Storage battery large-plate grid casting equipment

A battery and grid technology, applied in the field of large battery grid casting equipment, can solve the problems affecting the quality of the finished battery, large grid impact, easy deformation of the grid, etc. The effect of battery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

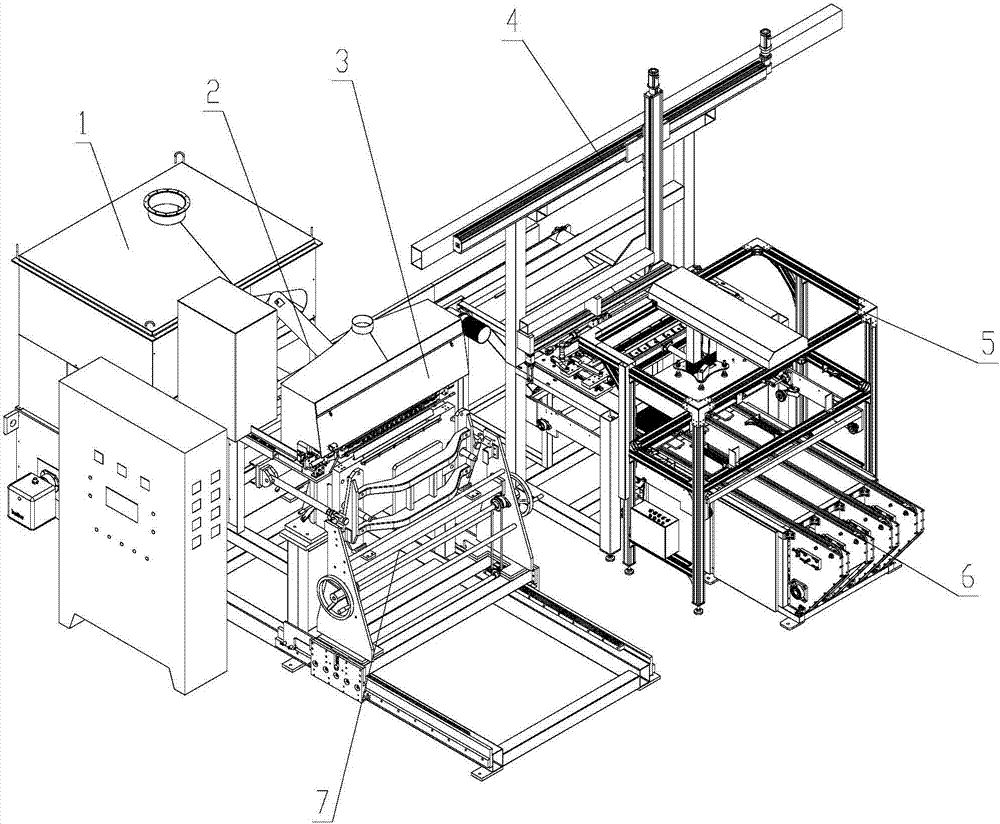

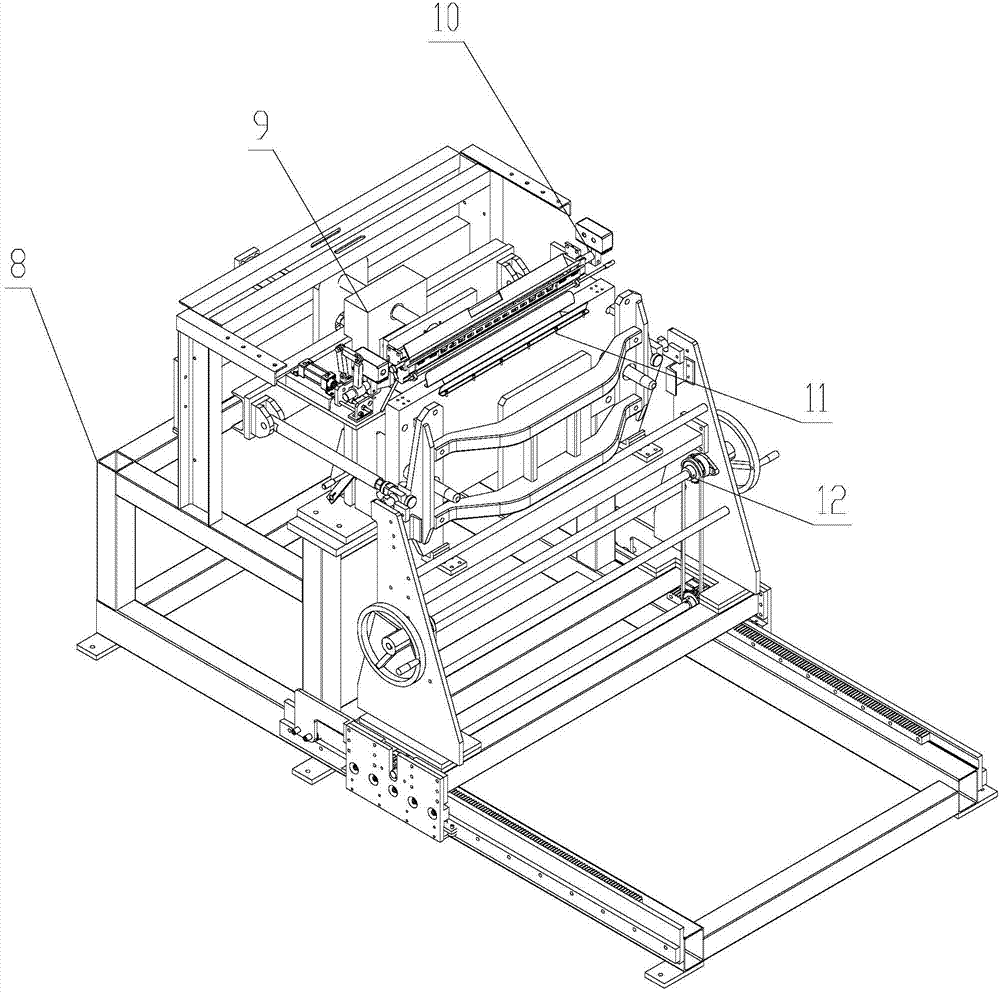

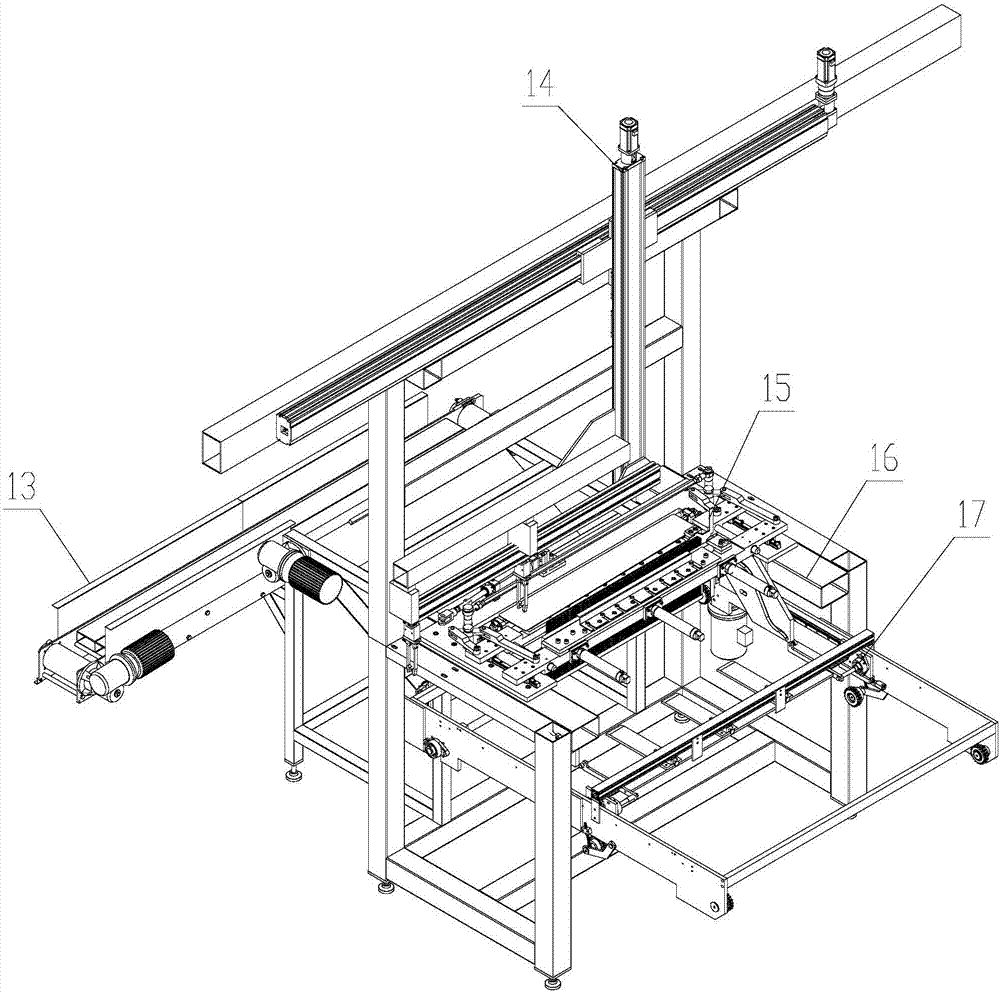

[0026] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the large-scale battery grid casting equipment of this embodiment includes a casting plate main machine 7 and a casting plate auxiliary machine 4; the casting plate main machine 7 is used for casting and forming a battery grid; The plate casting auxiliary machine 4 includes a vertical shear mechanism 15 for shearing the riser of the vertically placed grid, and a plate for driving the sheared grid to turn from a vertical state to a horizontal state. The grid turning device 17 and the truss manipulator assembly spanning between the cast slab main machine 7 and the vertical shearing mechanism 15 are used to vertically hoist the cast slab main machine 7 casted grid to the vertical shearing mechanism 15 14. The large-scale storage battery grid casting equipment of the present invention uses the casting plate main machine 7 to cast and form the battery grid, and uses the truss mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com