Feeding device for vertical centrifugal machine

A vertical centrifuge and feeding device technology, applied in centrifuges, grain processing, etc., can solve the problems of uneven distribution of materials, affecting the separation effect, and easy blocking of the feeding pipe, so as to achieve uniform flow, improve separation effect, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

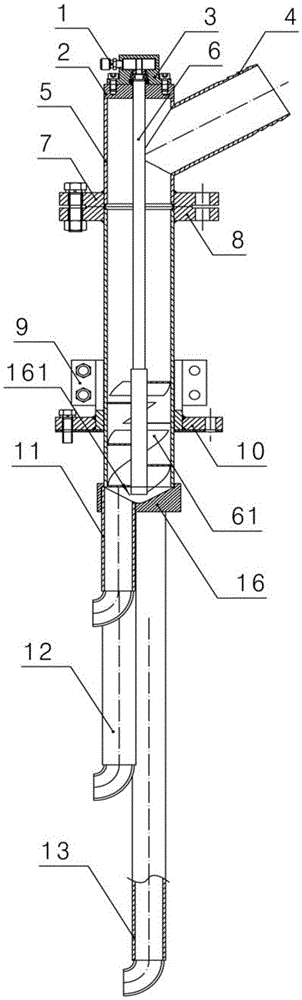

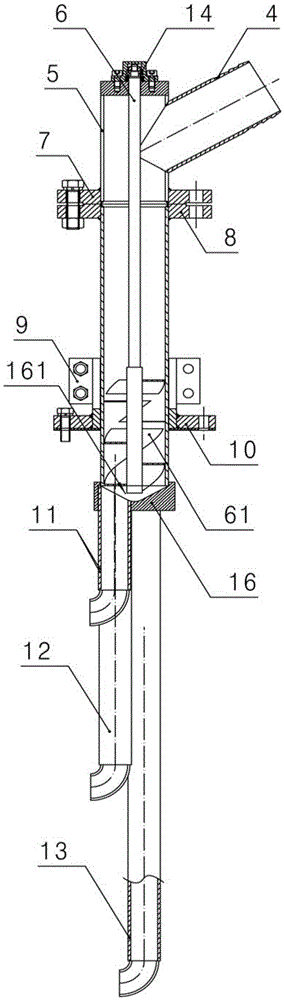

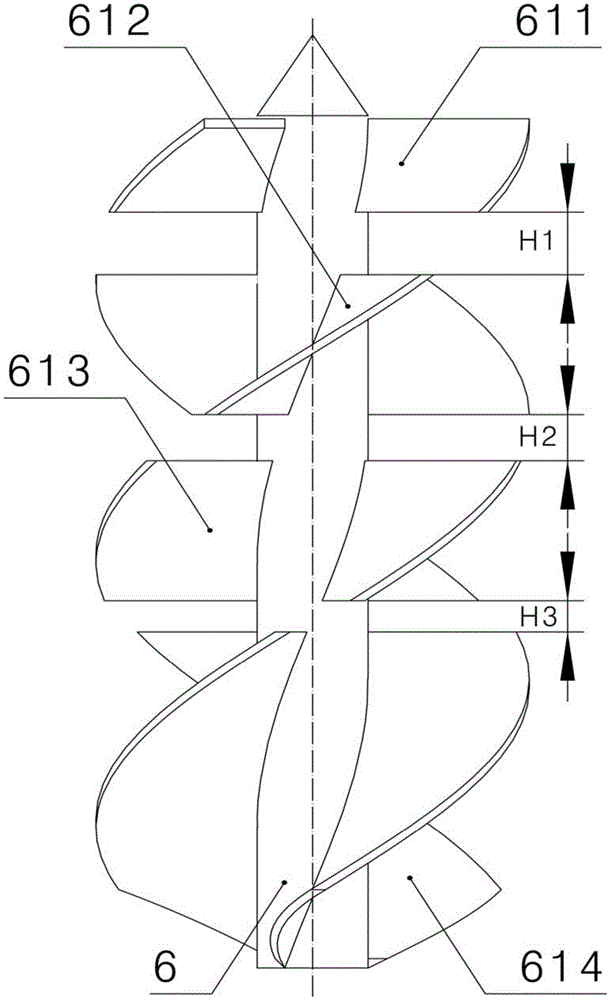

[0022] Attached below Figures 1 to 5 , to describe in detail the specific implementation of the feeding device used in the vertical centrifuge of the present invention.

[0023] Such as figure 1 As shown, the feeding device used in the vertical centrifuge according to the present invention includes: a pair of feeding flanges, that is, the upper flange 7 of the feeding pipe and the lower flange 8 of the feeding pipe are connected together The feed pipe 5 composed of the upper and lower feed pipes, the upper part of the feed pipe 5, that is, the upper feed pipe, is provided with a feed port, and the feed port is connected with a feed connection pipe 4, and the bottom end of the feed pipe 5 is the lower end. The bottom end of the feeding pipe is provided with a distributing pan 16, and the distributing pan 16 is provided with an upper distributing pipe 11, a middle distributing pipe 12 and a lower distributing pipe corresponding to the upper, middle and lower areas of the drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com