Quantitative control system for granular or fiber-like material discharging

A quantitative control, granular technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of low work efficiency, time-consuming and laborious, and achieve the effect of simple operation and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

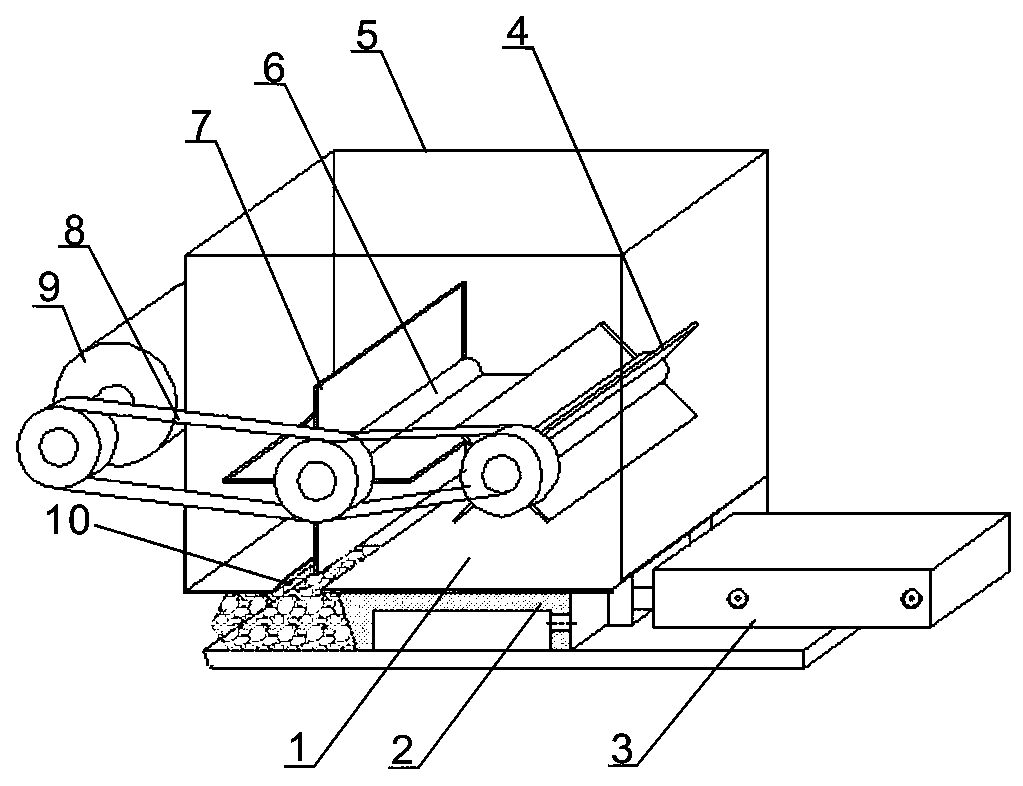

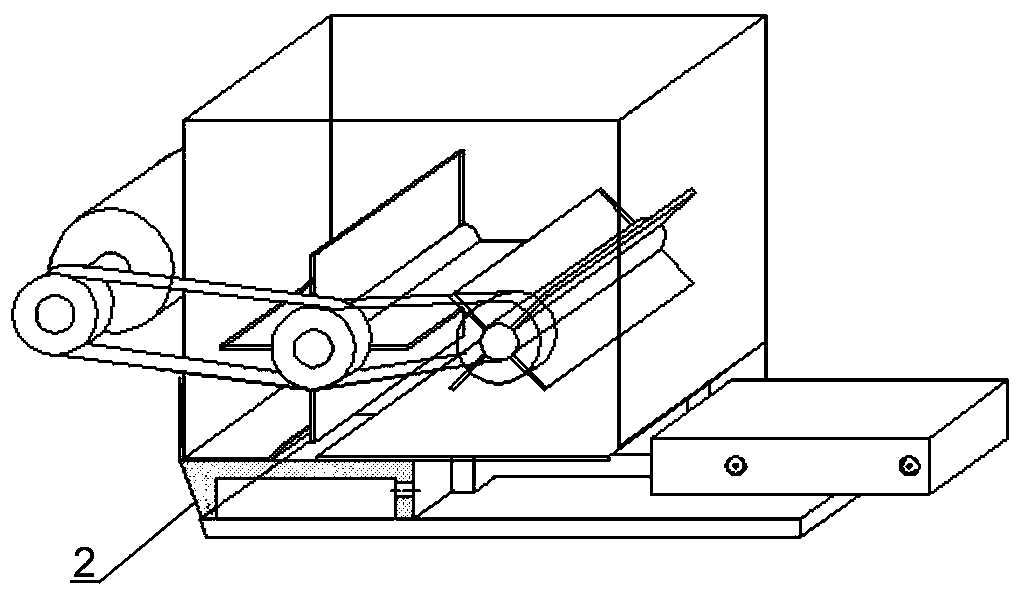

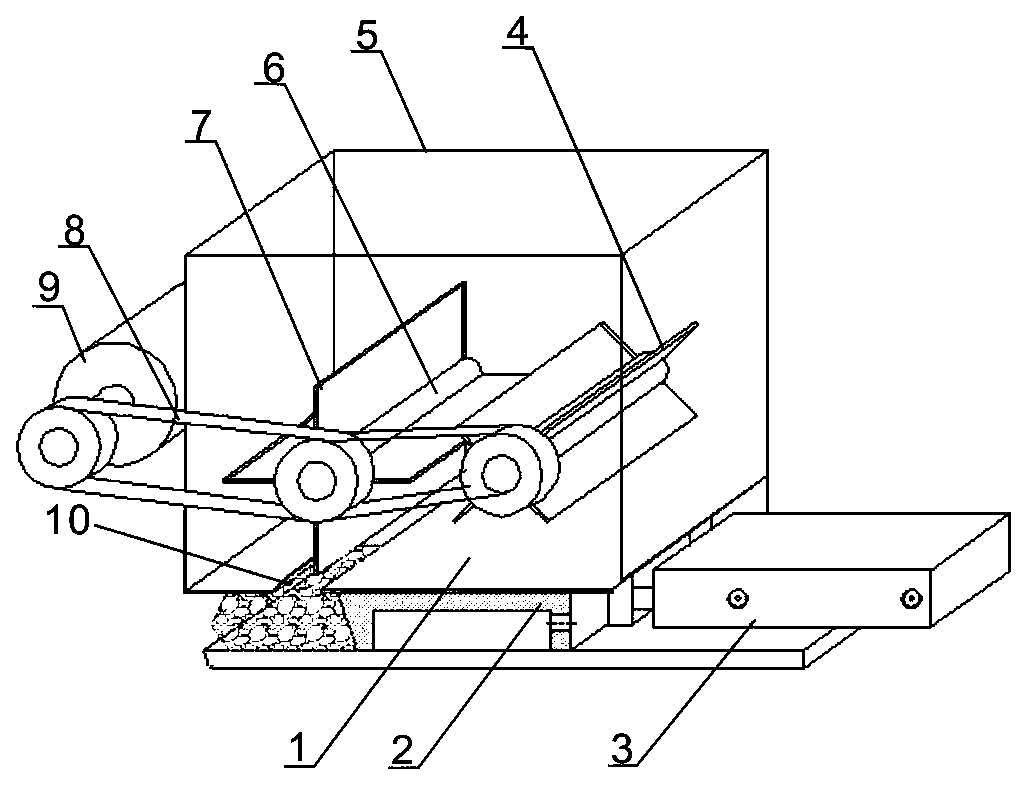

[0021] Such as figure 1 , 2 As shown, a quantitative control system for discharging granular or velvet materials includes a silo 5, a drive mechanism 3, a motor 9 and a dial wheel 6. The silo 5 is a hollow structure with an open upper end. There is a leaking plate 1 inside, and the leaking plate 1 divides the inner cavity of the silo 5 into two independent spaces, the upper and lower spaces. The material shifting wheel 6 above the material gap 10 is provided with a motor 9 on the outside of the material bin 5, and the motor 9 is connected to the material shifting wheel 6 through a belt 8, and a sliding bin door 2 located at the bottom of the leakage material plate 1 is arranged in the material bin 5 , the sliding bin door 2 is connected with a drive mechanism 3 capable of driving the sliding bin door 2 to slide lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com