Patents

Literature

282results about How to "Stable ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant extract and microbe composite deodorant

ActiveCN105536509AReduce generationGrowth inhibitionGas treatmentDispersed particle separationMicroorganismDeodorant

The invention relates to the field of deodorization, and especially relates to a plant extract and microbe composite deodorant. According to the invention, a plant extract and a microbial fermentation broth are mixed according to a ratio of 1:3; the mixture is placed in plastic buckets; and sealed anaerobic fermentation is carried out for 5-9 days, such that the composite deodorant is obtained. The microbial fermentation broth is obtained through the following steps: saccharomycetes, lactobacillus, bacillus subtilis, acetobacter pasteurianus and photosynthetic bacteria are inoculated according to the ratio of 1-4:2-6:5-25:1-4:1-2, and mixed fermentation is carried out; and after 60-84h of aerobic fermentation, the microbial fermentation broth is obtained. The invention aims at providing the plant extract and microbe composite deodorant. Deodorizing is realized with the combination of the plant extract and microbes. With the deodorant, fast and continuous deodorization can be realized; production cost is reduced; and a deodorization effect is good. With the deodorant, deodorization can be achieved fundamentally.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

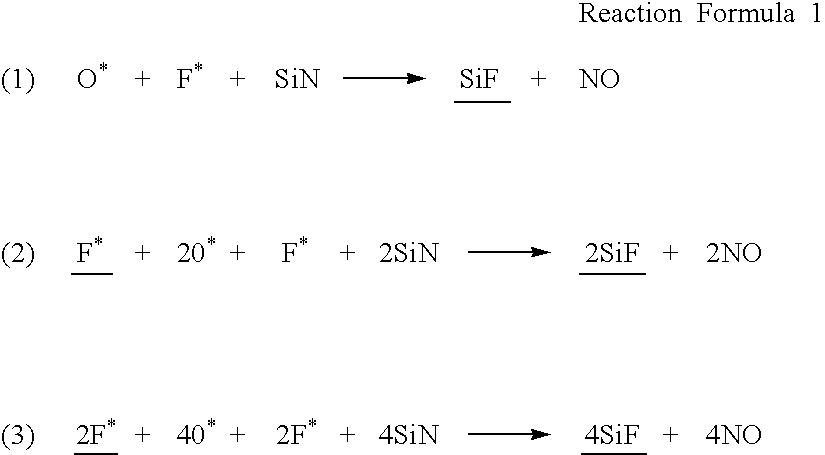

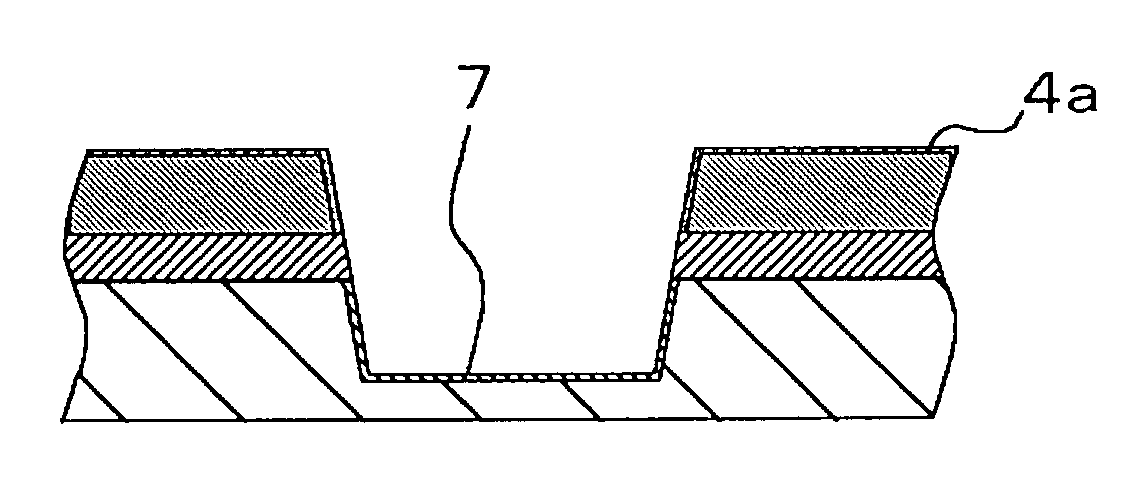

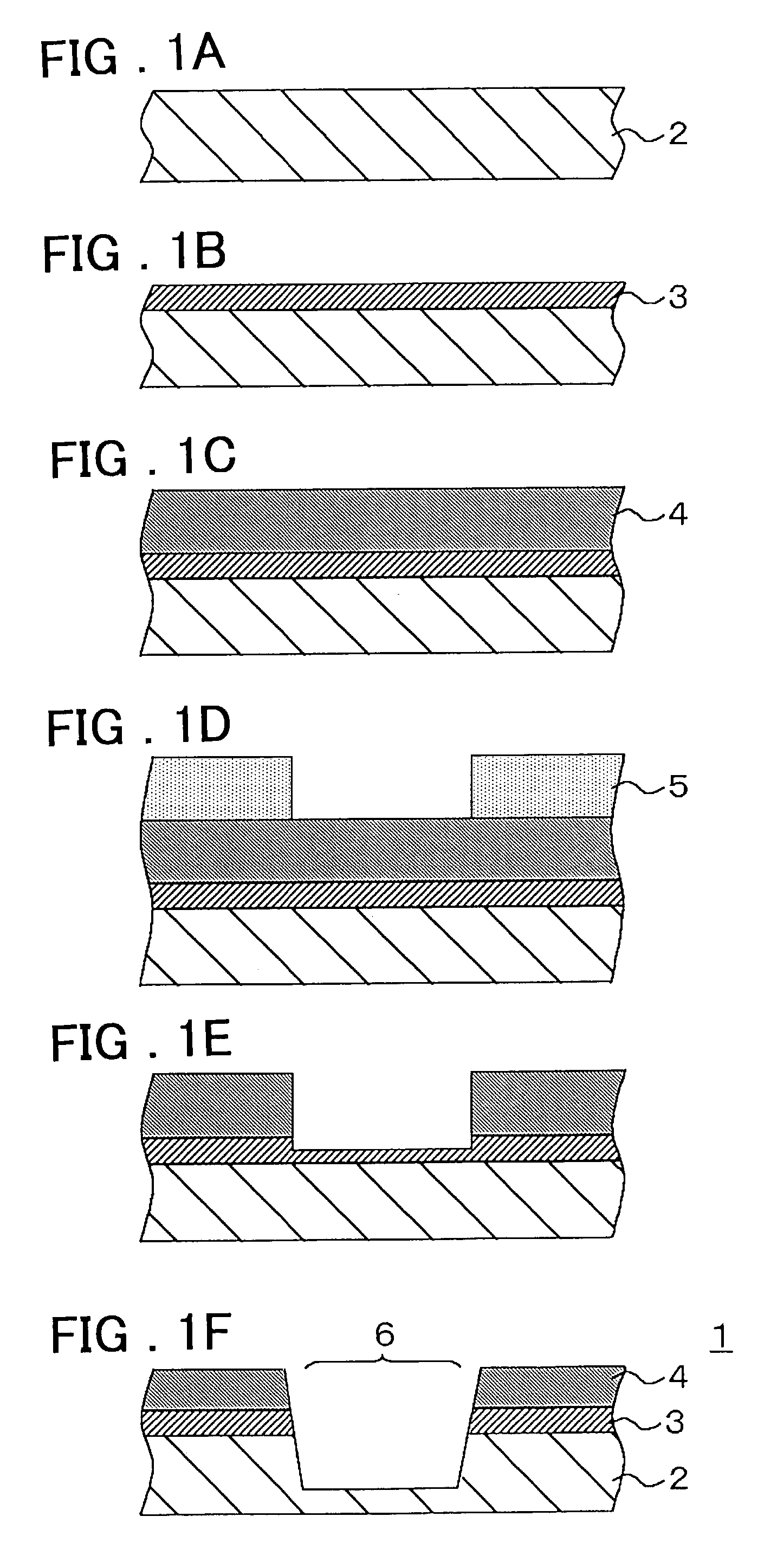

Etching method

InactiveUS20030194874A1Reduce the necessary timeProcess stabilityDecorative surface effectsSemiconductor/solid-state device manufacturingSemiconductorSilicon nitride

To provide an etching method for broadening a trench opening between patterns of an etching mask in a dry process. The etching method of a semiconductor substrate in which silicon and a silicon nitride film are exposed at least on a surface of the semiconductor substrate, comprises an oxidation step of oxidizing the silicon and the silicon nitride film from an exposed surface to a given film thickness by spraying the semiconductor substrate with substances excited by plasma discharge of O<subscript>2 < / highlight>gas as a reaction gas, and an etching step of etching the semiconductor substrate oxidized in the oxidation step by plasma using a reaction gas comprising at least O<subscript>2 < / highlight>gas and CH<subscript>2< / highlight>F<subscript>2 < / highlight>gas.

Owner:PS4 LUXCO SARL

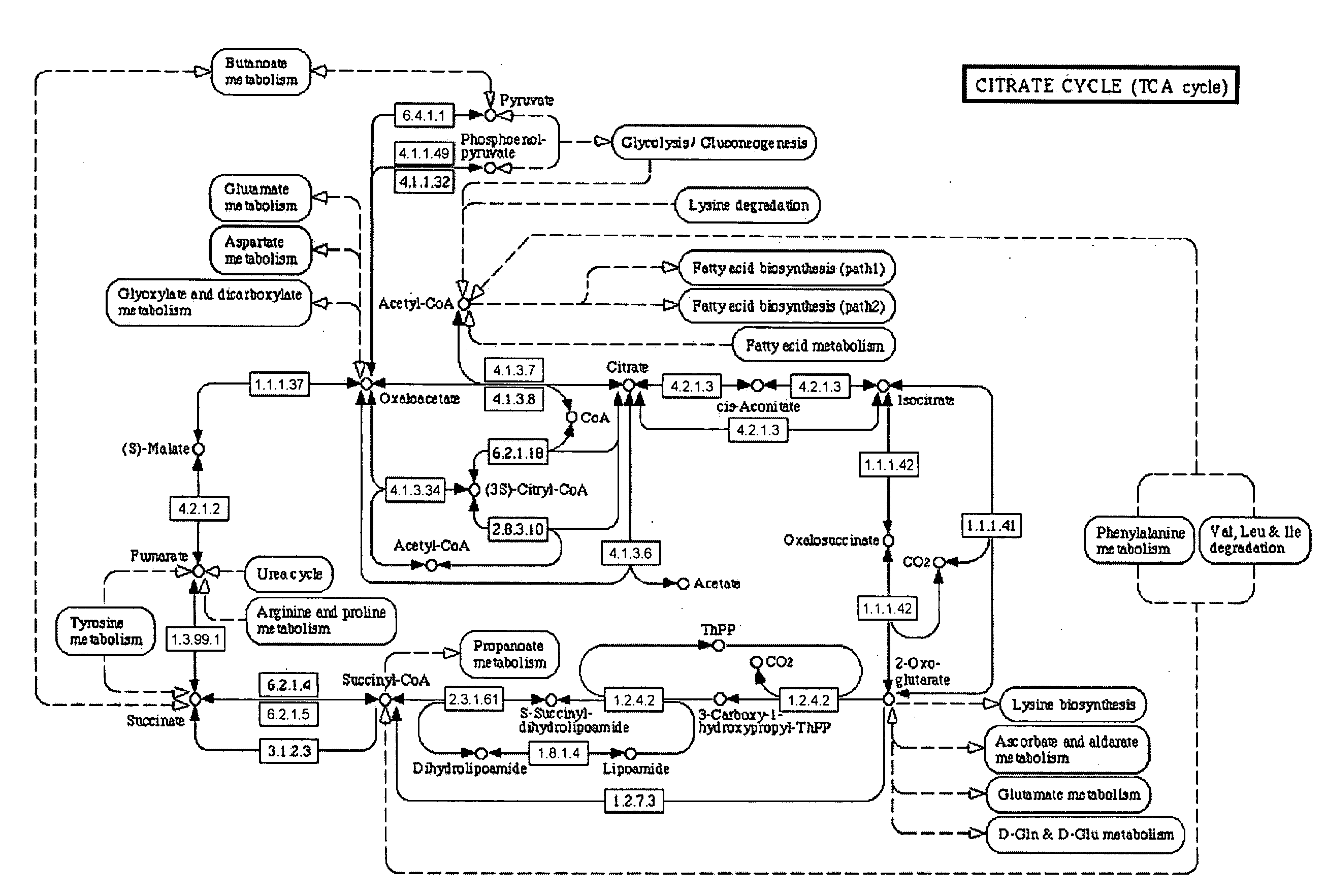

Noninvasive Measurement and Identification of Biomarkers in Disease State

ActiveUS20090104596A1Quick measurementQuickly and reliably and inexpensively identify disease stateMicrobiological testing/measurementDisease diagnosisArginineTyrosine

