Patents

Literature

70results about How to "Disperse thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

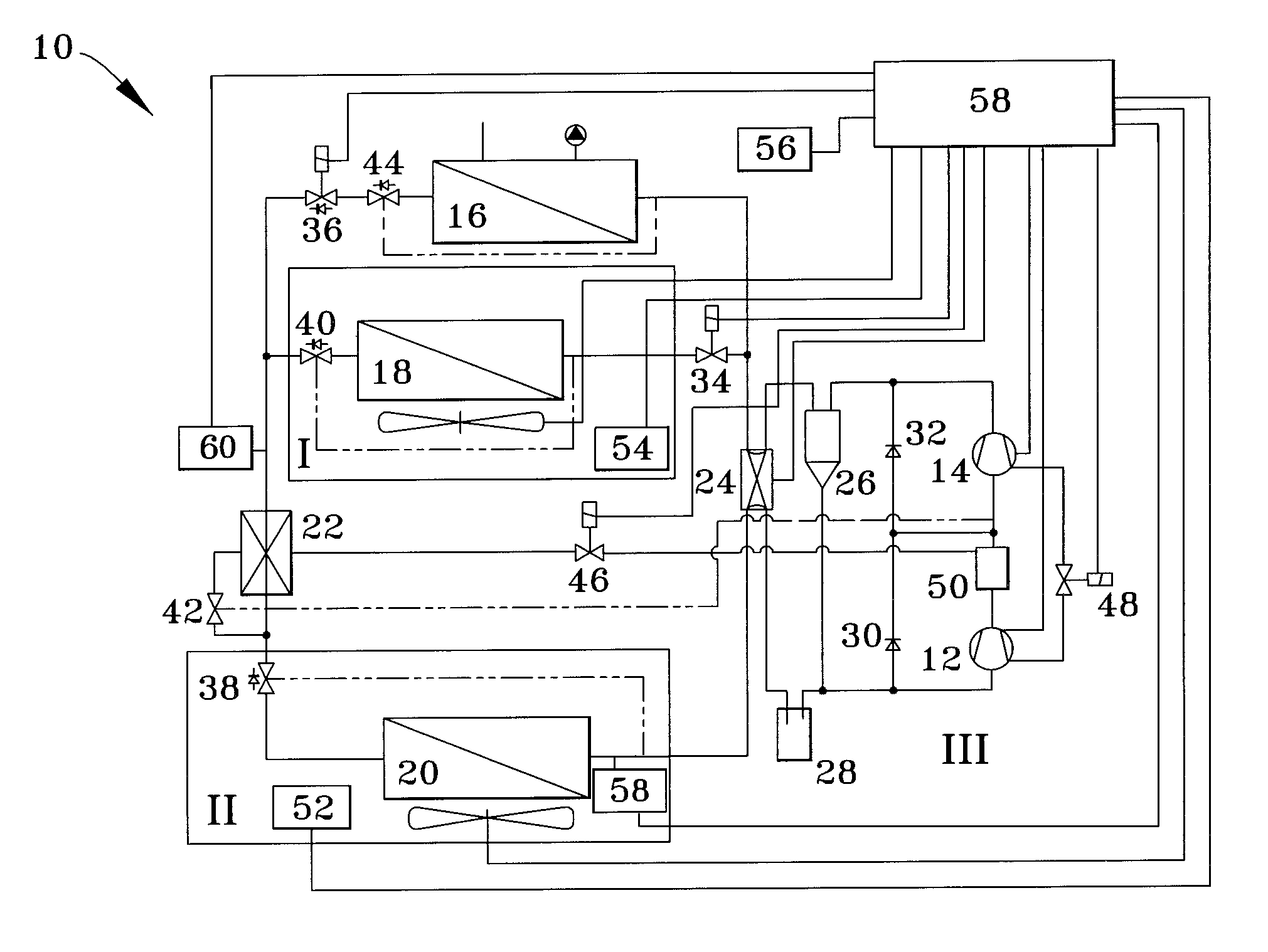

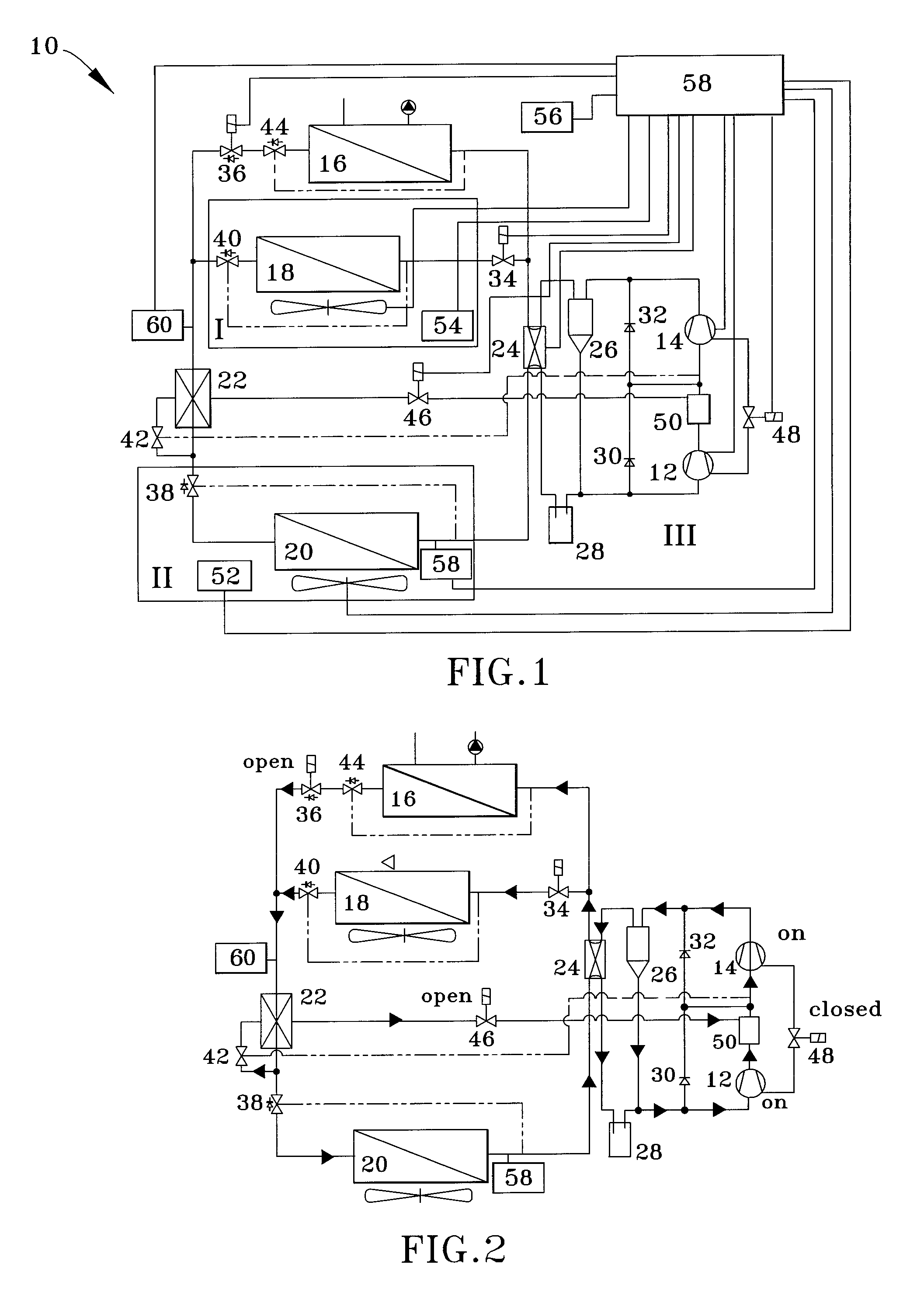

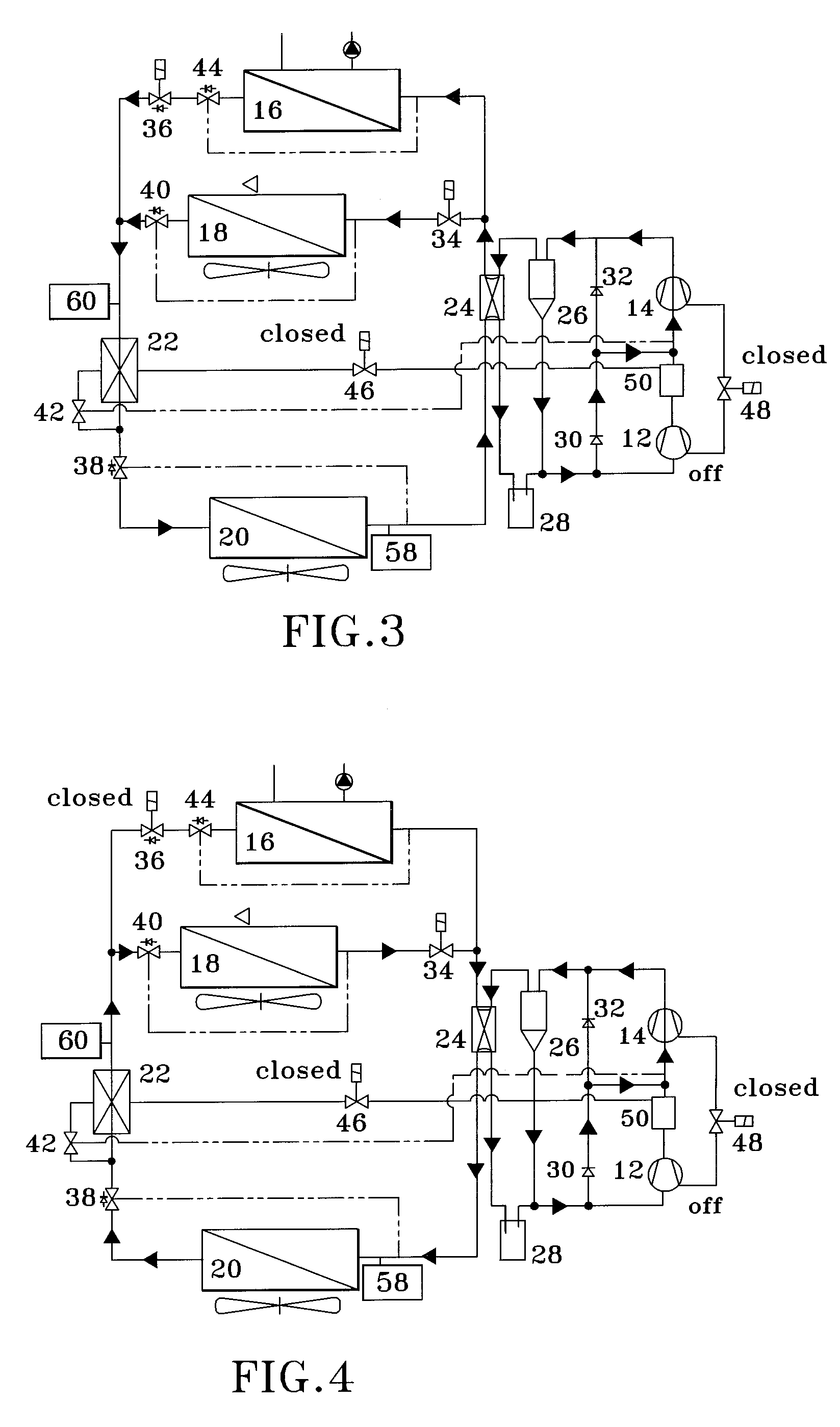

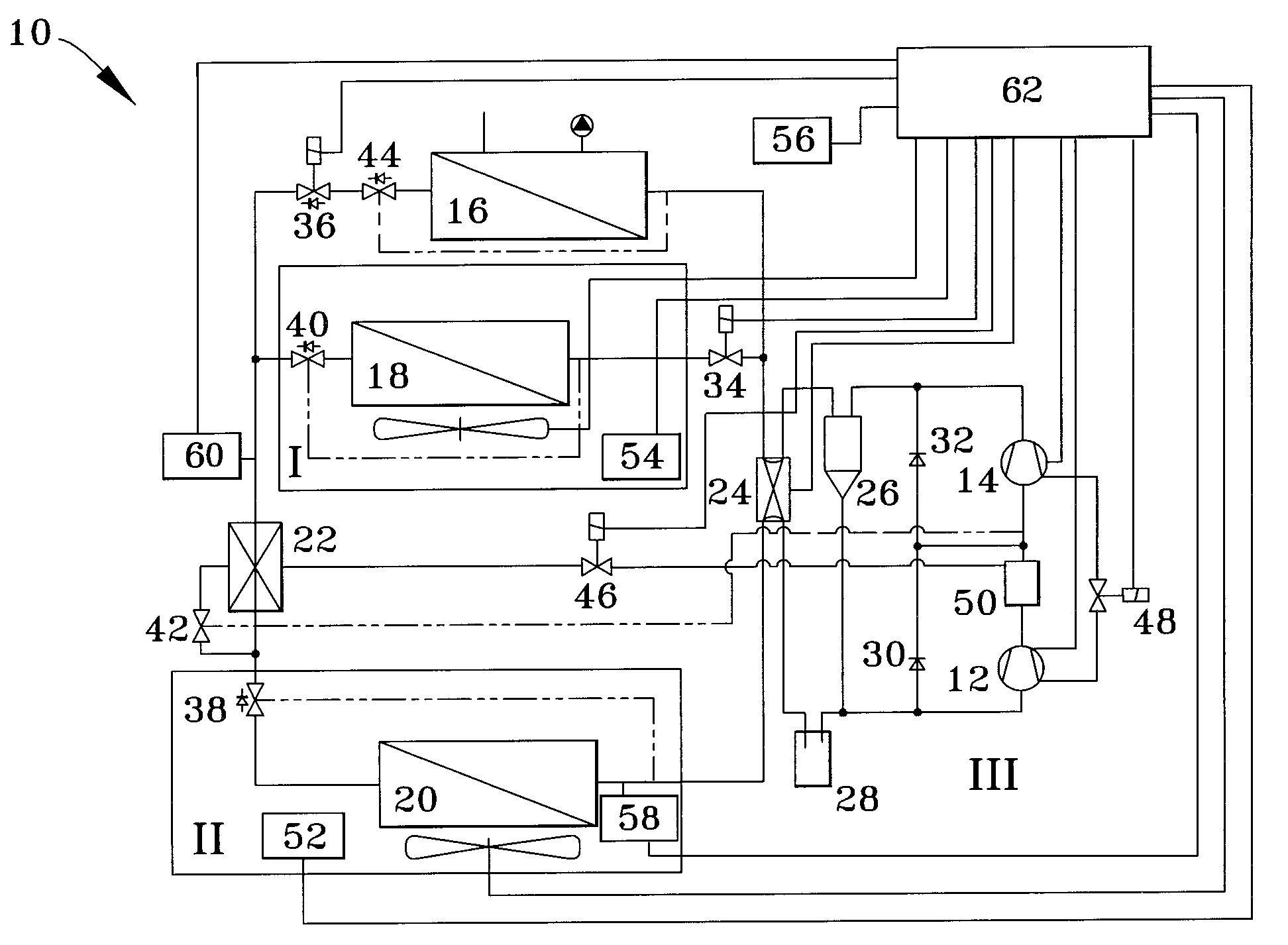

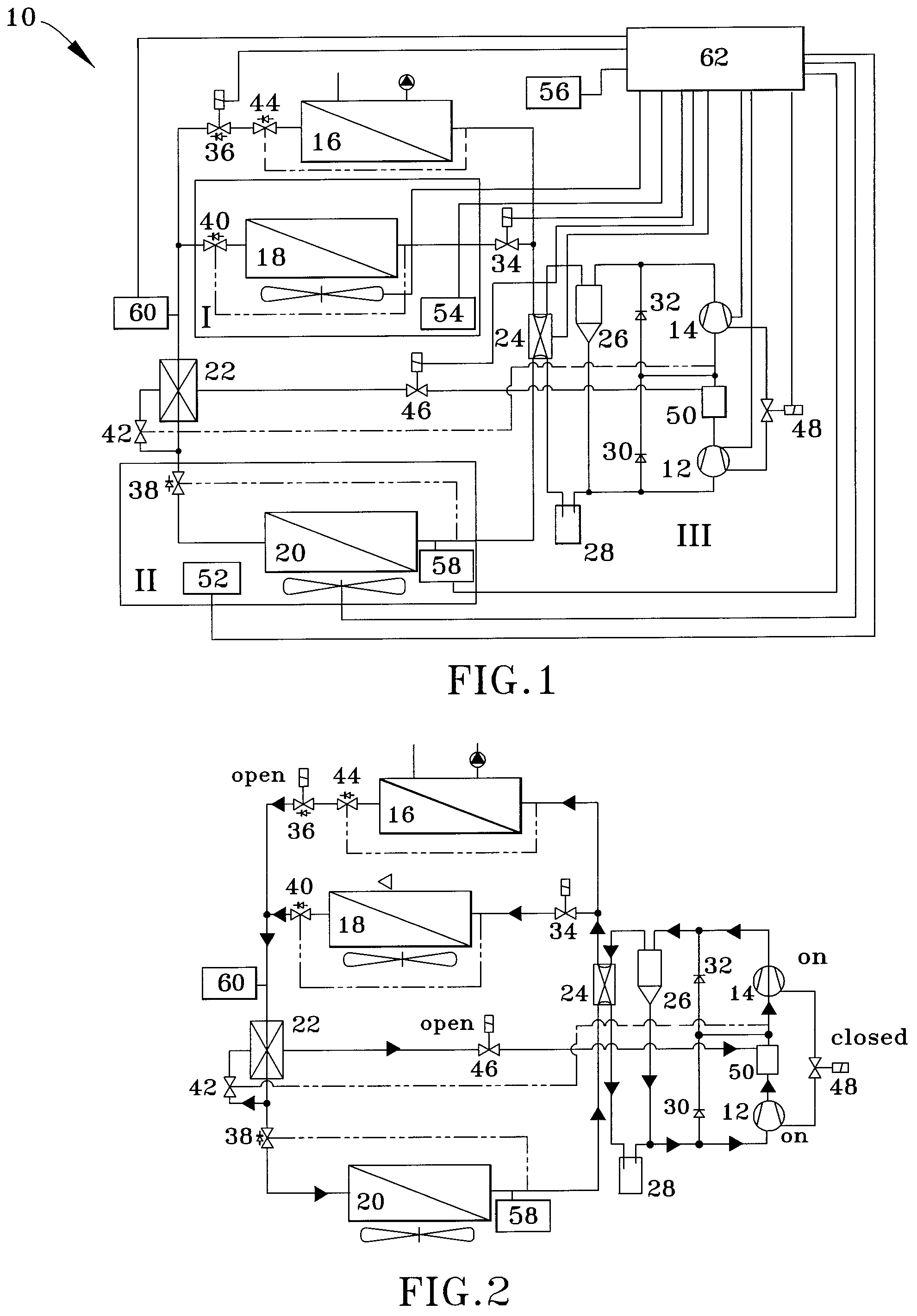

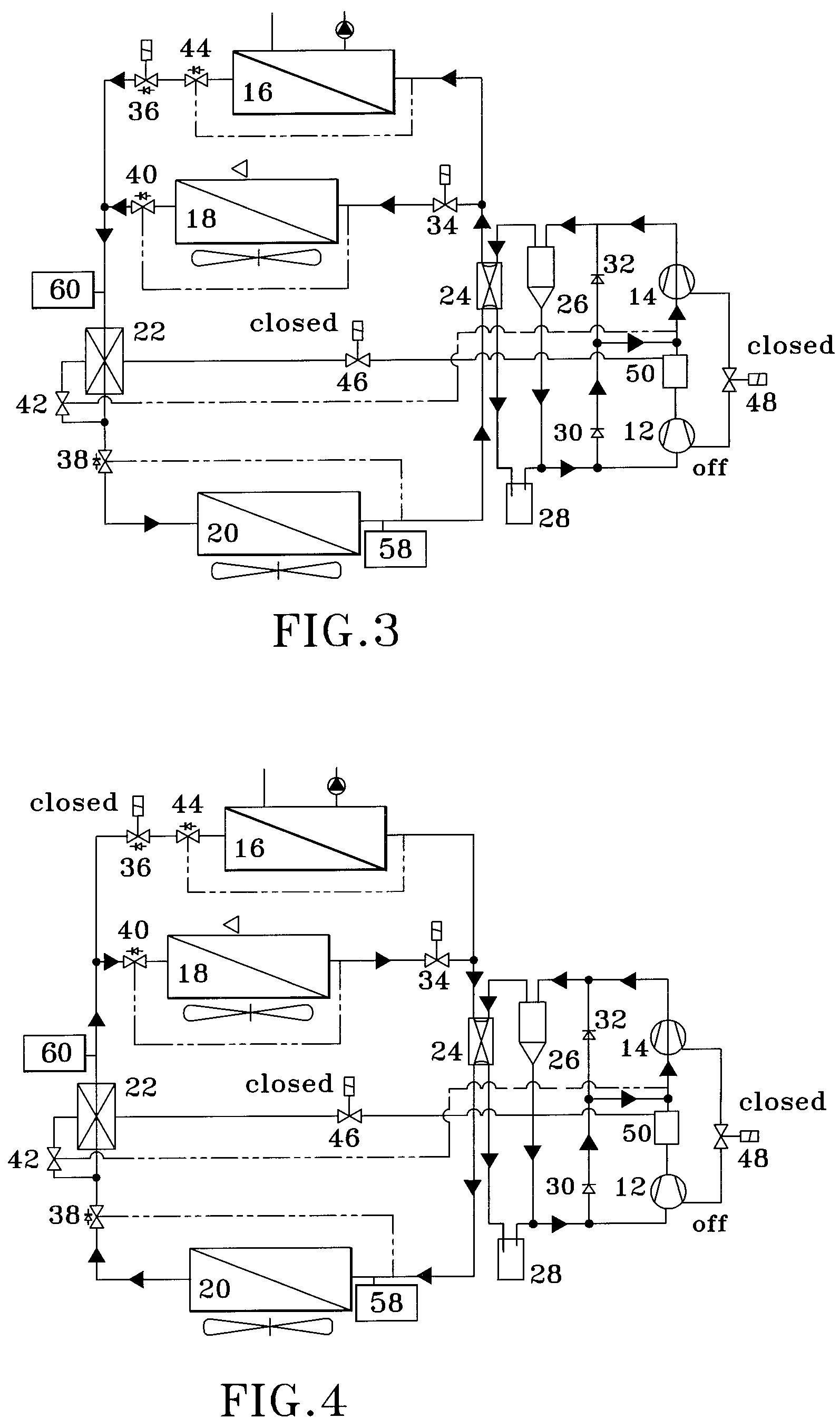

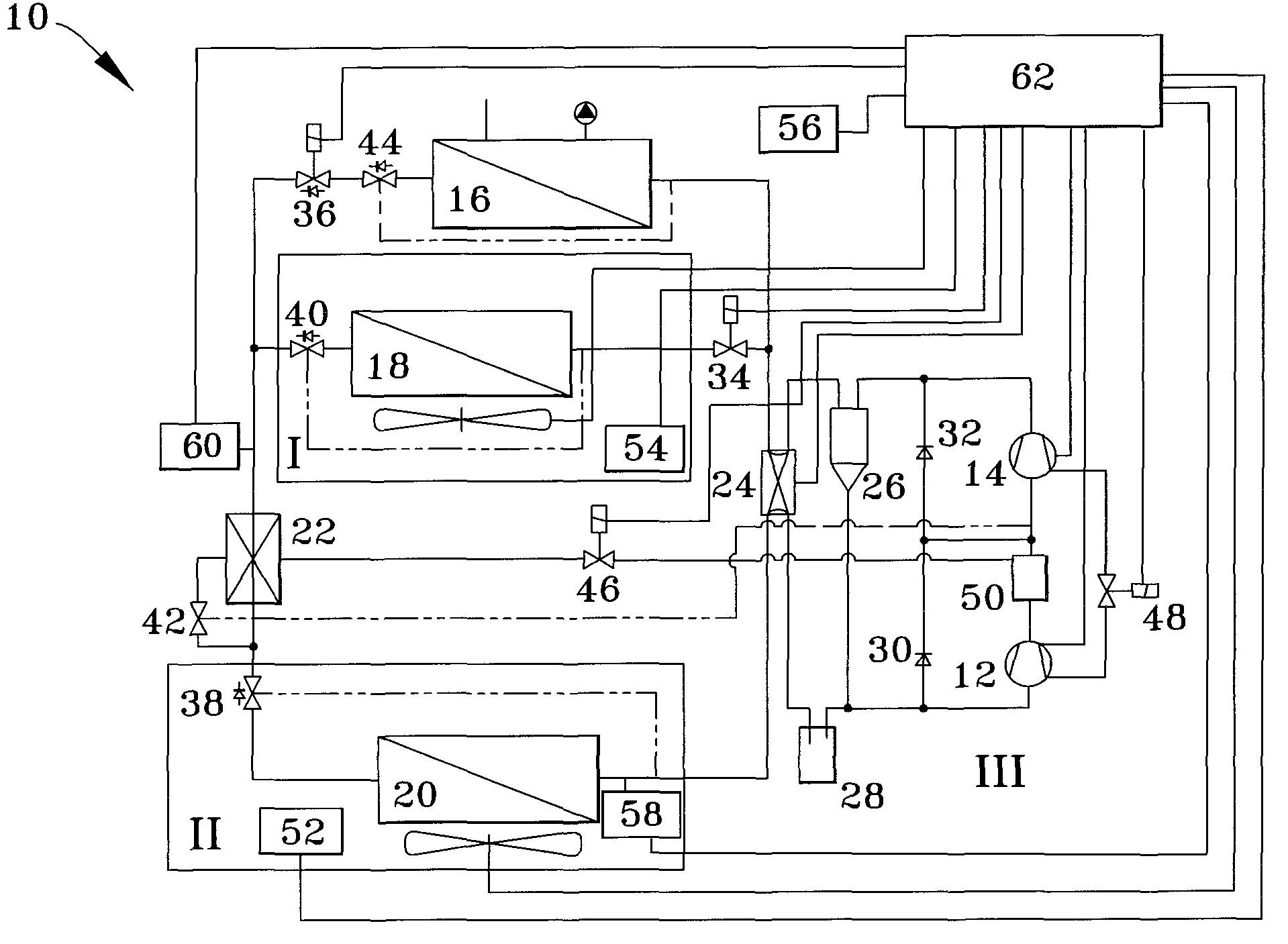

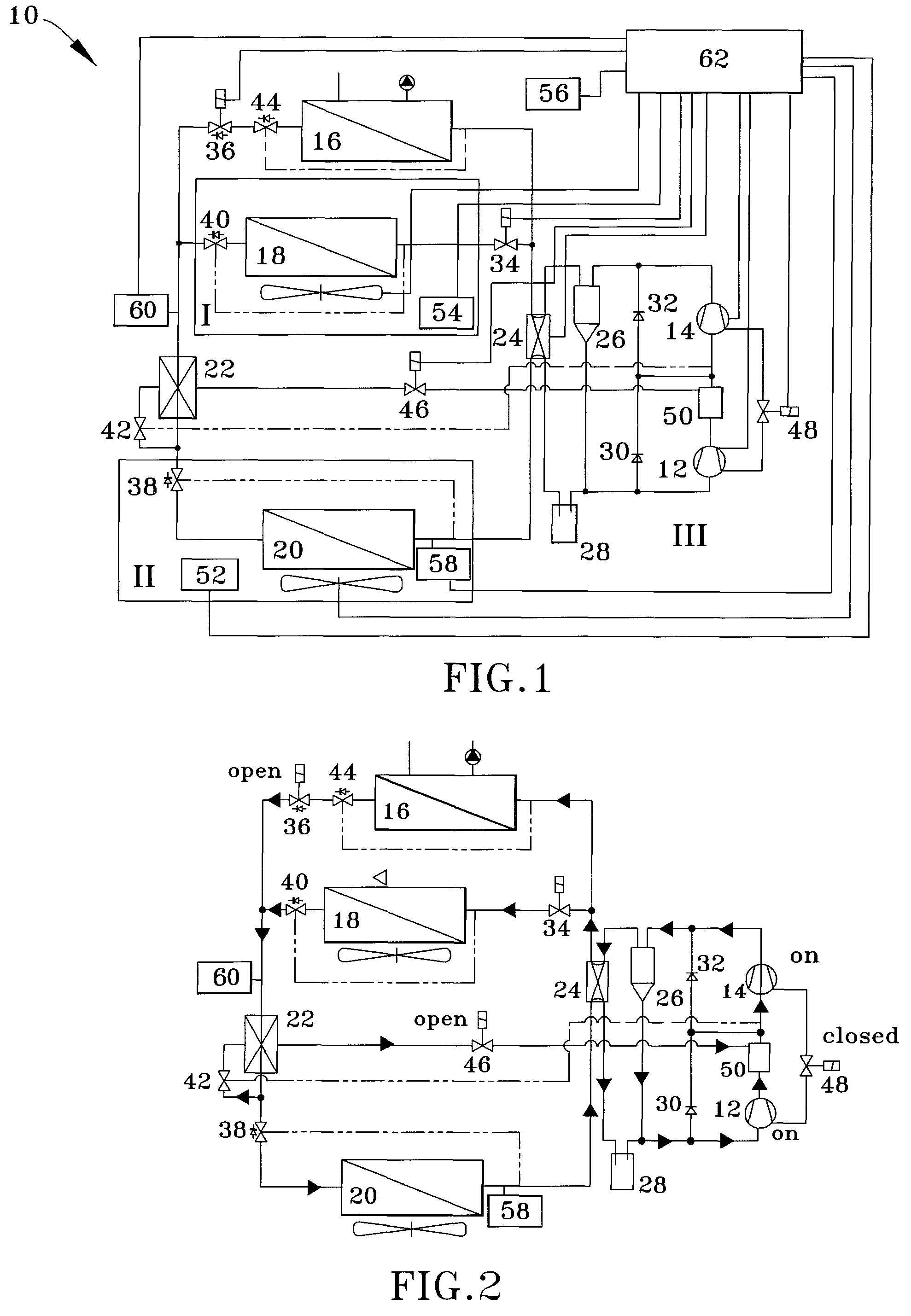

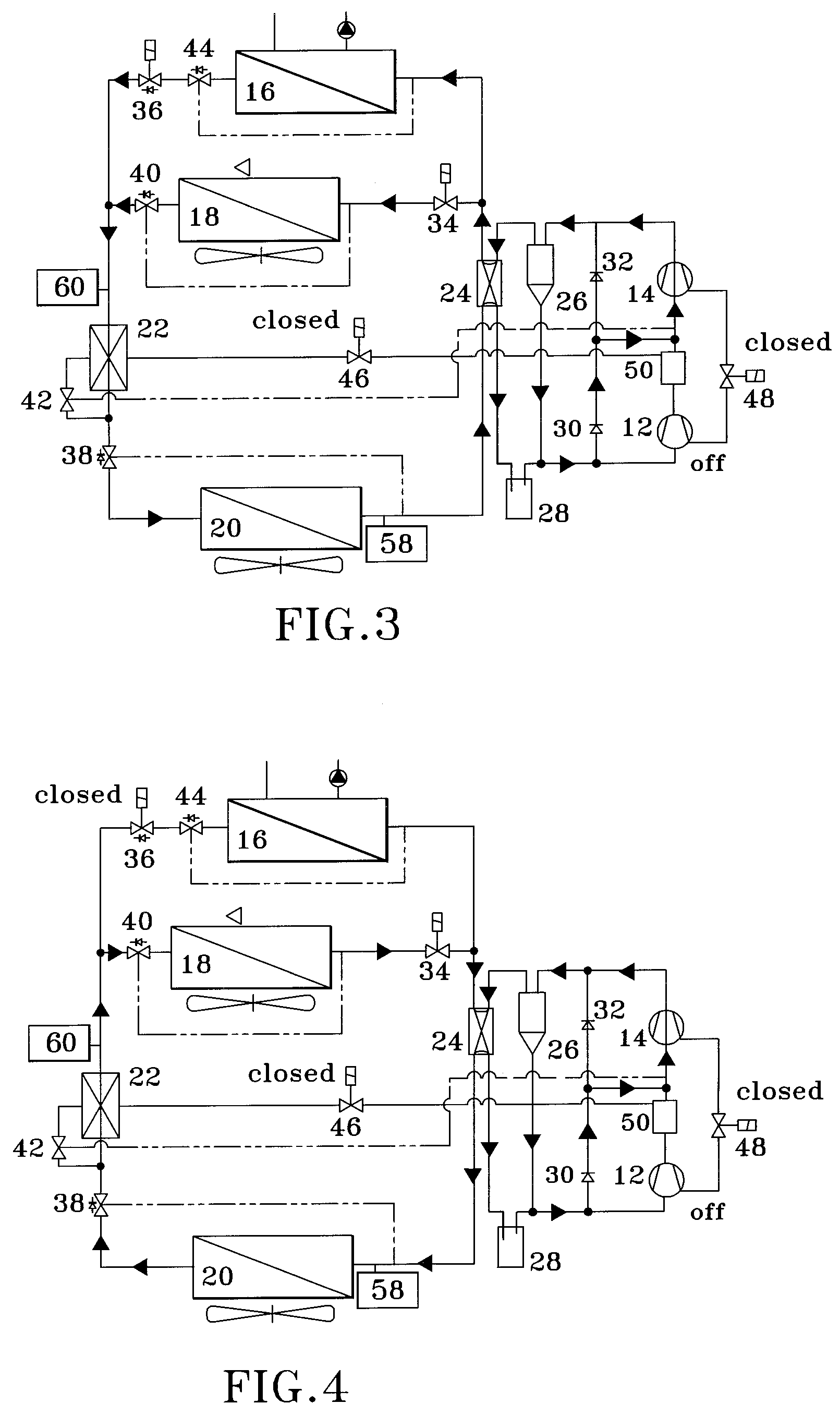

Heat pump system with multi-stage compression

InactiveUS20060266063A1Increase flexibilityIncrease productionCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

A multi-compressor heat pump system configured to provide heating and cooling over a range of ambient temperatures. The compressors can be operated independently and alone or together in series for maximum output. Heat exchangers are selectively fluidically connected to the compressors to enable refrigerant flow between the compressors and at least two heat exchangers in a manner that enables the heat pump system to be selectively operable in various modes. Preferred aspects include selectively operating the compressors based on the ratio of the evaporating and condensing pressures of the refrigerant within the heat pump system, a mixing chamber between the compressors, and a lubricant management system to prevent the accumulation of a lubricant in one of the compressors.

Owner:PURDUE RES FOUND INC

Heat pump system with multi-stage compression

InactiveUS7654104B2Increase flexibilityIncrease productionCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

A multi-compressor heat pump system configured to provide heating and cooling over a range of ambient temperatures. The compressors can be operated independently and alone or together in series for maximum output. Heat exchangers are selectively fluidically connected to the compressors to enable refrigerant flow between the compressors and at least two heat exchangers in a manner that enables the heat pump system to be selectively operable in various modes. Preferred aspects include selectively operating the compressors based on the ratio of the evaporating and condensing pressures of the refrigerant within the heat pump system, a mixing chamber between the compressors, and a lubricant management system to prevent the accumulation of a lubricant in one of the compressors.

Owner:PURDUE RES FOUND INC

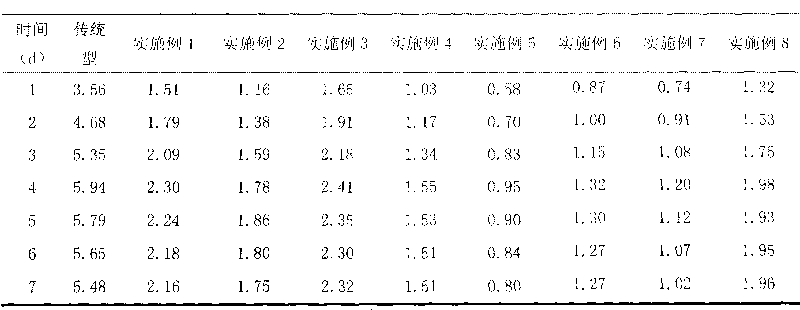

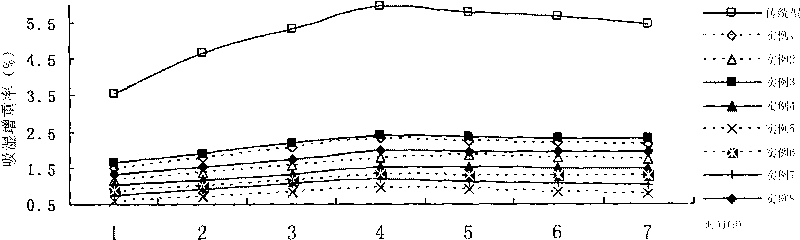

Film-coating premixing auxiliary material and preparation method thereof

ActiveCN101691429AGood dispersionGood flexibilityPharmaceutical delivery mechanismMethacrylic acid-ethyl acrylate copolymerPolyethylene glycol

The invention relates to a film-coating premixing auxiliary material which mainly comprises hydroxypropyl methylcellulose, polyvinylpyrrolidone-vinyl acetate copolymer (6:4), polyvinyl alcohol-polyethylene glycol copolymer, methacrylic acid-ethyl acrylate copolymer (1:1), polyethylene glycol, talcum powder and a colorant. The film-coating premixing auxiliary material has the advantages of favorable dampproof and anti-cracking properties, can disintegrate at a suitable time and uses water as dissolvent.

Owner:浙江瓯伦包衣技术有限公司

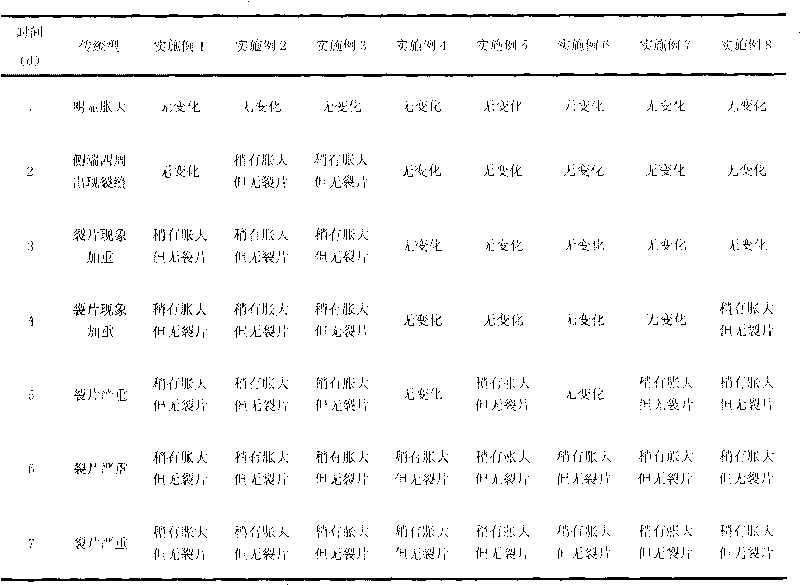

Preparation method of foundation make-up premix having minimal color difference

ActiveCN104055684AUniform surface propertiesEvenly distributedCosmetic preparationsBody powdersEmulsionEngineering

