Ejector with telescopic nozzles

An ejector and telescopic technology, applied in the field of nozzle retractable ejector, can solve the problems of affecting the fracturing effect, unsatisfactory perforation depth, and difficulty in ensuring the effectiveness of isolation, so as to improve the fracturing effect and increase reliability. The effect of reducing the cost of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

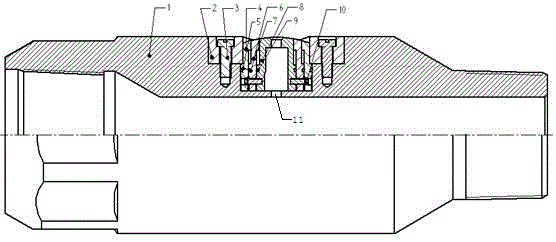

Embodiment 1

[0025] In order to overcome the problems of unsatisfactory perforation depth of existing hydraulic injection, difficulty in guaranteeing sealing effectiveness, and affecting fracturing effect, this embodiment provides a method such as figure 1 and figure 2 The nozzle retractable injector shown includes an injector body 1, and the injector body 1 is provided with a reserved hole 11, and a telescopic nozzle is arranged at the reserved hole 11, and the telescopic nozzle is arranged from the outside to the inside The outer layer nozzle 4, the middle layer nozzle 6 and the inner layer nozzle 8 are sequentially set, and the lower parts of the outer layer nozzle 4, the middle layer nozzle 6 and the inner layer nozzle 8 are fixed by nozzle connecting pins 10, and the outer layer nozzle 4 A large-diameter sealing ring 5 is provided between the injector body 1, a medium-diameter sealing ring 7 is provided between the outer nozzle 4 and the middle nozzle 6, and a small-diameter sealing ...

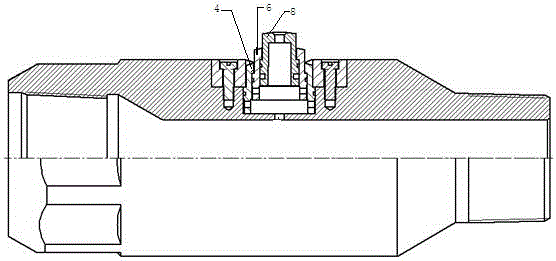

Embodiment 2

[0029] This embodiment provides an injector with a retractable nozzle, which includes an injector body 1, a reserved hole 11 is arranged on the injector body 1, and a telescopic nozzle is arranged at the reserved hole 11, and the telescopic nozzle is composed of The outer layer nozzle 4, the middle layer nozzle 6 and the inner layer nozzle 8 are sequentially set from the outside to the inside. The lower parts of the outer layer nozzle 4, the middle layer nozzle 6 and the inner layer nozzle 8 are fixed by nozzle connecting pins 10. A large-diameter sealing ring 5 is provided between the outer nozzle 4 and the injector body 1, a medium-diameter sealing ring 7 is provided between the outer nozzle 4 and the middle nozzle 6, and a middle-diameter sealing ring 7 is provided between the middle nozzle 6 and the inner nozzle 8. A small-diameter sealing ring 9 is arranged between them, and the outer layer nozzle 4 is pressed tightly by the gland 2, and the gland 2 is fixed on the injecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com