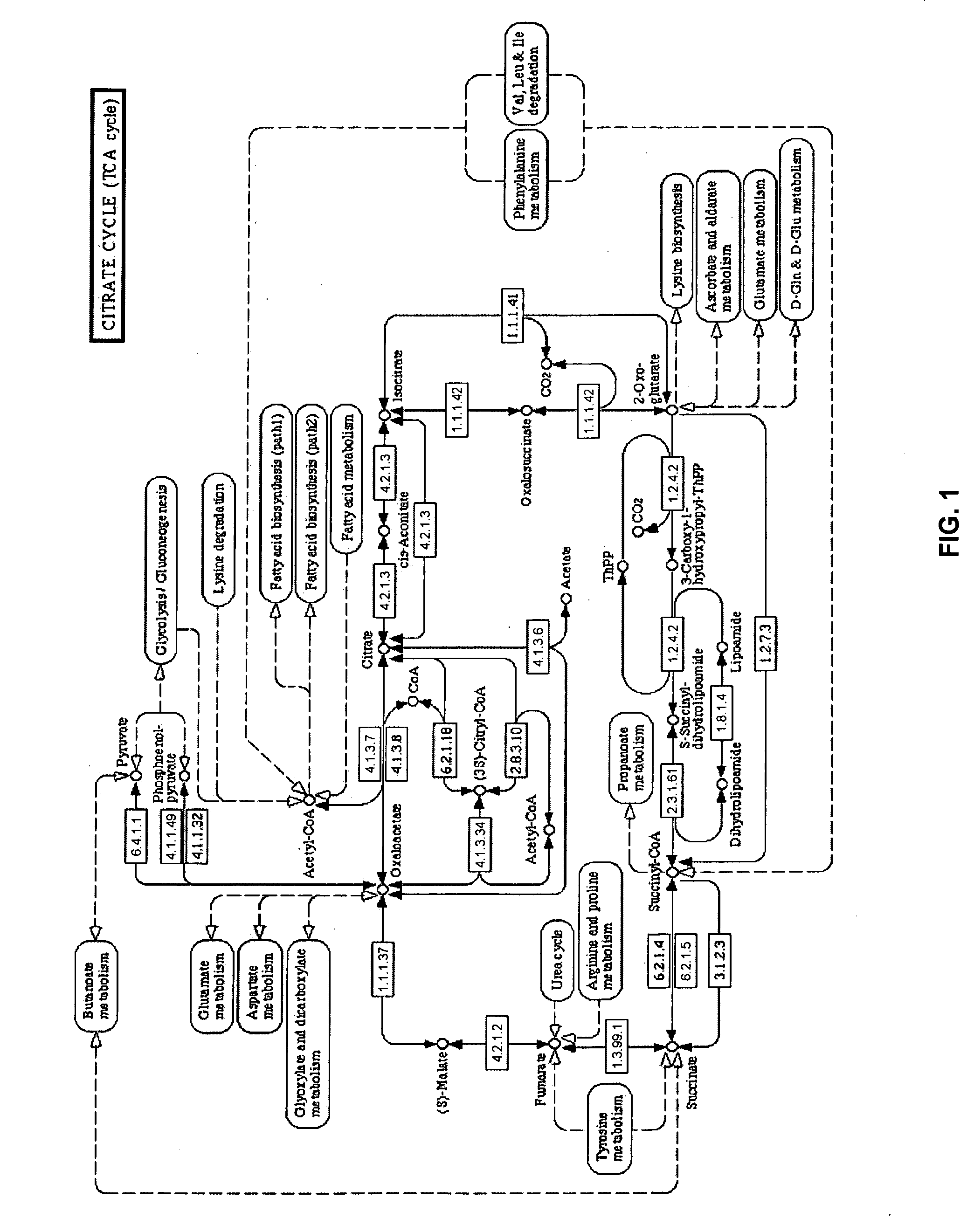

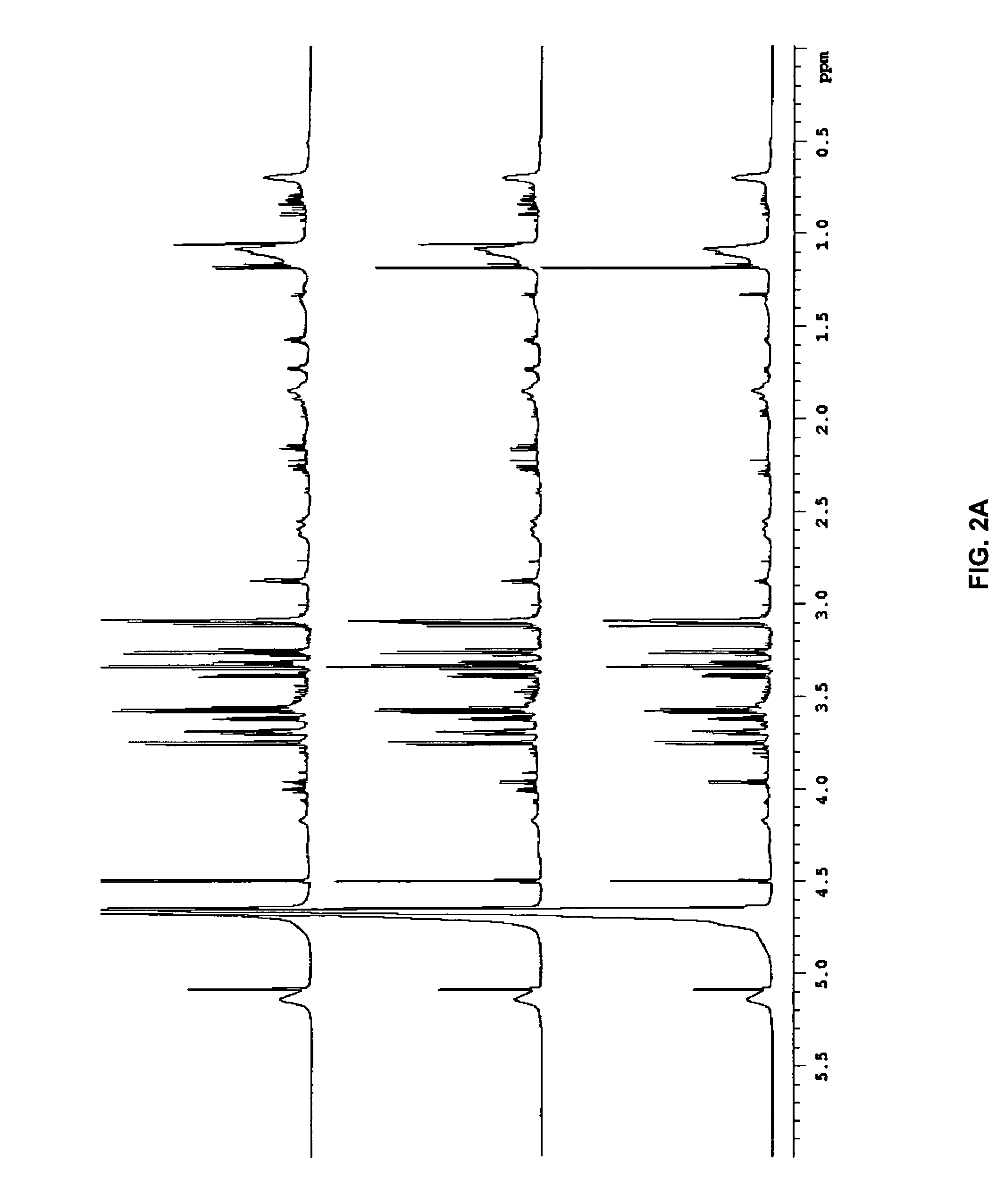

The invention is methods and related kits for diagnosing a disease state of cachexia by measuring biomarker profiles from a biological sample. Rapid measurement of early onset or progression of the disease in a subject is determined by measuring biomarker levels from the subject and optionally comparing the biomarker levels to a standard biomarker profile or metabolome phase portrait for the disease. The biomarkers measured in the assay and related kit for cachexia progression include biomarkers selected from the group consisting of lactate, citrate, formate, acetoacetate, 3-hydroxy butrate, alanine, glutamine, glutamate, valine, isoleucine leucine, thrionine, lysine, arginine, tyrosine, phenyl alanine, histidine and tryptophan.

Owner:WISCONSIN ALUMNI RES FOUND

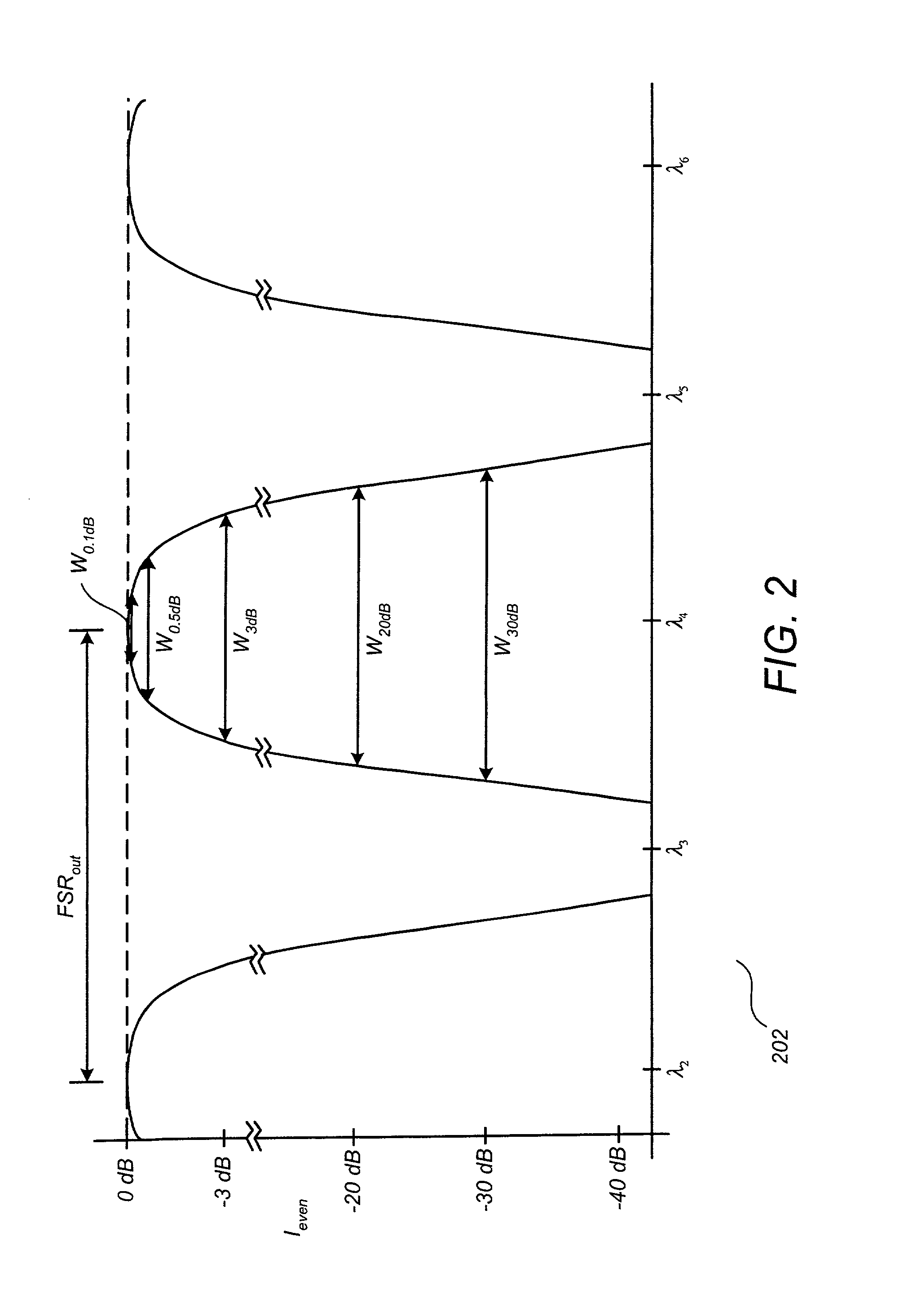

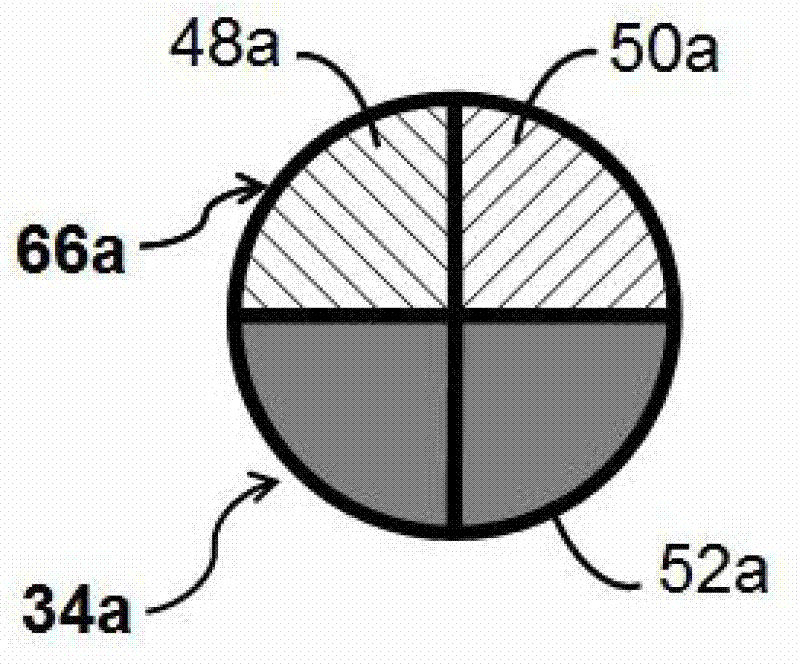

Optical interleaving with enhanced spectral response and reduced polarization sensitivity