The invention relates to a preparation method of a foundation make-up premix having minimal color difference, which comprises the following steps: (1) performing unified surface treatment on various raw material powder of the foundation make-up premix, and ensuring that the surface properties tend to be consistent; (2) uniformly stirring the treated raw material powder at a high speed to obtain the foundation make-up premix, performing subsequent treatment on the foundation make-up premix mixed by a high-speed stirrer through an airstream smashing method, and ensuring that the powder is uniformly dispersed; (3) measuring the color difference; (4) performing color mixing; and (5) monitoring the color difference, and ensuring that the color difference of the foundation make-up premix delta Ecmc is less than 0.8. According to the invention, the magnitude of the color difference is quantitatively analyzed in a digitization manner by means of an instrument; unified surface treatment is performed on various powder, so that unified surface properties are achieved, thereby ensuring that the powder can be uniformly dispersed and distributed in a dispersion medium or emulsion system; the airstream smashing method is adopted, thereby ensuring that the powder is thoroughly dispersed without bonding and accumulation phenomena; and the color of each batch of premix is comprehensively ensured to be uniform and consistent.

Owner:SHANGHAI CO FUN BIOTECH

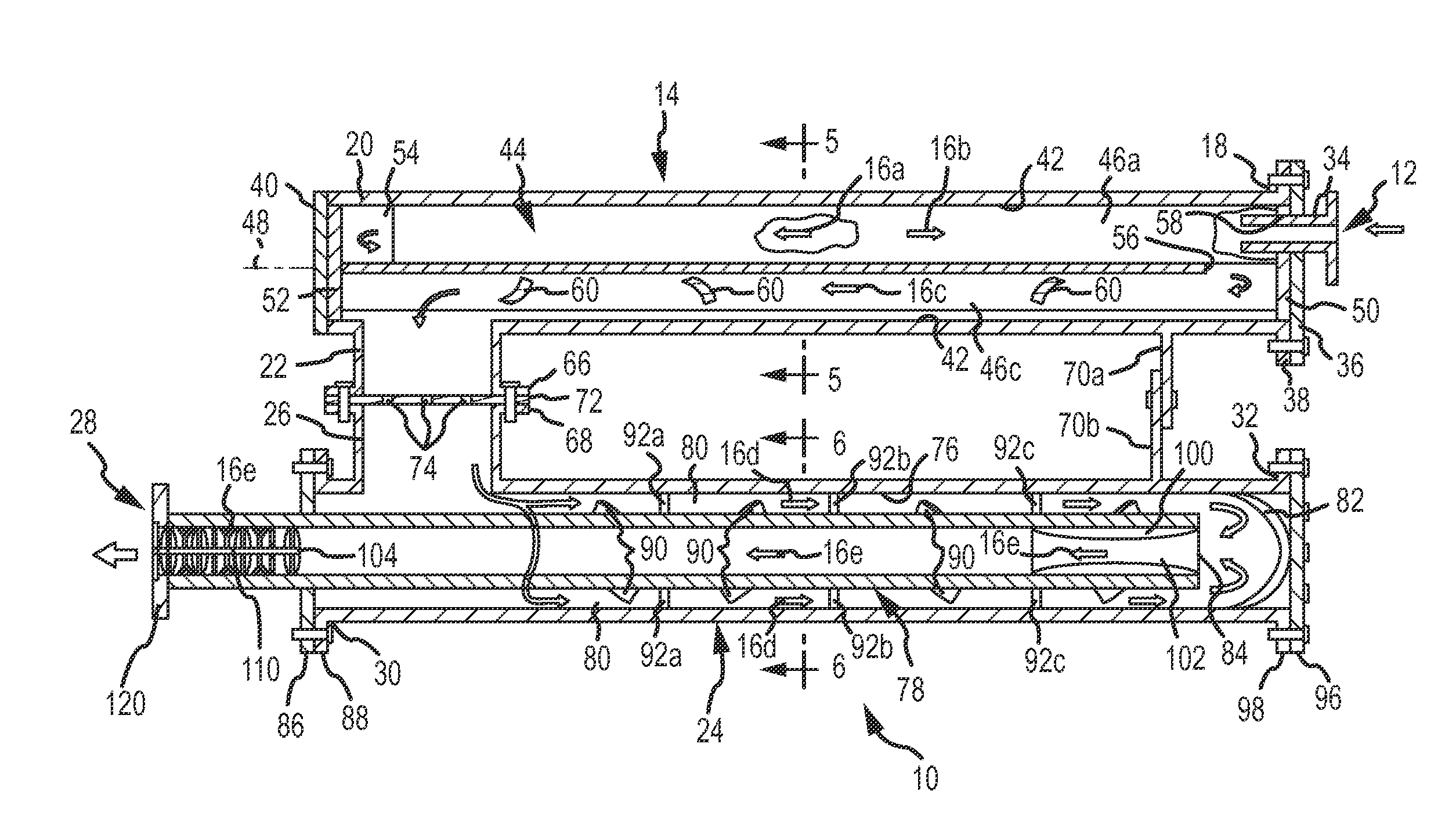

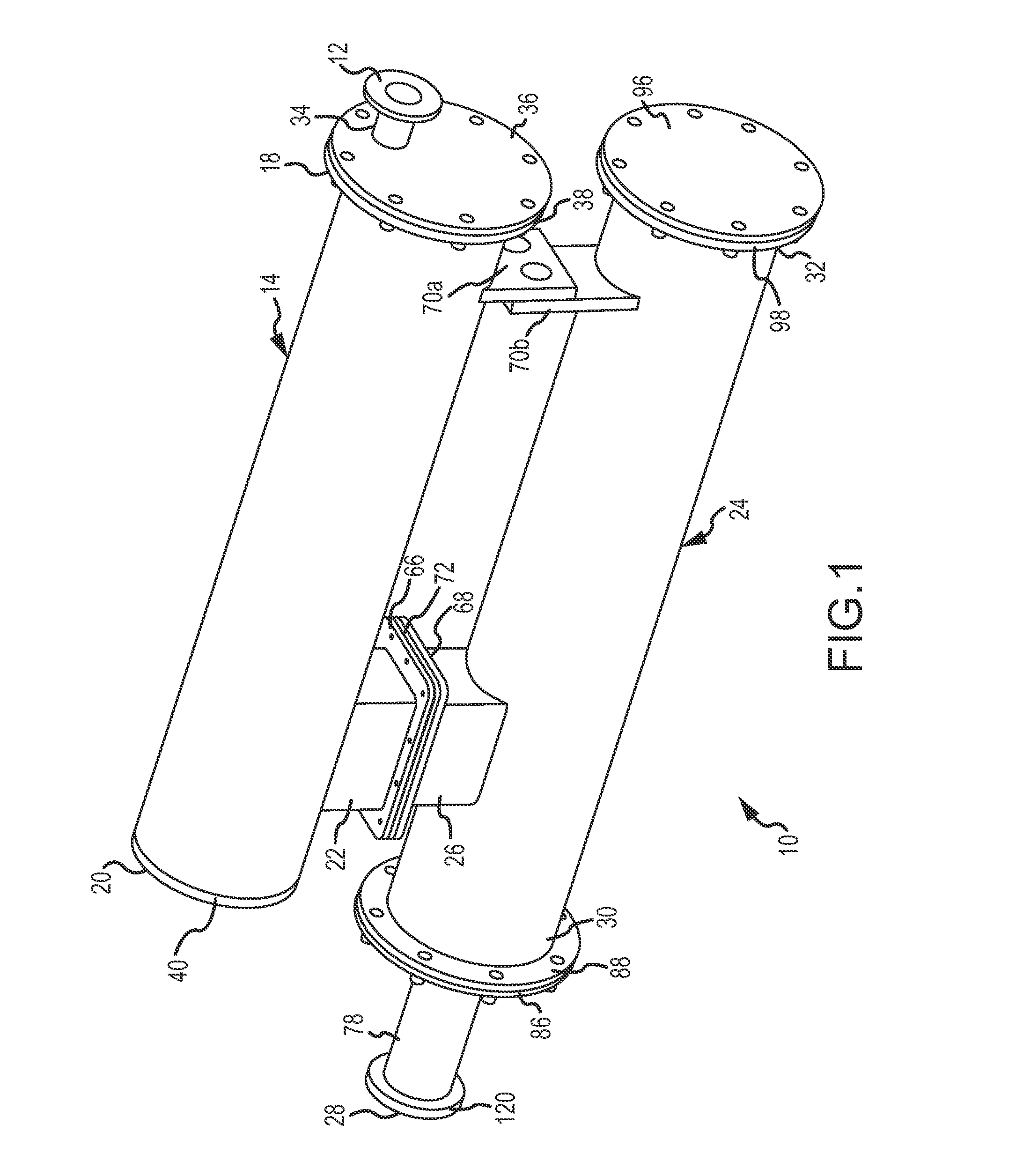

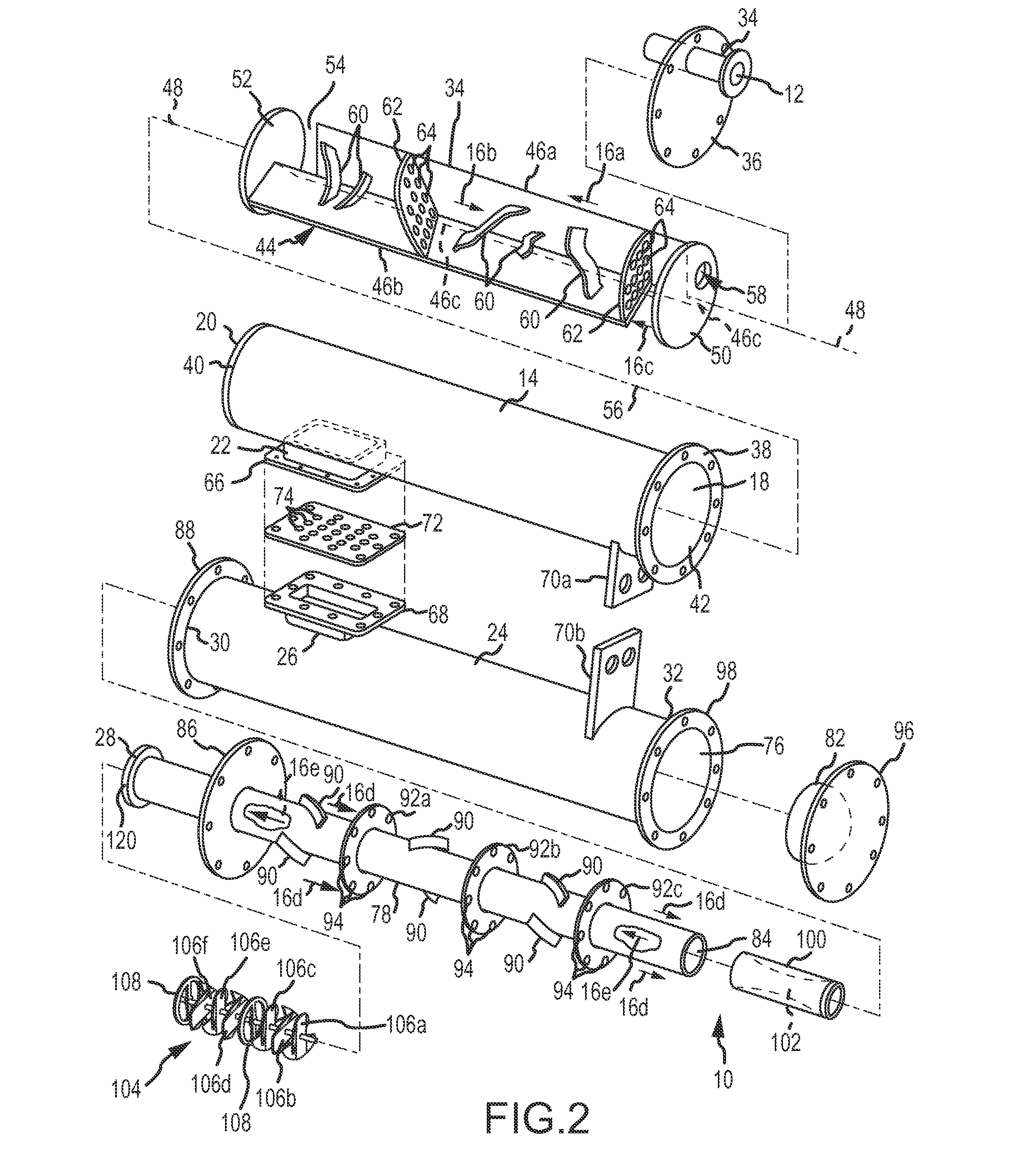

Flow Reversing Static Mixer and Method

InactiveUS20130128688A1Without consuming excessive energySmall and more energy efficientFlow mixersTransportation and packagingEngineeringStatic mixer

A static mixer includes first and second tubular housings which define elongated internal cavities. Dividers divide each internal cavity into a plurality of separate and sequential flow paths for the fluid mixture. Each separate flow path extends between the opposite ends of each housing, reverses direction substantially adjacent to an end of each housing, and conducts the fluid mixture in a direction opposite of the fluid mixture conducted by one of a preceding or succeeding flow path.

Owner:DOOLIN MICHAEL B +1

Heat pump system with multi-stage compression

InactiveUS7810353B2Increase flexibilityIncrease productionCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

A multi-compressor heat pump system configured to provide heating and cooling over a range of ambient temperatures. The compressors can be operated independently and alone or together in series for maximum output. Heat exchangers are selectively fluidically connected to the compressors to enable refrigerant flow between the compressors and at least two heat exchangers in a manner that enables the heat pump system to be selectively operable in various modes. Preferred aspects include selectively operating the compressors based on the ratio of the evaporating and condensing pressures of the refrigerant within the heat pump system, a mixing chamber between the compressors, and a lubricant management system to prevent the accumulation of a lubricant in one of the compressors.

Owner:PURDUE RES FOUND INC

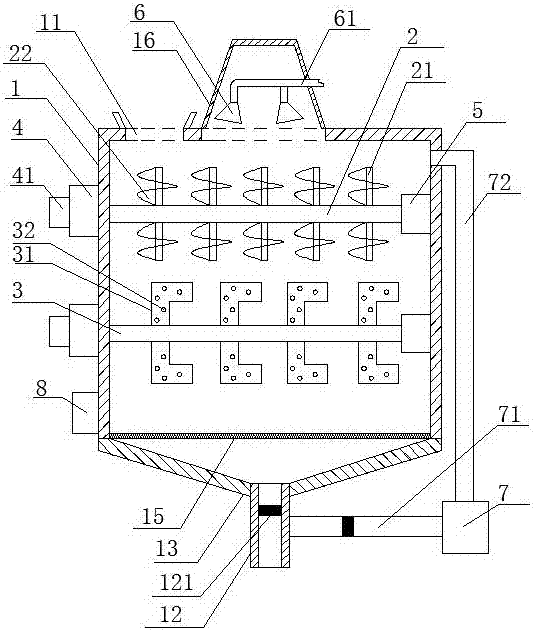

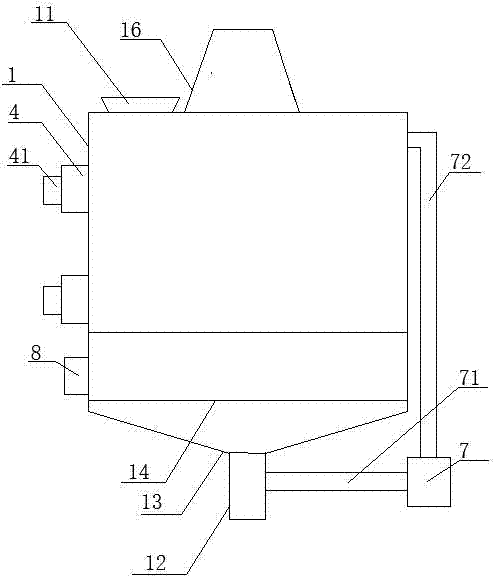

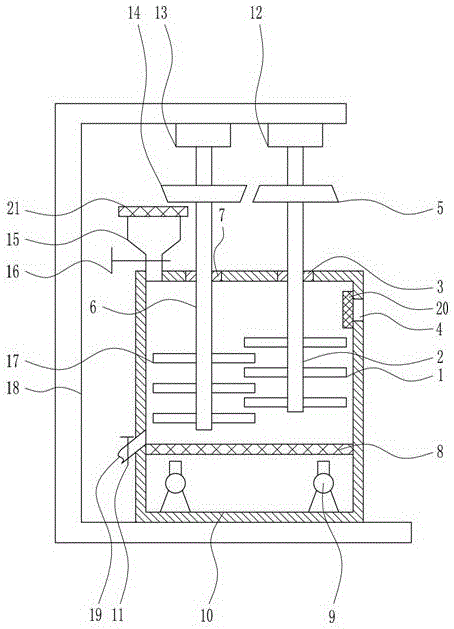

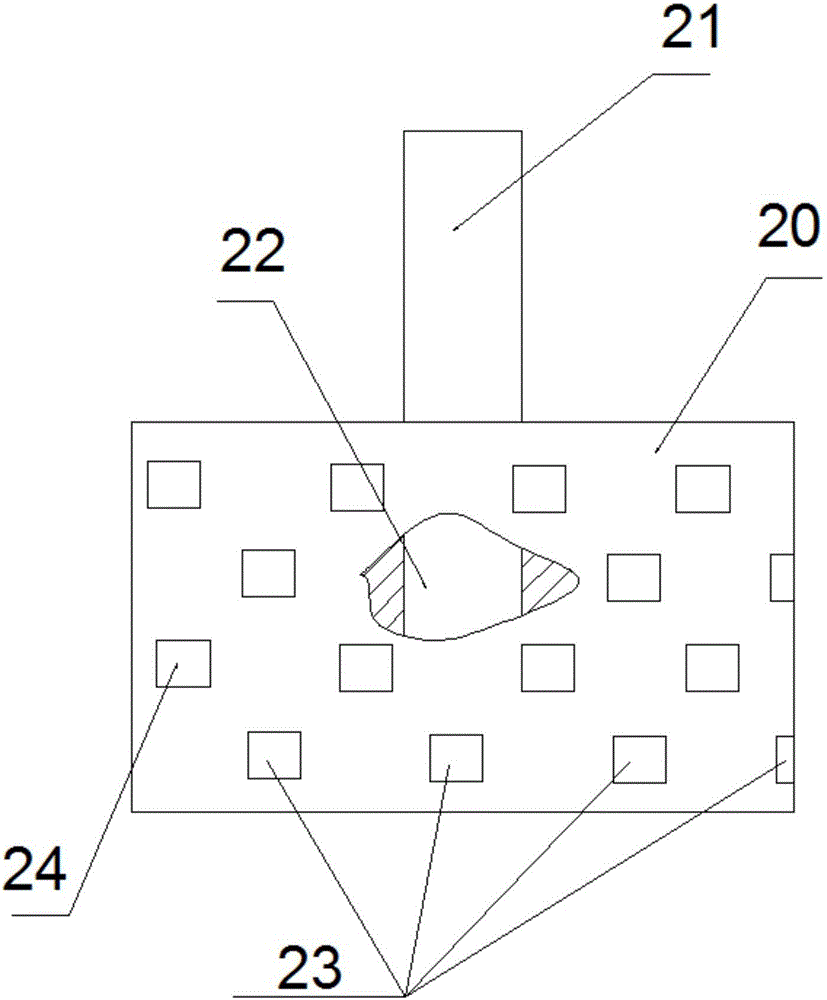

Paper pulp stirring device

InactiveCN107158989AImprove stirring efficiencyEasy to cleanFlow mixersRotary stirring mixersInternal cavityPulp and paper industry

The invention discloses a paper pulp stirring device, and belongs to the technical field of paper pulp preparation. The paper pulp stirring device comprises a stirring barrel; the stirring barrel comprises a feed inlet arranged on the top, a discharge pipe arranged on the bottom, and a stirring mechanism arranged in an internal cavity; the center of the top surface of the stirring barrel stretches to form a cavity upwards; the cavity is communicated with the internal cavity of the stirring barrel; a spray mechanism is arranged in the cavity, and is used for downward washing of the internal cavity of the stirring barrel. The paper pulp stirring device can be used for stirring and dispersing paper pulp effectively, no deposition is generated in the internal part, stirring efficiency is high, washing is convenient, operation is simple, and application is convenient.

