Preparation raw material, preparation method and application of online concentrated drag reduction liquid for fracturing

A fracturing and liquid-blocking technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of slow water solubility, poor drag reduction effect, and large addition amount, so as to achieve simple use process and reduce fracturing Effect of less cost and residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Raw materials for the preparation of online concentrated drag reducing fluid for fracturing

[0041] The raw materials for preparing the online concentrated drag reducing fluid for fracturing in this example consist of the following components: polymer, high-efficiency water diversion agent, micropore generator, base oil, main emulsifier and auxiliary emulsifier. The distribution of each group is as follows:

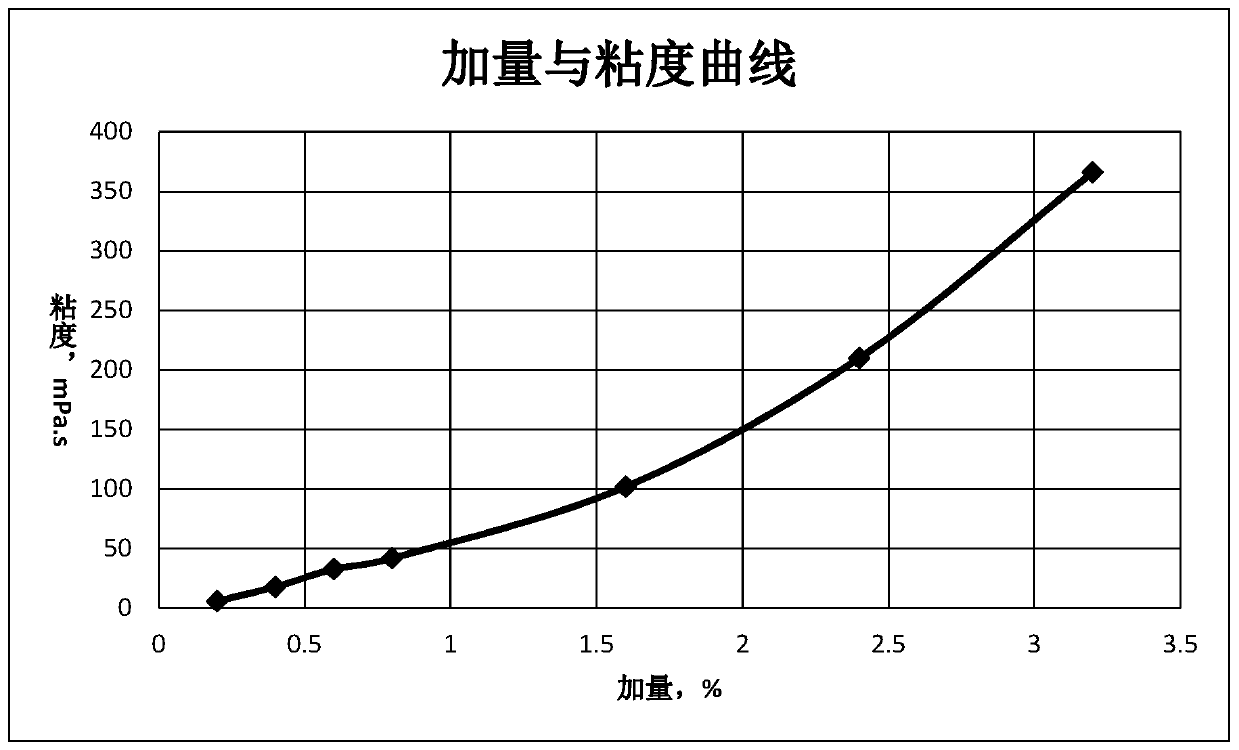

[0042] Polymer: 100 parts by mass; high-efficiency water-inducing agent: the added mass is 2.0%-10.0% of the polymer mass; microporous agent: the added mass is 3.0%-5.0% of the polymer mass; base oil: the added mass 100.0%-150.0% of the mass of the polymer; main emulsifier: 1.0-3.0% of the sum of the mass of the polymer and base oil; secondary emulsifier: 0.5-3.0% of the sum of the mass of the polymer and base oil 2.0%. The polymer is a polyacrylamide water-soluble polymer; the high-efficiency water diversion agent is one of a polyol-type surfactant ...

Embodiment 2

[0044] Example 2 Preparation method of online concentrated drag reducing fluid for fracturing

[0045] Utilize the preparation raw material of on-line concentrated drag reducing fluid for fracturing in embodiment 1 to prepare, specifically include the following steps:

[0046]Step 1, 100.0 kg of polymer (modified anionic polyacrylamide introduced into the market with temperature-resistant and salt-resistant groups, this embodiment adopts AP-P4 associative polymer produced by Sichuan Guangya Polymer Chemical Co., Ltd.), Diluted with deionized water to a concentration of 80% by mass, and stirred in a kneader for 1 hour to obtain a stock solution;

[0047] Step 2. Slowly add 10.0 kg of high-efficiency water-inducing agent isomeric tridecyl alcohol polyoxyethylene ether (commercially available product code is E-1302) into the stock solution described in step 1, and stir for 2 hours to make it fully mixed;

[0048] Step 3. Slowly add 5.0 kg of microporous generating agent sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com