A kind of aluminum ingot trimming and grinding equipment for metal processing

A metal processing and aluminum ingot technology, which is applied in the field of aluminum ingot trimming and grinding equipment for metal processing, can solve the problems of cumbersome operation, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

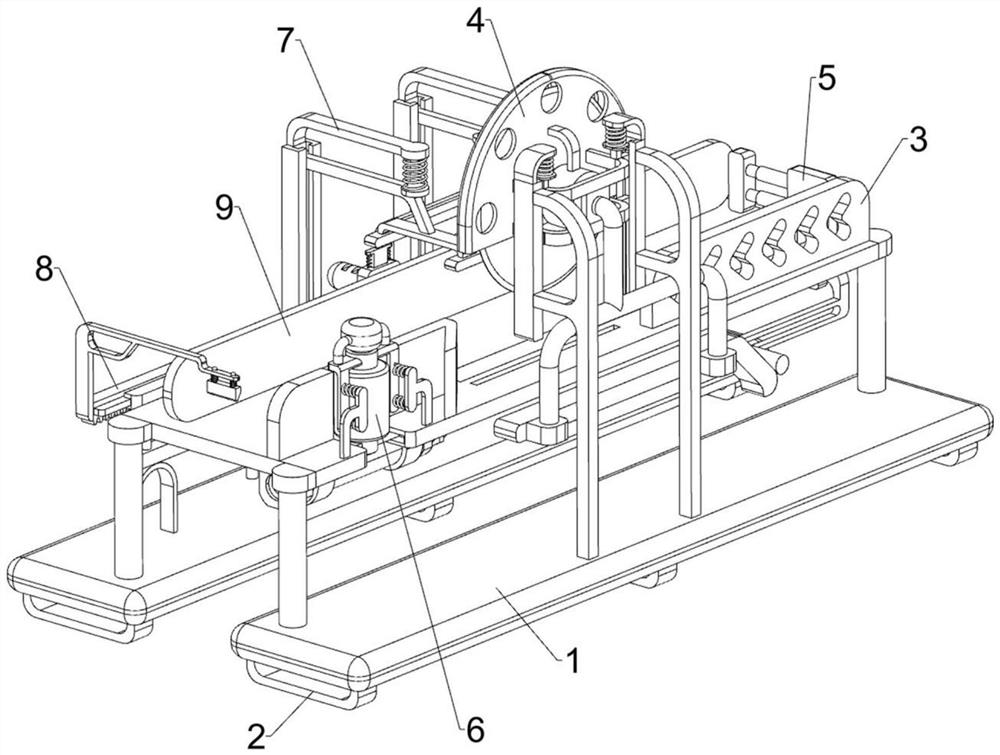

[0071] An aluminum ingot trimming and grinding equipment for metal processing, such as Figure 1-3 As shown, it includes a bottom plate 1, a tripod 2, a placement component 3 and a cutting mechanism 4. Three tripods 2 are arranged at the bottom of the bottom plate 1, and a placement component 3 is connected between the tops of the bottom plate 1, and the middle of the bottom plate 1 on the front side is provided with There are cutting mechanism 4.

