RH decarburization method during ultra-low-carbon steel production process by revolving furnace

A technology of ultra-low carbon steel and treatment method, applied in the field of iron and steel metallurgy, can solve the problems of RH insertion tube sticking slag and other problems, and achieve the effects of inhibiting the precipitation of high melting point phase, enhancing fluidity, and reducing melting point and viscosity

Inactive Publication Date: 2012-01-04

PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] The problem to be solved by the present invention is to overcome the problem of slag sticking in the RH insertion tube during the production of ultra-low carbon steel by the converter process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

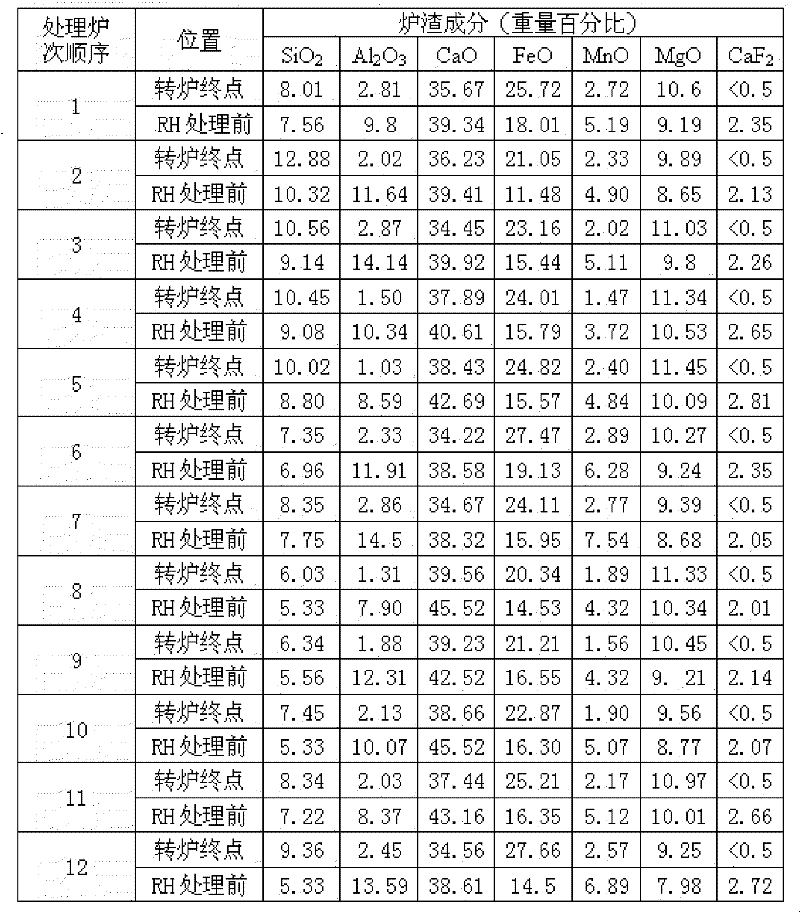

[0033] Embodiment 1 RH decarburization treatment method in the process of converter production of ultra-low carbon steel of the present invention

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

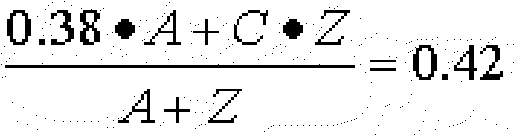

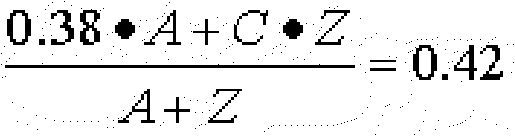

The invention relates to an RH decarburization treatment method in the process of producing ultra low carbon steel by a converter, and belongs to the technical field of ferrous metallurgy. The technical problem to be solved by the invention is that an RH insert tube is prevented from sticking slag in the process of producing the ultra low carbon steel by the converter process. The technical proposal is as follows: chemical compositions of ladle slag in the process of the RH decarburization treatment of the ultra low carbon steel are controlled as follows based on the weight percentages: 5.0-11.0% of SiO2, 40.0-48.0% of CaO, 7.5-15.0% of Al2O3, 7.5-12.0% of MgO, 20.0% of FeO, 7.0% of MnO, Fe2O3, CaF2 and micro constituents such as S, P, TiO2 and the like, thus improving the CaO / Al2O3 ratio and the (CaO / SiO2) / Al2O3 ratio, effectively inhibiting the separation of high-melting point phase of the ladle slag, reducing the melting point and the viscosity of the ladle slag, enhancing the flowability of the ladle slag, lightening the slag sticking of the RH insert tube and increasing the number of furnaces to be continuously treated without slag removal.

Description

technical field [0001] The invention relates to a RH decarburization treatment method in the process of producing ultra-low carbon steel by a converter, which can effectively prevent slag sticking to RH insertion pipes in the process of producing ultra-low carbon steel by the converter process, and belongs to the technical field of iron and steel metallurgy. Background technique [0002] RH vacuum treatment technology is an important means of refining outside the furnace to produce high-quality steel. At present, the production lines of many converter steelmaking plants in the world are equipped with RH refining furnaces, and this equipment is often used to decarburize ultra-low carbon steels including IF steels. In the production of IF steel or other ultra-low carbon steel, serious slag sticking phenomenon often occurs in the insertion pipe, which causes the insertion pipe to become thicker and larger, and the clearance of the ladle decreases during RH treatment, which affe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21C7/10C21C7/076

CPCY02P10/20

Inventor 陈天明曾建华杨素波陈永李桂军刘荣蒂李清春张敏翁建军陈亮

Owner PANGANG GROUP RESEARCH INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com