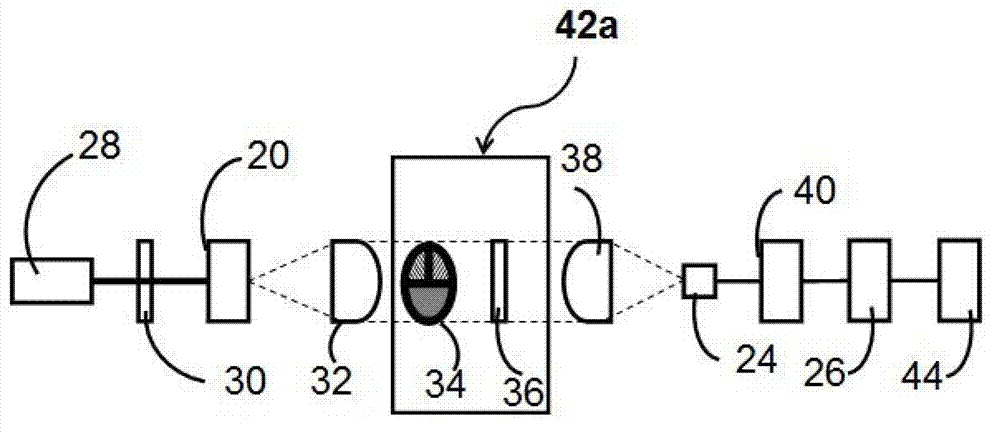

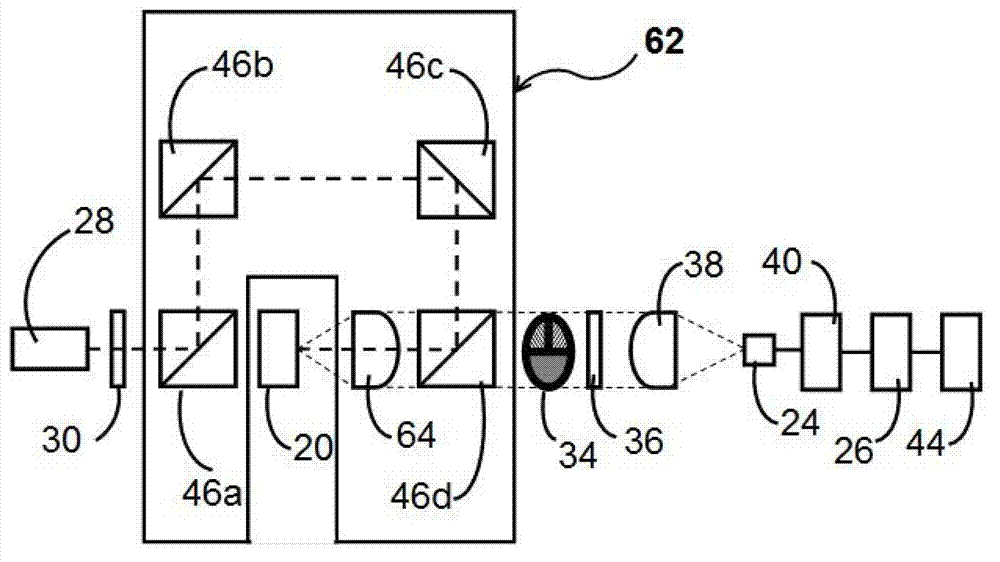

InactiveUS20020126354A1Enhance thermal stabilityImprove spectral responseWavelength-division multiplex systemsPolarising elementsResonatorPartially reflective surface

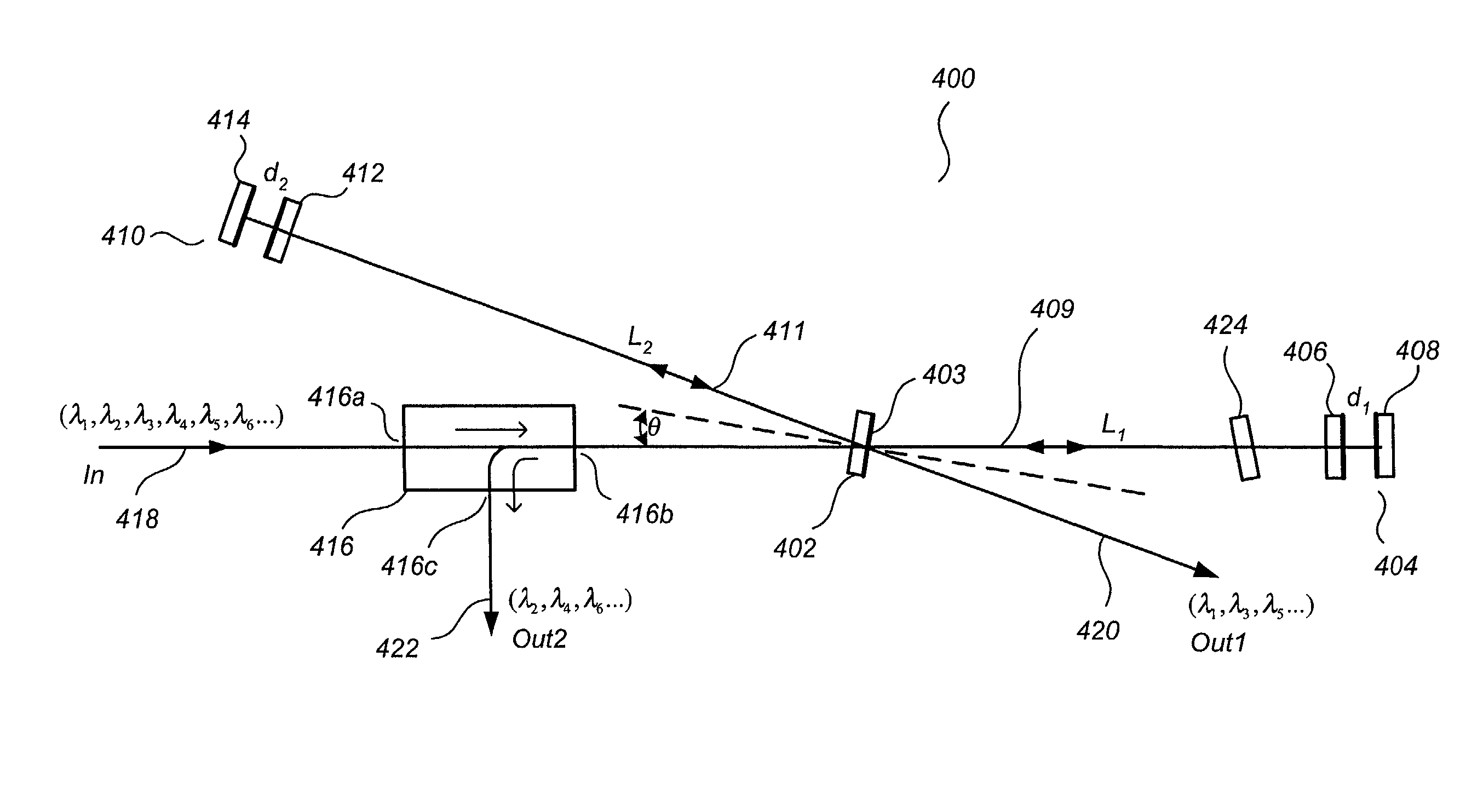

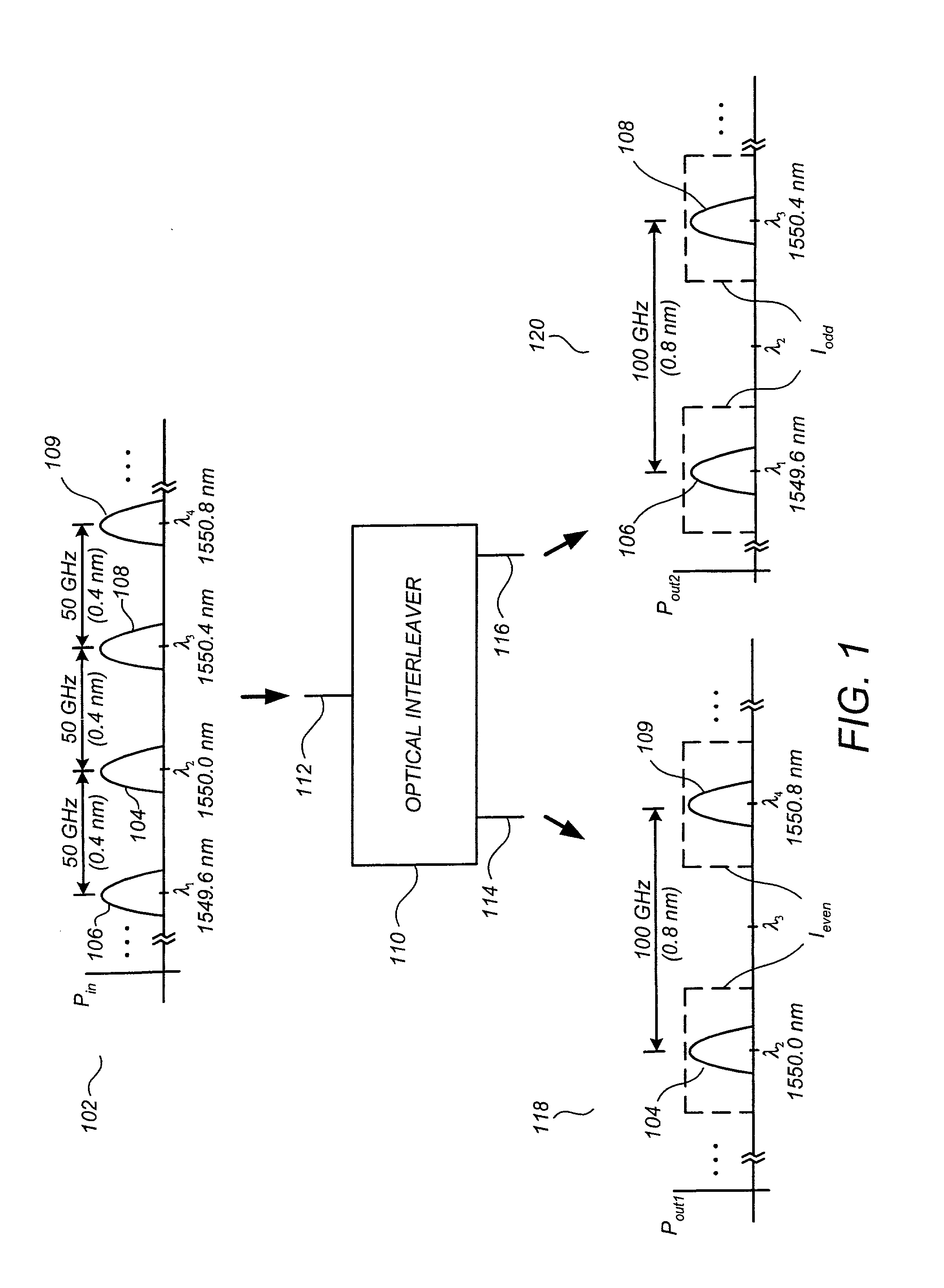

An optical interleaver for receiving an incident beam carrying a wavelength-division-multiplexed (WDM) signal comprising a plurality of channels at center wavelengths .lambda..sub.1, .lambda..sub.2, .lambda..sub.3, .lambda..sub.4, .lambda..sub.5, .lambda..sub.6, . . . and generating therefrom at least one de-interleaved output signal comprising the odd channels .lambda..sub.1, .lambda..sub.3, .lambda..sub.5, . . . or the even channels .lambda..sub.2, .lambda..sub.4, .lambda..sub.6, . . . is described. The optical interleaver comprises a splitting element for splitting an incident beam into a first optical signal directed along a first path and a second optical signal directed along a second path, a first resonant element positioned along the first path, a second resonant element positioned along the second path, and a combining element positioned to receive and to interferometrically combine the outputs of the first and second resonant to produce the output signal. The optical interleaver may be implemented using a free-space configuration using a beamsplitter and a plurality of resonant cavities such as asymmetric Fabry-Perot resonators or Michelson-Gires-Tournois resonators. In an alternative preferred embodiment, the optical interleaver may be implemented in a Mach-Zender-style configuration using couplers and fiber ring resonators. According to a preferred embodiment in which the optical interleaver is in a free-space configuration, the splitting element that receives the incident beam comprises a partially reflective surface positioned such that a normal to the reflective surface is at a less-than-30 degree angle with respect to the incoming beam for increased stability against polarizations in the incoming beam. According to another preferred embodiment, thermal stability of the optical interleaver is enhanced by configuring and dimensioning the optical interleaver such that the amount of glass or other optical material in the first and second split-beam paths is equalized. In accordance with reciprocity principles, the optical interleaver is readily adapted to operate as an interleaver, de-interleaver, or add / drop multiplexer.

