Full-automatic flocculating agent preparation device

A preparation device and flocculant technology, which is applied in the direction of transportation and packaging, driving agitator to dissolve, mixer, etc., can solve the problems affecting the quality and effect of flocculant, product concentration and other technical indicators are not accurate, and the dosage of dry powder cannot be real-time Monitoring and other issues, to achieve the effect of precise adjustment of dosage, good corrosion resistance and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

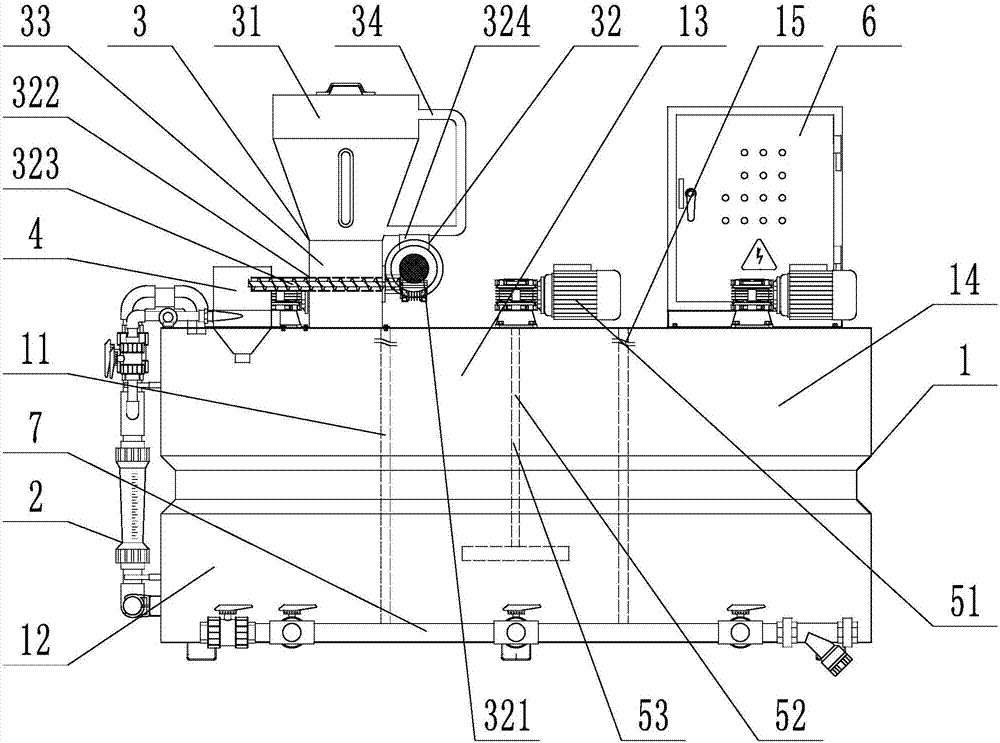

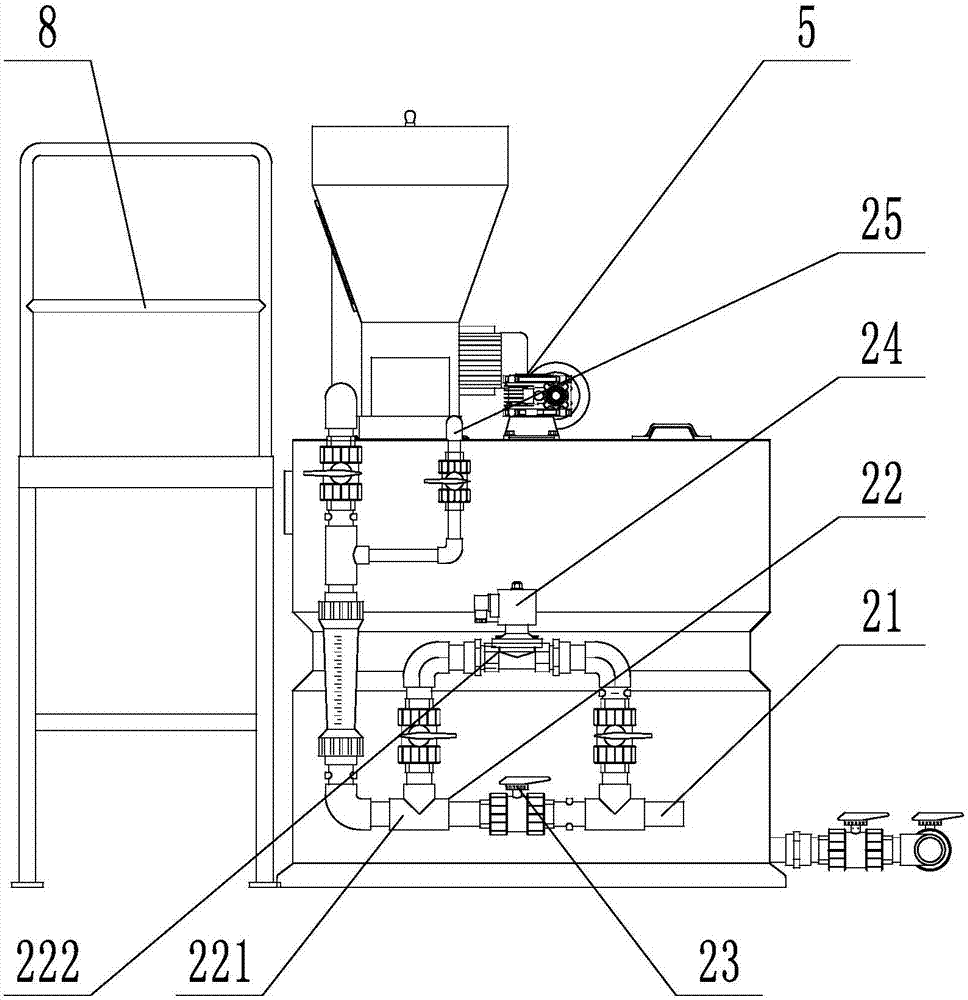

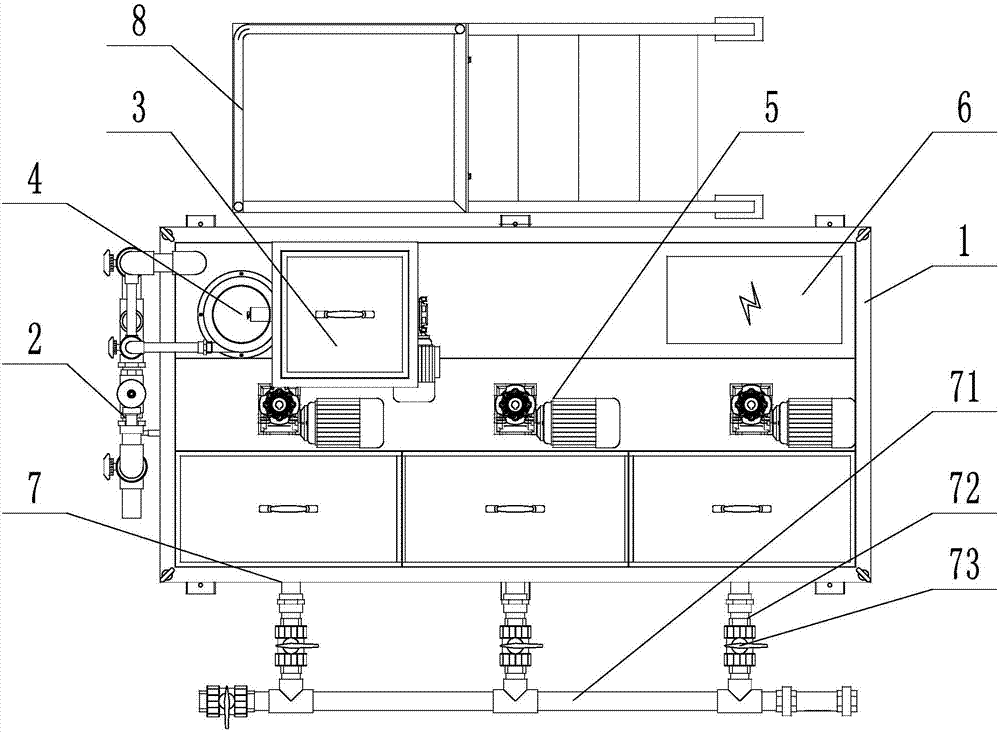

[0024] Such as Figure 1-3 As shown, the technical solution adopted in the present invention is: a fully automatic flocculant preparation device, including a box body 1, a water inlet system 2, a dry powder dosing system 3, a drug dissolving warehouse 4, a stirring system 5, an electric control cabinet 6, A drug delivery system 7 and an operating platform 8, a water inlet system 2 is installed on the left side of the box body 1, a dry powder dosing system 3 is installed on the left rear of the top of the box body 1, the top of the water inlet system 2 is connected with the dry powder A drug dissolving bin 4 is installed between the lower left end of the dosing system 3, the stirring system 5 is installed at the center line of the top of the box body 1, the electric control cabinet 6 is installed at the right rear of the top of the box body 1, and the drug delivery system 7 is installed on the bottom of the front side of the box body 1, and the operating platform 8 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com