Flow type flame retardant emulsifying and dispersing system

A technology of emulsification and dispersion and flame retardant, which is applied in the field of fluid flame retardant emulsification and dispersion system, which can solve the problems of delamination, influence on quality and incomplete dispersion, and achieve the effect of high quality and complete dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

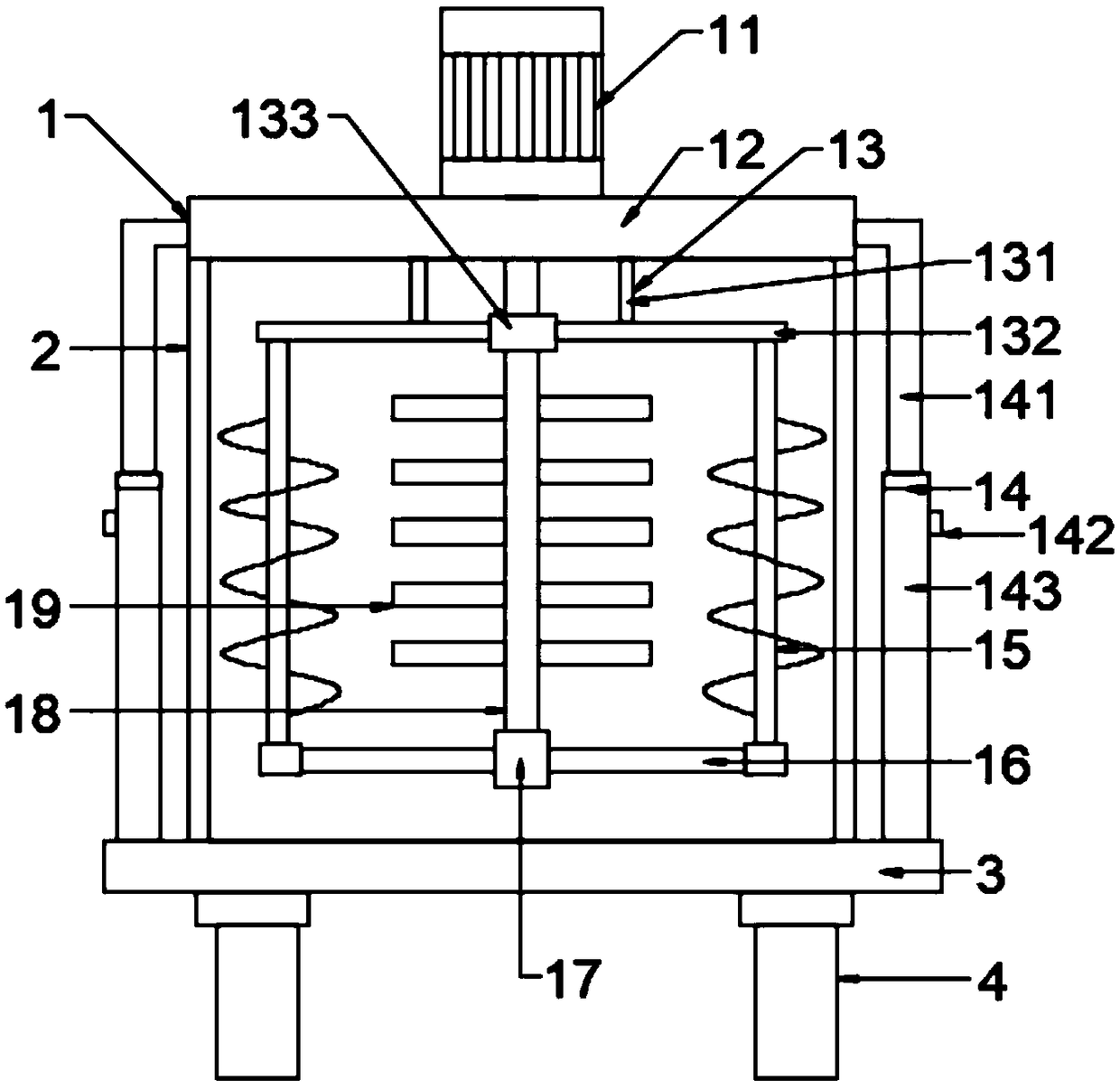

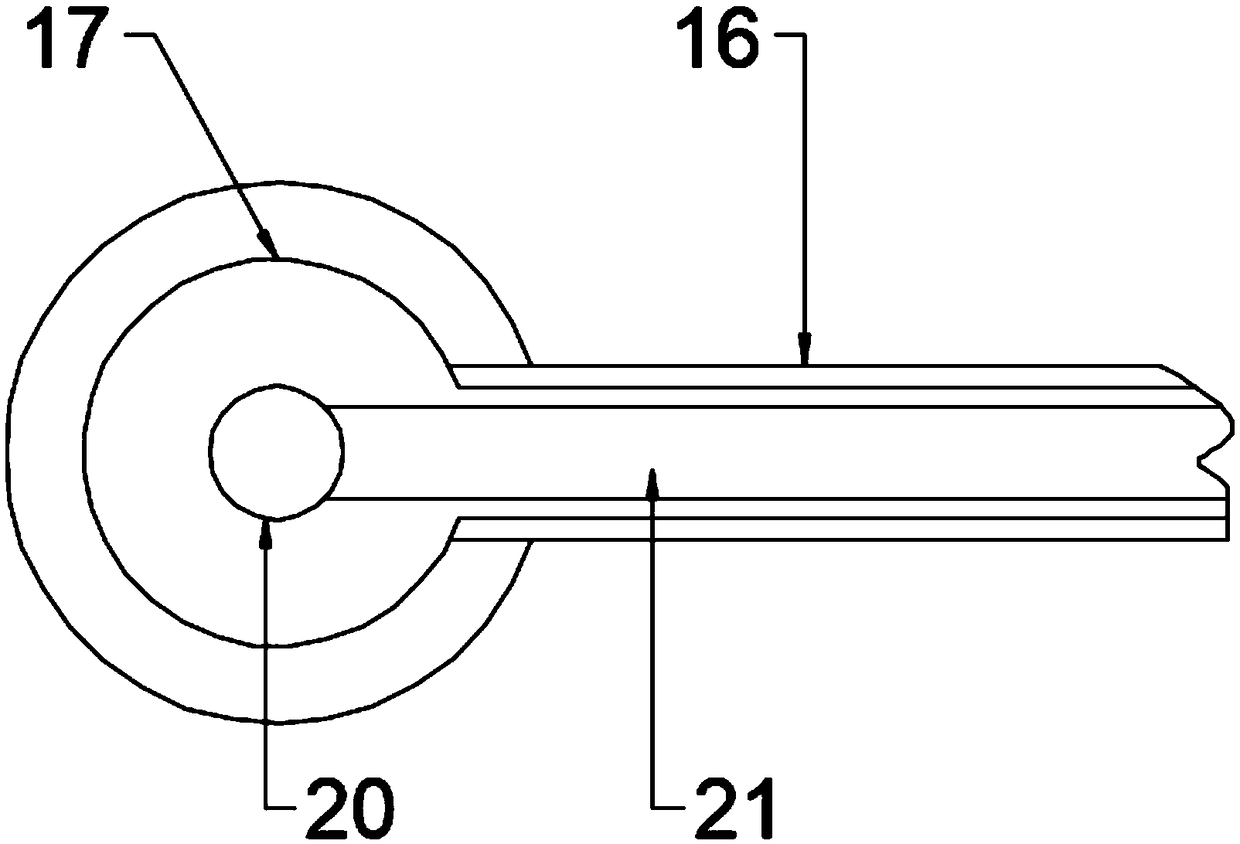

[0025] see figure 2 and image 3 , in an embodiment of the present invention, a flow type flame retardant emulsification dispersion system includes a dispersing device 1, the dispersing device 1 is installed inside the box body 2, a rotating shaft 18 is installed on the dispersing device 1, and on the rotating shaft 18 Stirring rods 19 distributed in an array are fixed. In order to realize flow-type dispersing and dispersing of flame retardants, an auger 15 is installed on the dispersing device 1. The auger 15 is connected to a rotating shaft 18 through a transmission arm 16. The annular array of auger 15 is provided with six After the rotation of the rotating shaft 18, the transmission arm 16 drives the auger 15 to rotate, and the auger 15 stirs the material to push down, and the bottom material is squeezed and moved upward from the middle and then stirred and broken up by the rotating stirring rod 19, flowing Dispersing and dispersing, complete dispersion and high quality....

Embodiment 2

[0028] A fluid flame retardant emulsification dispersion system, please refer to figure 1 and Figure 4 , the embodiment of the present invention is on the basis of embodiment 1, and further, the bottom of the box 2 is provided with a discharge pipe, the box 2 is fixed on the buffer base 3, and the lower end of the buffer base 3 is fixed with six ring-shaped arrays. The supporting legs 4 are distributed, the supporting legs 4 are provided with a fixed sleeve 41, the upper end of the fixed sleeve 41 is fixed on the buffer base 3, the inside of the fixed sleeve 41 is interspersed with a limiting plate 43, and the upper end of the limiting plate 43 is fixed with a spring 42, The lower end of the limiting plate 43 is fixed with a supporting column 44 , the lower opening of the fixing sleeve 41 cooperates with the supporting column 44 to fix the limiting ring 45 , and the lower end of the supporting column 44 is fixed with a supporting plate 46 .

[0029] The working principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com