Owner:合肥励仙电力工程有限公司

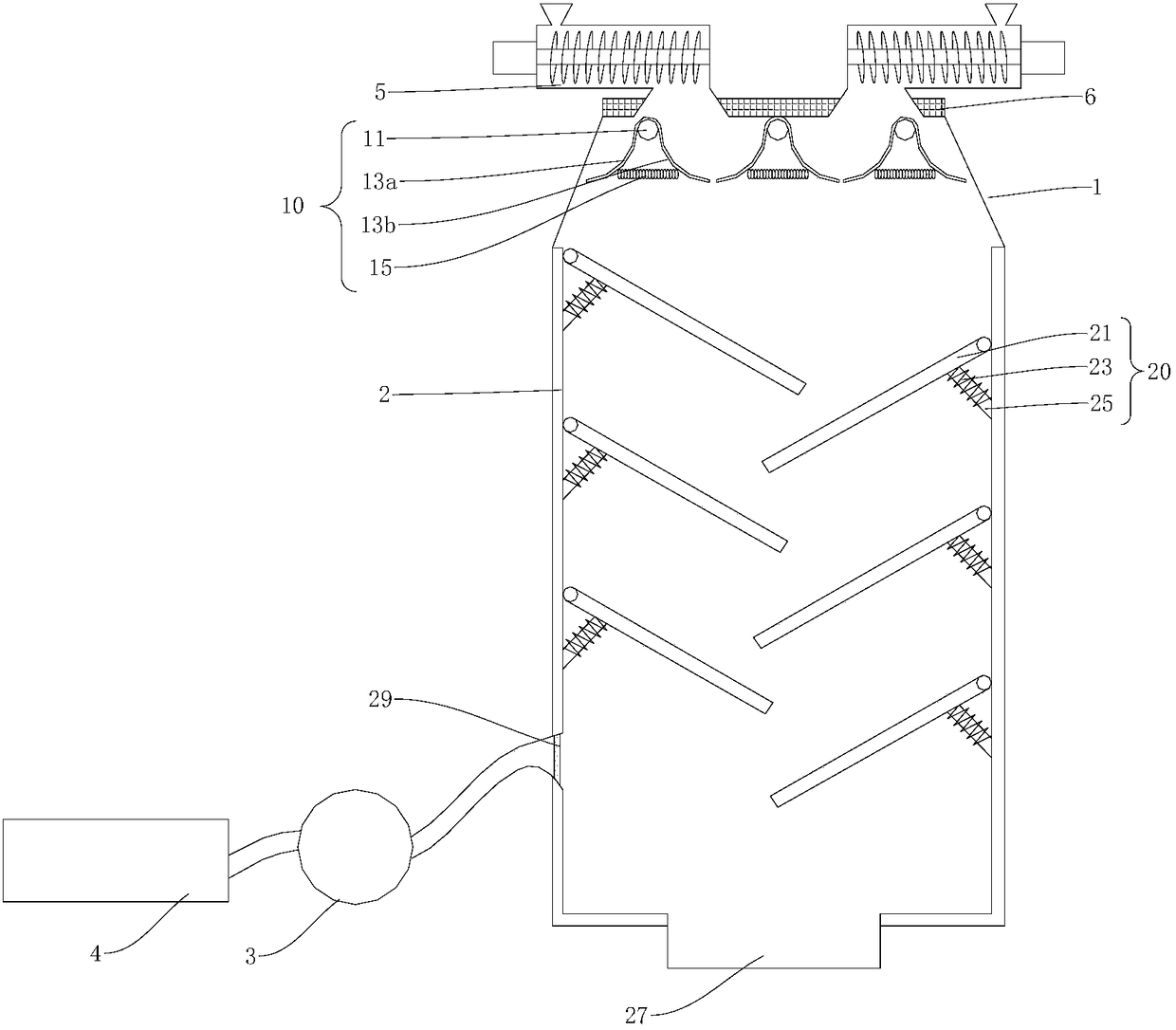

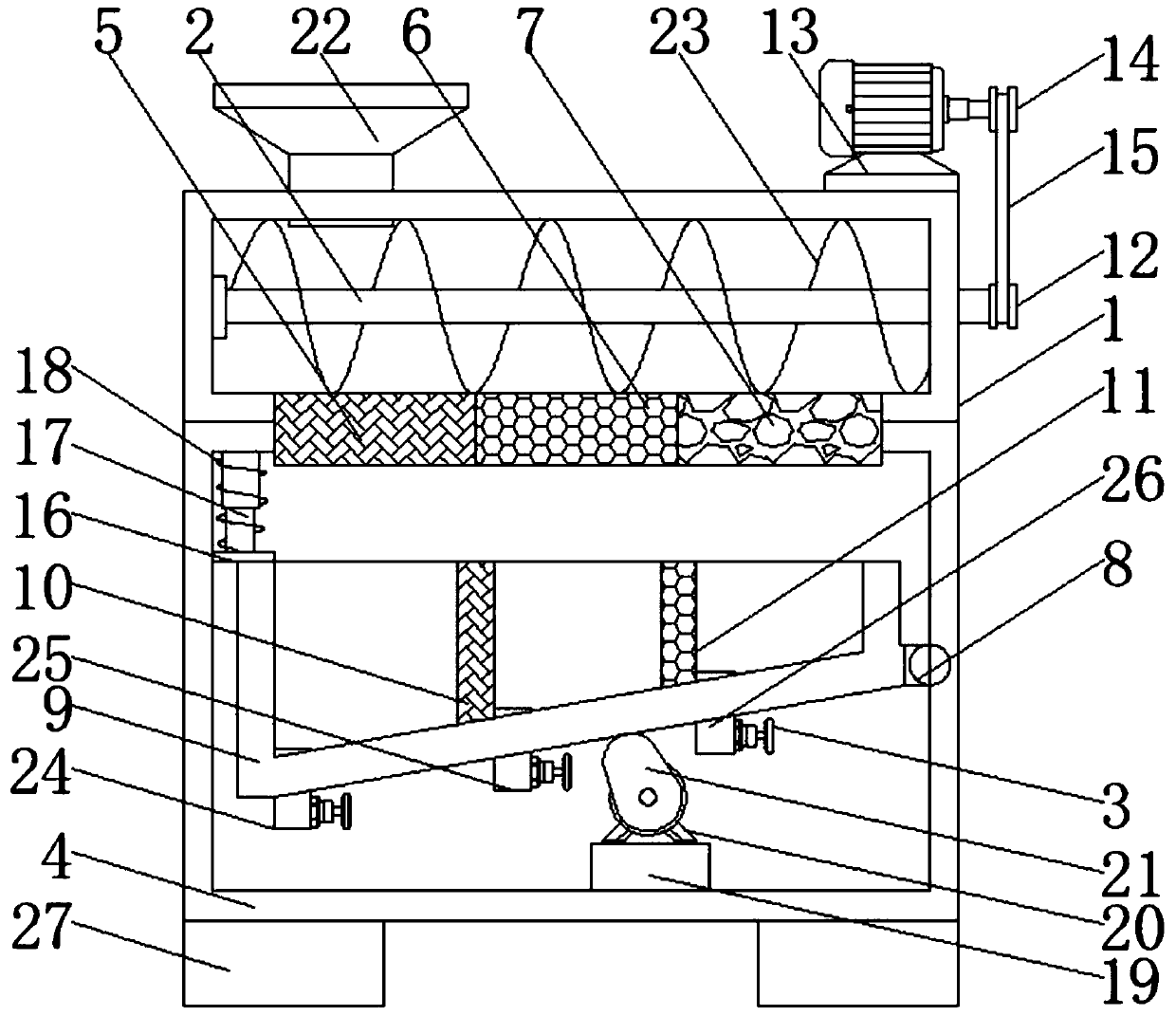

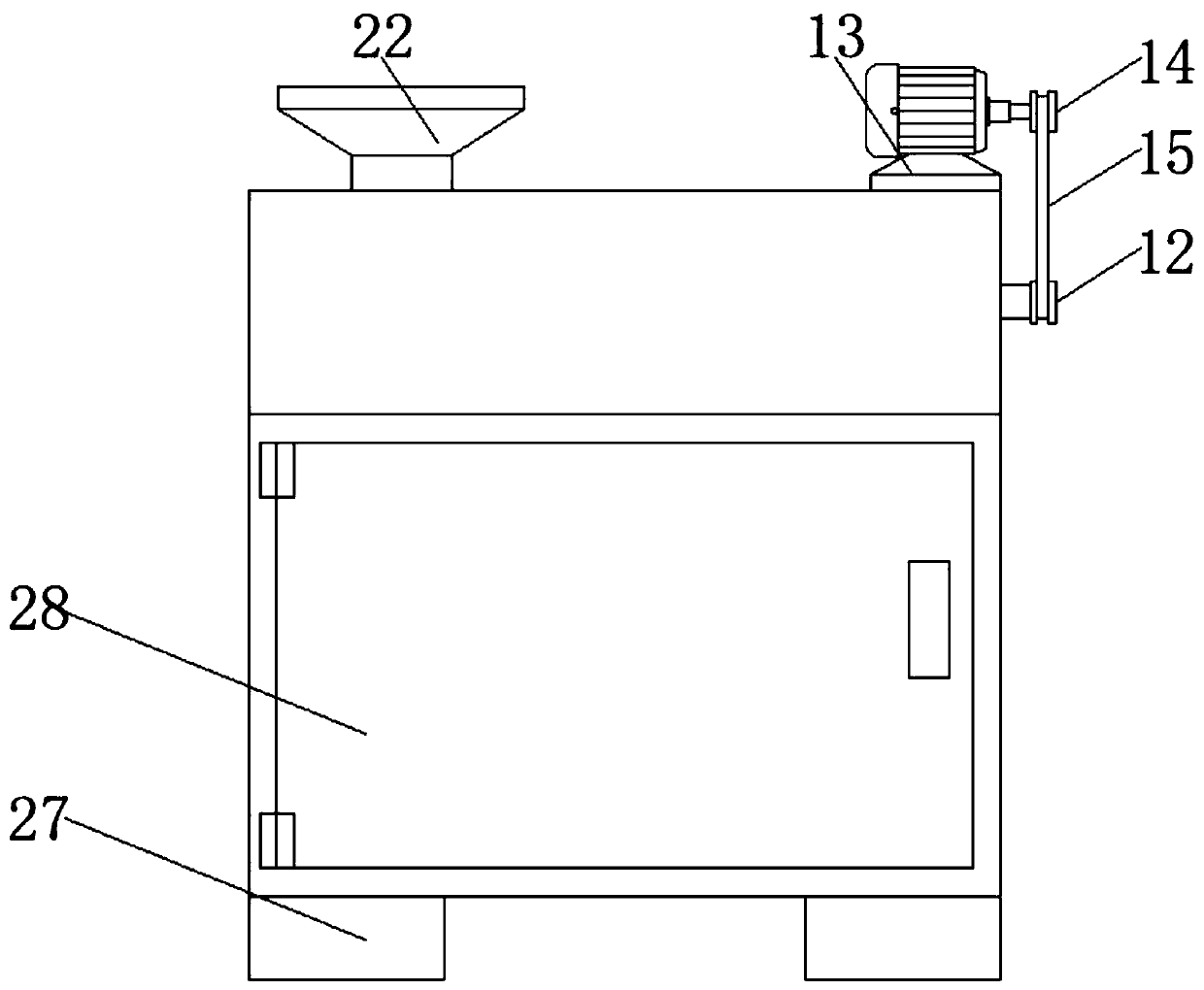

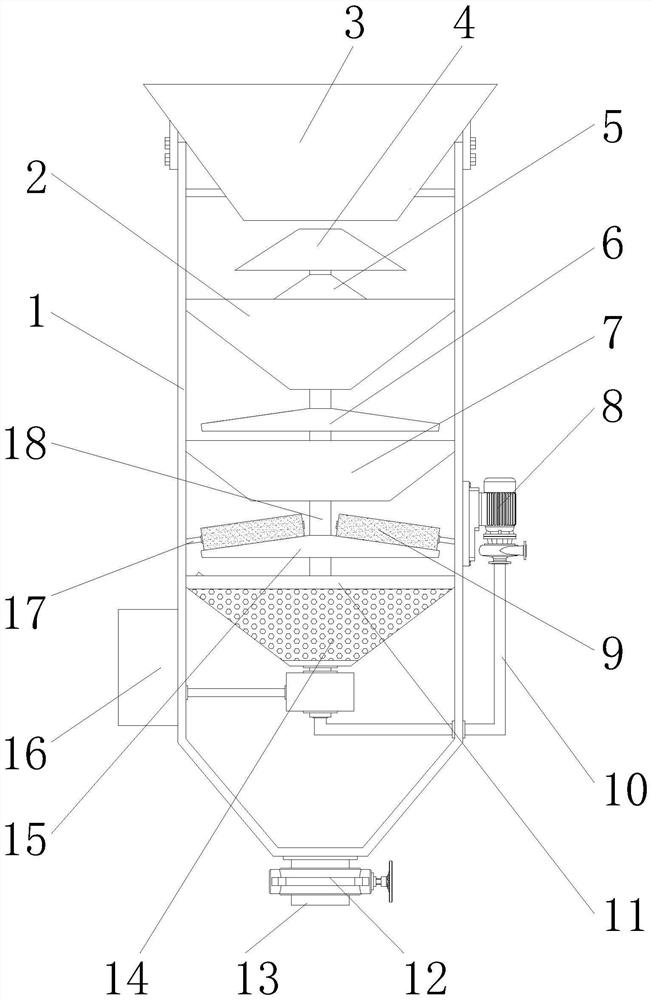

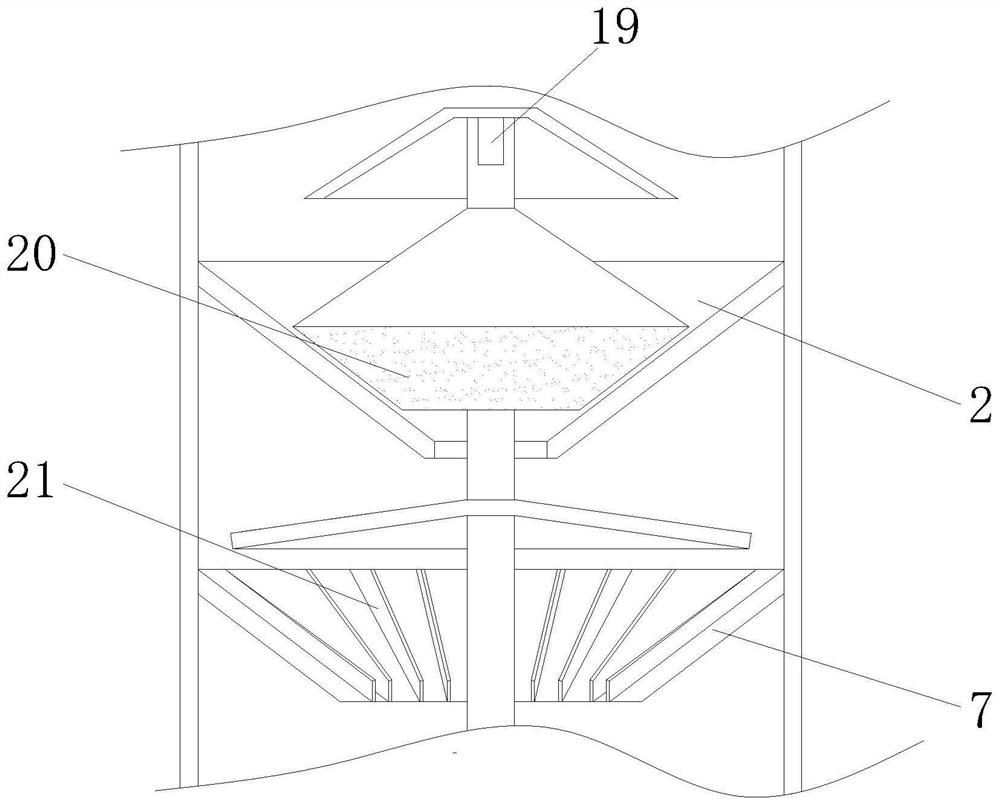

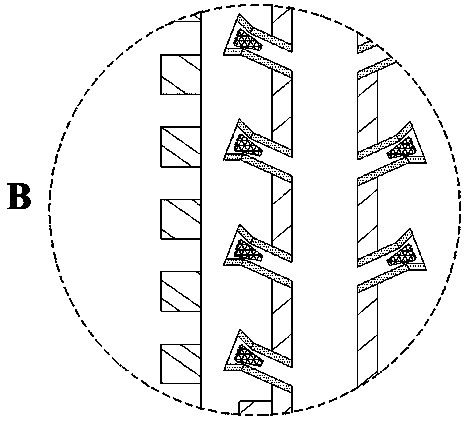

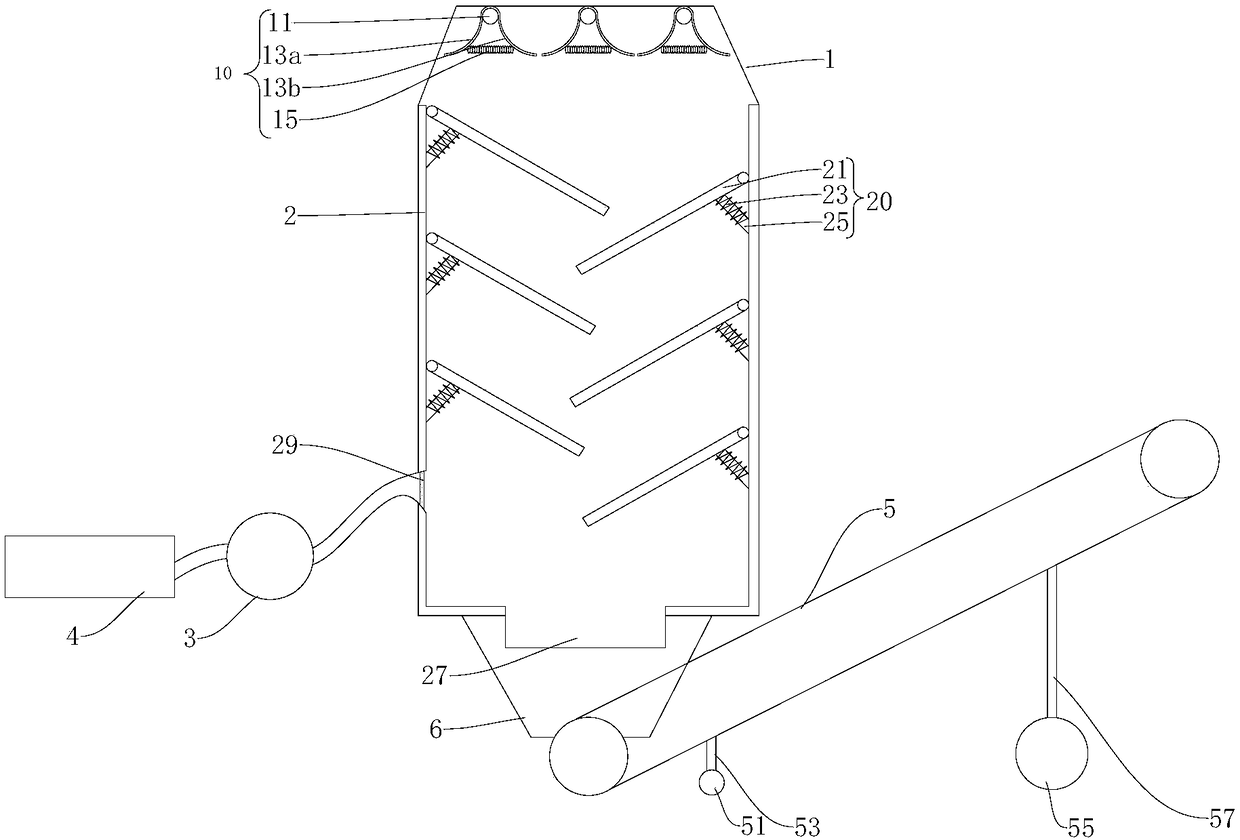

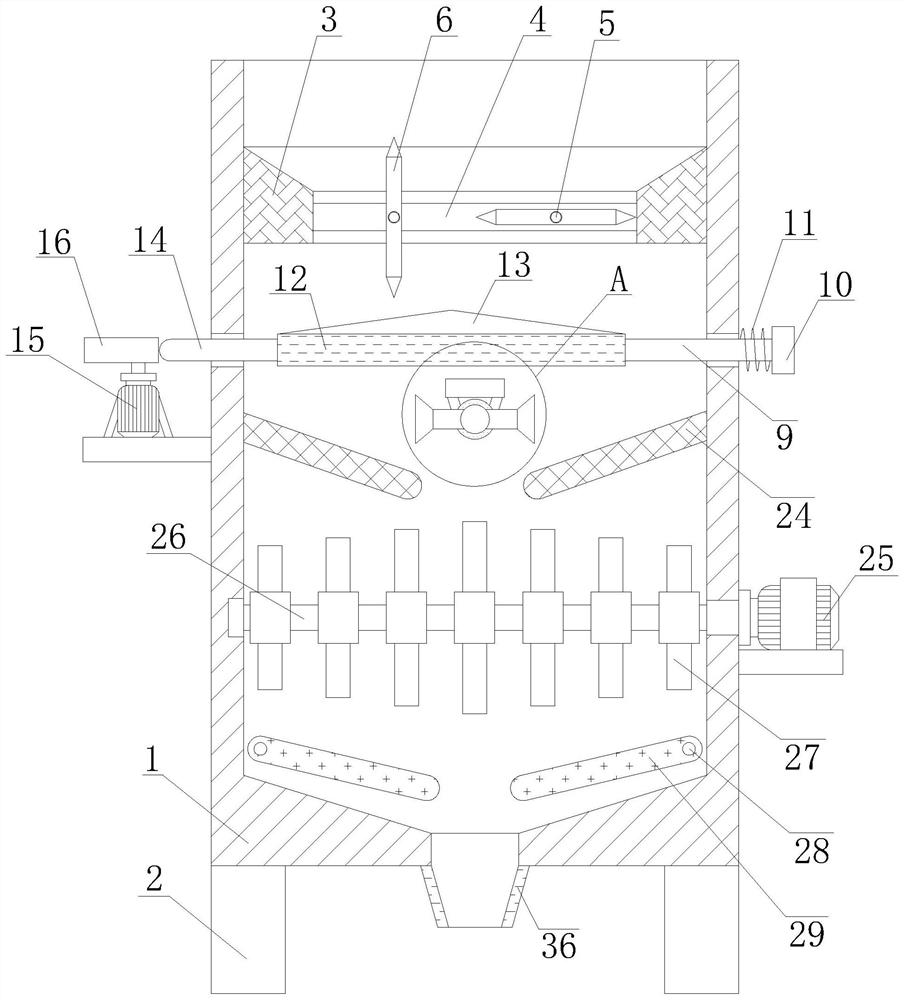

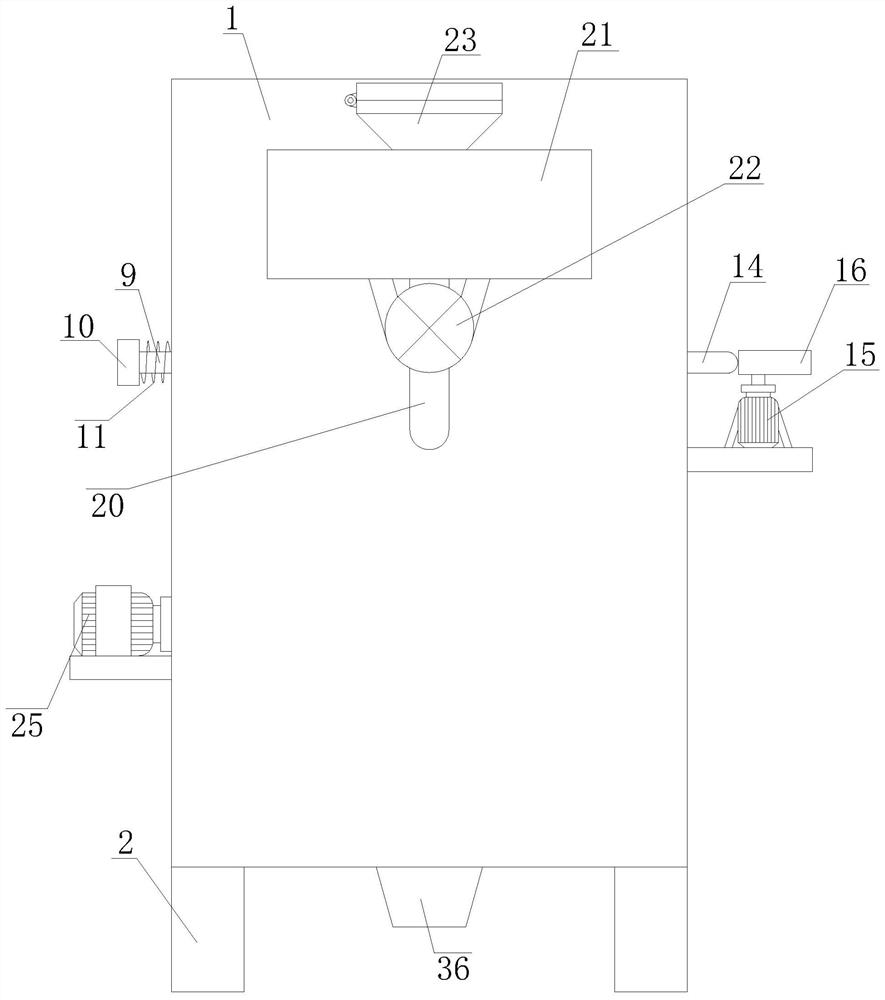

Buffering type dust removing and impurity removing device for grain

The invention discloses a buffering type dust removing and impurity removing device for grain, and relates to the field of grain processing equipment. The device comprises a feeding mechanism, a housing, an air pump, a dust storing device and a spiral conveying device, wherein the spiral conveying device, the feeding mechanism and the housing are sequentially connected; the spiral conveying deviceis connected to the feeding mechanism through a connecting plate; a plurality of flow guide mechanisms are arranged in the feeding mechanism; a plurality of vibrating assemblies which are arranged ina mutual staggering manner are sequentially arranged on the inner wall of the housing from top to bottom; the air pump communicates with the inner part of the housing; and a feeding port of the duststoring device is connected to an air outlet of the air pump through a pipeline. With the adoption of the device, the grain feeding quantity can be controlled, and moreover, dust and impurity in the grain can be separated through the flow guide mechanisms and the vibrating assemblies, so that the environment is prevented from being polluted by dust. The device has the characteristics of being simple in structure, low in production cost, and convenient to operate.

