Trimming cutter for textile fabric

A technology of textile cloth and trimming machine, which is applied in the cutting of textile materials, textiles and papermaking, etc. It can solve the problems of increasing machine maintenance costs, easy loose edges of cloth, and affecting the next use, so as to improve the cutting effect and maintain Effect of cleaning and preventing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

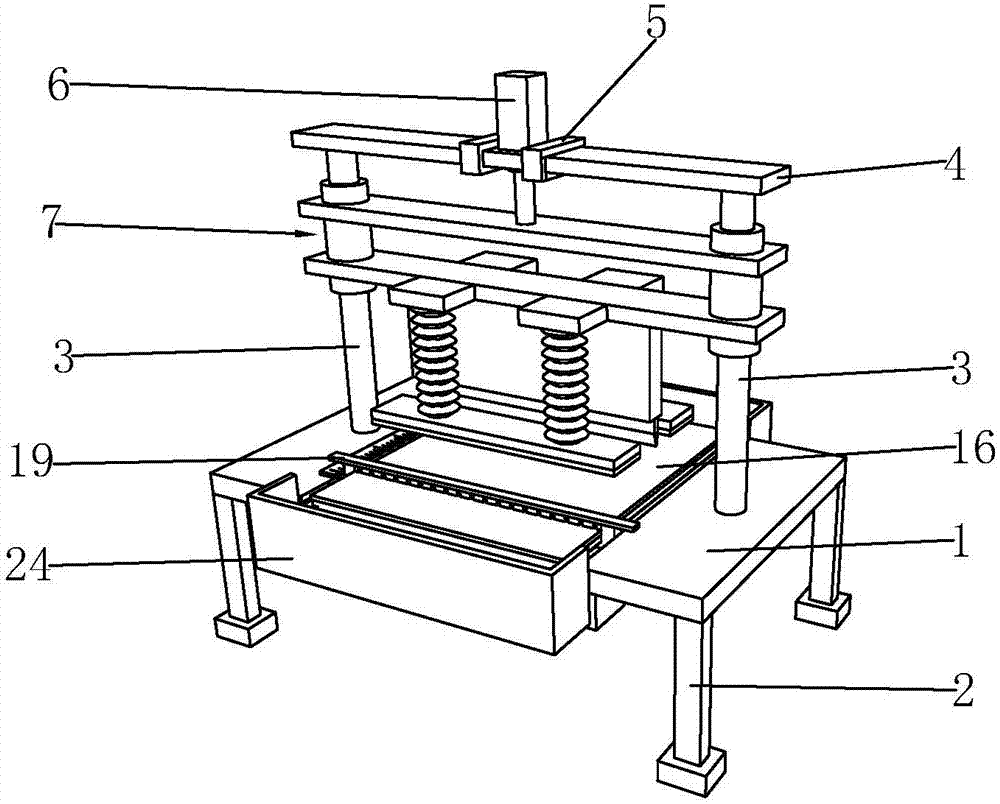

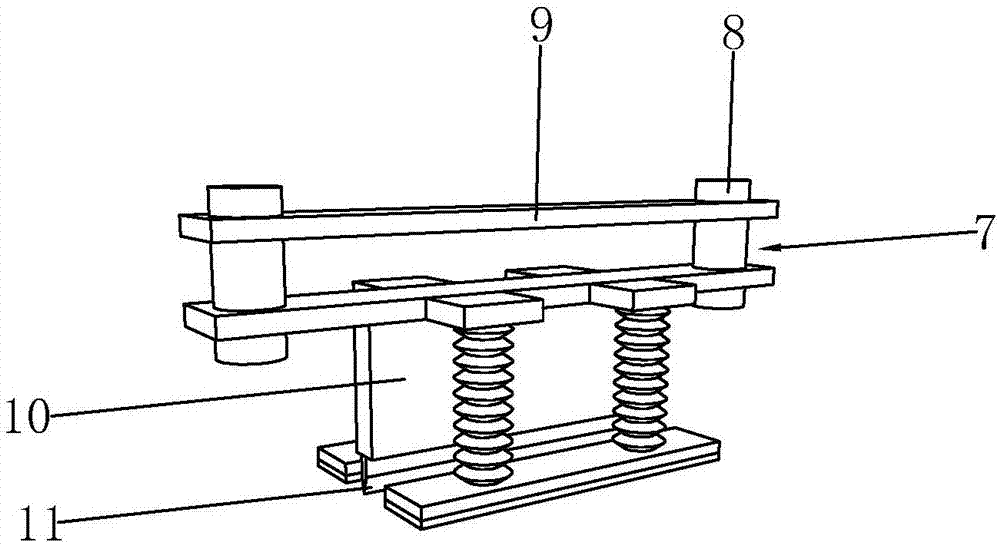

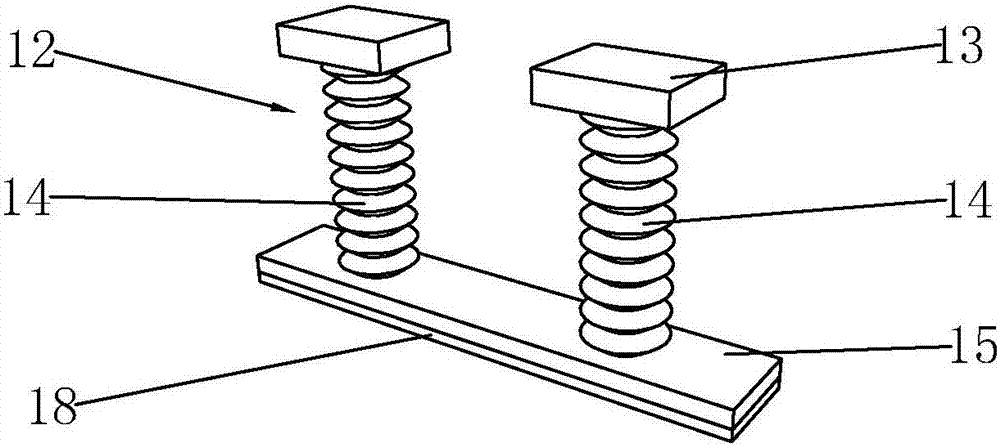

[0025] Such as Figure 1 to Figure 6 As shown, it is an edge trimmer for textile fabrics according to the present invention, which includes a working platform 1 and legs 2, and the supporting legs 2 are arranged on the four corners of the bottom surface of the working platform 1, which improves the overall stability. Support rods 3 are symmetrically distributed on the working platform 1, the top of the support rod 3 is provided with a fixed clip 4, one end of the fixed clip 4 is provided with a ferrule 5, and a drive cylinder 6 is arranged between the ferrules 5, and the ferrule 5 will The whole body of the driving cylinder 6 is effectively fixed, which improves the stability of the driving cylinder 6 after installation, and absorbs the vibration generated by the driving cylinder 6 through the fixed clamping plate 4 to maintain balance. A pressing plate assembly 7 is arranged between the support rods 3, and the pressing plate assembly 7 includes a casing 8, an upper push plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com