Owner:GAZILLION BITS

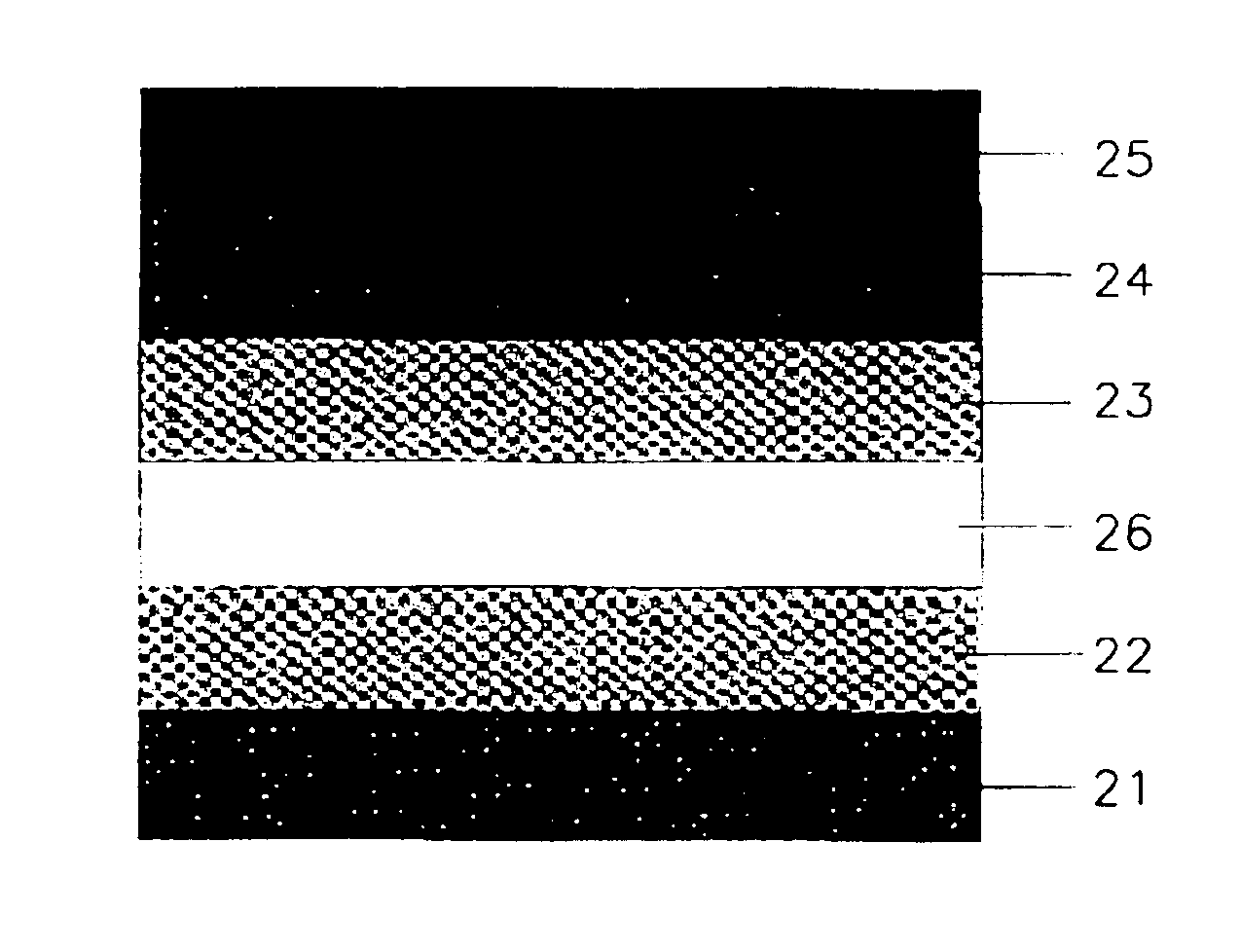

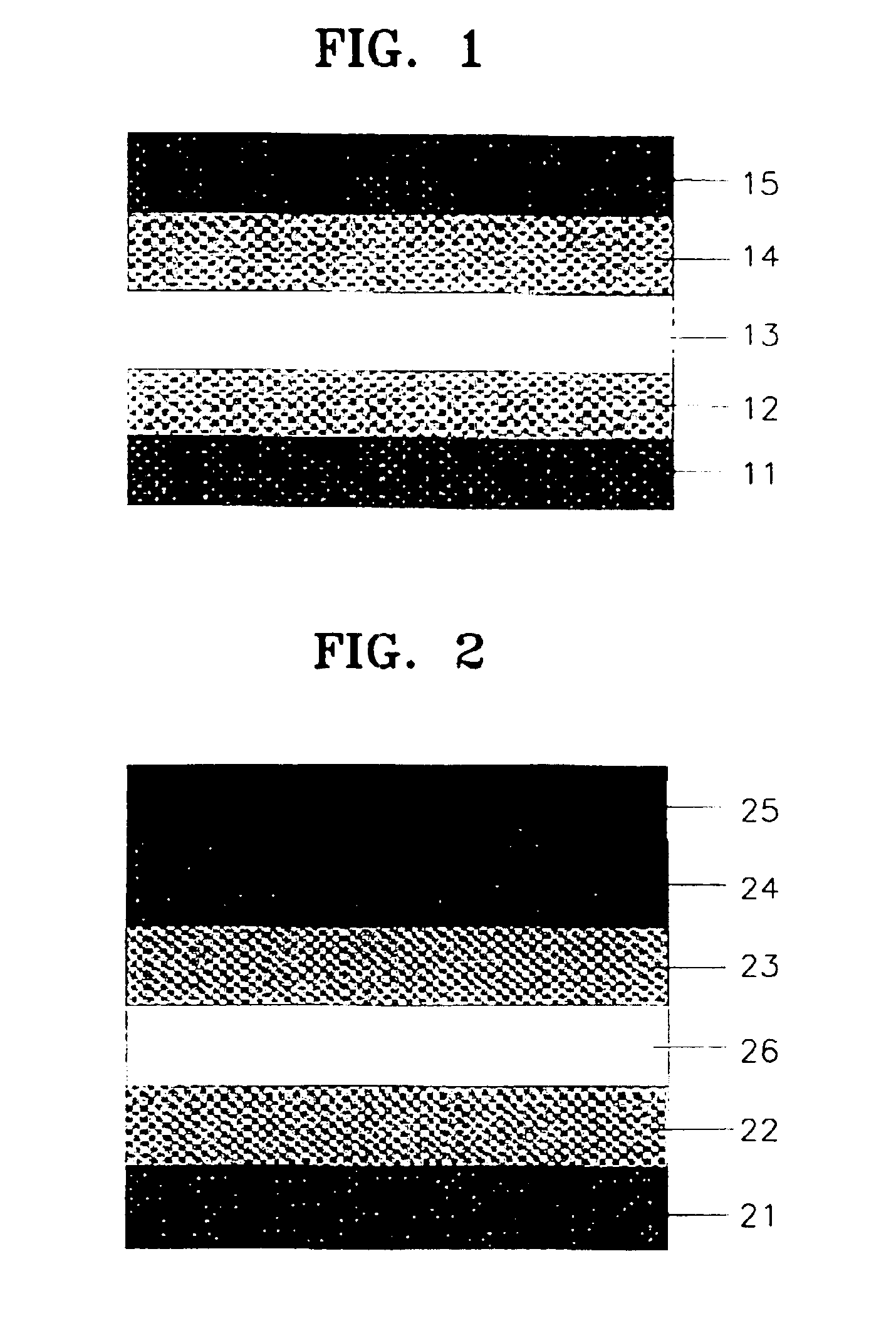

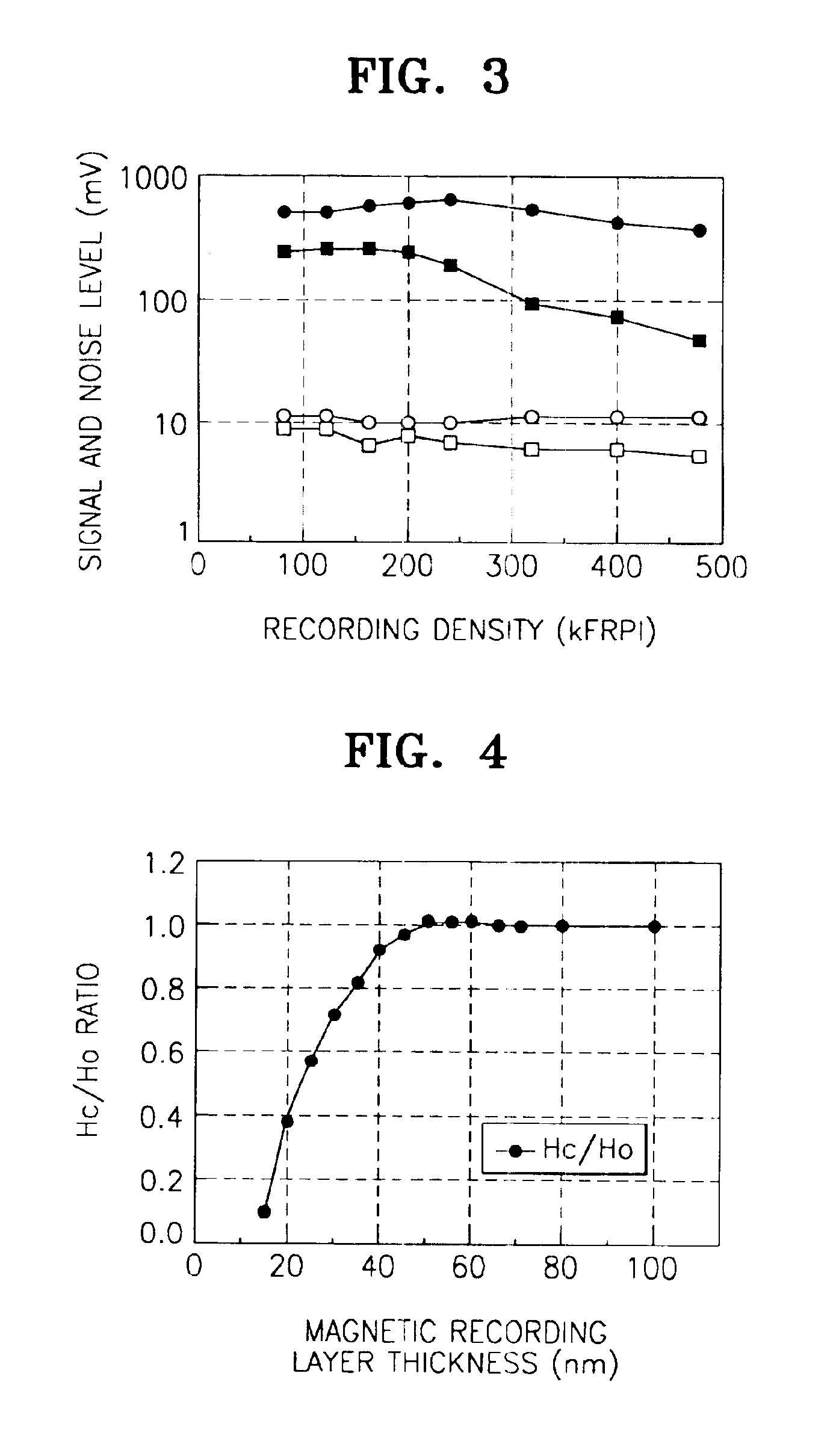

Perpendicular magnetic recording disk

InactiveUS7101600B1Reduce demagnetization energyImprove noise levelProtective coatings for layersBase layers for recording layersRecording layerNuclear magnetic resonance

A perpendicular magnetic recording disk is provided. The perpendicular magnetic recording disk includes an underlayer between a substrate and a perpendicular magnetic recording layer for inducing perpendicular orientation of the perpendicular magnetic recording layer, the perpendicular magnetic recording layer having a thickness in the range where the ratio of perpendicular coercivity Hc to maximum perpendicular coercivity Ho decreases with reduced thickness of the perpendicular magnetic recording layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Nano-molybdenum disulfide magnetic lubricant and preparation method thereof

ActiveCN105087105AGuaranteed MagneticStable ratioMaterial nanotechnologyAdditivesLubricationMolybdenum disulfide

The invention discloses a nano-molybdenum disulfide magnetic lubricant and a preparation method thereof, and particularly relates to a nano-Fe3O4@IF-MoS2-graphene. In the lubricant, the mass ratio of Fe3O4 to IF-MoS2 to graphene is 1:(2-20):(0.02-0.5), furthermore, each component is of a specific size and structure. The preparation method comprises the following steps: firstly, dispersing nano-Fe3O4 to the surface of graphene oxide; and then, in-situ synthesizing an MoS3 precursor outside Fe3O4, and reducing and desulfurizing to obtain the nano-molybdenum disulfide magnetic lubricant. The prepared lubricant product has the advantages of high yield, good purity, good dispersion, excellent magnetism and excellent lubricity, and has important application values in the fields of precision machinery lubrication, long-term lubrication and the like.

Owner:HEFEI UNIV OF TECH

Method for preparing Kefir sour milk

The invention discloses a method for preparing Kefir sour milk which comprises water, sugar and sour milk prepared from the fermentation of two different Kefir grains; the preparing method comprises the follow steps: 1. raw milk is sterilized and then cooled to the temperature of 20 DEG C to 30 DEG C; 2. the two different Kefir grains are activated and cultured separately; 3. the activated and cultured Kefir grains with inoculum size of 2 percent to 5 percen are respectively inoculated to the sterilized raw milk; 4. the raw milk is fermented for 15 hours to 24 hours at the temperature of 20 DEG C to 30 DEG C; 5. the Kefir grains are filtered out to obtain two filtrates which are fermentation agents; 6. the two fermentation agents are mixed; 7. the mixed fermentation agents with the inoculum size of 2 percent to 5 percent are inoculated to the sterilized original milks and then fermented at the variable temperature ranging from 20 DEG C to 45 DEG C for 4 hours to 6 hours; and 8. the fermented milk are blended, homogenized and canned. With the adoption of the fermentation agents for fermenting at the variable temperature, the flavor of Kefir milk is well improved. The ferment time of the product is short, the yeasts in the mixed fermentation agents are more stable and the difference between flavors of Kefir sour milk prepared in different batches is small. The product has health-care functions of regulating beneficial bacteria in intestinal canals, lowering blood lipids, resisting tumors and the like, thus being a low-cost functional beverage.

