Tamping device for construction

A technology of hydraulic telescopic rod and hydraulic device, which is used in infrastructure engineering, soil protection, construction, etc., can solve problems such as poor flexibility and unadjustable tamping weight, and achieve a high degree of automation, good tamping effect, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

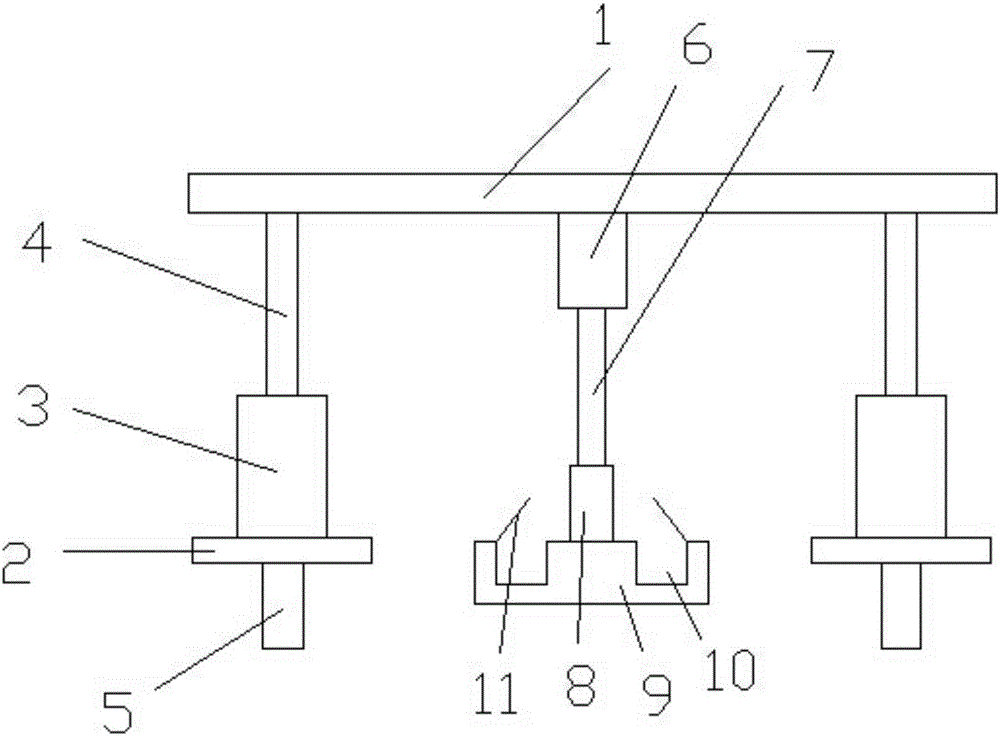

[0038] figure 1 The shown construction tamping device includes a support rod, two support plates are arranged symmetrically under the support rod, each support plate is provided with a first hydraulic device, the lower end of each support plate is connected to a roller, and the upper end of the first hydraulic device is connected to the second A hydraulic telescopic rod, the first hydraulic telescopic rod is slidably connected to the support plate, a second hydraulic device is provided between the two first hydraulic telescopic rods, the second hydraulic device is slidably connected to the support rod, and the lower part of the second hydraulic device is connected The second hydraulic telescopic rod, the lower part of the second hydraulic telescopic rod is detachably connected to the pressure block through the bushing, several grooves are symmetrically arranged on the pressure block, and the opening of the groove is connected with an openable cover plate.

[0039] Described ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com