Method for manufacturing specially-shaped sprue cup by colloidal forming

A colloidal molding and sprue cup technology, which is applied in the field of refractory materials, can solve the problems of affecting product quality, low strength, and high cost, and achieve the effects of shortening the production cycle, high strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

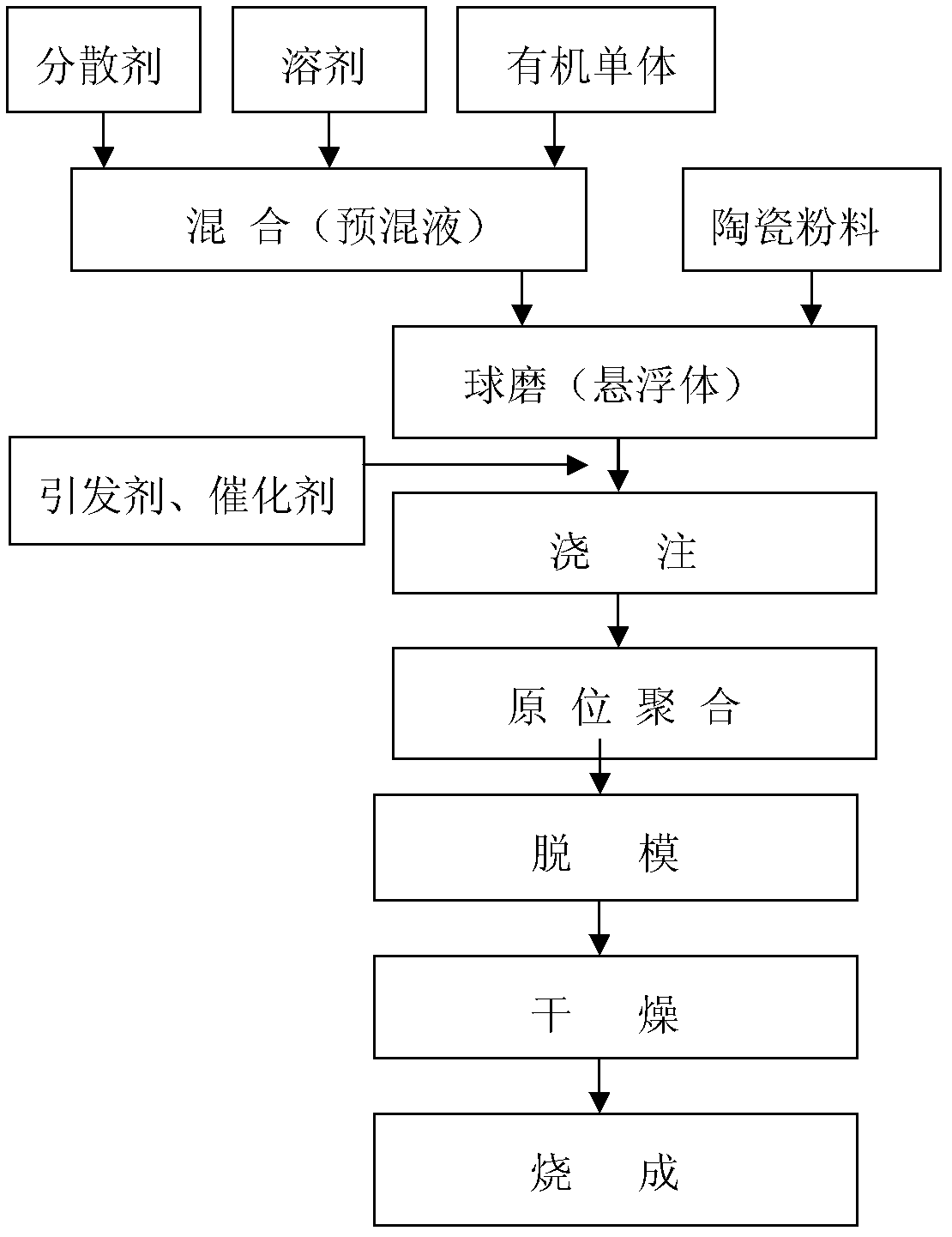

Method used

Image

Examples

Embodiment 1

[0025] The ceramic powder raw material adopts an average particle size of 1 micron. Prepare 1000ml monomer solution premix, mass ratio: 10% acrylamide monomer; 1% N,N-methylenebisacrylamide crosslinking agent; 2% polyacrylamide dispersant; 87% deionized water.

[0026] Prepare a slurry with a mass solid content of 60%, and ball mill and mix for 2 hours.

[0027] The catalyst tetramethylethylenediamine and the initiator ammonium persulfate were respectively added in an amount of 0.2% of the above slurry, then vacuum stirred and degassed for 15 minutes, then poured into a mold, and kept at 80° C. for 30 minutes. The mold is placed at room temperature, and after the mold is cooled, the mold is demoulded to obtain a sprue cup green body.

[0028] Put the green body in a constant temperature and humidity box with a humidity of 90%, until the green body no longer shrinks, then transfer it to an oven, and dry it in the air at 40, 60, 80 and 100 °C for 4 hours each to obtain a hard ...

Embodiment 2

[0030] The ceramic powder raw material adopts an average particle size of 1 micron. Prepare 1000ml monomer solution premix, mass ratio: 5% acrylamide monomer; 0.25% N,N-methylenebisacrylamide crosslinking agent; 4% polyacrylamide dispersant; 90.75% deionized water.

[0031] Prepare a slurry with a mass solid content of 70%, and ball mill and mix for 2 hours.

[0032] The catalyst tetramethylethylenediamine and the initiator ammonium persulfate were respectively added in an amount of 0.05% of the above slurry, then vacuum stirred and degassed for 15 minutes, then poured into a mold, and kept at 80°C for 30 minutes. The mold is placed at room temperature, and after the mold is cooled, the mold is demoulded to obtain a sprue cup green body.

[0033] Put the green body in a constant temperature and humidity box with a humidity of 90%, until the green body no longer shrinks, then transfer it to an oven, and dry it in the air at 40, 60, 80 and 100 °C for 4 hours each to obtain a ha...

Embodiment 3

[0035] The ceramic powder raw material adopts an average particle size of 1 micron. Prepare 1000ml monomer solution premix, mass ratio: 15% acrylamide monomer; 0.75% N,N-methylenebisacrylamide crosslinking agent; 0.4% polyacrylamide dispersant; 83.85% deionized water.

[0036] Prepare a slurry with a mass solid content of 80%, and ball mill and mix for 2 hours.

[0037] The catalyst tetramethylethylenediamine and the initiator ammonium persulfate were respectively added in an amount of 0.15% of the above slurry, then vacuum stirred and degassed for 15 minutes, then poured into a mold, and kept at 90° C. for 30 minutes. The mold is placed at room temperature, and after the mold is cooled, the mold is demoulded to obtain a sprue cup green body.

[0038] Put the green body in a constant temperature and humidity box with a humidity of 90%, until the green body no longer shrinks, then transfer it to an oven, and dry it in the air at 40, 60, 80 and 100 °C for 4 hours each to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com