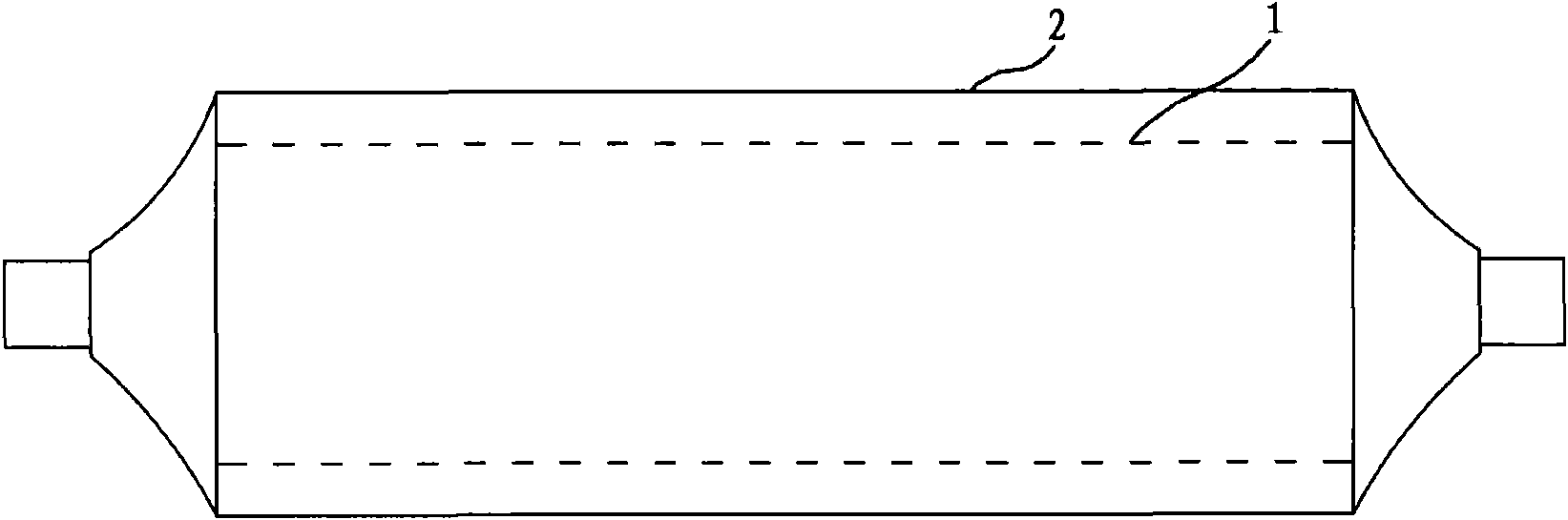

Sink roller and stabilizing roller

A technology of sinking roller and stabilizing roller, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of frequent replacement, non-dense, spray coating failure, etc., to reduce the number of processing and replacement, Ease of processing and manufacturing, and the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