Owner:于岚 +2

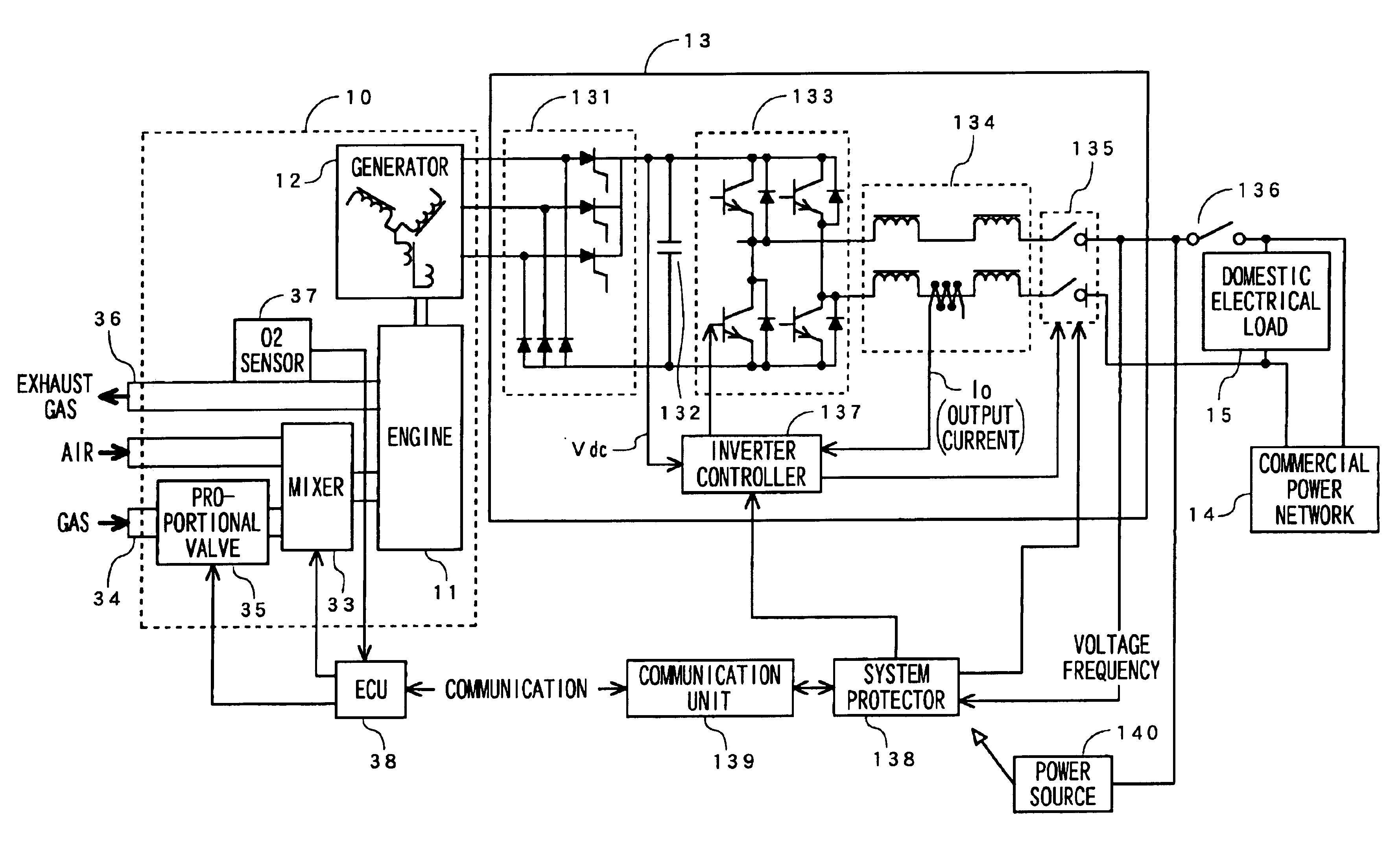

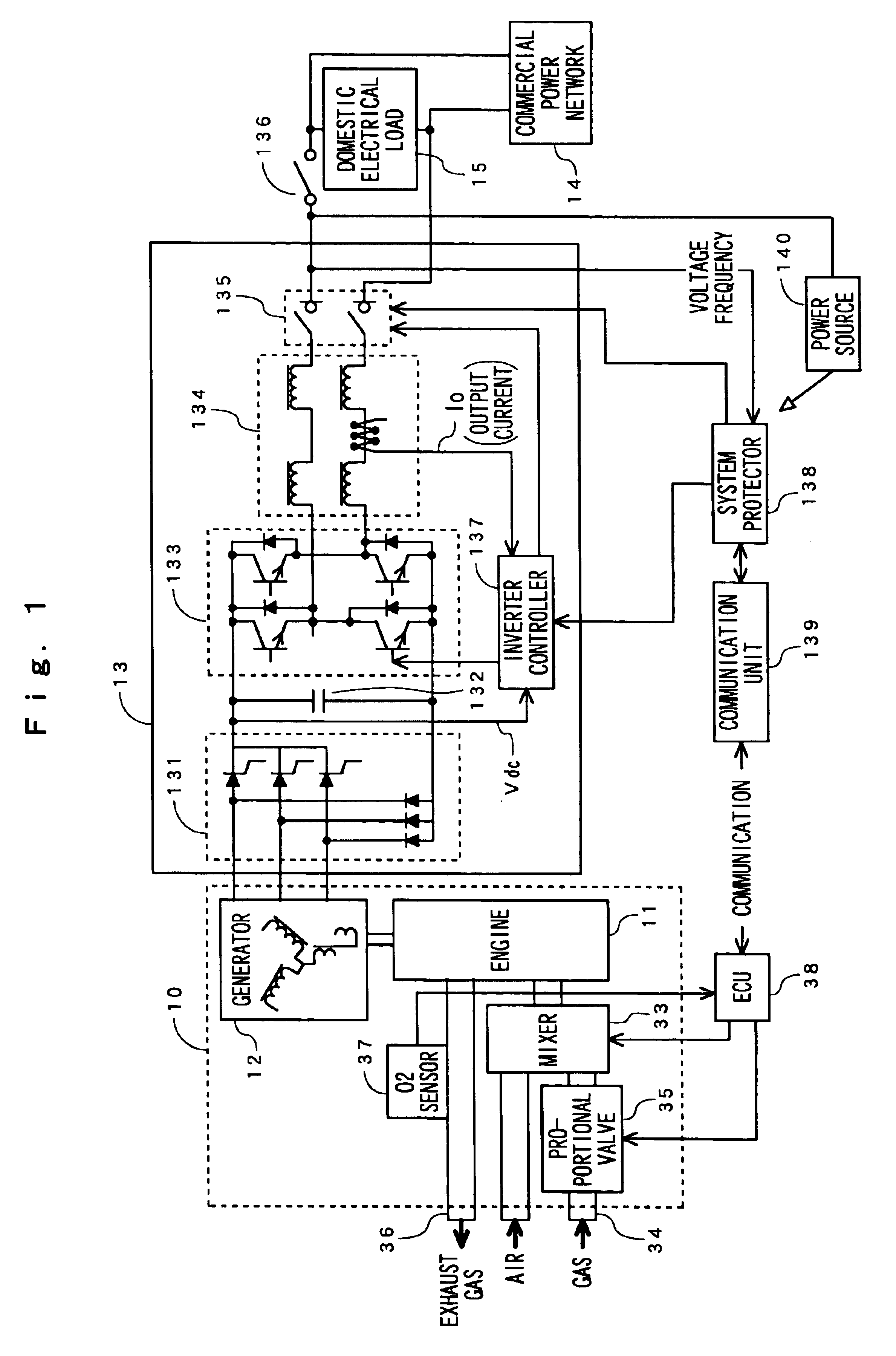

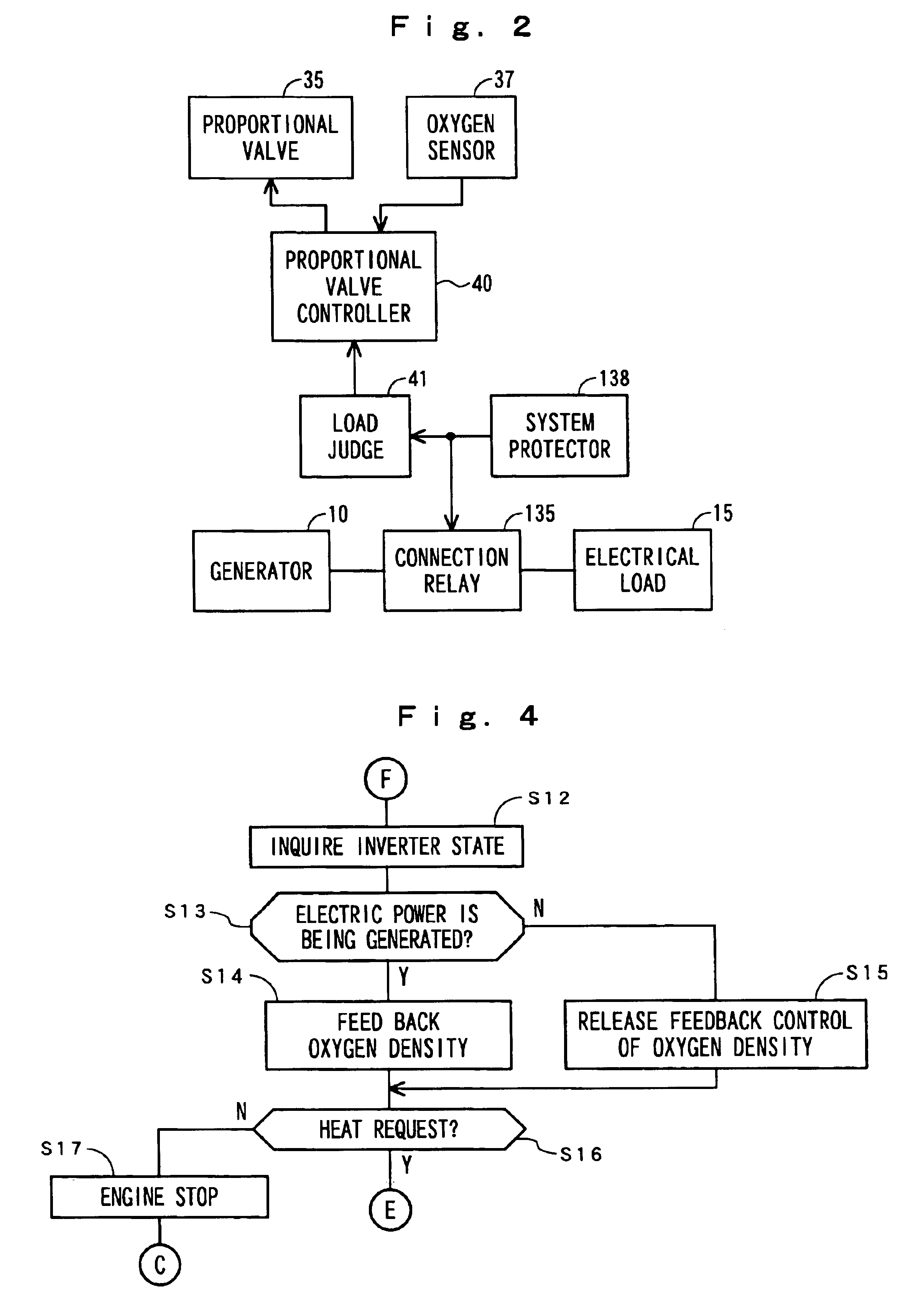

Engine generator apparatus

InactiveUS6894403B2Start fastStable ratioElectrical controlInternal combustion piston enginesOxygen sensorPower grid

An engine generator apparatus controls the air-fuel ratio in response to the stable output of an oxygen sensor. When a system protector 138 detects a disorder in a power network, it outputs failure signal. A connection relay 135 is opened in response to the failure signal to release connection of a generator to the power network to release load. When the failure signal is not detected, a load determination section 41 urges a proportional valve controller 40 and the controller 40 drives a valve 35 corresponding to the oxygen density to perform a control of the air-fuel ratio. The load determination section 41 determines that the load is released by the failure signal to send a notification of no load to the controller 40. The controller 40 stops the control of the air-fuel ratio based on the oxygen density in response to this notification.

Owner:HONDA MOTOR CO LTD

High-solid and averaged-molecular weight non-toxic polyurethane curing agent for sub-gloss varnish and preparation method thereof

The invention belongs to the technical field of curing agents and discloses a high-solid and averaged-molecular weight non-toxic polyurethane curing agent for a sub-gloss varnish and a preparation method thereof. The method comprises the steps of (1) in the nitrogen protection environment, adding a catalyst drop by drop in a reaction vessel filled with a solvent and toluene diisocynate during the stirring process, reacting at the temperature of 40-55 DEG C, cooling on the condition that the content of NCO is lowered to be 13%-23%, and adding an acidic polymerization inhibitor to obtain a toluene diisocyanate trimer; (2) mixing a polyhydroxy compound with a dehydrating agent, adding the obtained mixture in the toluene diisocyanate drop by drop, reacting and cooling to obtain a polyurethane addition product; (3) stirring and mixing the toluene diisocyanate trimer with the polyurethane addition product, separating in a film evaporator, adding a dilution solvent and stirring evenly to obtain the high-solid and averaged-molecular weight non-toxic polyurethane curing agent. The curing agent is centralized in the distribution of molecular weight, low in viscosity, and high in content of effective isocyanate groups. After a varnish is prepared by the curing agent, a paint film is fast in drying speed, good in levelability and high in fullness.