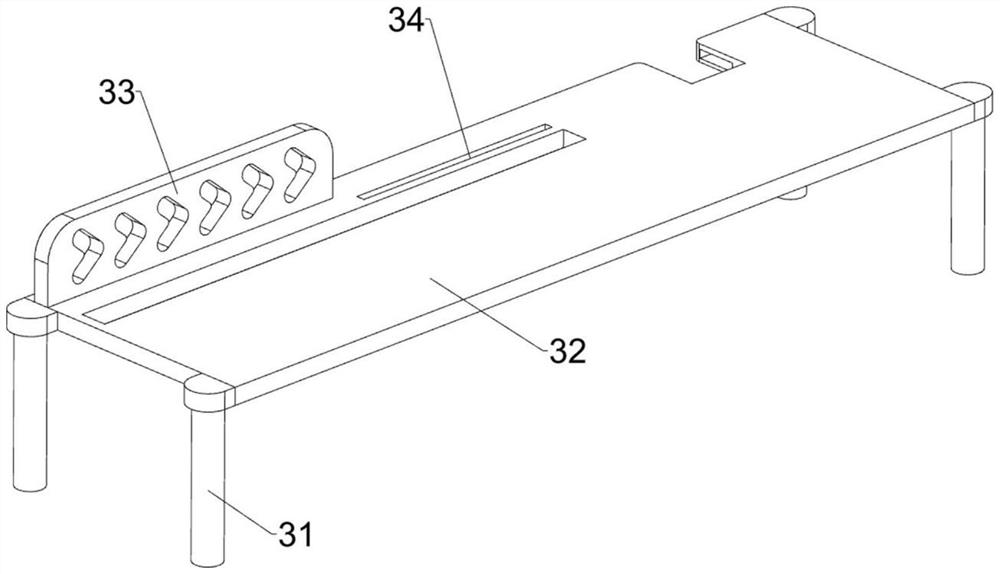

[0072] The placement assembly 3 includes a support column 31, a workbench 32 and a limit plate 33. The left and right sides of the bottom plate 1 are provided with a support column 31. A workbench 32 is provided between the tops of the support columns 31. A limit plate is provided on the right front side of the workbench 32. The plate 33 is provided with a cutting groove 34 in the middle of the front side of the workbench 32 .

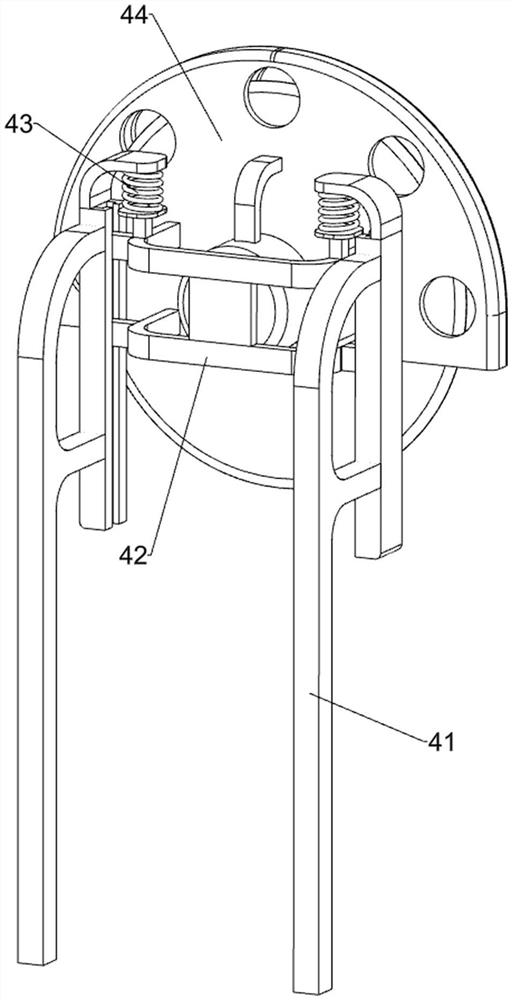

[0073]The cutting mechanism 4 includes a first guide rail frame 41, a sliding connection frame 42, a fi...

Embodiment 2

[0076] On the basis of Example 1, such as Figure 4-8 Shown, also include pusher mechanism 5, pusher mechanism 5 includes fixed ring 51, cylinder 52, connection block 53, telescopic push plate 54, extruding frame 55, inclined-plane frame 56 and first connecting frame 57, workbench 32 bottom left front sides are provided with two fixed rings 51, are provided with cylinder 52 between the fixed rings 51, and workbench 32 right front sides are slidingly connected with connection block 53, and connection block 53 is connected with cylinder 52 right sides, and connection block 53 tops are provided with There is a telescopic push plate 54, an extruding frame 55 is provided on the front side of the connecting block 53 bottom, a first connecting frame 57 is provided on the front side of the sliding connecting frame 42, and an inclined plane frame 56 is provided on the first connecting frame 57 bottom.

[0077] When people need to trim the aluminum ingot, first adjust the telescopic pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com