Method for preparing multifunctional composite monodisperse nano film solution

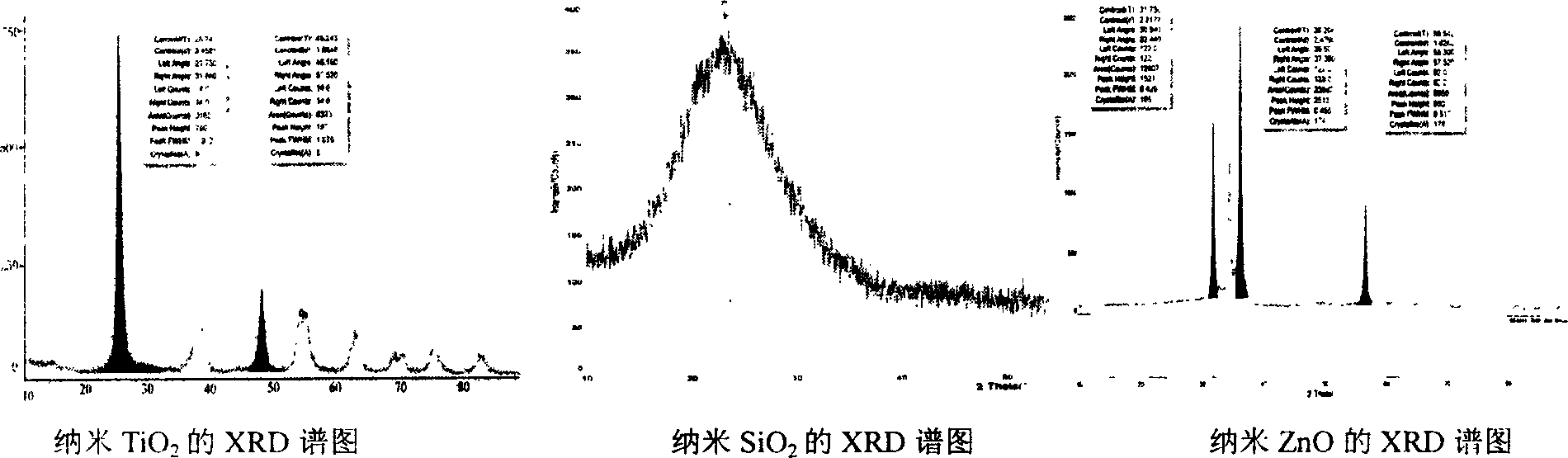

A nano-composite, monodisperse technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of difficult to obtain high-performance, monodisperse aqueous suspensions, etc., to broaden the wavelength of ultraviolet light absorption , improve weather resistance, improve the effect of photocatalytic speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1. with 1.0g nanocomposite powder (wherein TiO 2 0.80g., ZnO0.10g, SiO 2 0.10 g) was added into 200 ml of deionized water, and the primary dispersion was carried out for 2 hours with an ultrasonic oscillator. Use 2-amino-2-methyl-1-propanol (AMP-95) to adjust the pH of the system to about 8.5, and then continue to ultrasonically disperse the suspension for 48 hours (continuously supplement the water lost during the ultrasonic process). In the above-mentioned dispersed liquid that has been thoroughly dispersed, add high molecular polyvinyl alcohol solution (1%) as a film-forming aid, and the addition amount is to make its concentration in the dispersion liquid reach 1000ppm; Silica sol (SiO 2 Concentration is 8%), and the addition amount is 10% of dispersion liquid weight, makes multifunctional monodisperse nano-composite alkaline film-forming liquid. The performance evaluation results of the dispersion (or coating film) are shown in Table 1. No obvious se...

Embodiment 2

[0021] Embodiment 2. with 2.0g nanocomposite powder (wherein TiO 2 1.60g., ZnO0.20g, SiO 2 0.20 g) was added into 200 ml of deionized water, and the primary dispersion was carried out for 2 hours with an ultrasonic oscillator. Use ammonia water to adjust the pH of the system to about 8.5, and then continue ultrasonically dispersing the suspension for 48 hours (constantly replenish the water lost during the ultrasonic process). In the above-mentioned dispersed liquid that has been thoroughly dispersed, add high molecular polyvinyl alcohol solution (1%) as a film-forming aid, and the addition amount is to make its concentration in the dispersion liquid reach 1000ppm; Silica sol (SiO 2 Concentration is 8%), and the addition amount is 10% of dispersion liquid weight, makes multifunctional monodisperse nano-composite alkaline film-forming liquid. The performance evaluation results of the dispersion (or coating film) are shown in Table 1. No obvious sedimentation of the particle...

Embodiment 3

[0022] Embodiment 3. with 4.0g nanocomposite powder (wherein TiO 2 3.2g., ZnO0.40g, SiO 20.40 g) was added into 200 ml of deionized water, and the primary dispersion was carried out for 2 hours with an ultrasonic oscillator. Use dilute NaOH to adjust the pH of the system to about 8.5, and then continue to ultrasonically disperse the suspension for 48 hours (continuously supplement the water lost during the ultrasonic process). Add high molecular weight polyvinyl alcohol solution (1%) as a film-forming aid to the above-mentioned dispersion liquid that has been thoroughly dispersed, and the addition amount is to make its concentration in the dispersion liquid reach 1000ppm, and then add silica sol as a film-forming adhesive (SiO 2 Concentration is 8%), and the addition amount is 10% of dispersion liquid weight, makes multifunctional monodisperse nano-composite alkaline film-forming liquid. The performance evaluation results of the dispersion (or coating film) are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com