Owner:SOUTH CHINA UNIV OF TECH

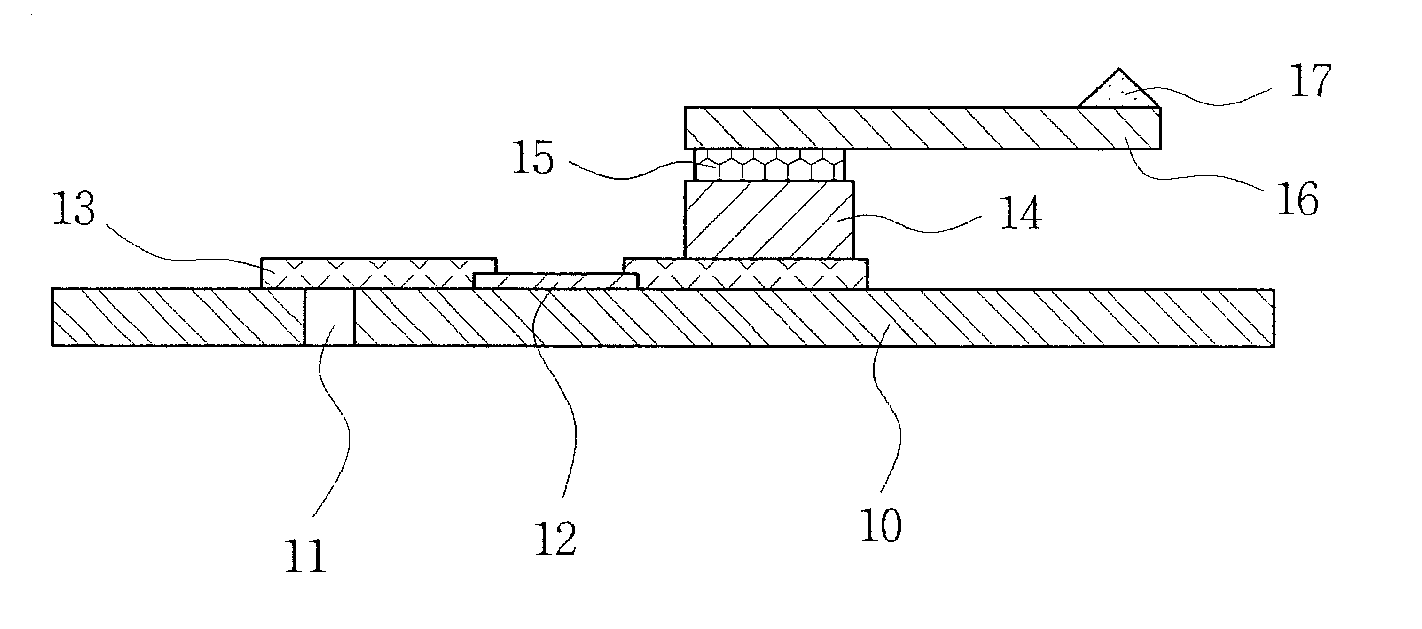

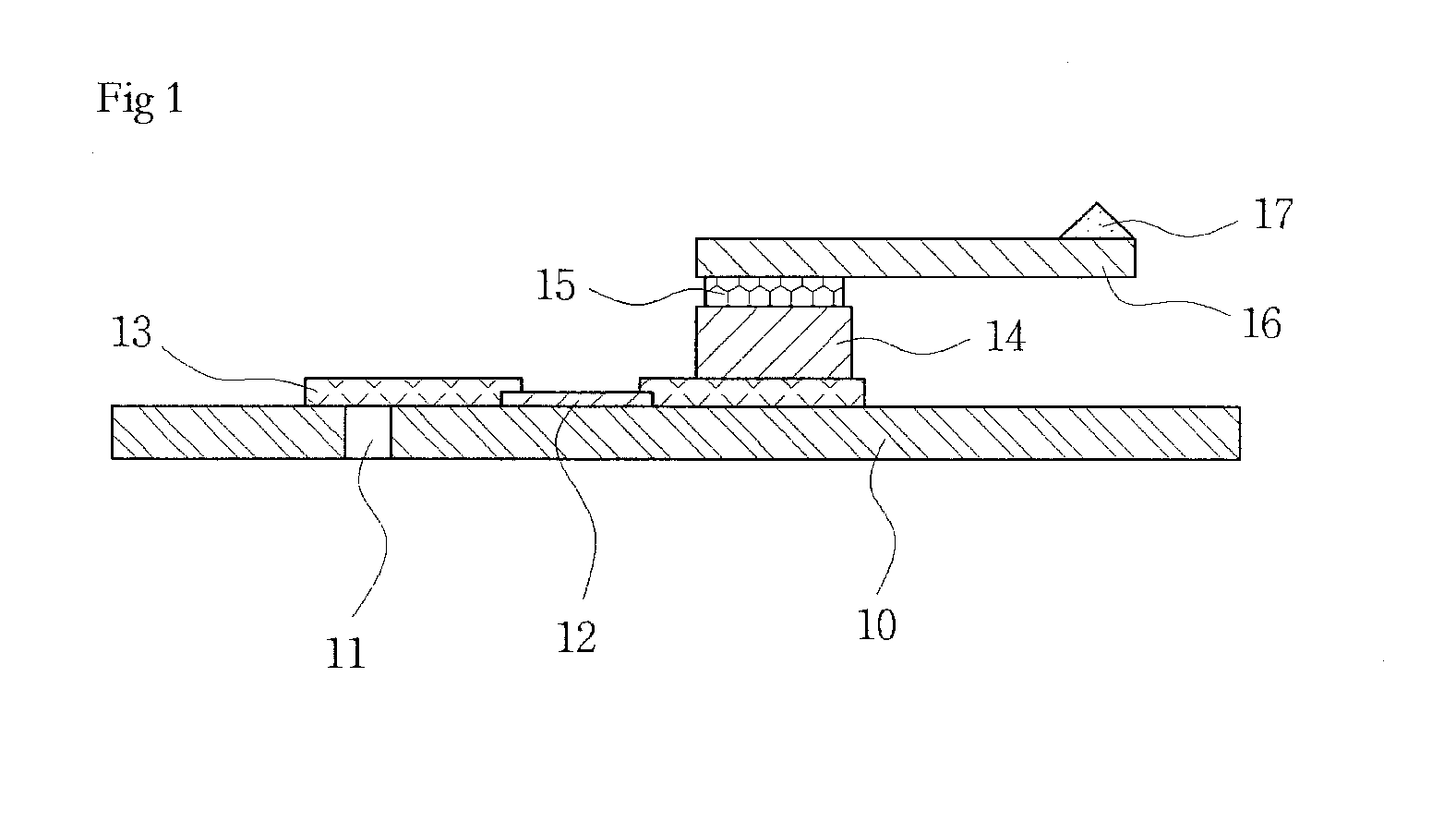

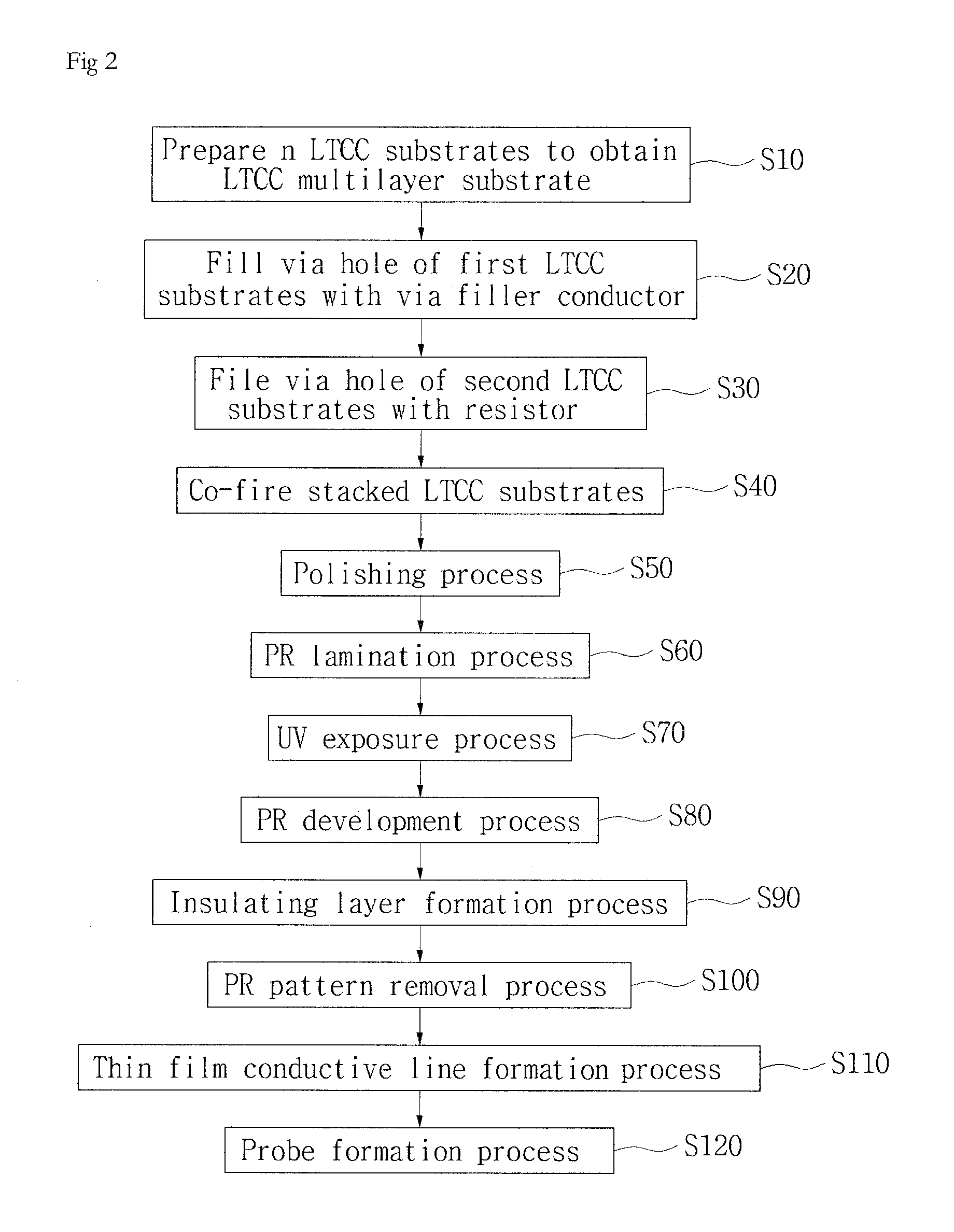

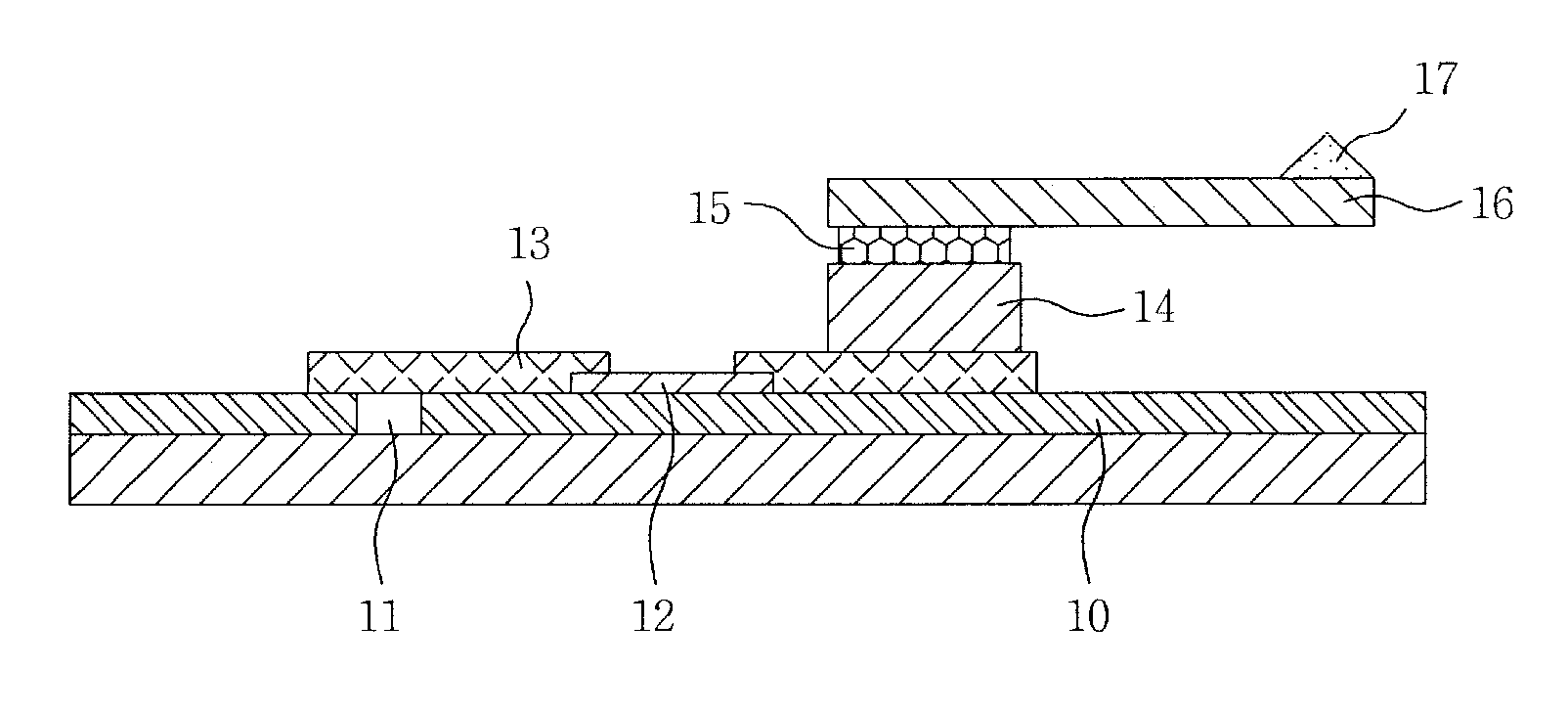

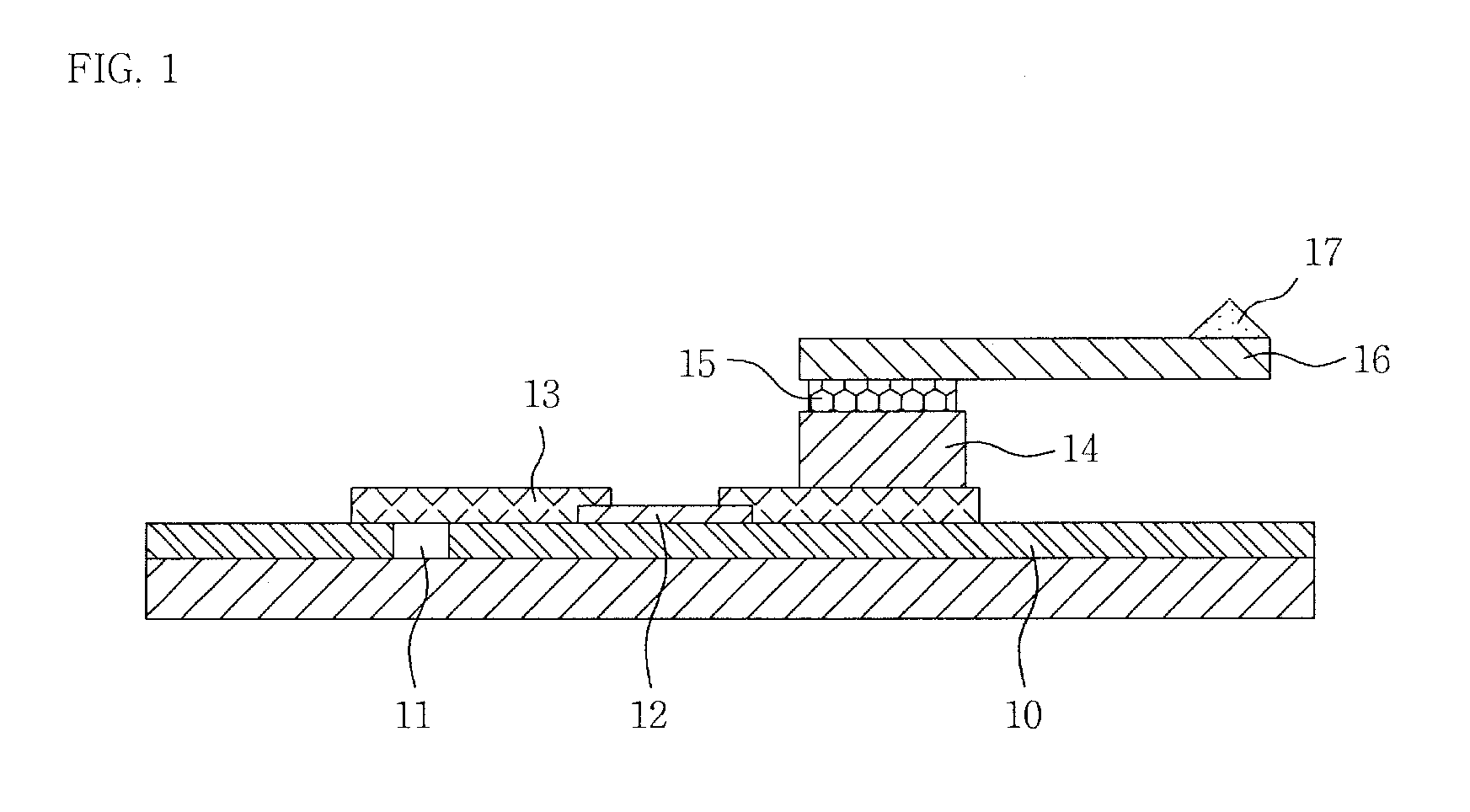

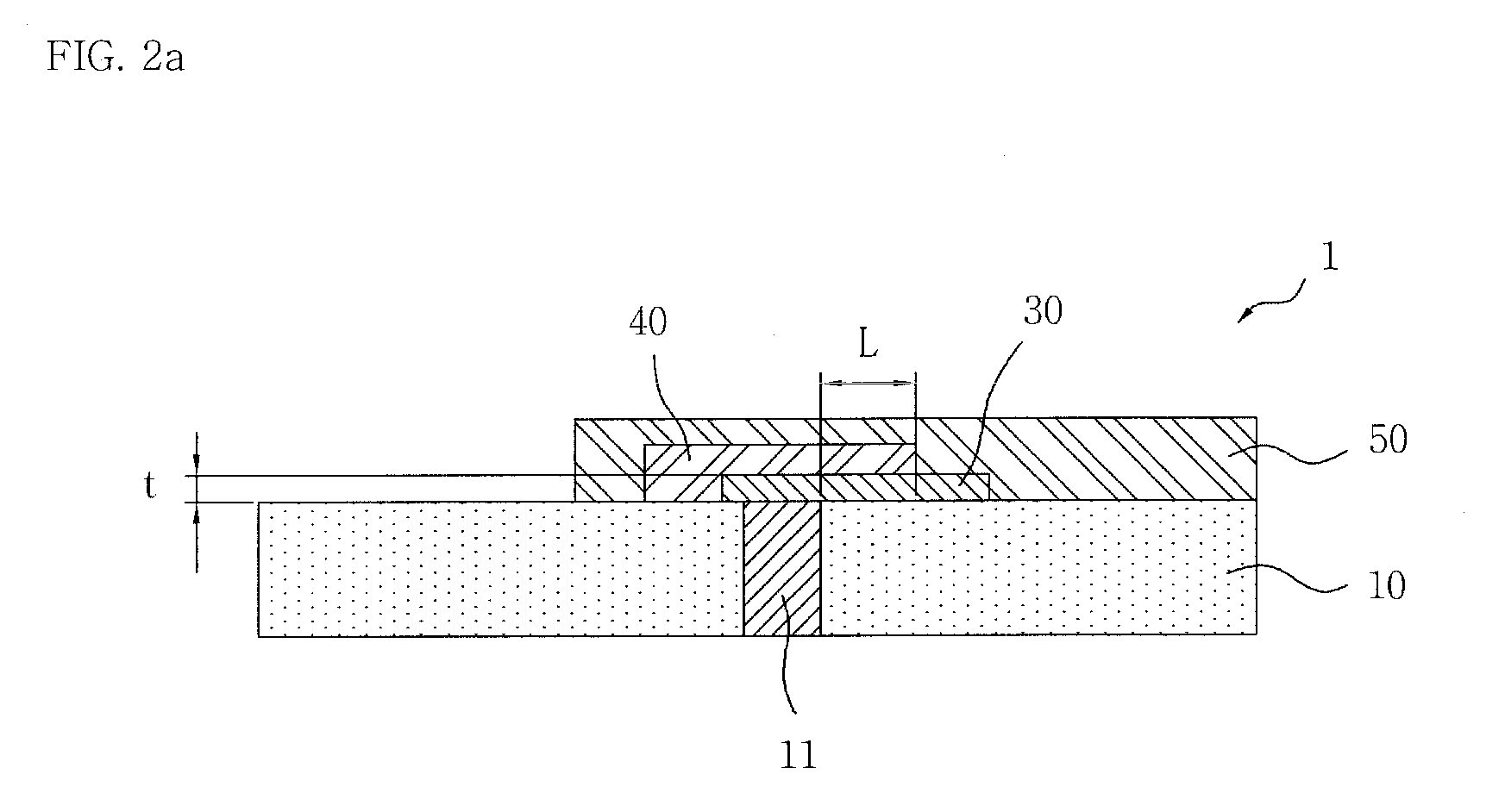

MEMS probe card and manufacturing method thereof

PendingUS20110089967A1Stable resistance ratioEasy to useSolid-state devicesVacuum evaporation coatingCo-fired ceramicEngineering

Provided are a micro-electro-mechanical system (MEMS) probe card and a method for manufacturing the same. The method includes preparing first to nth low-temperature co-fired ceramic (LTCC) substrates each having a via hole, filling each via hole with a via filler conductor or a resistor, stacking the first to nth LTCC substrates and firing the stacked substrates at a temperature of 1,000° C. or less to prepare a LTCC multilayer substrate, forming an insulating layer on the surface of the LTCC multilayer substrate, and forming a thin film conductive line on the surfaces of the insulating layer and the via filler conductor.

