Copolymer and lubricating oil composition

A technology of lubricating oil composition and copolymer, applied in lubricating composition, petroleum industry, base material, etc., can solve the problems of limited use range, low viscosity, difficult application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

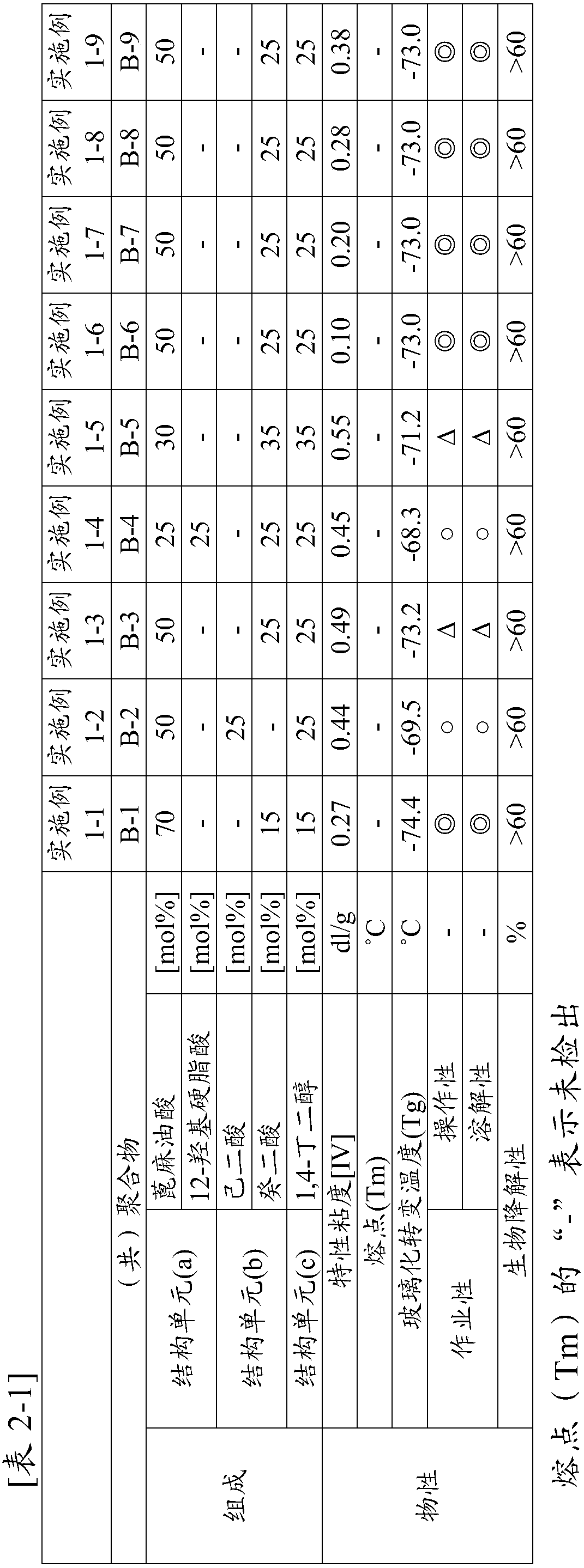

[0204] [Example 1-1] (manufacture of copolymer B-1)

[0205] 40.0 parts by mass of ricinoleic acid, 5.8 parts by mass of sebacic acid, and 5.2 parts by mass of 1,4-butanediol were heated from normal temperature to 210° C. over 30 minutes. After reaching 210° C., 0.20 parts by mass of titanium tetrabutoxide and 0.03 parts by mass of a 20 wt % aqueous solution of ethylammonium hydroxide were added, and the mixture was kept at 210° C. for 5 hours to conduct an esterification reaction.

[0206] After completion of the esterification reaction, 1.36 parts by mass of titanium tetrabutoxide was added as a polymerization catalyst, and the pressure was reduced to 0.133 kPa (1 Torr) while raising the temperature to 230° C. over 60 minutes to perform a polycondensation reaction. This polycondensation reaction was performed while stirring the reaction mixture. Here, as the polycondensation reaction proceeds, the stirring torque required for stirring the reaction mixture gradually increase...

Embodiment 1-2

[0207] [Example 1-2] (manufacture of copolymer B-2)

[0208] 40.0 parts by mass of ricinoleic acid, 10.2 parts by mass of adipic acid, and 9.7 parts by mass of 1,4-butanediol were heated from normal temperature to 210° C. over 30 minutes. Thereafter, polyester was obtained in the same manner as in Example 1-1.

Embodiment 1-3

[0209] [Example 1-3] (manufacture of copolymer B-3)

[0210] 40.0 parts by mass of ricinoleic acid, 13.6 parts by mass of sebacic acid, and 9.7 parts by mass of 1,4-butanediol were heated from normal temperature to 210° C. over 30 minutes. Thereafter, polyester was obtained in the same manner as in Example 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com