Preparation method for self-suspension propping agent in laboratory

A proppant and self-suspension technology, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of adsorption damage, residue damage, plugging proppant filling layer, etc., and achieve high fracturing efficiency and production, reduce equipment pump pressure requirements, and reduce fracturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

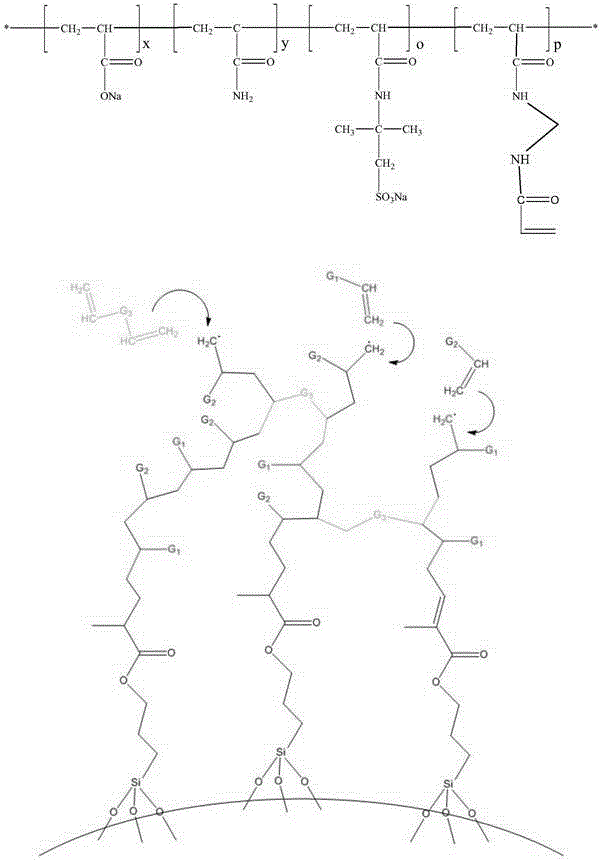

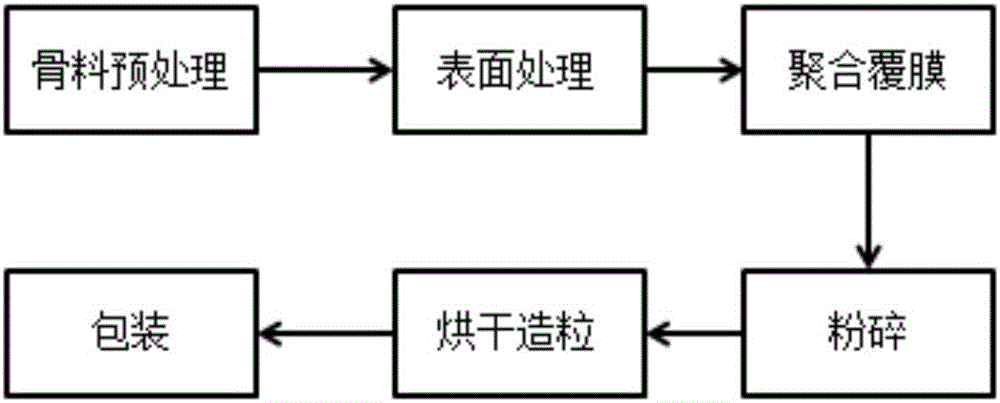

Method used

Image

Examples

Embodiment 1

[0032] Table 1: Laboratory synthesis of self-suspending proppants

[0033]

Embodiment 2

[0035] Sand ratio / % 5 10 15 20 25 Viscosity / mPa.s 28.5 73.5 177 519 720

[0036] Example 3:

[0037] Group No 1 2 3 4 5 6 7 8 9 10 Diameter (μm) 640 920 590 630 770 870 1030 670 990 640 Settling time (s) 300 727 278 380 375 864 605 308 855 315

Embodiment 4

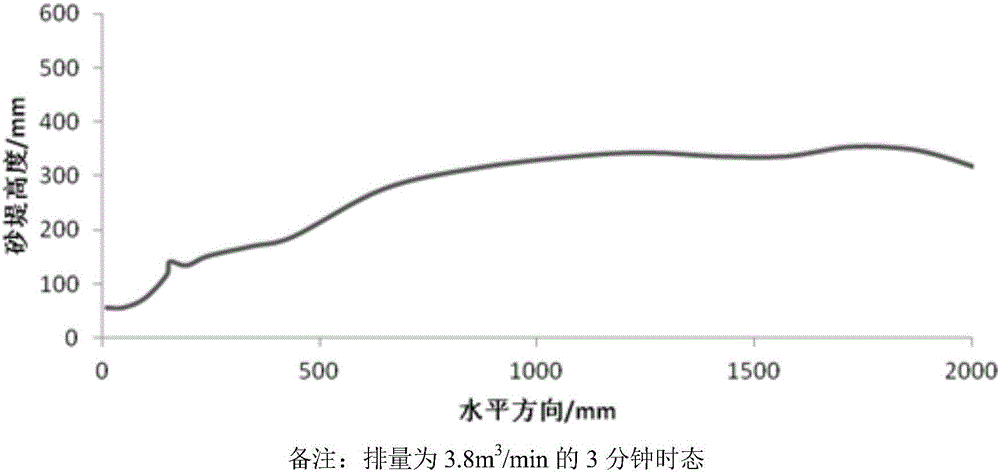

[0038] Embodiment 4: Displacement is 3.8m 3 / min, at 3 minutes, the shape of the large-scale molded sand embankment can be seen image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com