Cutting equipment for square timber board cutting used for wooden product production

A technology for cutting equipment and wood products, applied in the direction of sawing equipment, unloading equipment, sawing components, etc., can solve the problems of long cutting time, harmful to workers' health, and short cutting time, so as to improve feeding efficiency and save labor costs. The effect of material handling and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

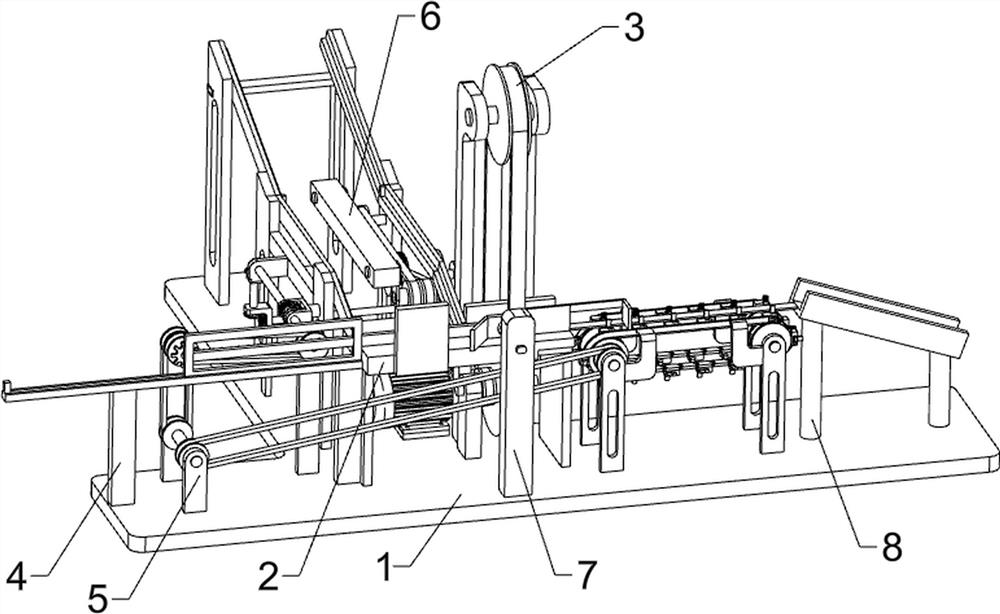

[0071] A square wood panel cutting equipment for wood product production, such as figure 1 As shown, it includes a base plate 1, a cutting platform 2, a cutting mechanism 3 and a material pushing mechanism 4, the middle part of the base plate 1 is provided with a cutting mechanism 3, the base plate 1 is provided with a cutting platform 2, and the left part of the base plate 1 is provided with a material pushing mechanism 4, The pushing mechanism 4 is connected with the cutting platform 2 .

[0072] When people need to cut the material, first place the material on the cutting platform 2, manually operate the pushing mechanism 4 to move to the right to push the material onto the cutting platform 2, and then start the cutting mechanism 3 to cut the material. The material is taken out, and the cutting mechanism 3 is closed.

Embodiment 2

[0074] On the basis of Example 1, such as Figure 2 to Figure 7 As shown, the cutting mechanism 3 includes a first support frame 31, a motor 32, a first belt assembly 33, a saw blade assembly 34 and a second support frame 35, the left side of the middle part of the bottom plate 1 is provided with a motor 32, and the left and right sides of the middle part of the bottom plate 1 A first support frame 31 is provided, and a second support frame 35 is provided on the left and right sides of the middle part of the bottom plate 1. The second support frame 35 is located at the rear side of the first support frame 31. A saw blade assembly 34 is rotatably connected between them, and a first belt assembly 33 is connected between the lower left side of the saw blade assembly 34 and the output shaft of the motor 32 .

[0075] When people need to cut the material, start the motor 32, the output shaft of the motor 32 drives the first belt assembly 33 to move, the first belt assembly 33 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com