Owner:ZHENGZHOU DAXUAN ELECTRONICS TECH CO LTD

Demulsifying dehydration method of oil-water emulsion

ActiveCN102876358ADifficulty in demulsification and dehydrationDisperse thoroughlyDewatering/demulsification with chemical meansDemulsifierWater in oil emulsion

The invention relates to a demulsifying dehydration method of an oil-water emulsion. The method comprises a step that demulsifying dehydration is carried out through mixing the oil-water emulsion with salt-containing water and a demulsifying agent, wherein the total ion concentration of the salt-containing water is 10000-300000mg / L, and the application amount of the salt-containing water is 10-50% of the volume of the oil-water emulsion; and the oil-water emulsion is a water-in-oil emulsion formed by viscous oil and water, and contains an emulsified viscosity reducer. The method is suitable for the demulsifying dehydration of oilfield produced fluids containing the viscous oil and the emulsified viscosity reducer.

Owner:CHINA PETROLEUM & CHEM CORP +1

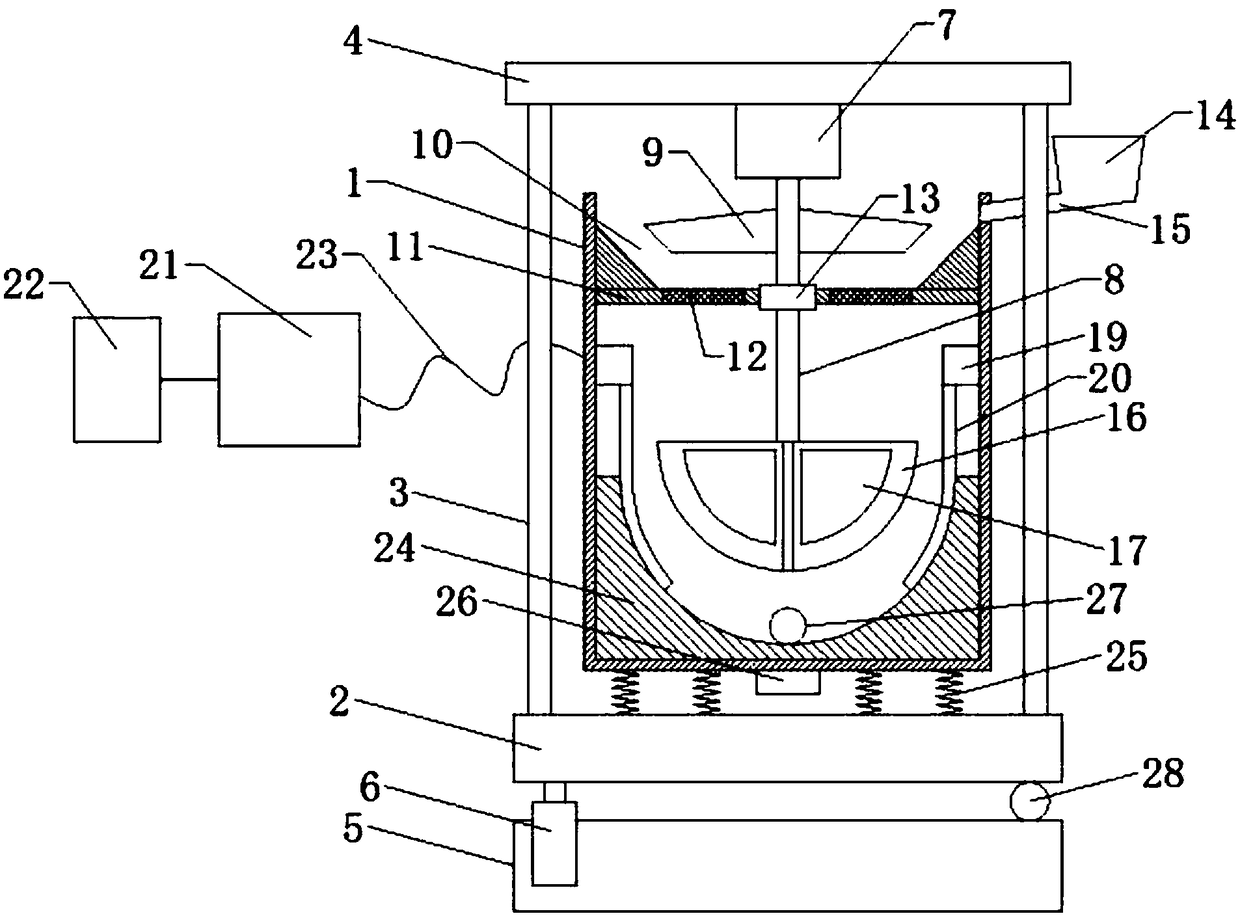

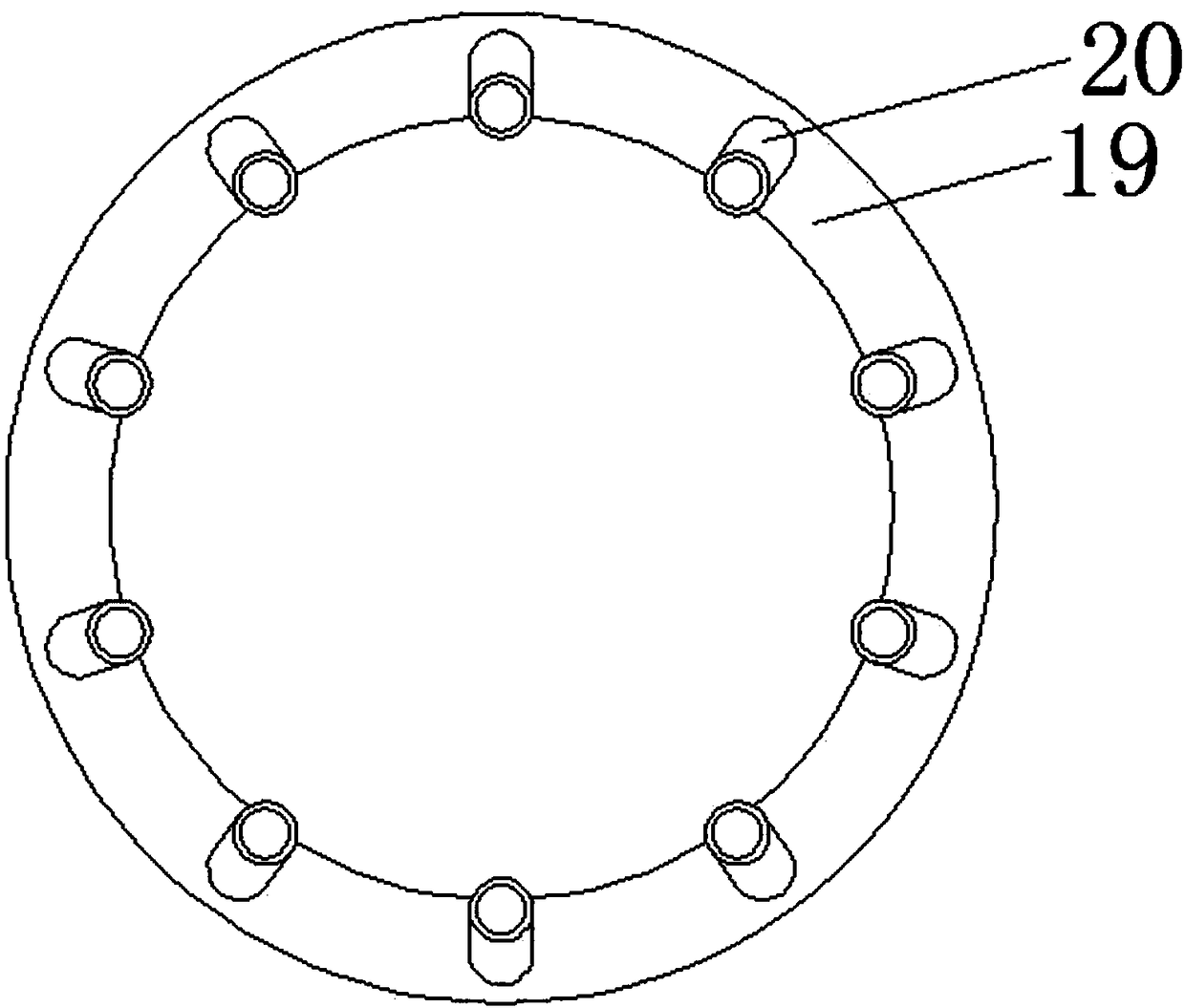

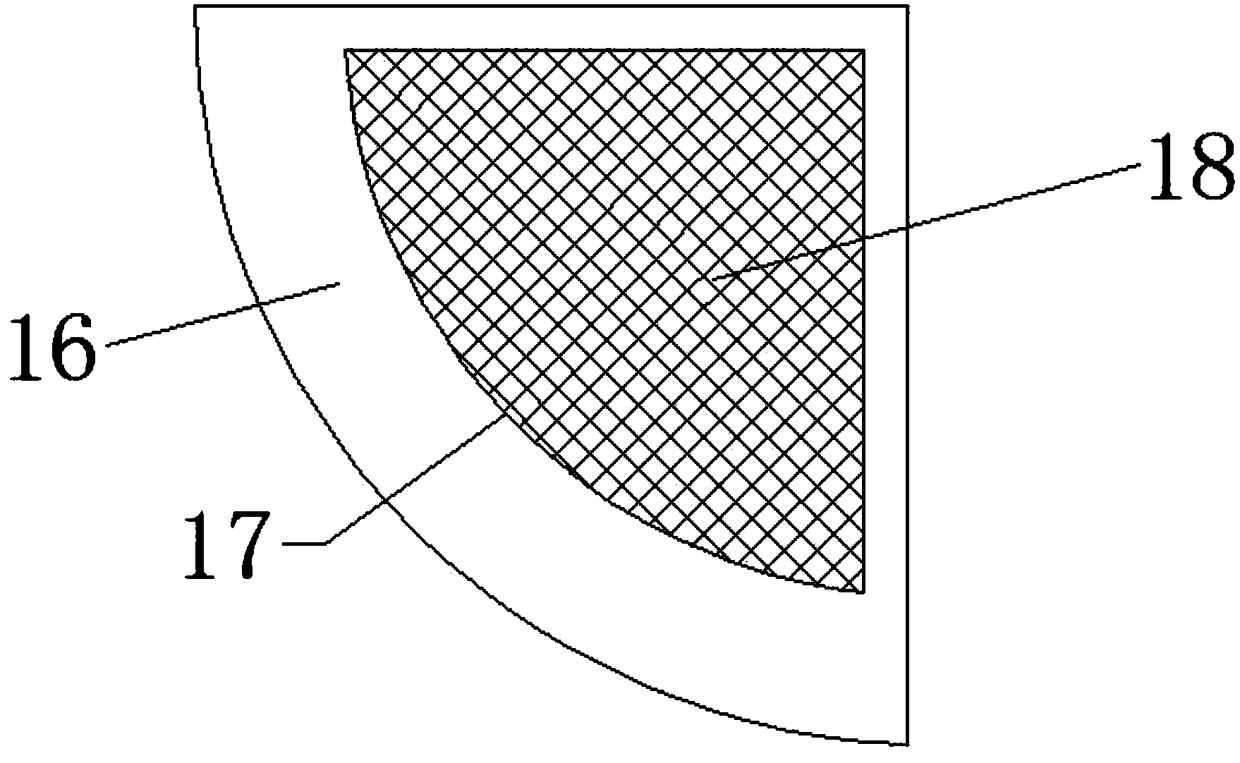

Stirring equipment with adjustable angle of hot-air blowing turbulent flow

InactiveCN108525586ADisperse thoroughlyImprove the mixing effectShaking/oscillating/vibrating mixersFeeding-stuffEngineeringMixing effect

The invention discloses stirring equipment with an adjustable angle of a hot-air blowing turbulent flow. The equipment comprises a cylinder body, a base seat, supporting rods, a top plate and a motor;a plurality of springs are fixedly connected between the cylinder body and the base seat, and a vibration motor is fixedly installed at the bottom of the cylinder body; a horizontal supporting seat is arranged below the base seat, one end of the base seat is rotatably connected with one end of the supporting seat through a pin shaft, and the other end of the base seat and the supporting seat is provided with a vertical lifting mechanism; the lower end of the output shaft of the motor is fixedly connected with a rotating shaft extending vertically into the cylinder body; a horizontal material-distributing tray is fixed on the part, located above a baffle, of the rotating shaft; and a plurality of vertical stirring blades are fixedly installed at the lower end of the rotating shaft. According to the equipment disclosed by invention, the swinging base seat is arranged, so that raw materials in the equipment flow, the raw materials located at different positions are moved, the raw materials are dispersed more thoroughly, and the mixing effect of the raw materials is improved; and hot air blown into the bottom enables the raw materials collected at the bottom to be blown off, and mixing of the raw materials is facilitated.

