Ceramic wash basin blank trimming device

A technology of washing table and green body, which is applied in the direction of grinding drive device, grinding/polishing safety device, machine tool suitable for grinding the edge of workpiece, etc., which can solve problems such as low efficiency and hidden safety hazards of operators, and improve efficiency , improve stability and save working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

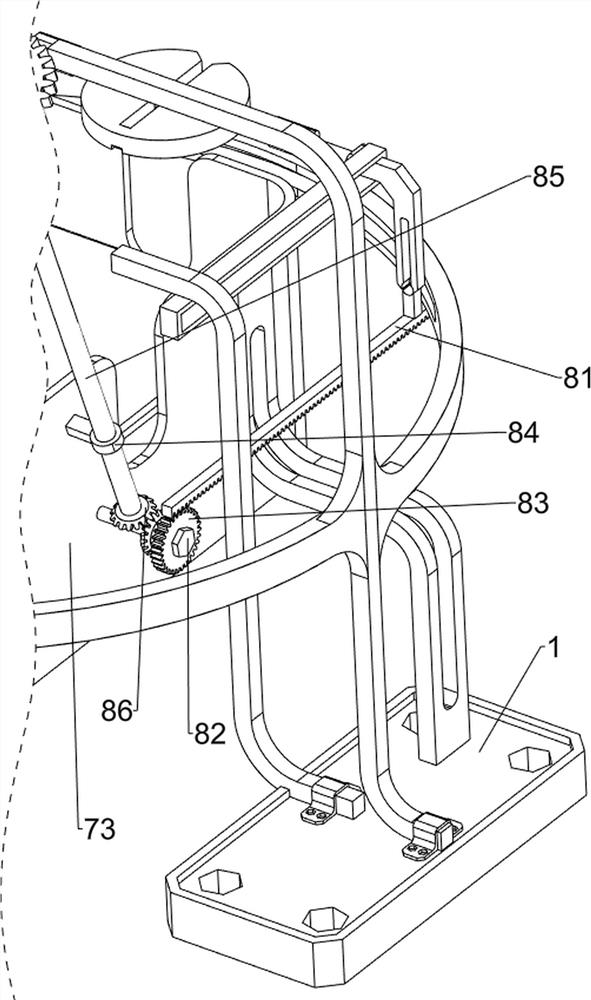

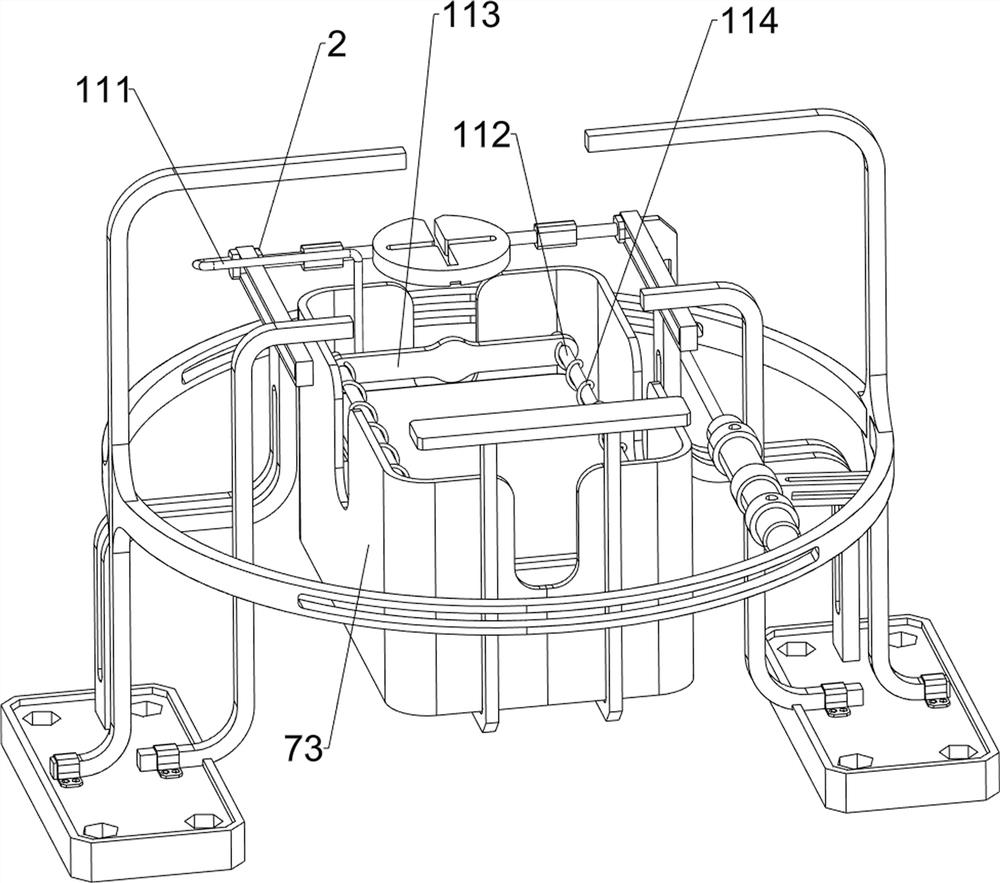

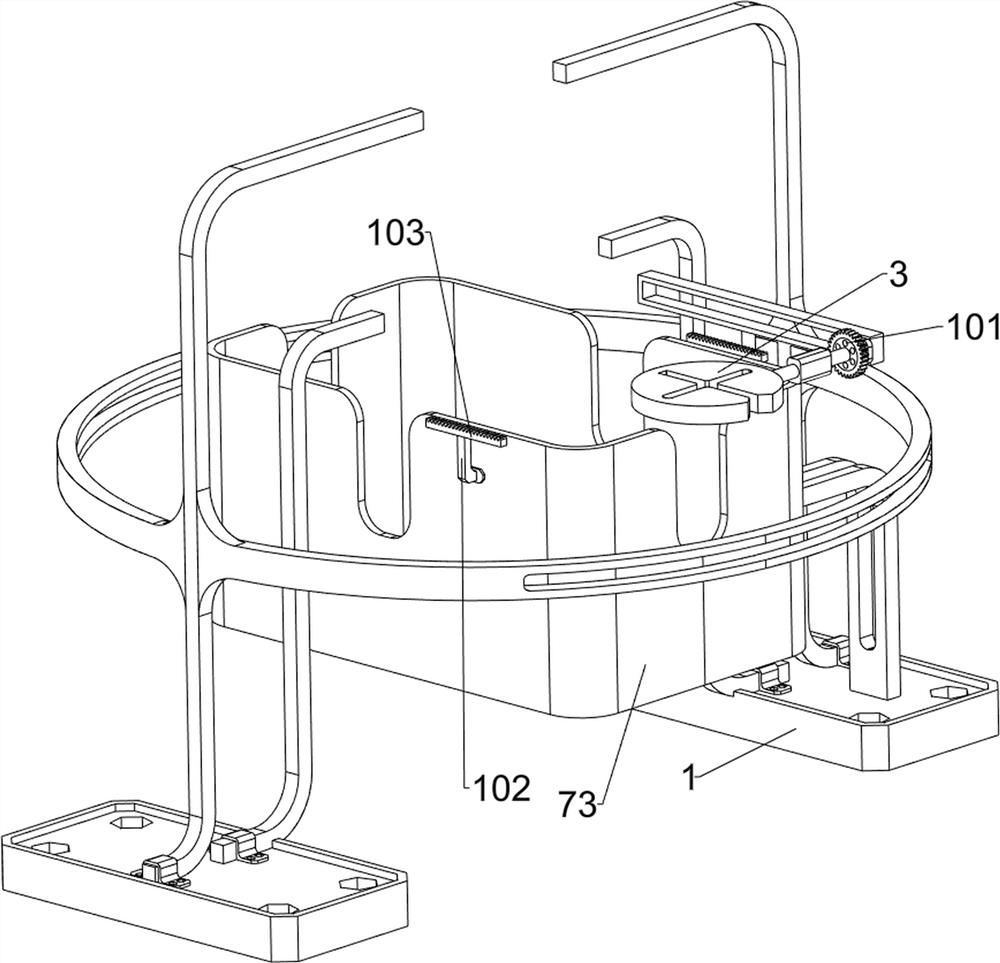

[0032] A device for trimming the body of a ceramic washbasin, such as Figure 1-13 As shown, it includes a frame 1, a first connecting block 2, a connecting plate 3, a frame 4, a cylinder 5, a grinding mechanism 6 and a charging mechanism 7, and the first connecting block 2 is slidably connected to the left and right sides of the upper part of the frame 1. Between the first connecting block 2, a connecting plate 3 is connected in a rotating manner. A frame 4 is provided on the left rear side of the frame 1, and a cylinder 5 is arranged on the frame 4. The first connecting block 2 on the front side and the left side of the telescopic rod of the cylinder 5 Connection, a grinding mechanism 6 is provided between the frame 1 and the connecting plate 3, and a charging mechanism 7 is provided on the frame 1.

[0033] The grinding mechanism 6 includes a first fixed rod 61, a second connecting block 62, a motor 63, a grinding wheel 64, a first wedge-shaped block 65 and a second wedge-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com