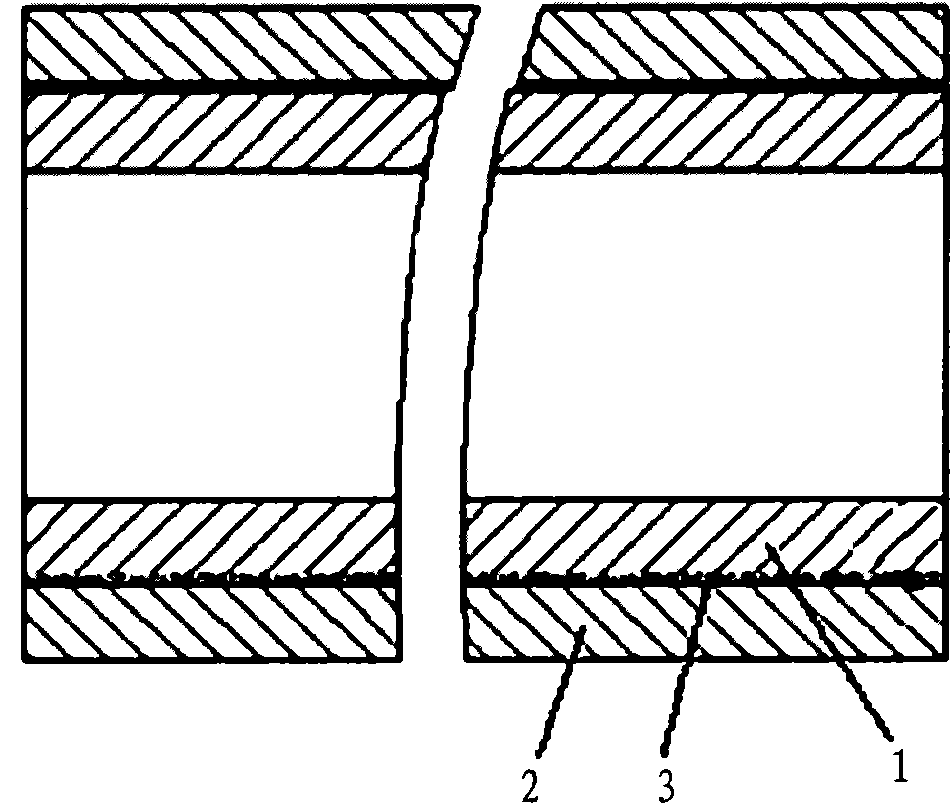

Embodiment 1

[0036] The substrate of sinking roller and stabilizing roller is 00Cr17Ni14Mo2 stainless steel (equivalent to austenitic ultra-low carbon stainless steel SUS316L), and its chemical composition is C≤0.03wt%, Cr 16wt%~18wt%, Ni10wt%~14wt%, Mo 2.00wt% %~3.00wt%, Mn≤2.00wt%, Si≤1.00wt%; the roller cover is installed on the substrate, the material of the roll cover is cobalt-based alloy, and the composition of cobalt-based alloy is: Cr 25wt%, Ni 0.2wt% , W 15wt%, Mo 3wt%, V 0.01wt%, Ti 0.1wt%, C 0.3wt%, Fe 6wt%, Si 2.0wt%, Mn 3.0wt%, Al 5.0wt%, Nb 5.0wt%, P< 0.07wt%, S<0.07wt%, and the rest is Co. The roller sleeve and the substrate adopt clearance fit, the thickness of the roller sleeve is 29mm, and the roller sleeve and the substrate are installed on the substrate by shrink fit and interference fit.

[0037] The sinking roll and the stabilizing roll of embodiment 1 are used in the same unit as the sinking roll and the stabilizing roll of the prior art, and the result of use show...

Embodiment 2

[0039] The substrate of the sinking roller and the stabilizing roller is made of 1Cr17Mo ferritic heat-resistant stainless steel, and its chemical composition is C≤0.12wt%, Cr 16wt%~18wt%, Mo 0.75wt%~1.25wt%, Mn≤0.8wt%, Si ≤0.8wt%; the roller sleeve is installed on the substrate, the material of the roller sleeve is cobalt-based alloy, and the composition of the cobalt-based alloy is: Cr 20wt%, Ni 10wt%, W 0.2wt%, Mo 5.5wt%, V 3.0wt% %, Ti 5.0wt%, C 0.6wt%, Fe 20wt%, Al 5.0wt%, Mn 0.2wt%, Nb 0.02wt%, Si 0.4wt%, P<0.07wt%, S<0.07wt%, the rest are Co. The thickness of the roller cover is 50mm, and the roller cover and the base body are installed together by opening four key grooves and installation keys on the base body and the roll cover.

[0040] The sinking roll and the stabilizing roll of embodiment 2 are used in the same unit as the sinking roll and the stabilizing roll of the prior art, and the result of use shows that after the sinking roll of the present invention and t...

Embodiment 3

[0042] The matrix of sinking roll and stabilizing roll is austenitic-ferritic stainless steel 0Cr18Ni9Cu3, and its chemical composition is C≤0.08wt%, Si≤1.00wt%, Mn≤2.00wt%, P≤0.035wt%, S≤0.030wt% %, Ni 8.50wt% ~ 10.50wt%, Cr 17.00wt% ~ 19.00wt%, Cu 3.00wt% ~ 4.00wt%; the roll sleeve is installed on the substrate, the material of the roll sleeve is cobalt-based alloy, and the composition of cobalt-based alloy For: Cr30wt%, Ni 15wt%, W 10wt%, Mo 0.1wt%, V 0.2wt%, Ti 3.0wt%, C 1.5wt%, Fe 15wt%, Al 0.02wt%, Mn 0.7wt%, Nb 3.0wt% %, Si 3.0wt%, P<0.07wt%, S<0.07wt%, and the rest is Co. The thickness of the roller sleeve is 1mm, and it is installed and fixed on the substrate by welding the end of the roller sleeve.

[0043] The sinking roll of embodiment 3 and the stabilizing roll are used in the same unit as the sinking roll of the prior art and the stabilizing roll, and the result of use shows that the service time of the sinking roll of the present invention and the stabilizing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com