Owner:合肥智龙机械设计有限公司

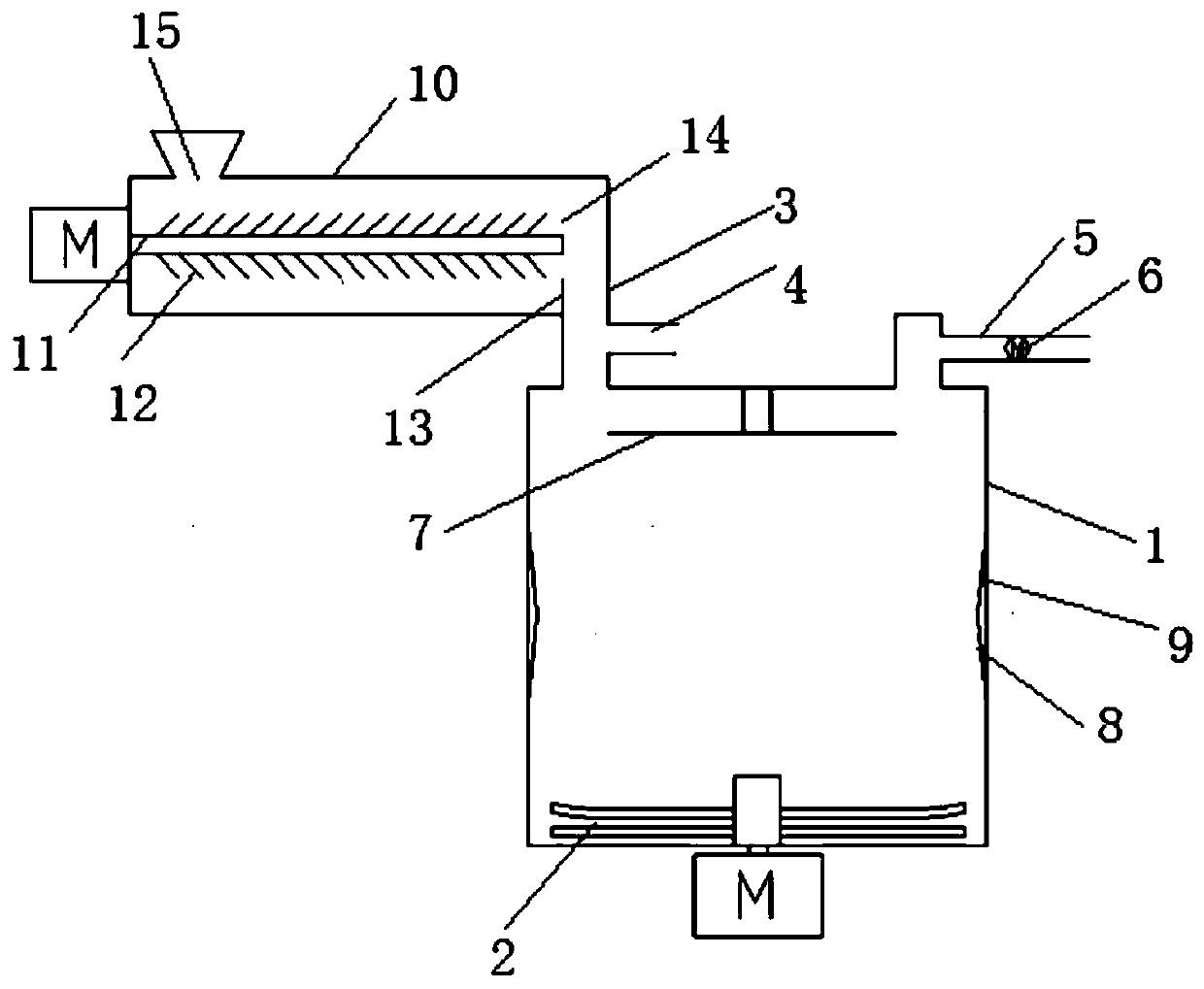

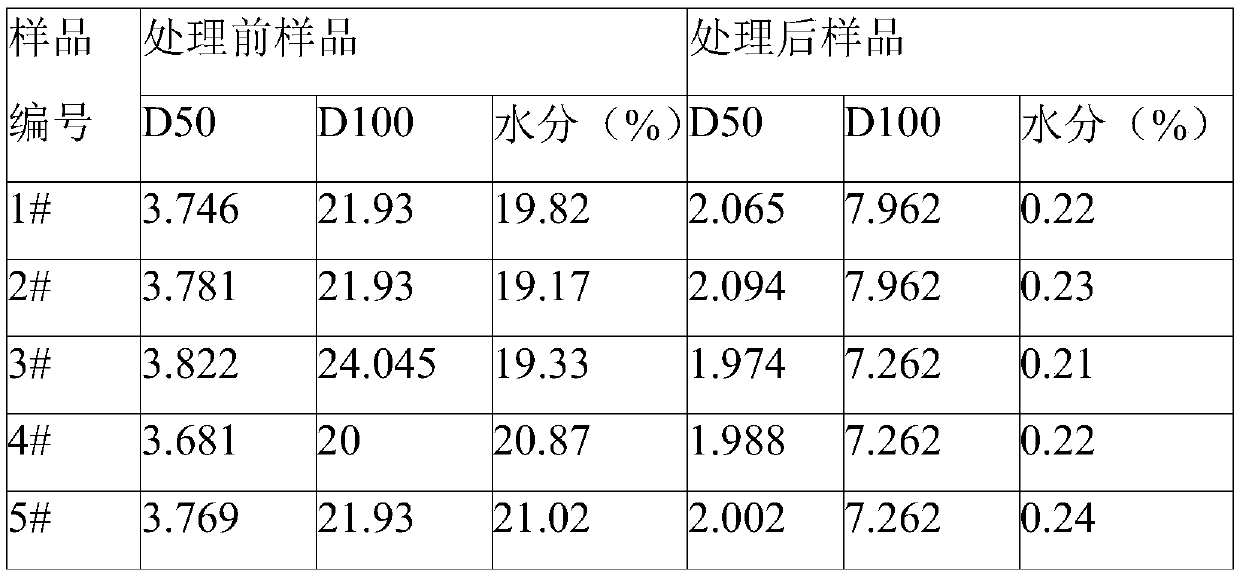

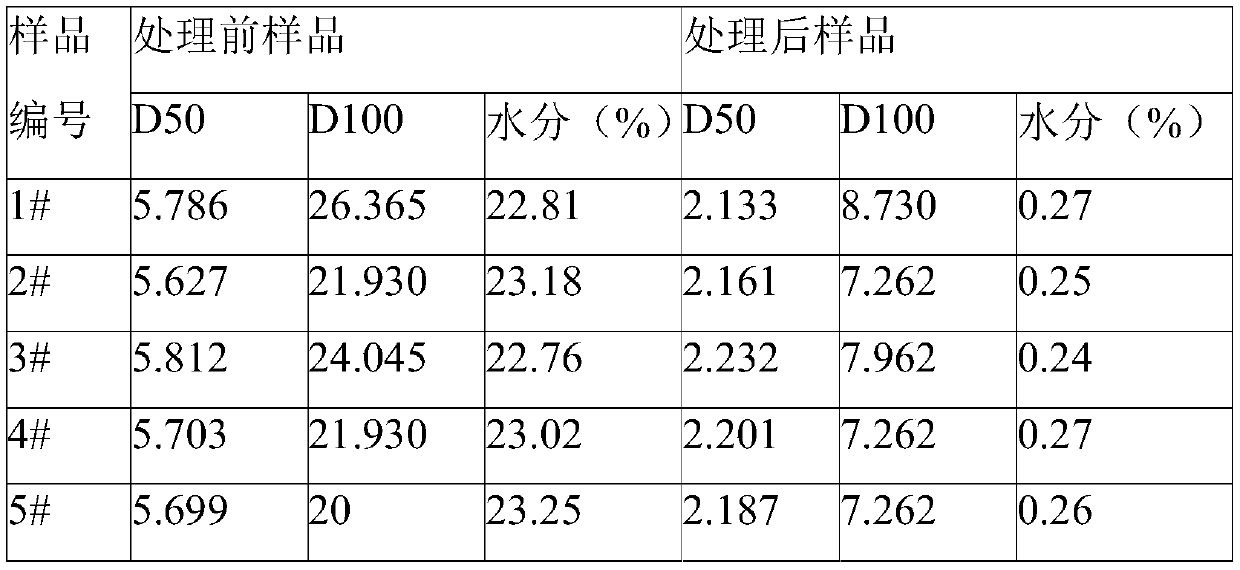

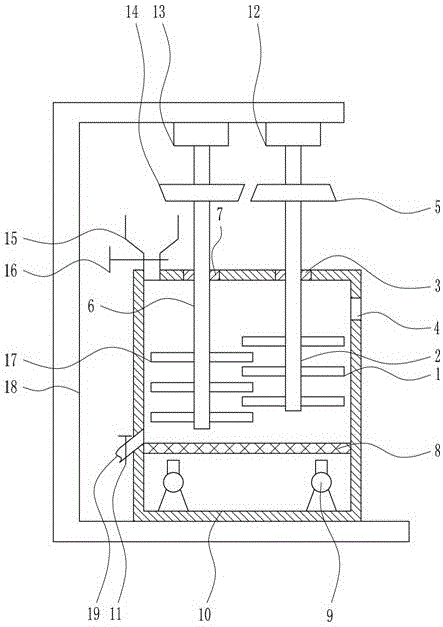

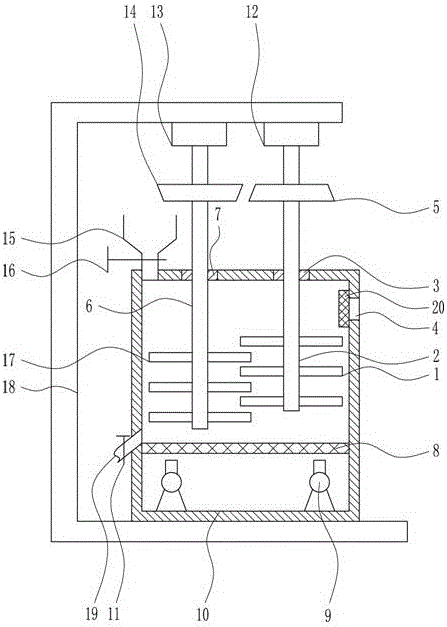

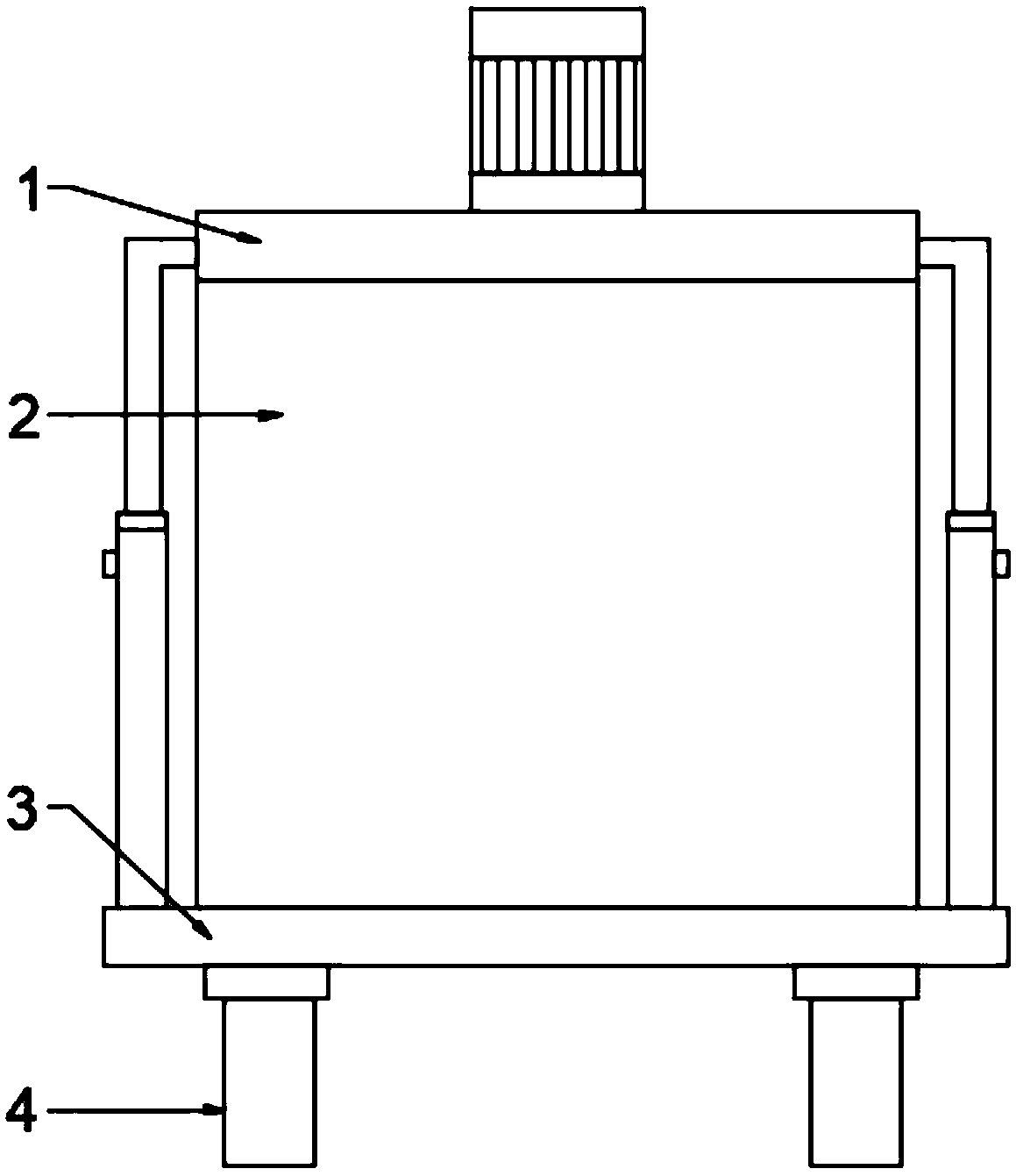

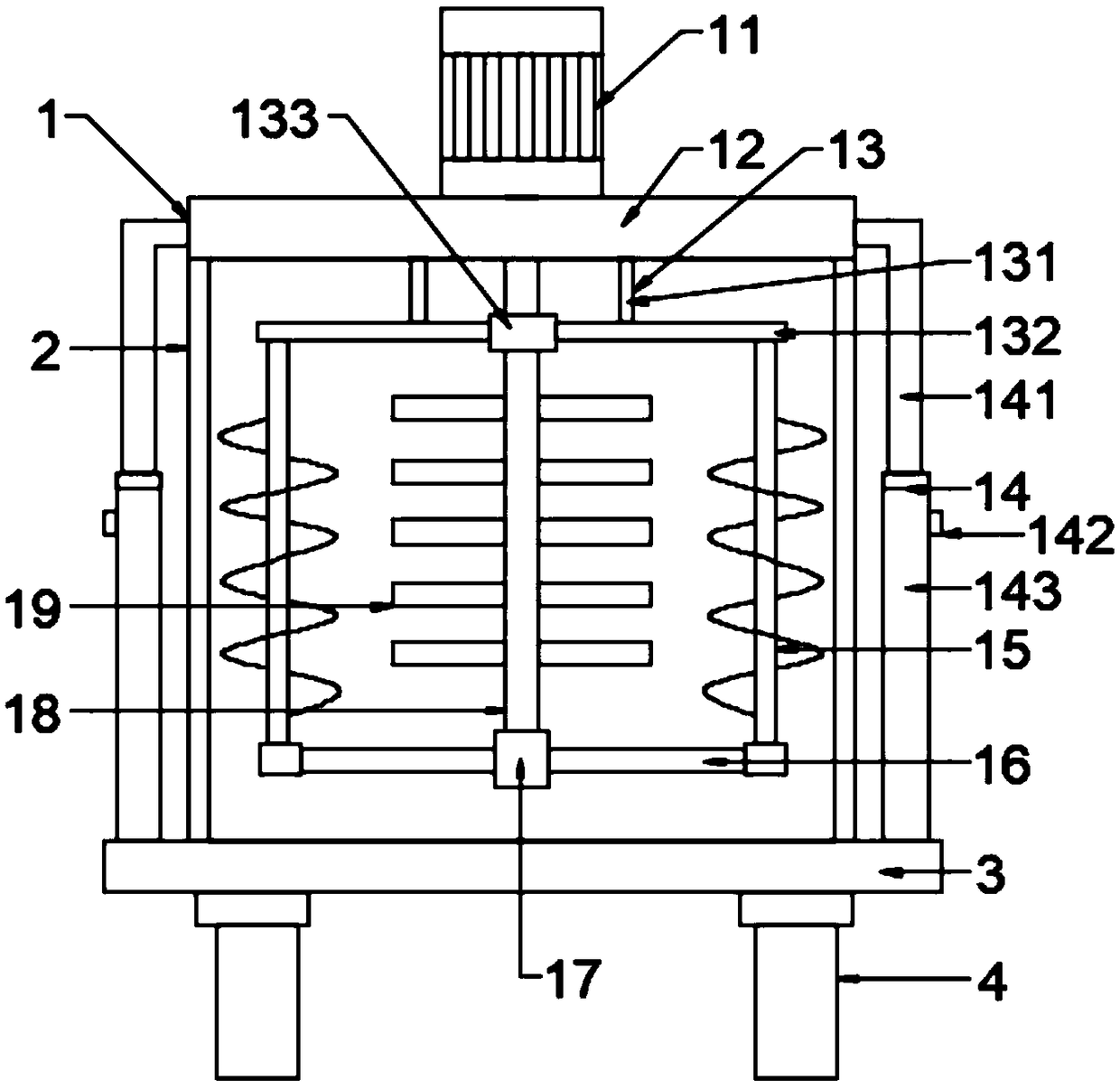

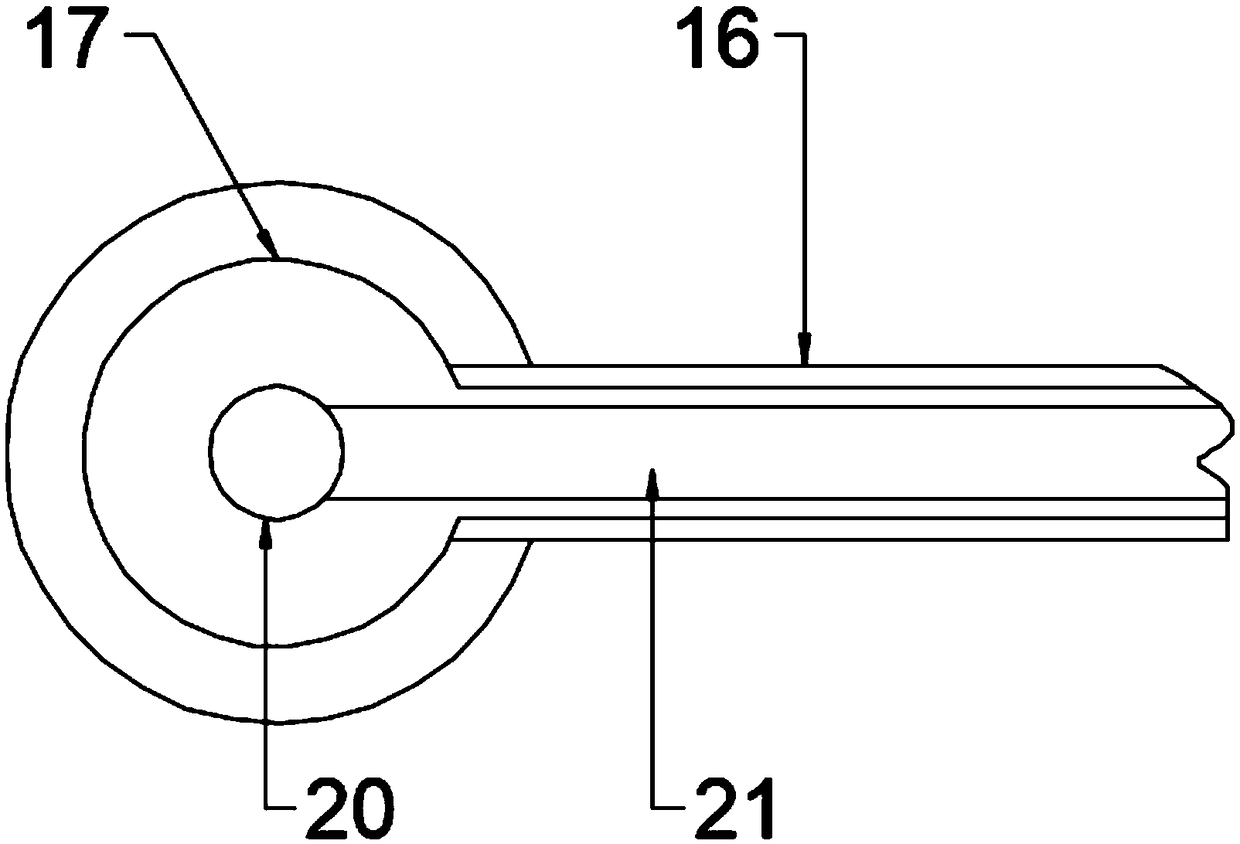

Powder drying and dispersing device

ActiveCN111380329AAvoid hard clumpingEvenly heatedDrying solid materials with heatDrying gas arrangementsExhaust pipeFilter cake

The invention relates to the field of powder drying and discloses a powder drying and dispersing device. The powder drying and dispersing device comprises a drying cylinder (1), a stirring mechanism (2), a feeding pipe (3), a gas inlet pipe (4) and an exhaust pipe (5), wherein the drying cylinder (1) is used for accommodating to-be-treated powder and is arranged vertically; the stirring mechanism2 is arranged in the drying cylinder (1); and the feeding pipe (3) communicates with the top of the drying cylinder (1). By the above technical solution, a filter cake or a crushed material is stirredor dispersed by stirring, and kinetic energy generated by stirring serves as energy for heating and drying as well as crushing and dispersing, so that hard agglomeration of powder caused by rapid evaporation of water can be avoided, a heating device is not required and energy conservation and environmental friendliness are achieved; furthermore, the materials are heated uniformly and dried completely, so the powder drying and dispersing device is suitable for various powder materials, has high dispersion efficiency and quality, achieves dispersion uniformity and avoids the agglomeration phenomenon.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

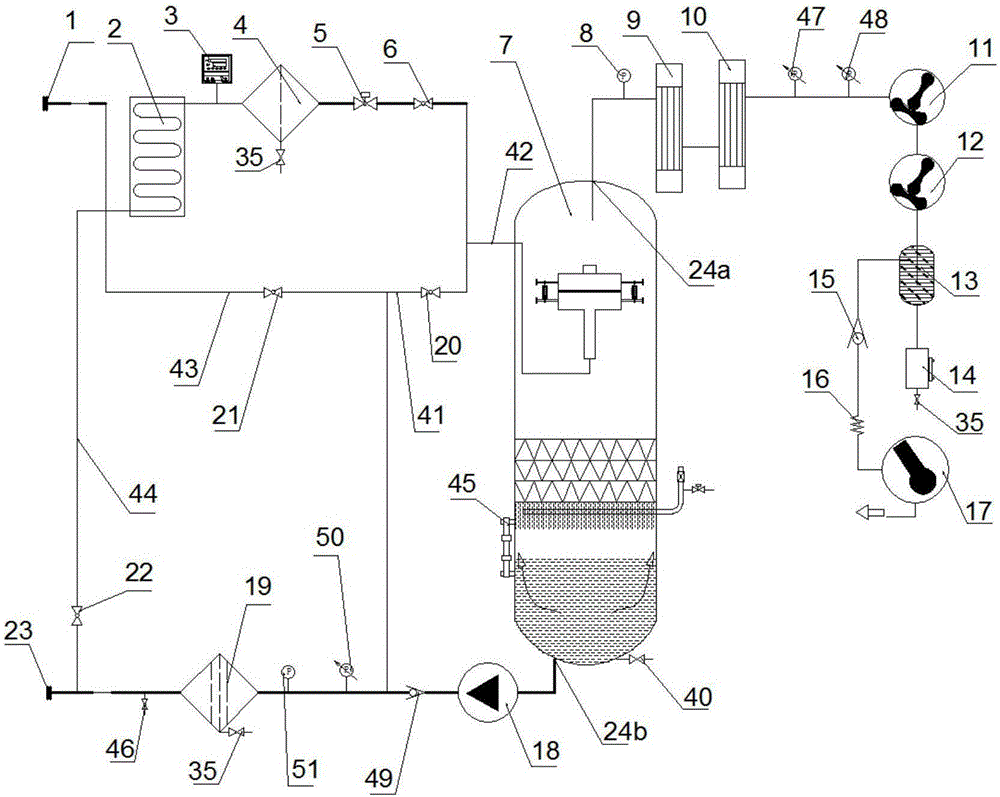

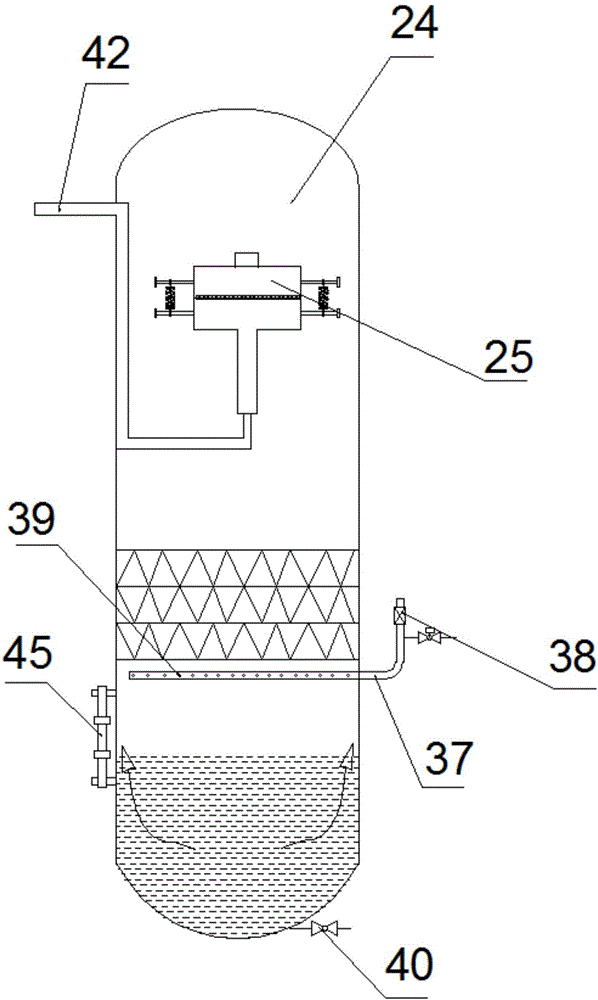

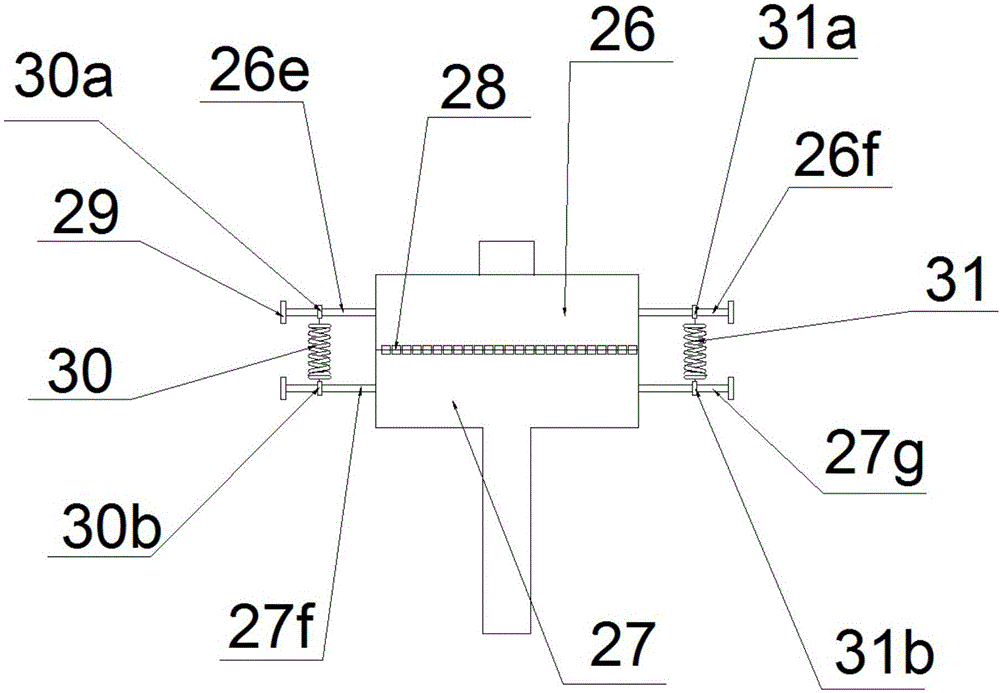

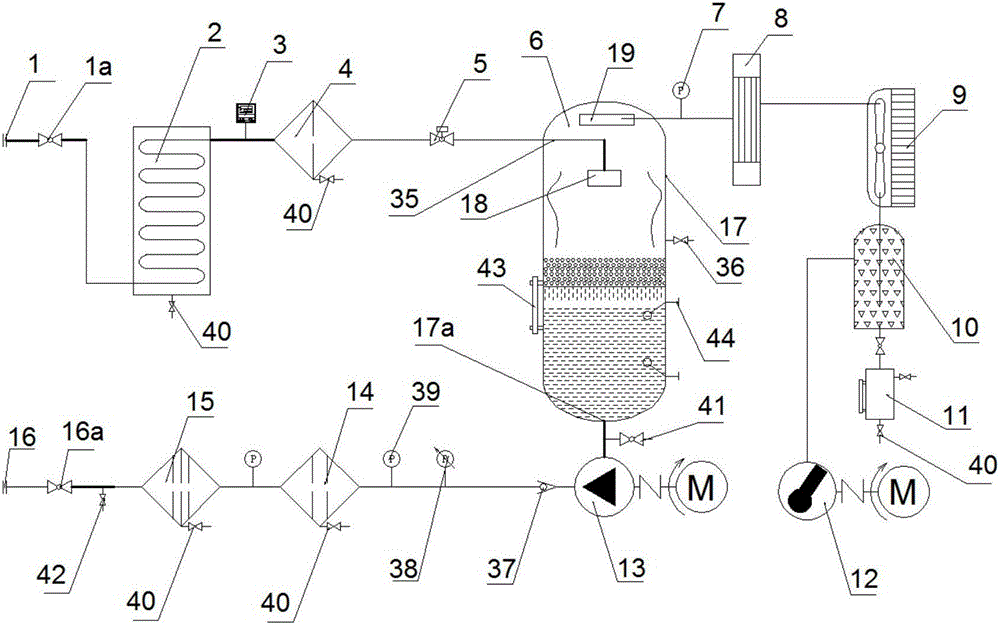

Three-stage high-vacuum oil filter system

ActiveCN106479660AEasy to separateHeating oil filter effect is goodLubricant compositionThree stagePressure reduction

The invention provides a three-stage high-vacuum oil filter system, comprising a vacuum separation system, comprising a vacuum tank and an atomizer arranged in the upper space in the vacuum tank. The three-stage high-vacuum oil filter system has the advantages that as an oil circuit outlet is added, oil can be turned into oil droplets more thoroughly and can be atomized better; as an oil circuit is divided into two paths by a Y-shaped oil spout, which is equivalent to a sudden pressure reduction, oil and water gain a wider diffusion range at the oil circuit outlet, atomizing is more thorough, and it is easier to make separation.

Owner:山东沃特润滑科技有限公司

Material dispersion facility for electronic product production

InactiveCN106492696AIncrease contact areaDisperse thoroughlyTransportation and packagingMixersEngineeringBevel gear

The invention relates to a material dispersion facility, particularly a material dispersion facility for electronic product production. The invention aims to provide a thorough-dispersion material dispersion facility for electronic product production. In order to solve the technical problems, the invention provides a material dispersion facility for electronic product production. The material dispersion facility for electronic product production comprises first blade, a first rotating rod, a first bearing, a first bevel gear, a second rotating rod, a second bearing, a screen, a blower, a box body, a second valve, a motor and the like, wherein the center of the bottom in a mounting rack is welded with the box body; the lower part in the box body is welded with a screen; the left and right sides of the bottom in the box body are symmetrically connected with the blower through bolts; the lower part of the left wall of the box body is obliquely welded with a discharge pipe; and the discharge pipe is provided with the second valve. The first bevel gear and second bevel gear are arranged to change the rotation directions of the first blades and second blades, so that the dispersion is more thorough. Besides, the bottom of the box body is provided with the blower.

Owner:WUXI TONGXIN PLASTIC PROD

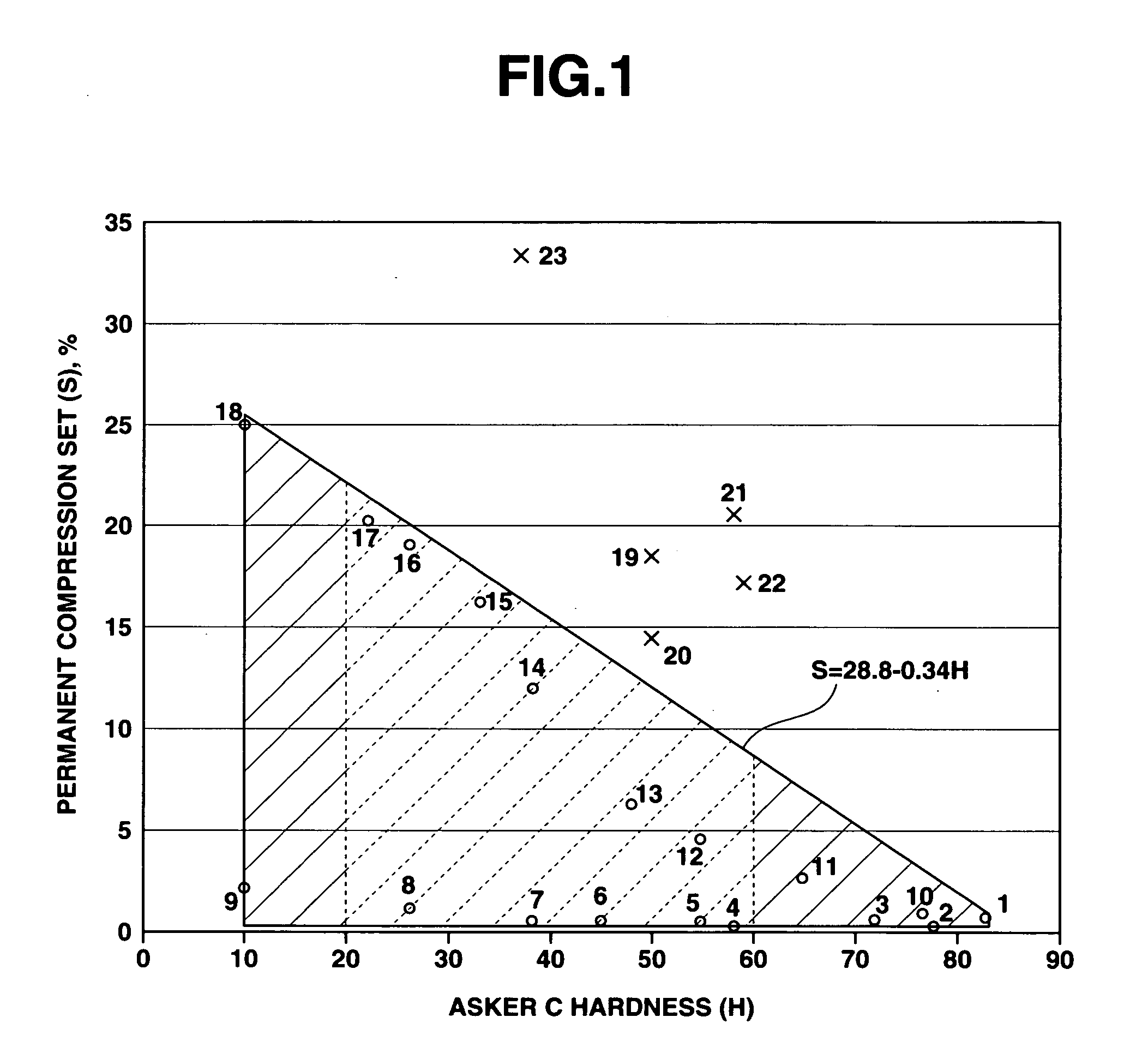

Crosslinked rubber product

A crosslinked rubber product which is molded into a desired shape with crosslinking from a rubber compound composed of liquid rubber and compounding ingredients, wherein the crosslinked rubber product is characterized by having a value of permanent compression set (S) of 0.2 to 25% (measured according to JIS K6262) and a value of Asker C hardness (H) of 10 to 83 (measured according to JIS K6253), with S and H satisfying the next following (1). S≦28.8−0.34H (1) The crosslinked rubber product has high performance (small permanent compression set as well as low hardness) which has never been achieved by ones in the past.

