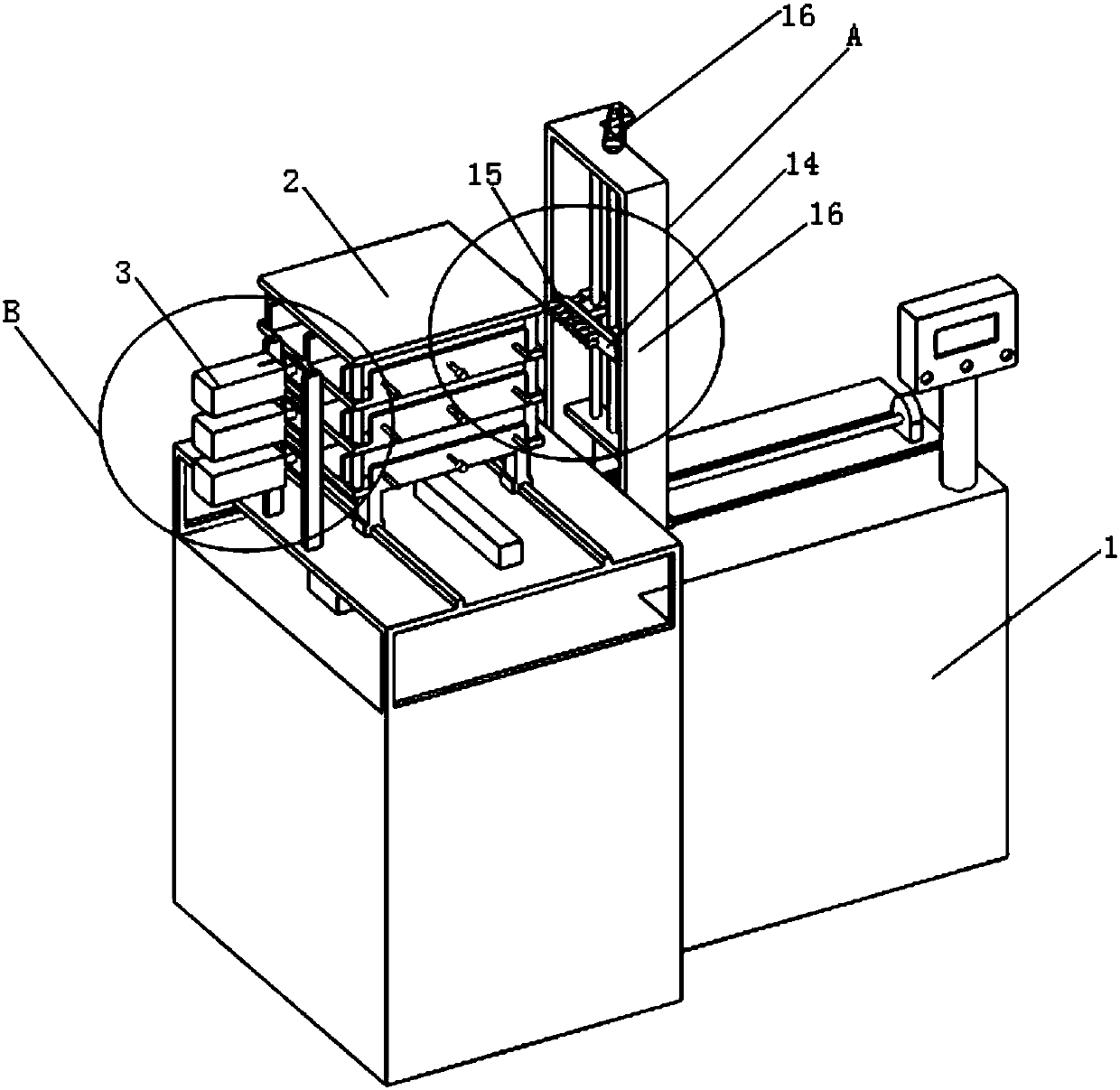

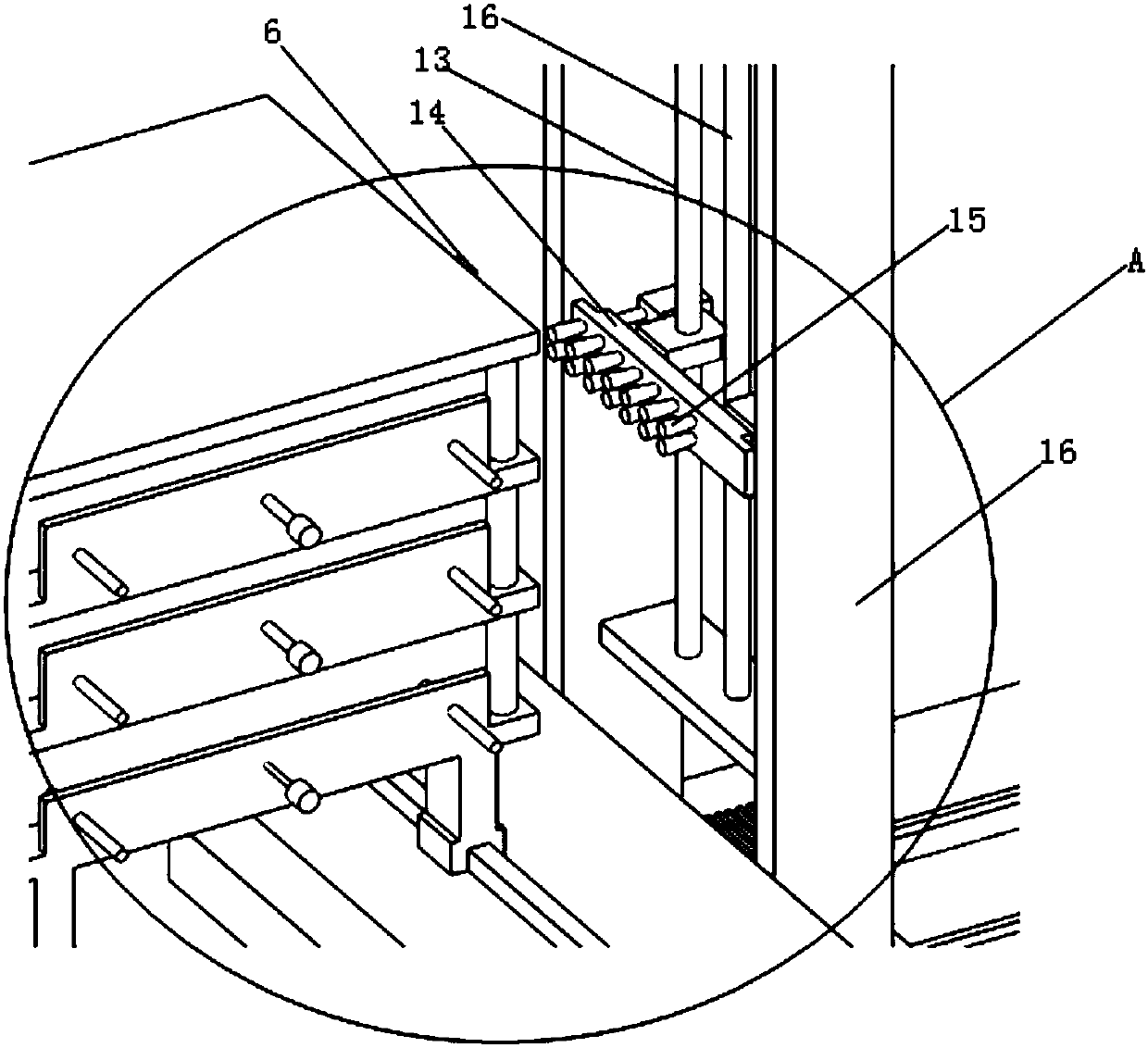

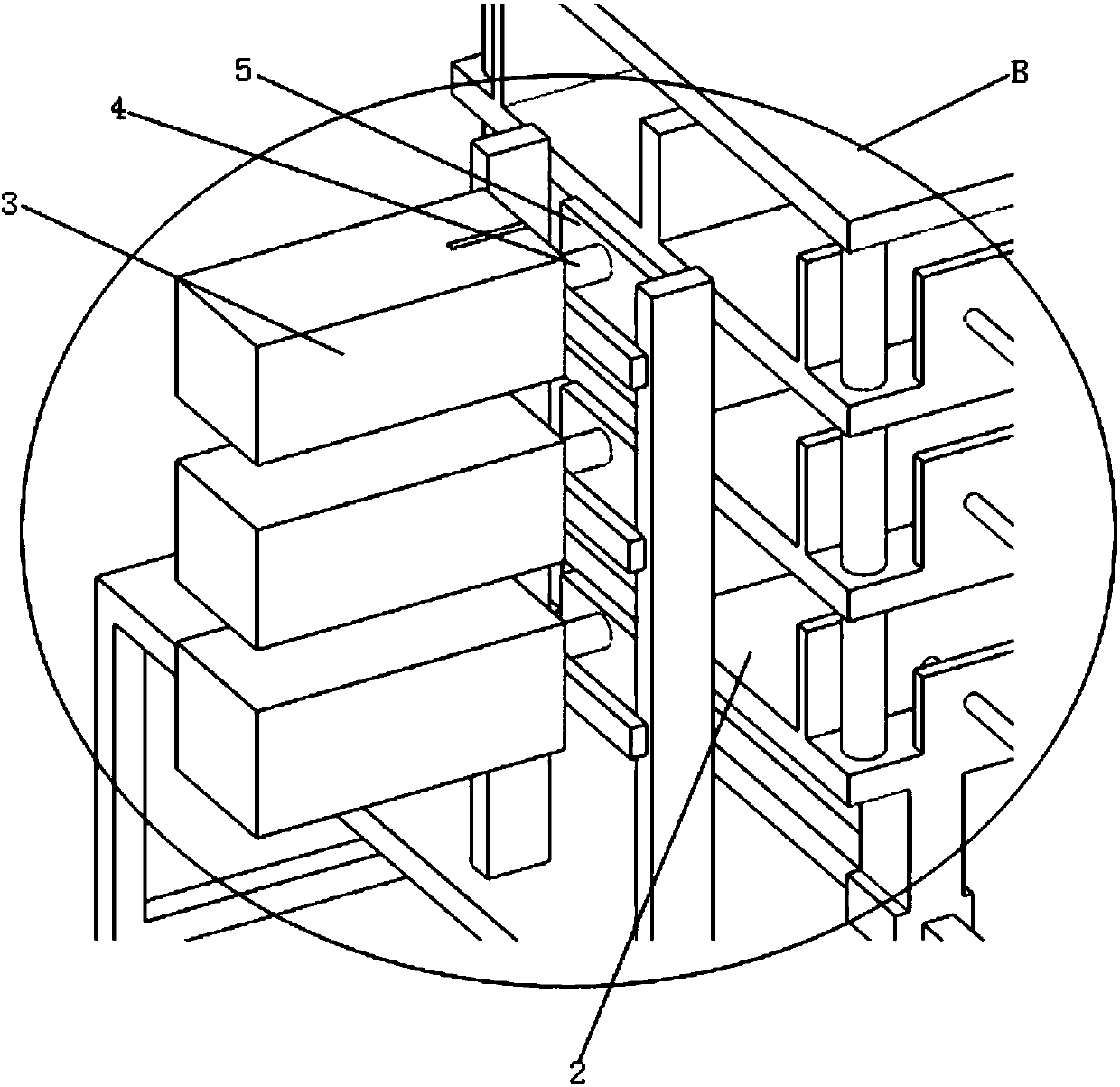

[0012] See attached Figure 1-4 As shown, a finned evaporator automatic loading device includes a frame 1 and a storage box 2 arranged on the frame 1, and a cylinder 3 is arranged on the rear side of the storage box 2, and the cylinder 3 is connected to the push rod 4, and a push plate 5 is arranged on the push rod 4, and the push plate 5 is arranged in the material storage box 2, and a fin limit bar is provided on the front side of the material storage box 2 6. A first linear guide rail 7 and a second linear guide rail 8 are arranged on the frame 1 on the lower side of the storage box 2, and a chip arrangement mold 9 is arranged on the first linear guide rail 7. On the second linear guide rail 8 is a sheet arranging limiting plate 10, connected with the sheet arranging mold 9 is a first screw motor 11, and connected with the sheet arranging limiting plate 10 is a second screw motor 12 The inserting device is installed on the side of material storage box 2, and it comprises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com