Owner:BRIDGESTONE CORP

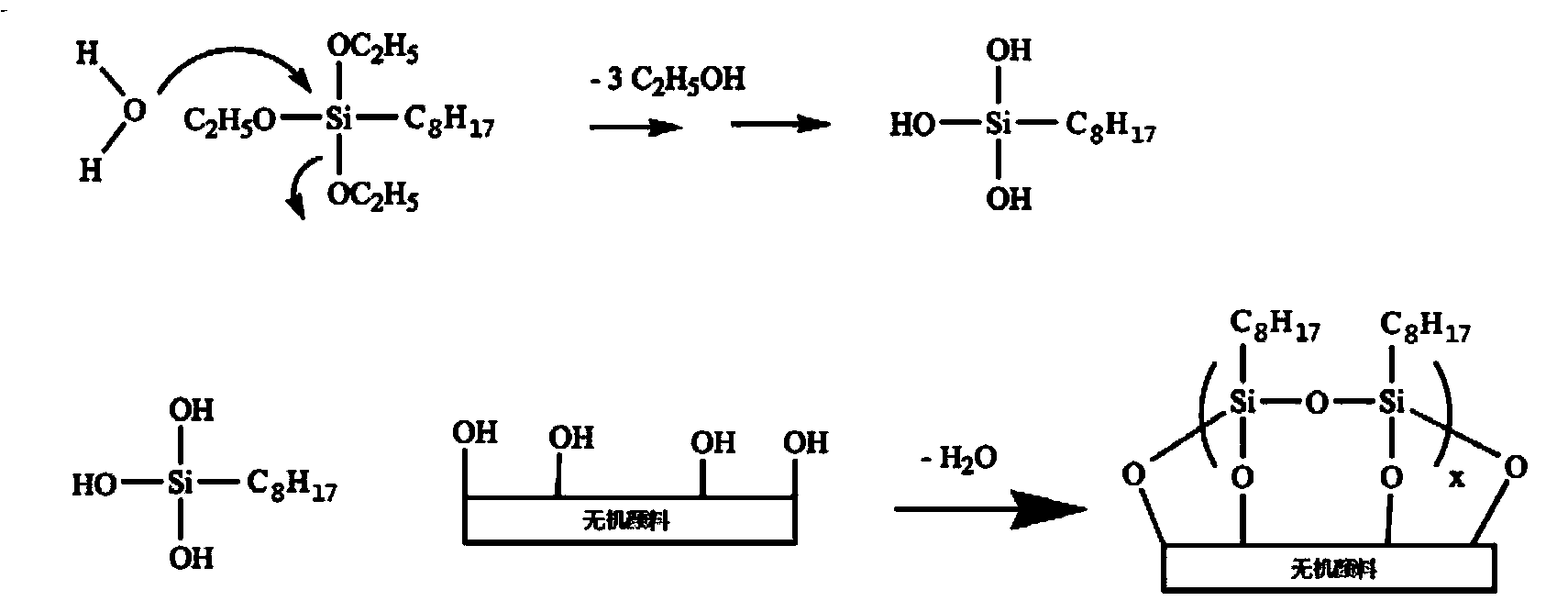

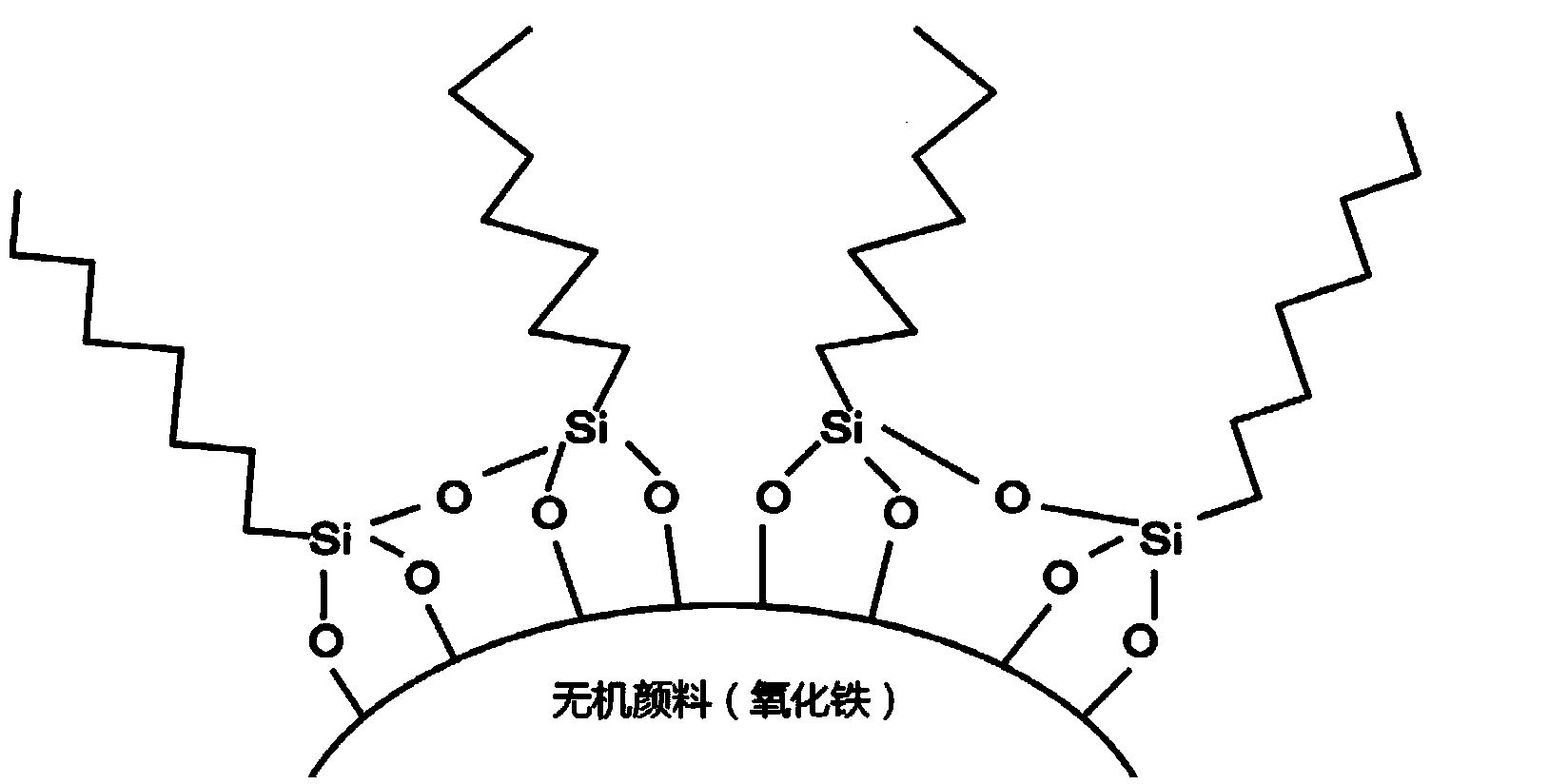

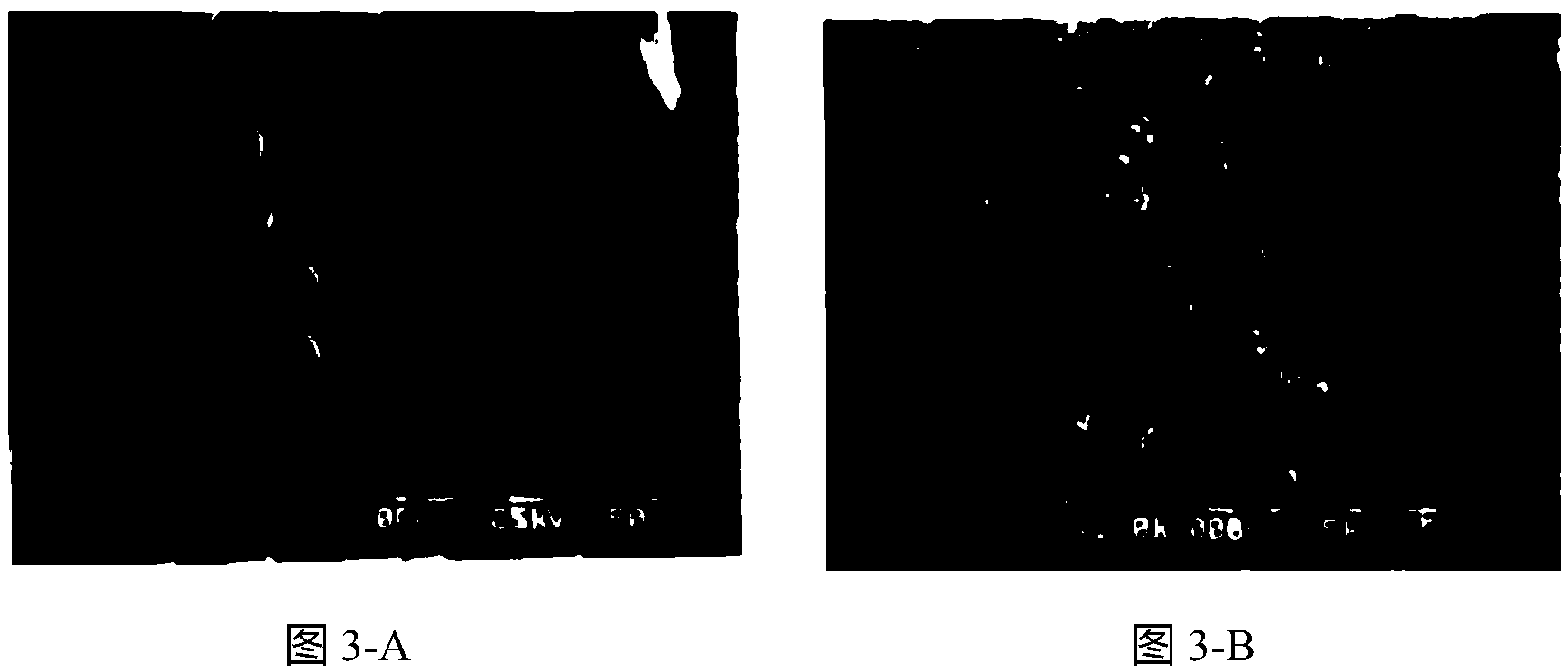

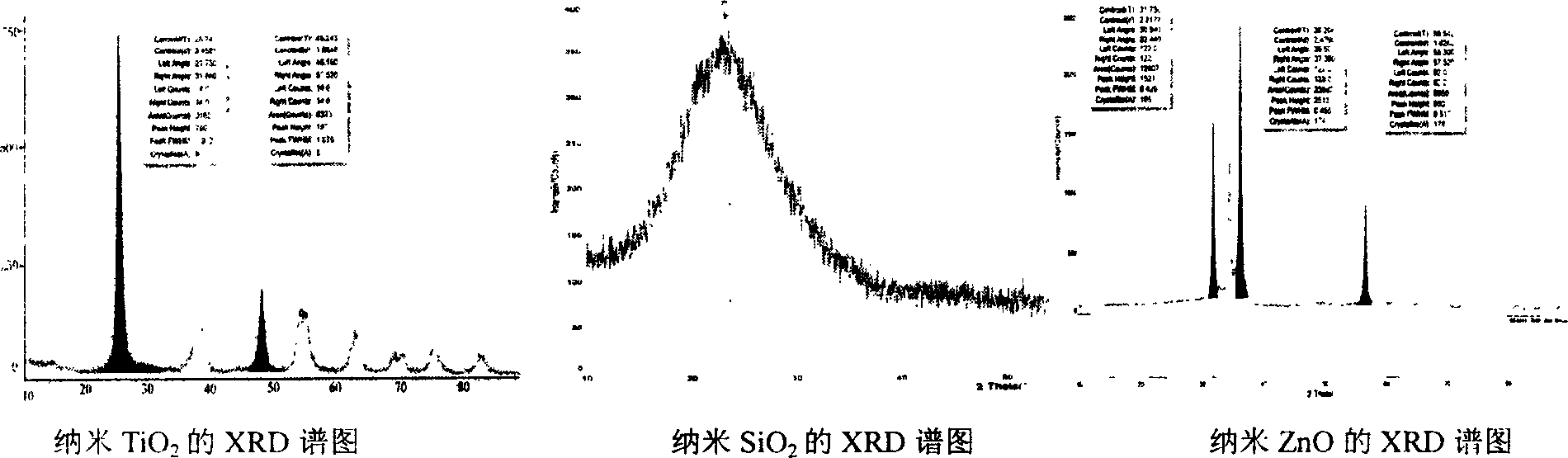

Method for preparing multifunctional composite monodisperse nano film solution

InactiveCN1687247AEliminate soft clumpingGood weather resistanceInorganic pigment treatmentComposite filmFilm-forming agent

The present invention discloses a multifunctional monodisperse nano composite film-forming liquor and its preparation method, belonging to the field of nano material application technology. It is characterized by that it utilizes functional complementary property of nano TiO2, ZnO and SiO2 to disperse nano TiO2, ZnO and SiO2 powders in the water according to a certain ratio, and regulates pH value of system, and adds film-forming adjuvant and film-forming agent to make the above-mentioned material form film. Said invention also provides its advantages are its application range.

Owner:SICHUAN UNIV

Carbon nanomaterial screening and scattering device

PendingCN110560363ADisperse thoroughlyAvoid secondary mixingSievingScreeningCarbon nanomaterialsMechanical engineering

The invention provides a carbon nanomaterial screening and scattering device. The carbon nanomaterial screening and scattering device comprises a conveying pipe; one end of the conveying pipe is rotationally connected with a rotating shaft; one end of the rotating shaft penetrates through the conveying pipe, and extends to the external of the conveying pipe; a collecting box is fixedly connected to the bottom of the conveying pipe; a first screening net, a second screening net and a third screening net penetrate through the bottom of the conveying pipe in sequence from left to right; the conveying pipe and the bottoms of the first screening net, the second screening net and the third screening net all penetrate through the top of the collecting box, and extend into the collecting box; andone side of the inner wall of the collecting box is rotationally connected with a rotating plate. The carbon nanomaterial screening and scattering device can achieve more thorough scattering and moreuniform screening of carbon nanomaterials through vibration screening; and the scattered and screened carbon nanomaterials are isolated in different separation layers to prevent secondary mixing afterscreening.

Owner:LINYI UNIVERSITY

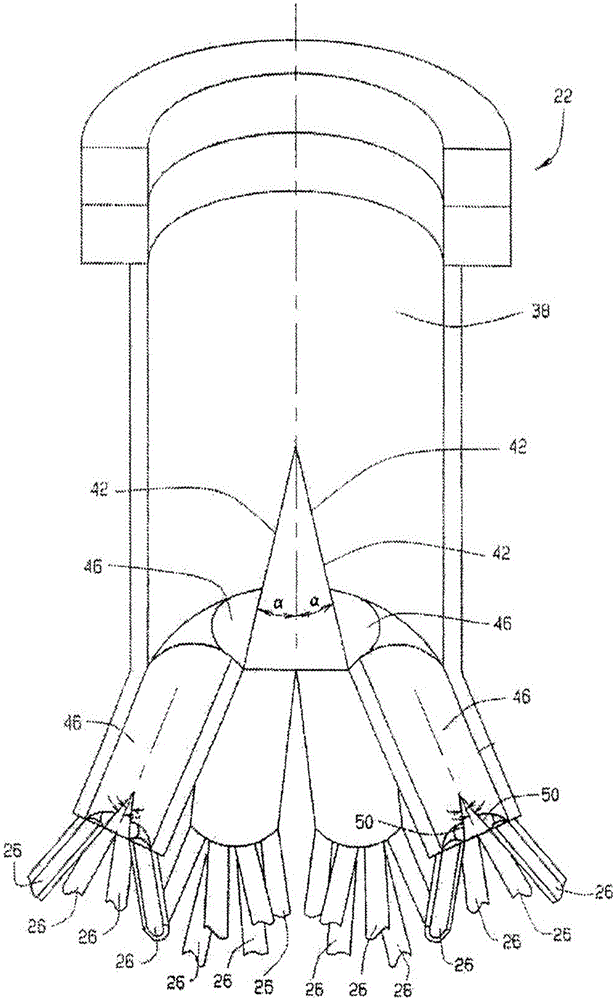

Intelligent grinding equipment capable of improving crushing effect through split-flow feeding

InactiveCN114643095AEvenly dispersedDisperse thoroughlyGrain treatmentsIndustrial engineeringRaw material

The invention relates to intelligent grinding equipment capable of improving the crushing effect through split-flow feeding, the intelligent grinding equipment comprises a treatment bin, a primary grinding bin, a dispersing bin, a split-flow bin and a secondary grinding bin which are sequentially distributed from top to bottom are fixed on the inner peripheral wall of the treatment bin, and a rotatable rotating pipe is further arranged in the treatment bin along the central axis of the treatment bin; the rotating pipe vertically penetrates through the primary grinding bin, the dispersing bin, the flow dividing bin and the secondary grinding bin and is fixed to the dispersing bin and the secondary grinding bin, a grinding circular truncated cone is fixed to the rotating pipe, a plurality of flow dividing plates are fixed to the inner circumferential wall of the flow dividing bin along the diameter of the flow dividing bin, and a grinding roller is rotationally arranged on the inner wall of the treatment bin. Raw materials pass through the primary grinding bin and then sequentially pass through the dispersing bin and the flow dividing bin, the raw materials are uniformly dispersed in the flow dividing bin through rotation of the dispersing bin, then the raw materials are divided into multiple strands through the flow dividing plate, and finally the raw materials fall on the top face of the secondary grinding bin, in the whole process, raw material flow dividing is more thorough, the grinding area is larger during grinding, and the grinding effect is better.

Owner:广东鸿凯高科有限公司

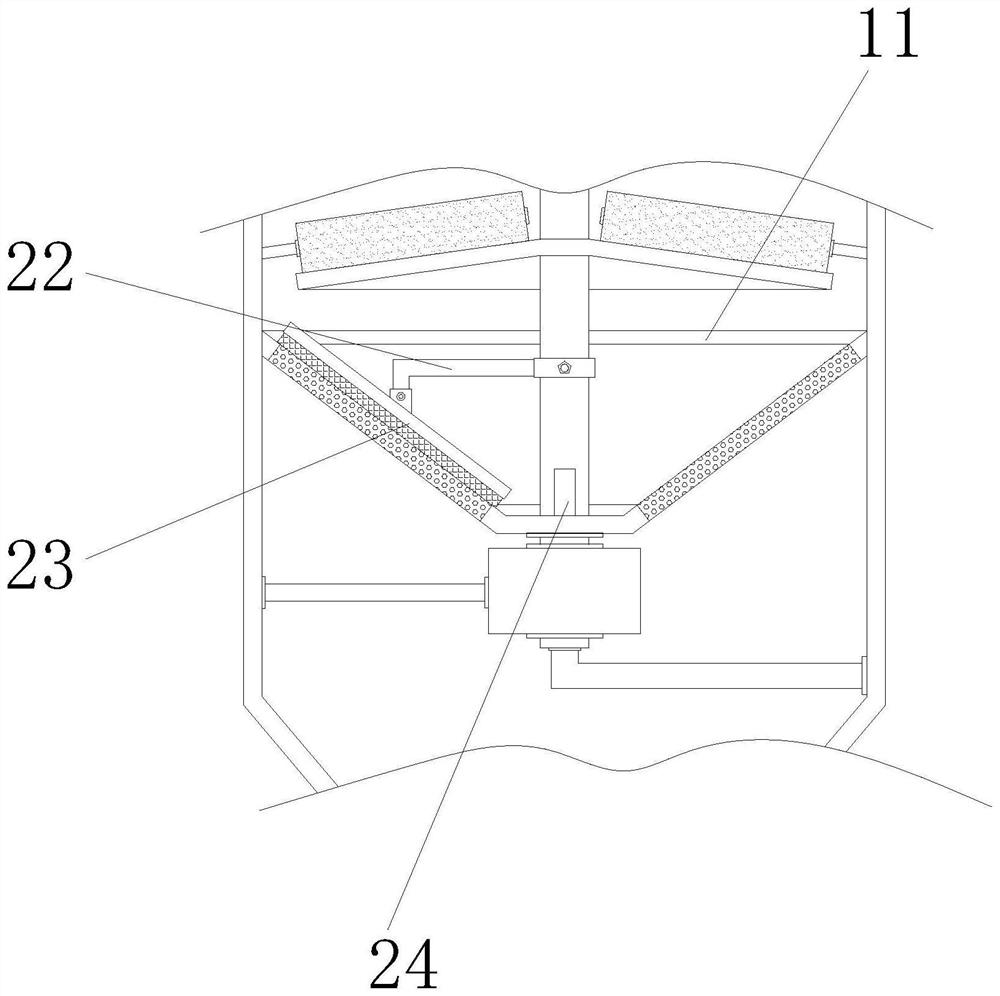

Flow type flame retardant emulsifying and dispersing system

The invention discloses a flow type flame retardant emulsifying and dispersing system. The flow type flame retardant emulsifying and dispersing system comprises a scattering device, the scattering device is arranged inside a box body, a rotating shaft is arranged on the scattering device, stirring rods distributed in an array mode are fixed on the rotating shaft, spirals are arranged on the scattering device, and the spirals are connected with the rotating shaft through transmission arms. According to the flow type flame retardant emulsifying and dispersing system, a motor is started, the motor drives the rotating shaft, the rotating shaft drives the spirals to rotate through the transmission arms after rotation, materials are pushed downwards in the stirring process of the spirals, the materials at the bottom move upwards from the middle due to being extruded and then are stirred and scattered by the rotary stirring rods, flow type scattering and dispersing are achieved, then the dispersion is thorough, and the quality is high.

Owner:刘建宏

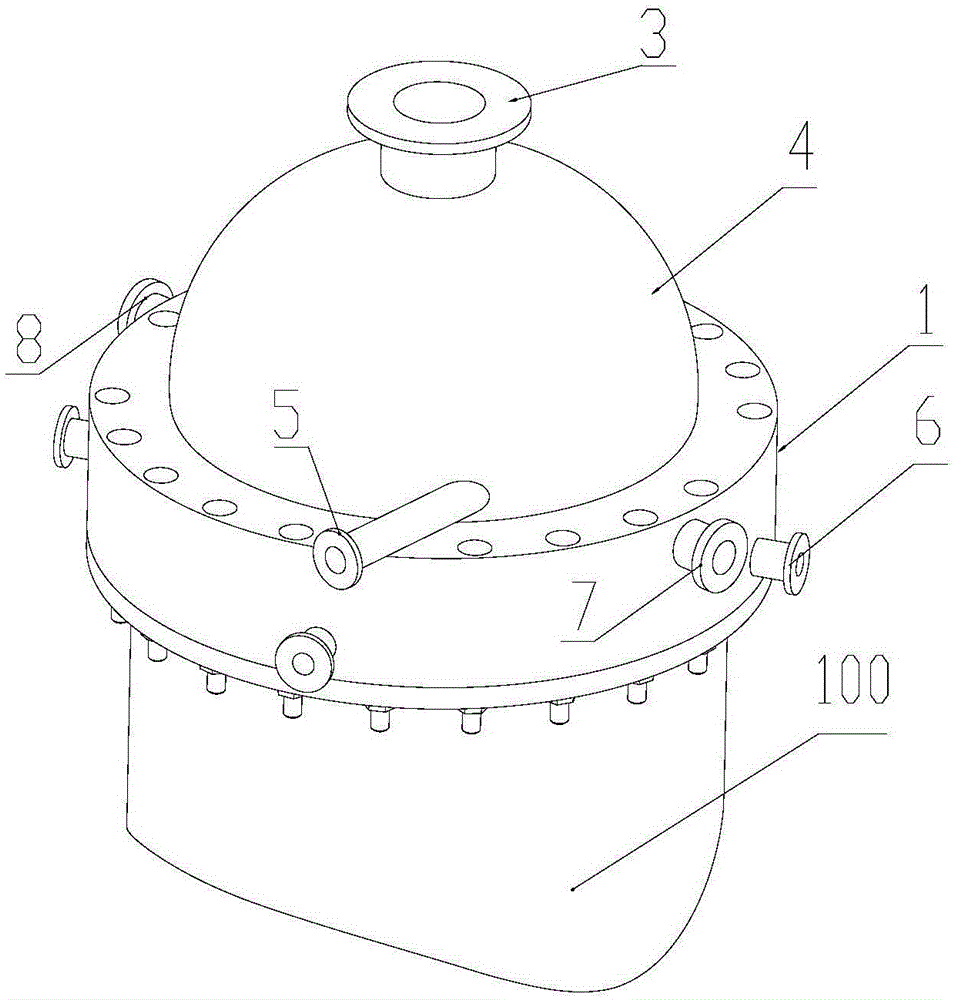

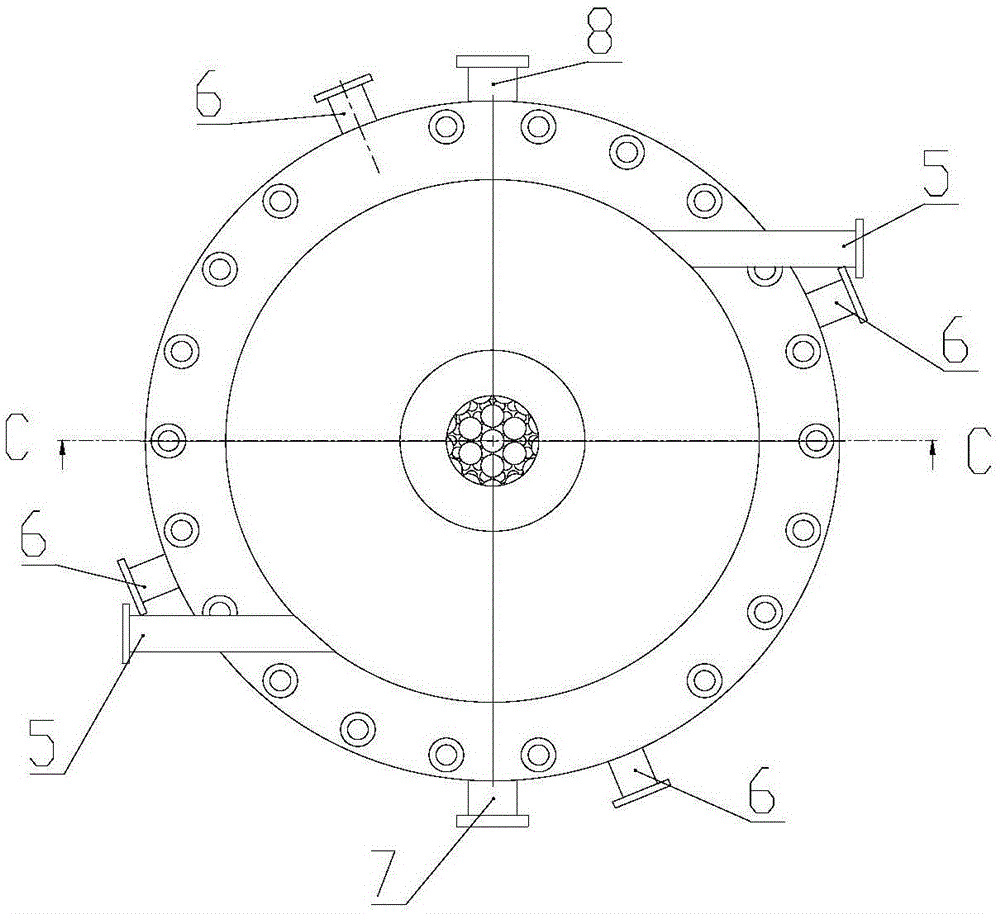

Gasification nozzle and gasification reactor

ActiveCN106433792ASimple structureHomogeneous premixGranular/pulverulent flues gasificationReaction rateEngineering

The invention discloses a gasification nozzle and a gasification reactor. The gasification nozzle comprises a connection flange (1), a material stream conveying pipe joint (3) and a material stream distributor, wherein the bottom portion of the connection flange is installed on the gasification reactor (100), the top surface of the connection flange is provided with a plurality of upper-and-down-penetrating holes used as nozzle branch pipes (11) and distributed at intervals, the material stream distributor is arranged on the top surface of the connection flange and comprises a cylinder having an inner cylinder cavity, the area of the top surface inlet of the inner cylinder cavity is smaller than the area of the bottom surface outlet so as to make the material stream entering from the top surface inlet outflow from the bottom surface outlet in a dispersed manner, the top surface inlet is connected to the material stream conveying pipe joint, the bottom surface outlet is butted to the plurality of the nozzle branch pipes, and the material stream outflowing from the bottom surface outlet in the dispersed manner can enter the gasification reactor through the plurality of the nozzle branch pipes. According to the present invention, the gasification nozzle has advantages of simple structure and convenient processing, and can effectively improve the dispersibility and the uniform distribution of the coal powder and improve the reaction rate of the gasification reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

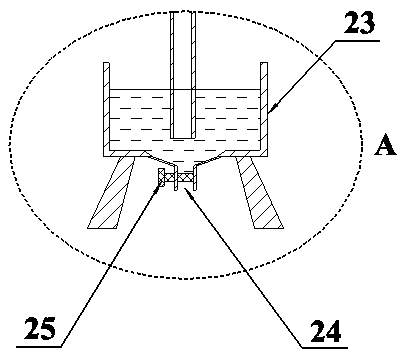

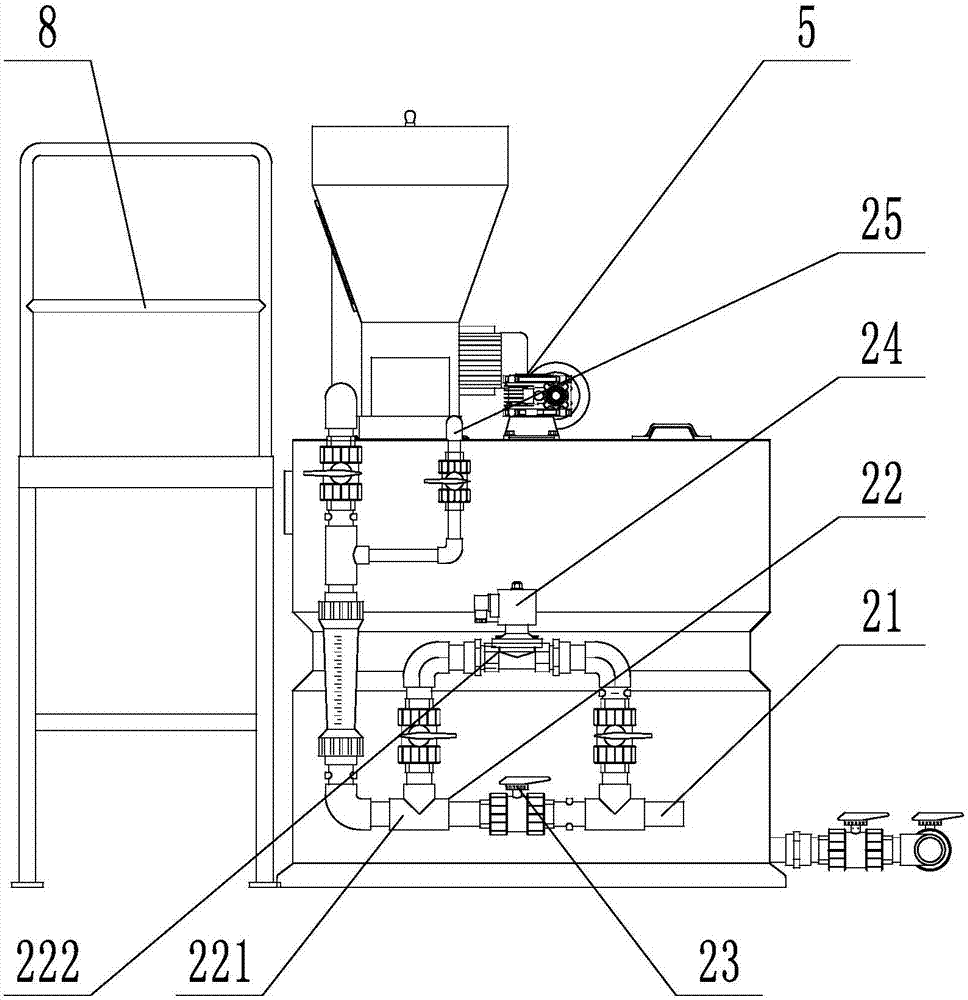

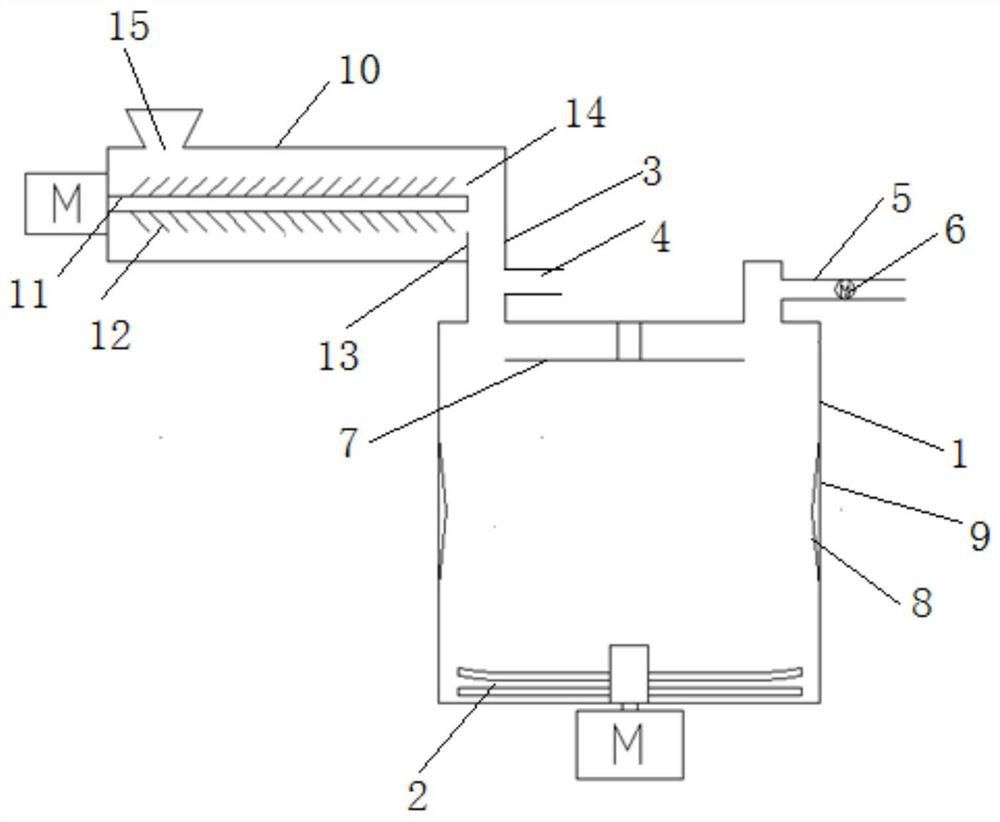

Sewage treatment dry powder wet agent adding device free of dust leakage and thorough in dispersion

PendingCN109966972ACreate troubleDisperse thoroughlyTransportation and packagingMixer accessoriesPulp and paper industrySewage treatment

The invention discloses a sewage treatment dry powder wet agent adding device free of dust leakage and thorough in dispersion, and belongs to a mixer in the technical field of water treatment. The device is mainly formed by an agent dissolving tank, a liquid storage cavity, an air stirring device and an exhaust device and is characterized in that 1, an agent powder dispersing link and a pump conveying link are separated through the agent dissolving tank and the liquid storage cavity; 2, multi-center pneumatic stirring is utilized or combined with mechanical stirring; 3, negative pressure is formed in the agent dissolving tank. Compared with the prior art, the device has the advantages that 1, pump blocking is avoided by designing the agent dissolving tank and the liquid storage cavity; 2,by means of multi-center pneumatic stirring or combination of multi-center pneumatic stirring and mechanical stirring, agent powder and water are dispersed thoroughly; 3, by means of the negative pressure of the agent dissolving tank, the dry agent powder which is not wet by spraying cannot flutter out of an agent adding chute opening, and inconvenient influence on an operator is avoided.

Owner:李成义

Conveying system capable of conducting dust and impurity removal of grain

InactiveCN108405331ADisperse thoroughlyAvoid pollutionGas current separationEngineeringMechanical engineering

The invention discloses a conveying system capable of conducting dust and impurity removal of grain, and relates to the field of grain conveying equipment. The conveying system comprises a dust removal device and a conveying mechanism, wherein the conveying mechanism is used for conveying the grain. The dust removal device comprises a feeding mechanism, a shell, an air suction pump and a dust storage device. A plurality of flow guide mechanisms which are used for separating the flow and buffering the grain are arranged inside the feeding mechanism. A plurality of vibrating assemblies which areused for vibrating are arranged on the inner wall of the shell in sequence from top to bottom, and arranged in a mutually-staggered mode. The air suction pump communicates with the interior of the shell, and a feeding inlet of the dust storage device is connected with an air outlet of the air suction pump through a pipeline. One end of the conveying mechanism is located below a discharging outletof the dust removal device, and the other end of the conveying mechanism is located in an inlet of a granary. By the adoption of the conveying system capable of conducting dust and impurity removal of the grain, the step of dust and impurity removal of the grain can be accomplished in the dust removal device, the dust in the grain is effectively prevented from polluting the air, and the grain which is clean is stored.

Owner:ZHENGZHOU DAXUAN ELECTRONICS TECH CO LTD

Efficient homogenizing and mixing device for organic fertilizer processing

ActiveCN112246164AAvoid cakingFully dispersedTransportation and packagingRotary stirring mixersAgricultural engineeringOrganic fertilizer

The invention relates to the technical field of organic fertilizer homogenizing and mixing, and discloses an efficient homogenizing and mixing device for organic fertilizer processing. The efficient homogenizing and mixing device comprises a working box, wherein an opening is formed in the top of the working box, two supporting bases are symmetrically and fixedly connected to the bottom of the working box, and a fixing block is fixedly connected between the inner side walls of the working box; a cavity is formed in the top of the fixing block, a through cavity is formed in the inner bottom wall of the cavity, a plurality of transverse rods are fixedly connected between the left inner wall and the right inner wall of the through cavity at equal intervals, two first rotating shafts are symmetrically and rotationally connected to the inner wall of the rear side of the through cavity, and the front ends of the two first rotating shafts penetrate through the multiple transverse rods and arerotationally connected with the inner wall of the front side of the through cavity. The invention solves the problems that when an existing organic fertilizer mixing device is used for mixing organicfertilizer and auxiliary materials, the mixing uniformity is not enough, long mixing time is needed, and the mixing processing efficiency and effect are seriously reduced.

Owner:安徽沃园生物科技有限公司

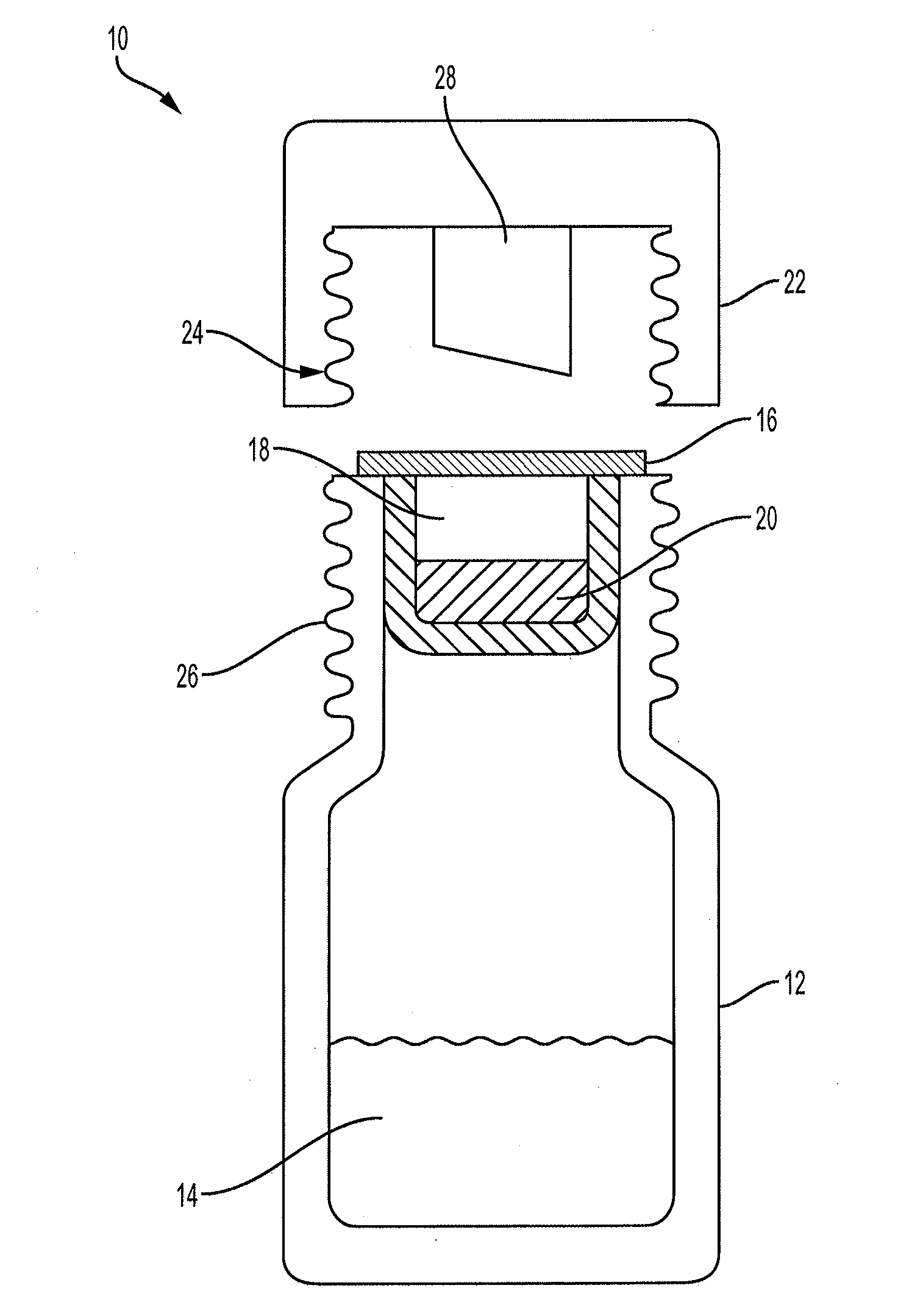

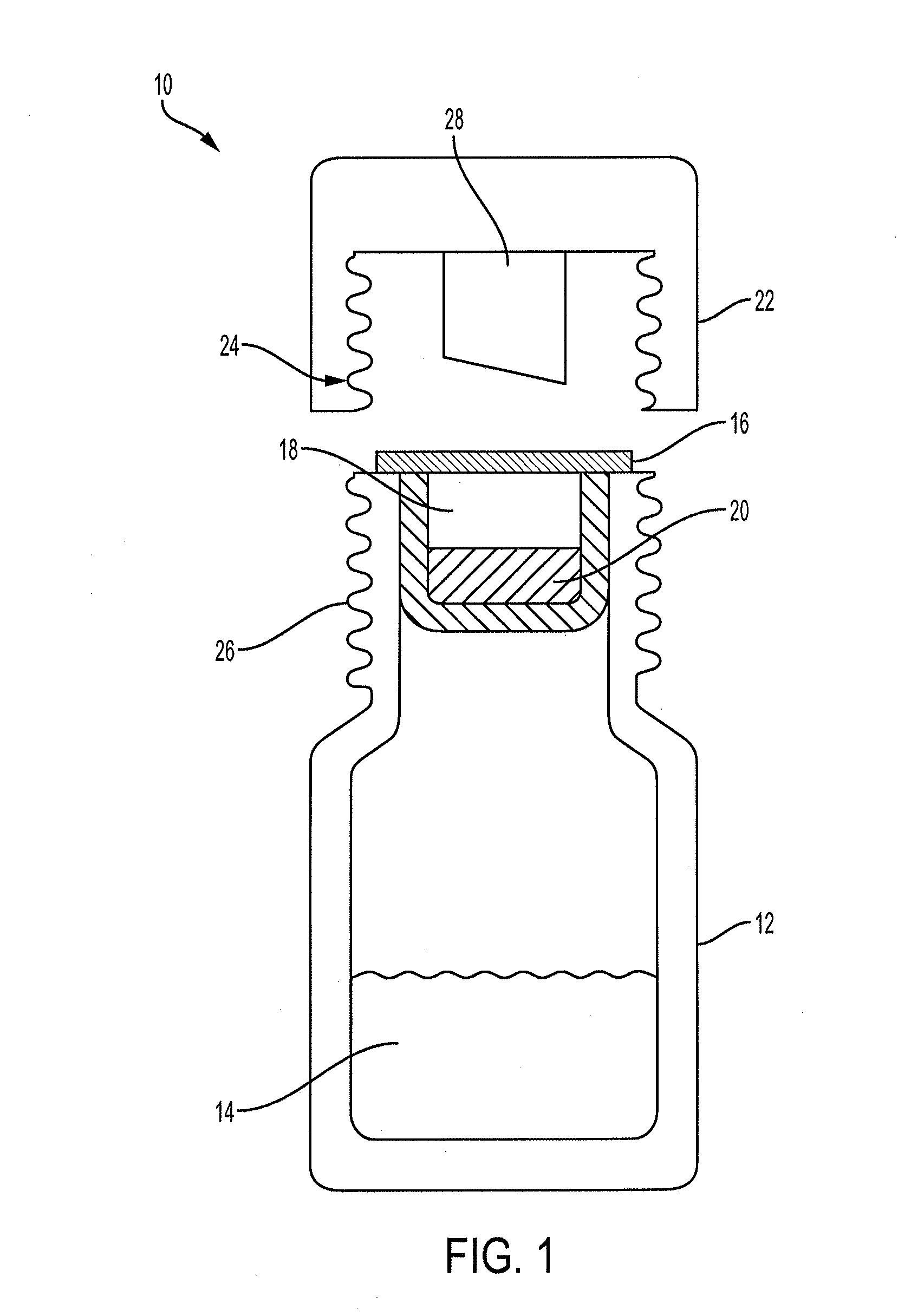

L-Ascorbic Acid Formulations and Methods of Use for Skin Care

InactiveUS20160200500A1Disperse thoroughlyBiocideCosmetic preparationsSkin treatmentsGastroenterology

L-ascorbic skin treatment formulations are provided in a storage container in the form of a vial construction having separate first and second compartments. Solid L-ascorbic acid is located in the first compartment and a liquid vehicle composition is located in the second compartment. The vial is constructed to allow for the combining of the L-ascorbic acid and the liquid vehicle composition by a user immediately prior to a topical application of the combined formulation to the skin. The first compartment may be in the form of a plug for the vial. A cover may be provided which, when screwed down, punctures a wall of the first compartment to allow the mixing of the contents of the two compartments.

Owner:LAVICO INC

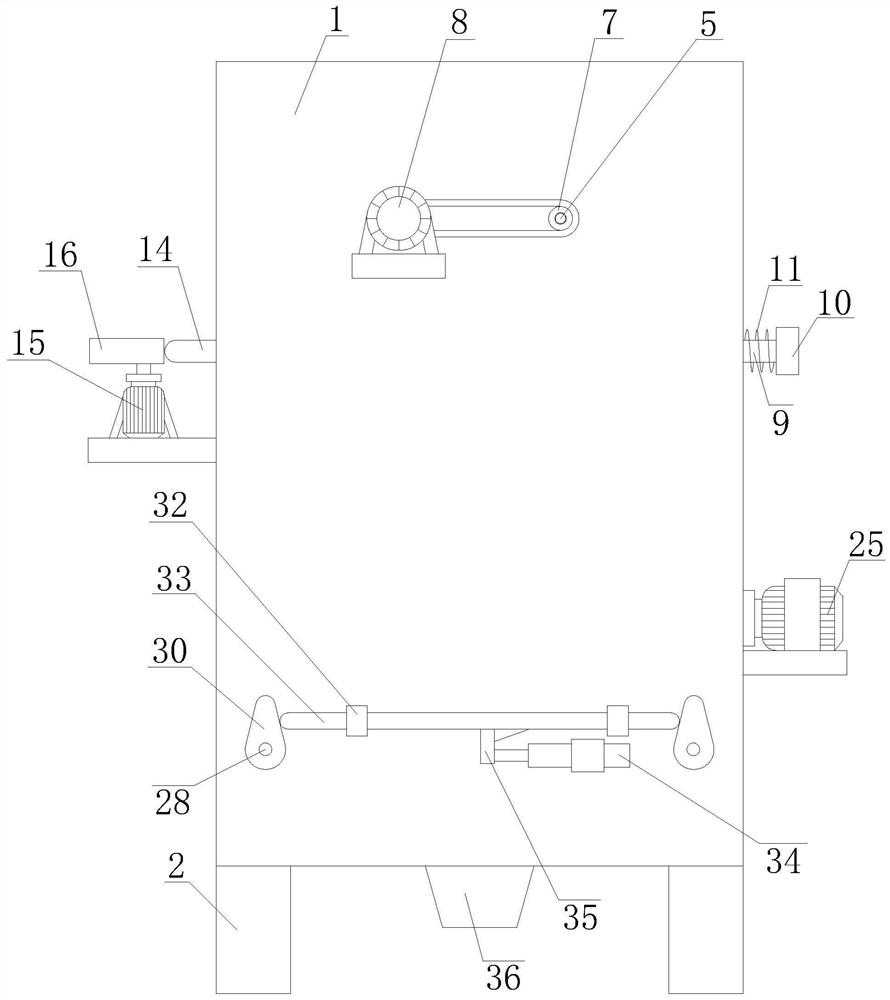

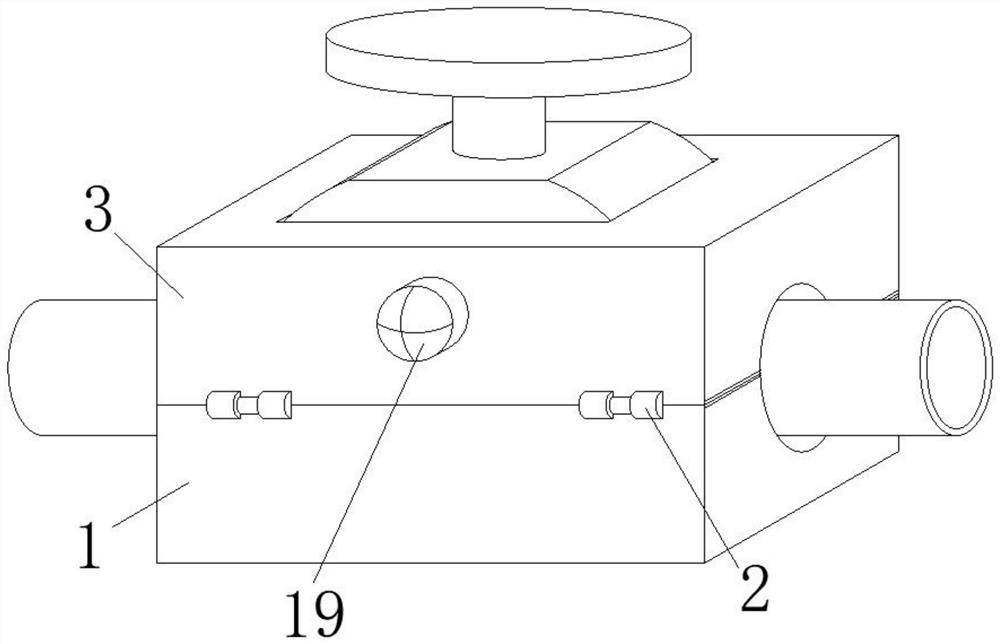

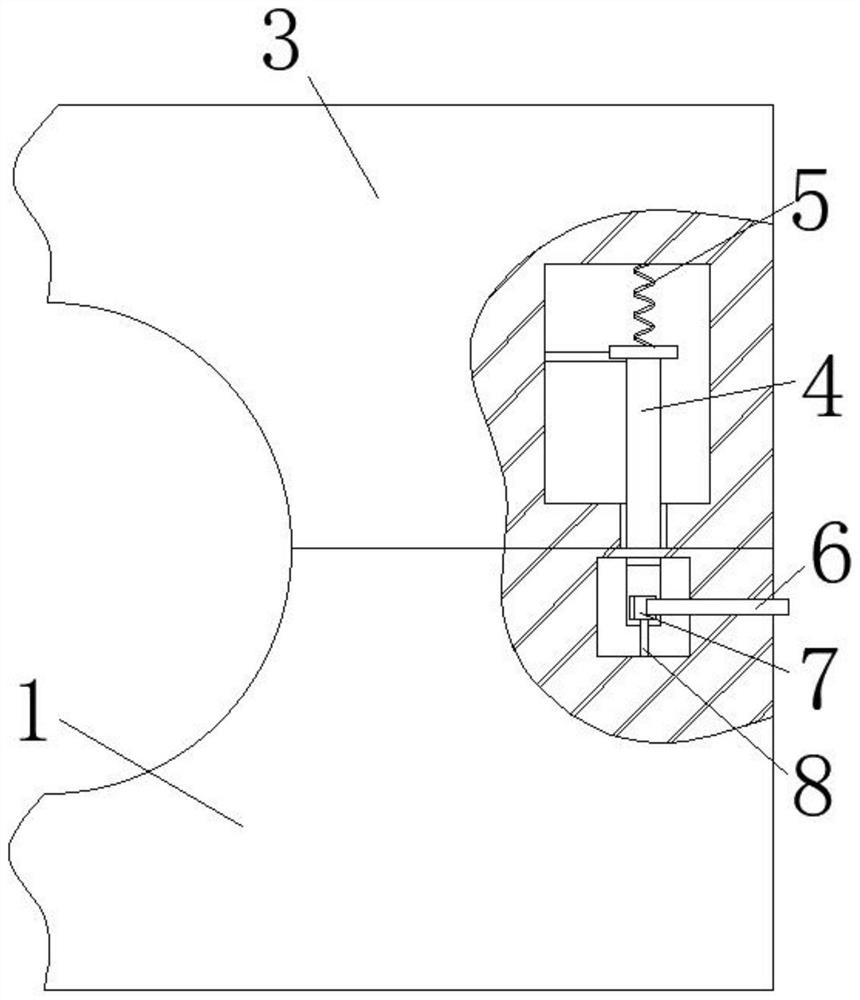

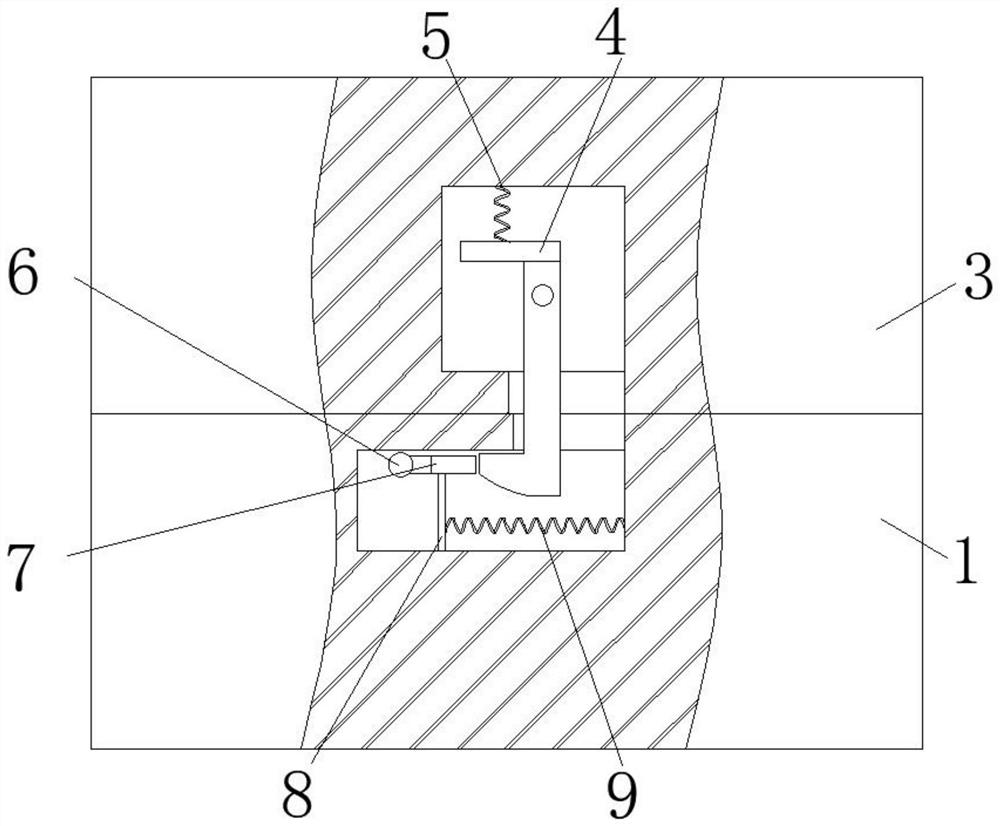

Gas tightness detection device for gas valve

InactiveCN112461454AImprove repair efficiencyPurpose of unpinningDetection of fluid at leakage pointFire rescueStructural engineeringAir tightness

The invention discloses a gas valve airtightness detection device. The device comprises a bottom plate, wherein a hinge is installed at the top end of the bottom plate, a top plate is fixedly connected to the other side of the hinge, a clamping groove is formed in the bottom plate, a lead screw is connected to the side wall of the bottom plate in an engaged and sleeved mode, the other end of the lead screw extends into the clamping groove, and a push rod is connected to the extending end of the lead screw in a contact mode; a sliding rod is fixedly connected to the bottom face of the push rod,a second spring is installed between the sliding rod and the side wall of the clamping groove, a groove is formed in the bottom face of the top plate, a clamping rod is rotatably connected to the side wall of the groove, a first spring is installed on the top face of the clamping rod, and the other end of the first spring is fixedly connected with the top face of the groove. The gas tightness detection device for the gas valve can achieve a purpose of being convenient to disassemble and assemble, so repair efficiency of the gas valve is improved, cost consumption is reduced, sparks generatedwhen the device is disassembled cannot ignite gas, and potential safety hazards are reduced.

Owner:吴瑶

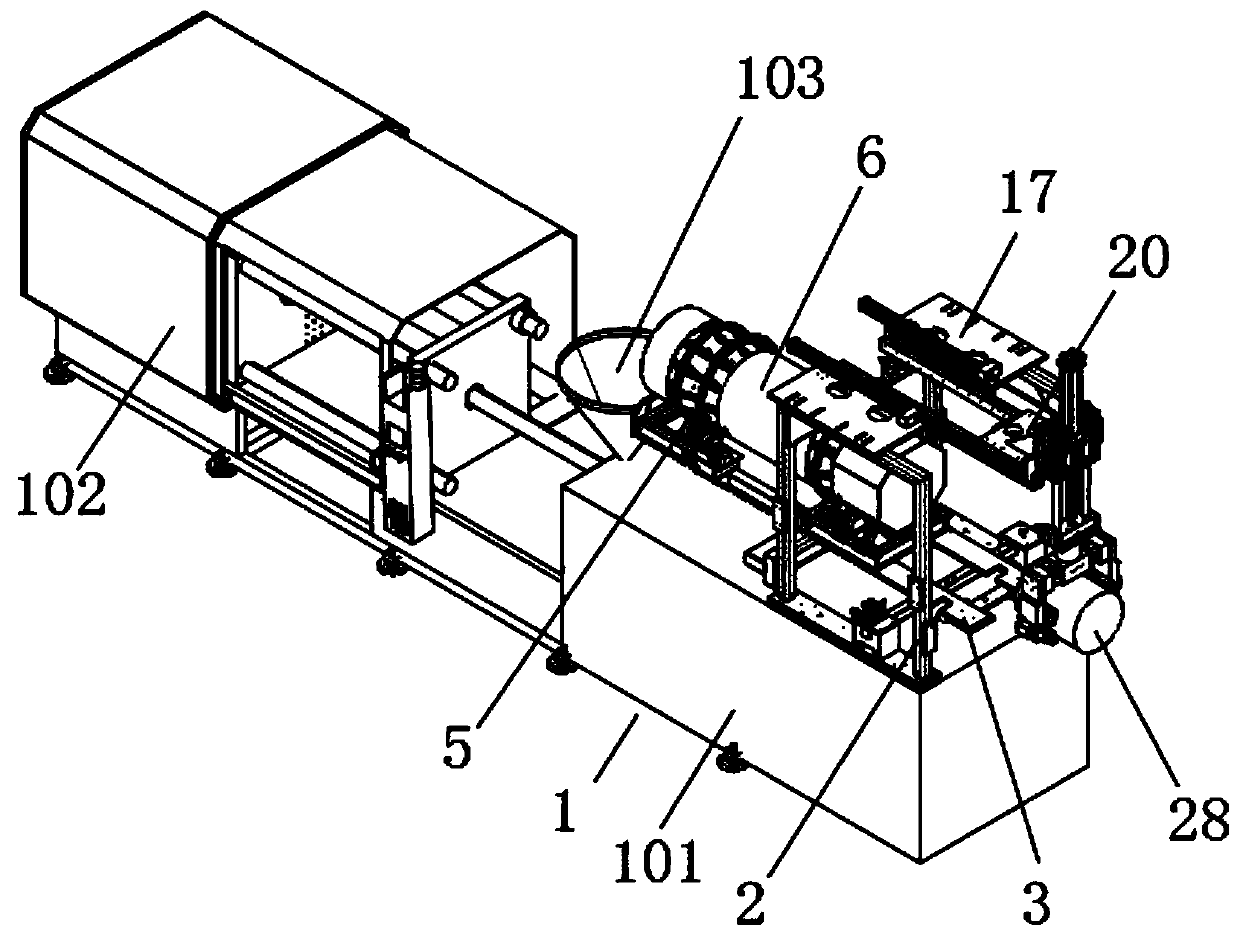

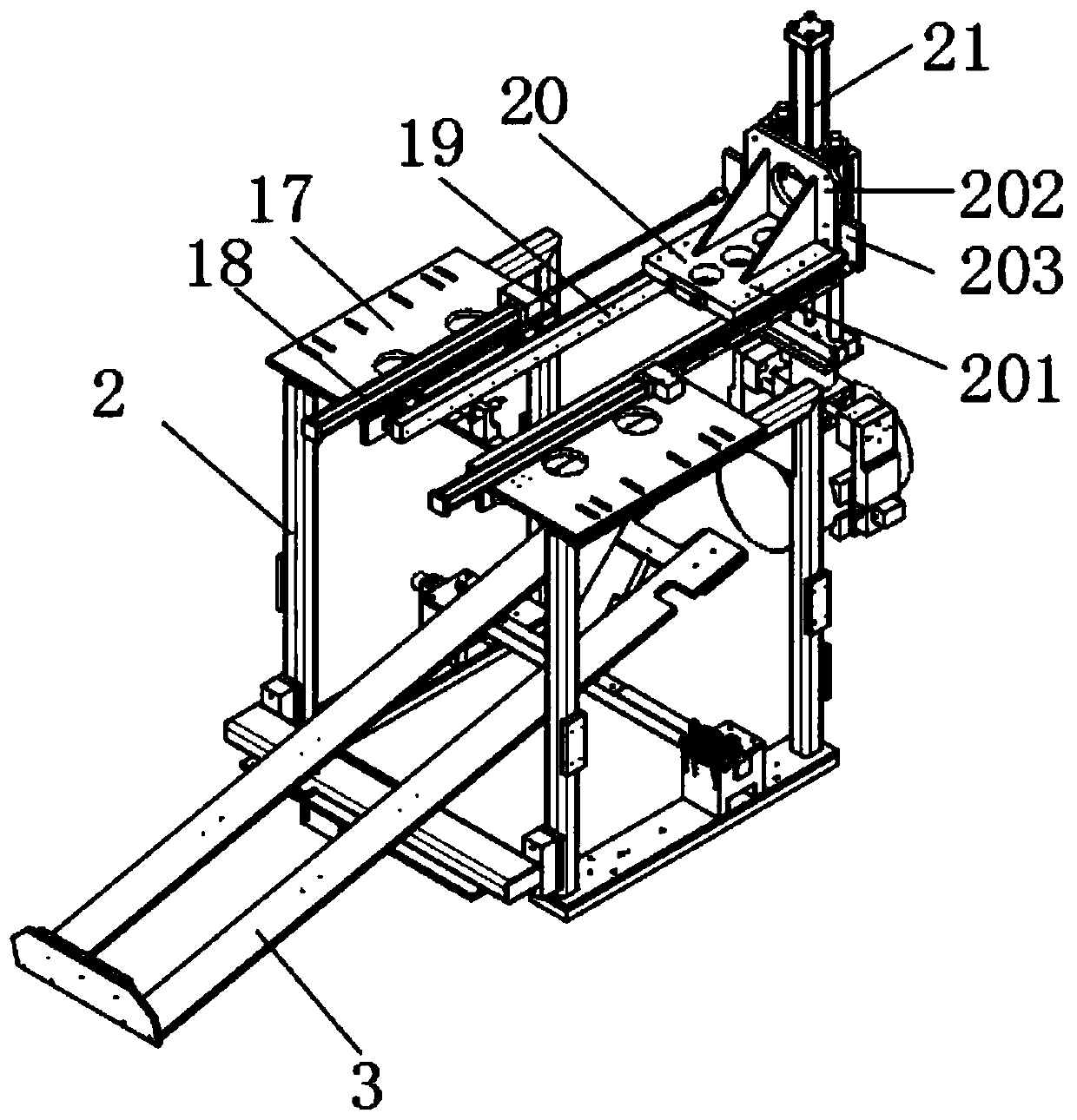

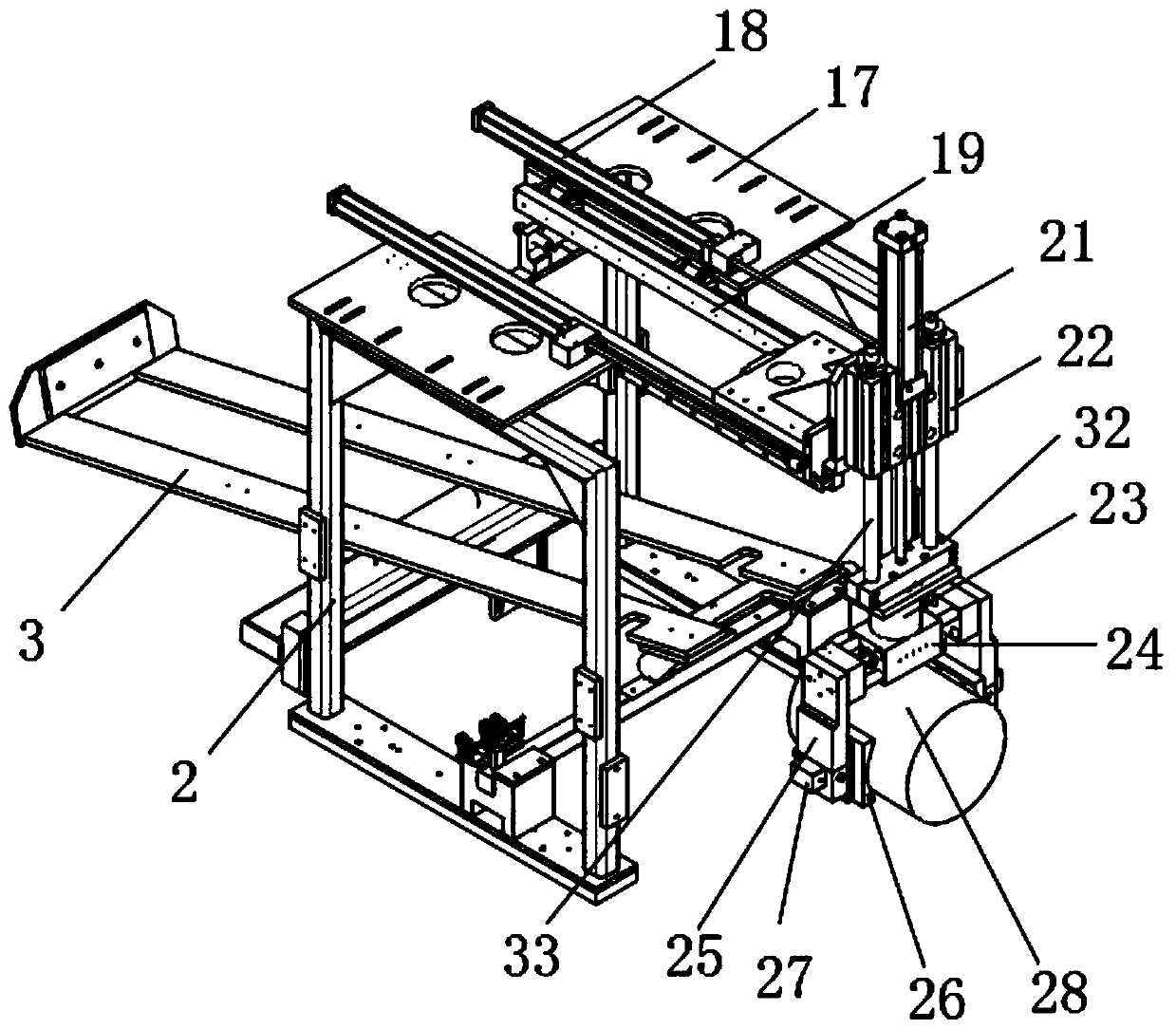

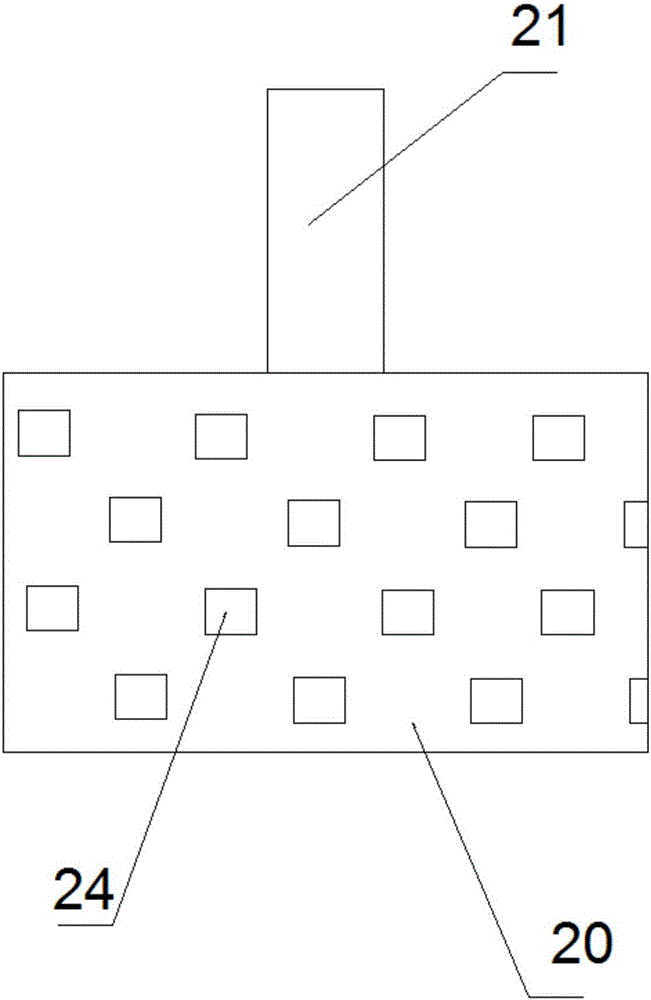

Injection molding machine with automatic material taking assembly and working method of injection molding machine

ActiveCN110936562ASimple structureSimple and fast operationElectric machineryInjection molding machine

The invention discloses an injection molding machine with an automatic material taking assembly and a working method of the injection molding machine. The injection molding machine comprises an injection molding machine body; a first feeding hole is formed in the upper surface of an injection bin; a support frame is mounted on the upper surface of the injection bin; a mounting bottom plate is arranged on the inner side of the support frame; a mounting frame is mounted on the upper surface of the mounting bottom plate; a feeding cylinder and a feeding bin are mounted on the mounting frame; twomounting top plates are mounted at the top of the supporting frame; a second rotating motor is mounted at the bottom of a lifting cylinder; a double-head cylinder is mounted at the output shaft end ofthe second rotating motor; a connecting plate is mounted at the end of the double-head cylinder; clamping plates are fixedly mounted at the bottoms of the two connecting plates; and a pouring barrelis mounted between the two clamping plates. the injection molding machine can keep injection molding raw materials dry, prevent the injection molding raw materials from caking and guarantee the quality of injection molding products, is simple in structure and easy and convenient to operate, effectively reduces the production cost, can achieve automatic feeding and works rapidly and efficiently.

Owner:汕头市博美塑胶有限公司

High-fiber-content sugar-free steamed cake and preparation method thereof

InactiveCN109349312APromote efficient decompositionAvoid breakingDough treatmentPre-baking dough treatmentPectinaseFiber

The invention relates to the technical field of food processing, in particular to a high-fiber-content sugar-free steamed cake and a preparation method thereof. The problem is solved that the sugar content of a cake is high, and on the basis of not adding sugar, the steamed cake has the same flavor and appearance as a sugar processed cake; raw materials include fruits, wheat bran, cellulase, pectinase, flour, eggs and edible oil; the wheat bran is grinded and then puffed, after the fruits are pulped and then mixed with the puffed wheat bran, the cellulase and the pectinase are added, after enzymolysis and heating, a mixture material is obtained, and then other raw materials are added into the mixture material to process the steamed cake; compared with the prior art, the prepared high-fiber-content sugar-free steamed cake maintains the flavor and appearance of the cake prepared through an original preparation method on the basis of not adding refined sugar components, meanwhile, the prepared high-fiber-content sugar-free steamed cake contains abundant vitamin and mineral substances, the calorie of the steamed cake is greatly reduced, and the steamed cake is applicable to patients suffering from hypertension, hyperlipidemia, hyperglycemia and diabetes.

Owner:山西绿牧德品乳业股份有限公司

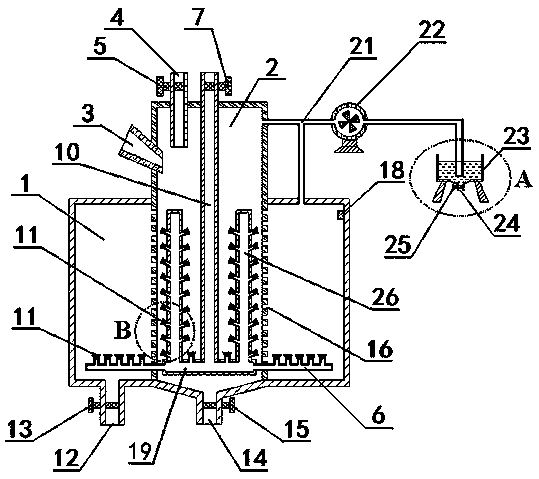

Dedicated vacuum oil filtering system for high-viscosity lubricating oil

ActiveCN106753745ADispersion is large and non-repetitiveDisperse thoroughlyFiltration circuitsLubricant compositionPulp and paper industryOil water

The invention provides a dedicated vacuum oil filtering system for high-viscosity lubricating oil. The dedicated vacuum oil filtering system comprises a vacuum separating device; the vacuum separating device comprises a vacuum tank, an atomizer and a vacuum separator; the atomizer comprises a body and an oil conveying pipe, wherein four groups of atomization channel sets are sequentially arranged in the body from top to the bottom; the vacuum separator comprises a shell and a separating net, wherein the separating net comprises a vertical-horizontal intersected net face and a separating part. The dedicated vacuum oil filtering system has the beneficial effects that oil-water mixture experiences a compression process before entering an atomization channel, the compressed oil-water mixture is suddenly pressed and reduced when leaving the middle of the atomization channel along with enlargement of the cross sectional area, the oil-water mixture is not completely pressed from the atomization channel to the outer wall end of the body, and the oil-water mixture can suddenly scatter in an explosion shape under an effect of vacuum negative pressure after entering the vacuum tank; thus, an oil atomization effect is good, and an oil-water separation effect is good.

Owner:DAQING ANWEITE TECH

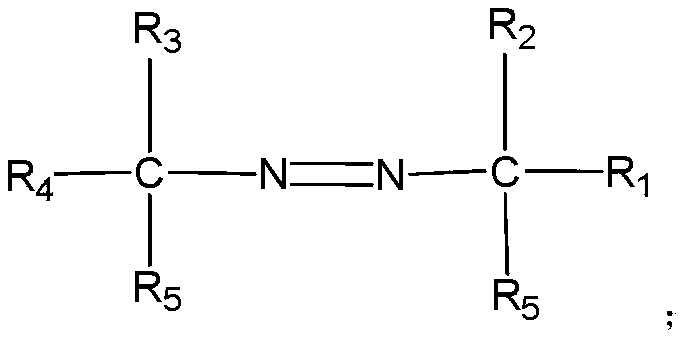

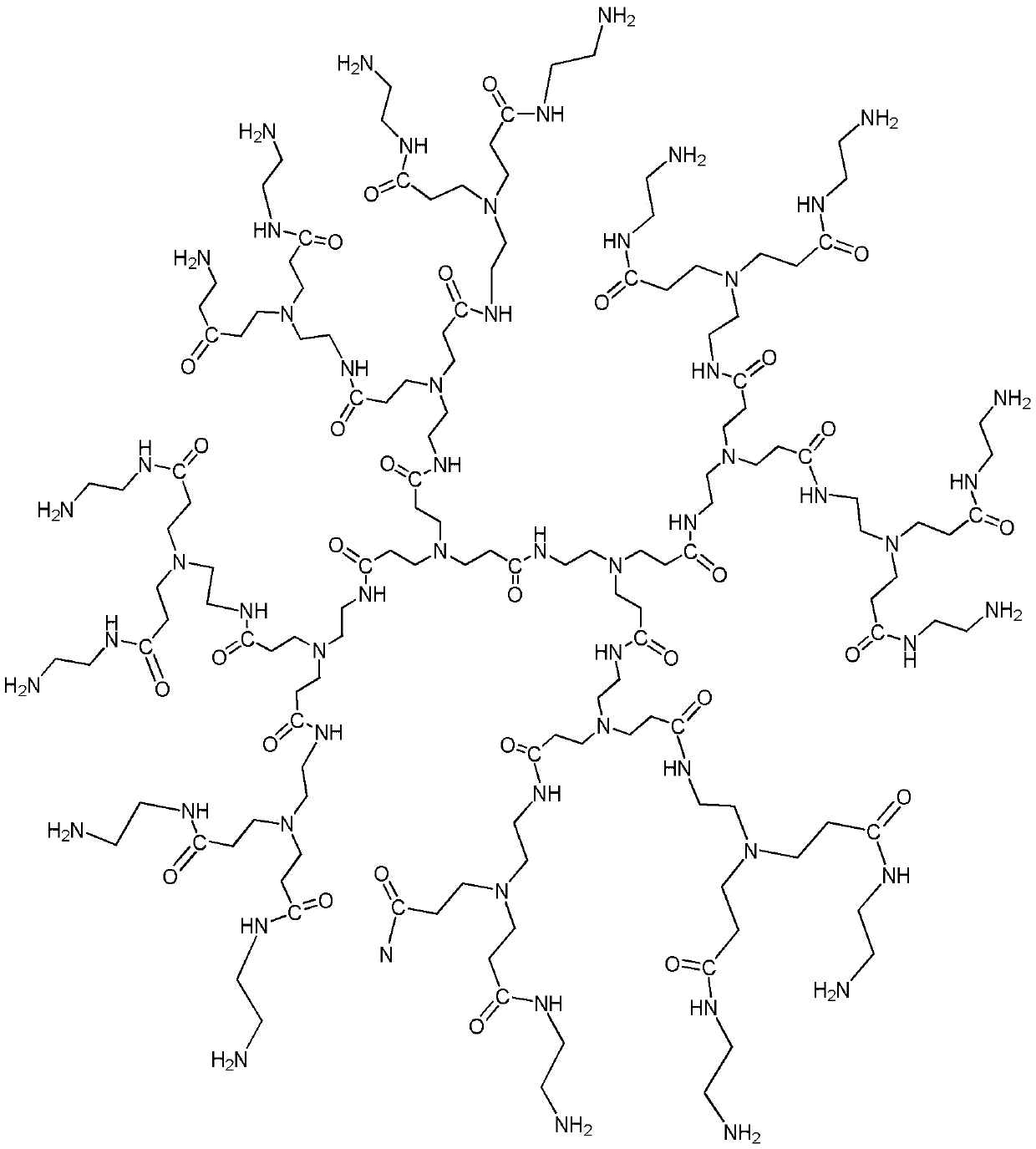

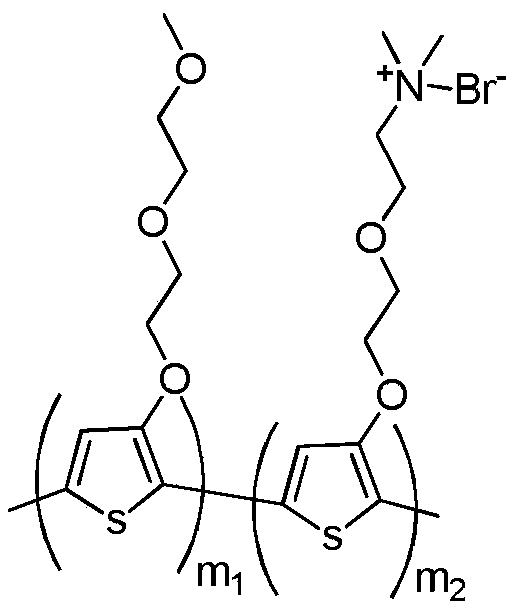

Porous nano-material and preparation method thereof

InactiveCN109745956ASimple preparation processWith adsorptionMaterial nanotechnologyOther chemical processesDendrimerToxic gas

The invention discloses a porous nano-material and a preparation method thereof. The porous nano-material comprises an azo compound, a dendrimer, a functional nano-material, a fluorescent conjugated polymer and deionized water. The preparation method includes the steps: weighing raw materials according to ratio; mixing the raw materials; performing ultrasonic treatment after mixing; adding the rawmaterials into a reactor for reaction; cooling, centrifuging, washing, drying and calcining the raw materials to obtain the porous nano-material. The preparation technology is simple, the prepared porous nano-material has the functions of adsorption, bacteria resisting, odor removing and the like, generated negative oxygen ions can react with harmful gas such as formaldehyde and methylbenzene inair, toxic gas can be thoroughly decomposed as the dendrimer is combined with the azo compound, and purification efficiency is improved. The fluorescent conjugated polymer is assembled on a graphene oxide slice layer, and harmful bacteria are killed in the air purification process.

Owner:苏州逸纪杰电子科技有限公司

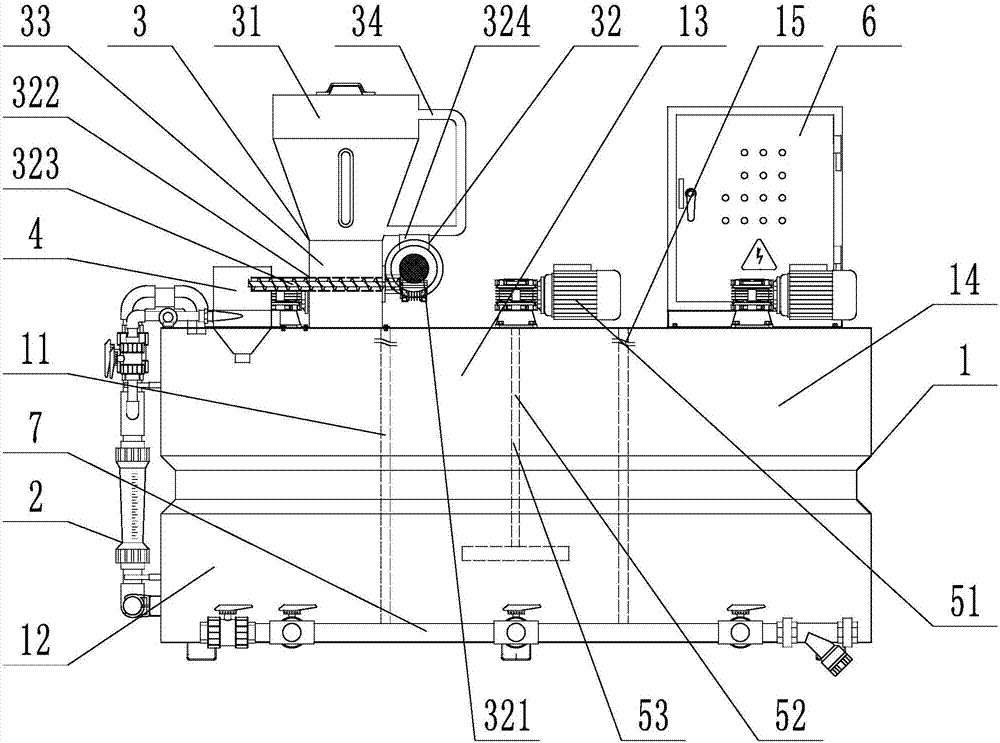

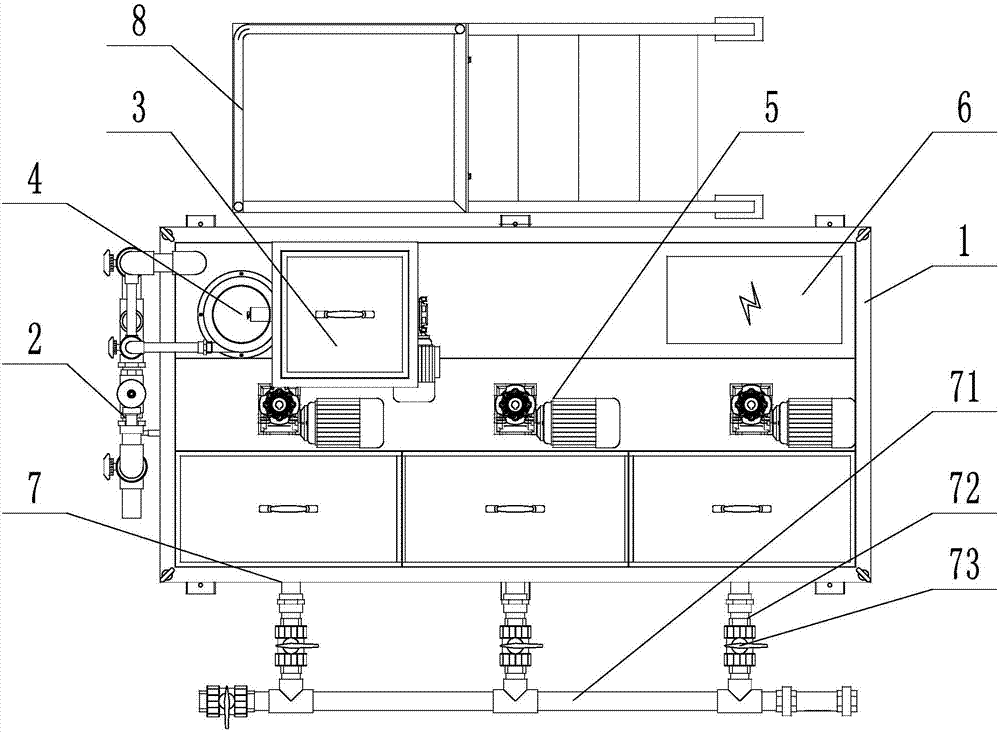

Full-automatic flocculating agent preparation device

InactiveCN107096404ALabor savingImprove corrosion resistanceTransportation and packagingMixer accessoriesBiochemical engineeringElectric control

The invention discloses a full-automatic flocculating agent preparation device. The full-automatic flocculating agent preparation device comprises a tank body, a water inlet system, a dry powder adding system, an reagent dissolving cabin, a stirring system, an electric control cabinet, an reagent discharging system, and an operation platform; the water inlet system is arranged on the left side surface of the tank body; the dry powder adding system is arranged on the top left back part of the tank body; the reagent dissolving cabin is arranged between the top of the water inlet system and the left lower end of the dry powder adding system; the stirring system is arranged at the center line of the top of the tank body; the electric control cabin is arranged on the top right back part of the tank body; the reagent discharging system is arranged at the bottom of the front side surface of the tank body; the operation platform is arranged on the back part of the tank body; and the installation height of the operation platform is slightly lower than the top of the dry powder adding system. The full-automatic flocculating agent preparation device is capable of realizing intelligent full-automatic continuous preparation of solution, and monitoring flocculating agent adding amount continuously.

Owner:山东中科贝特环保装备股份有限公司

A drying device and method for improving the dispersibility of ultrafine powder

ActiveCN111380329BAvoid hard clumpingEvenly heatedDrying solid materials with heatDrying gas arrangementsExhaust pipeFilter cake

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com