Owner:TOP ENG CO LTD

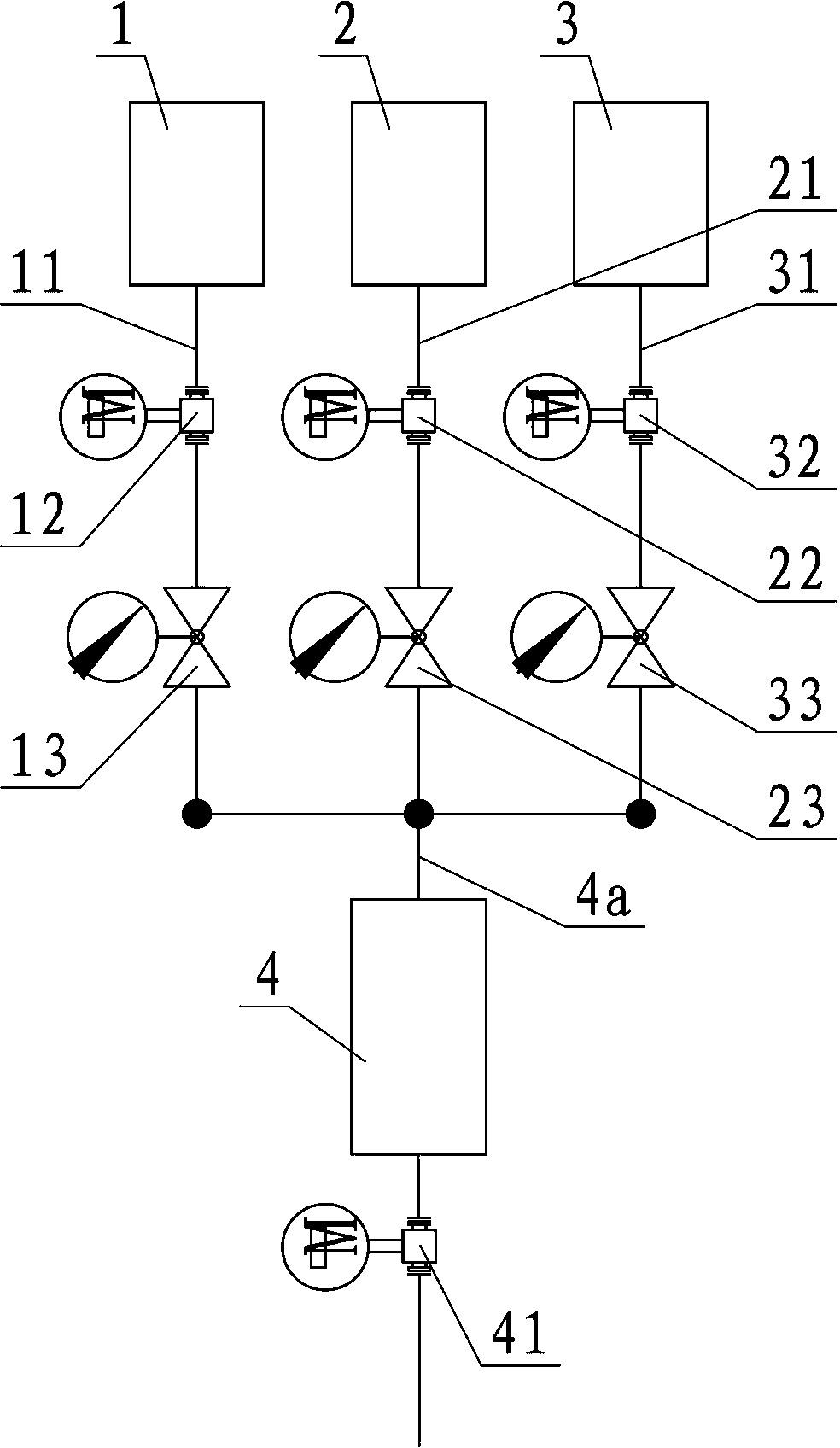

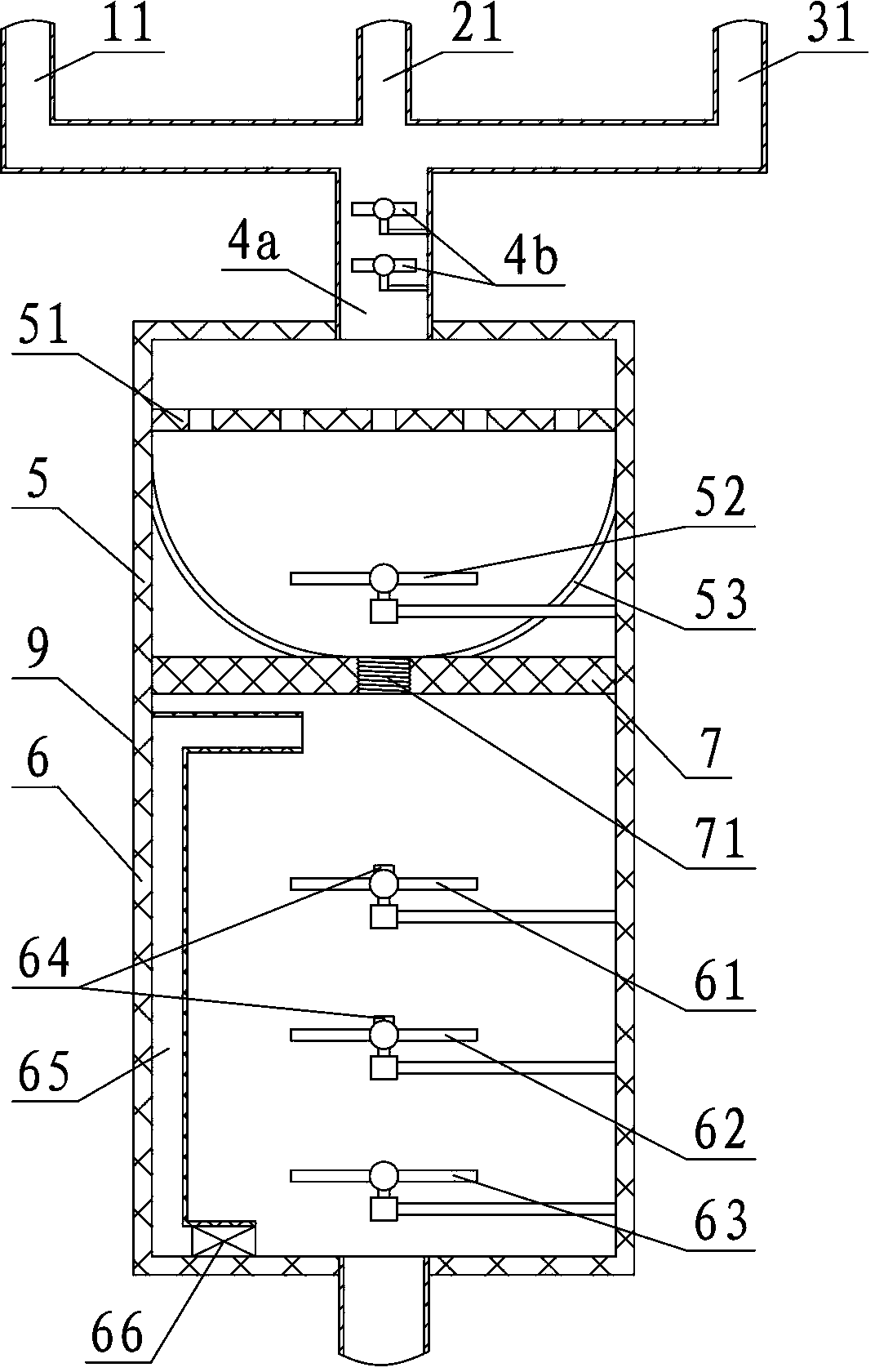

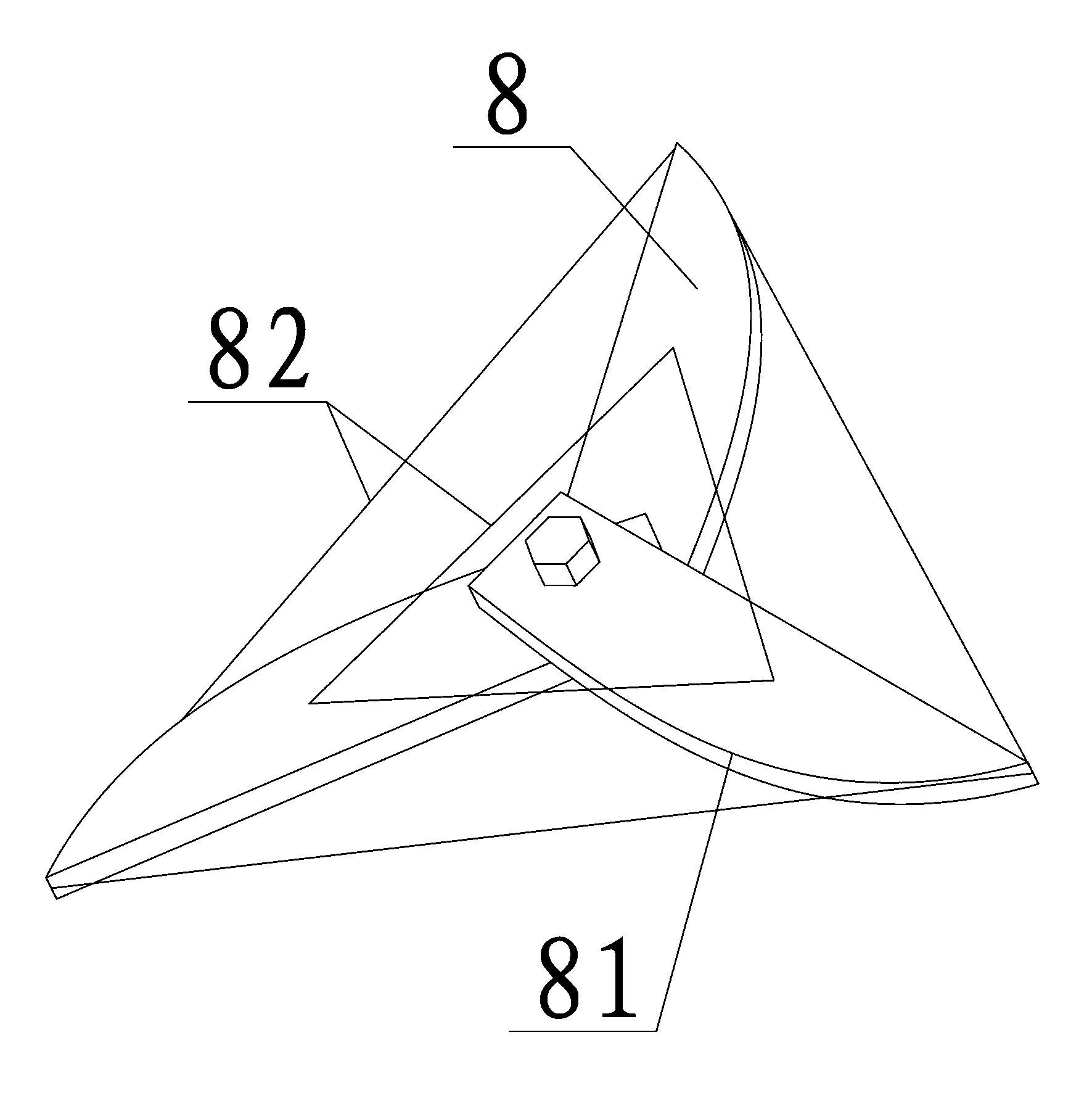

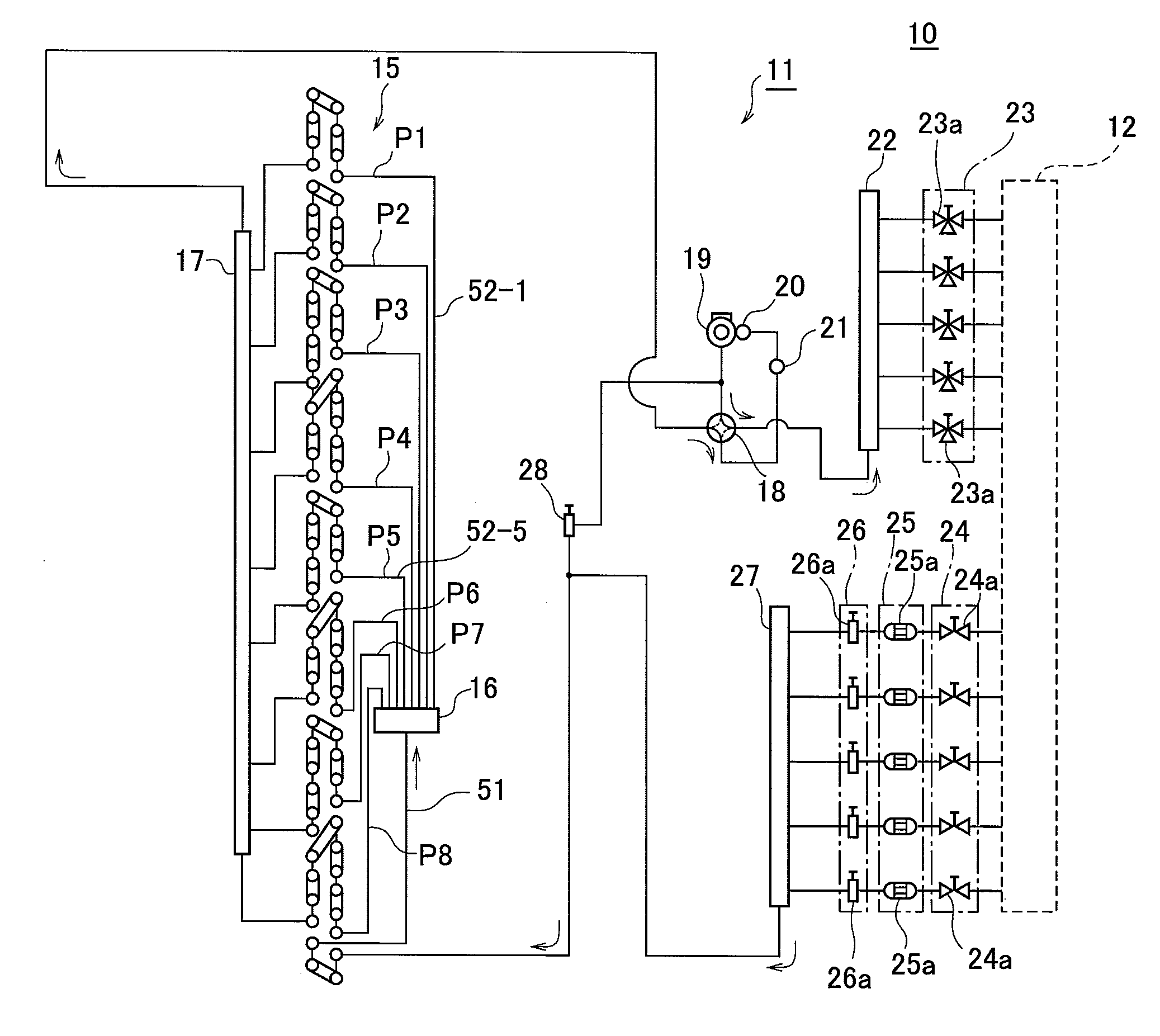

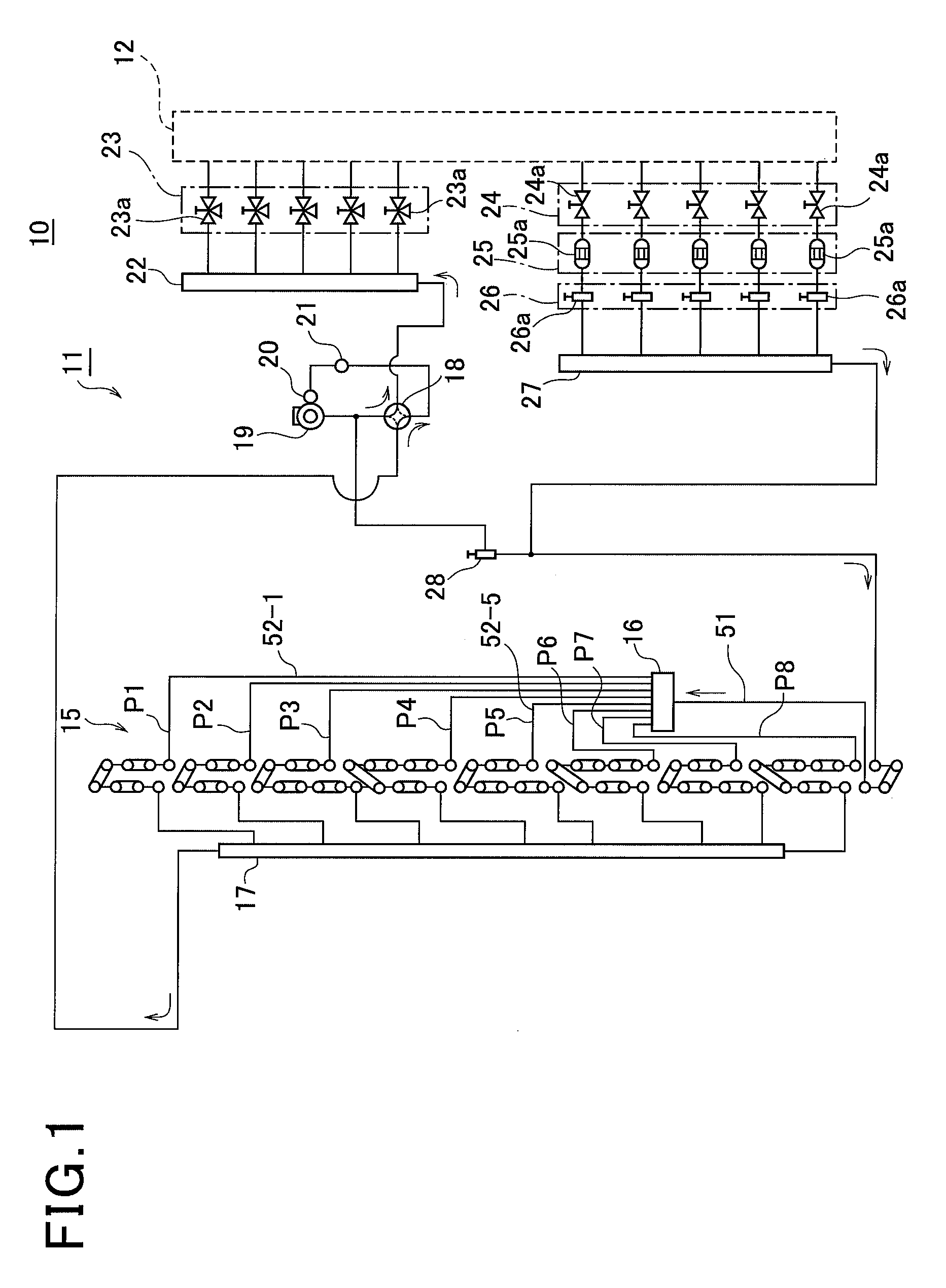

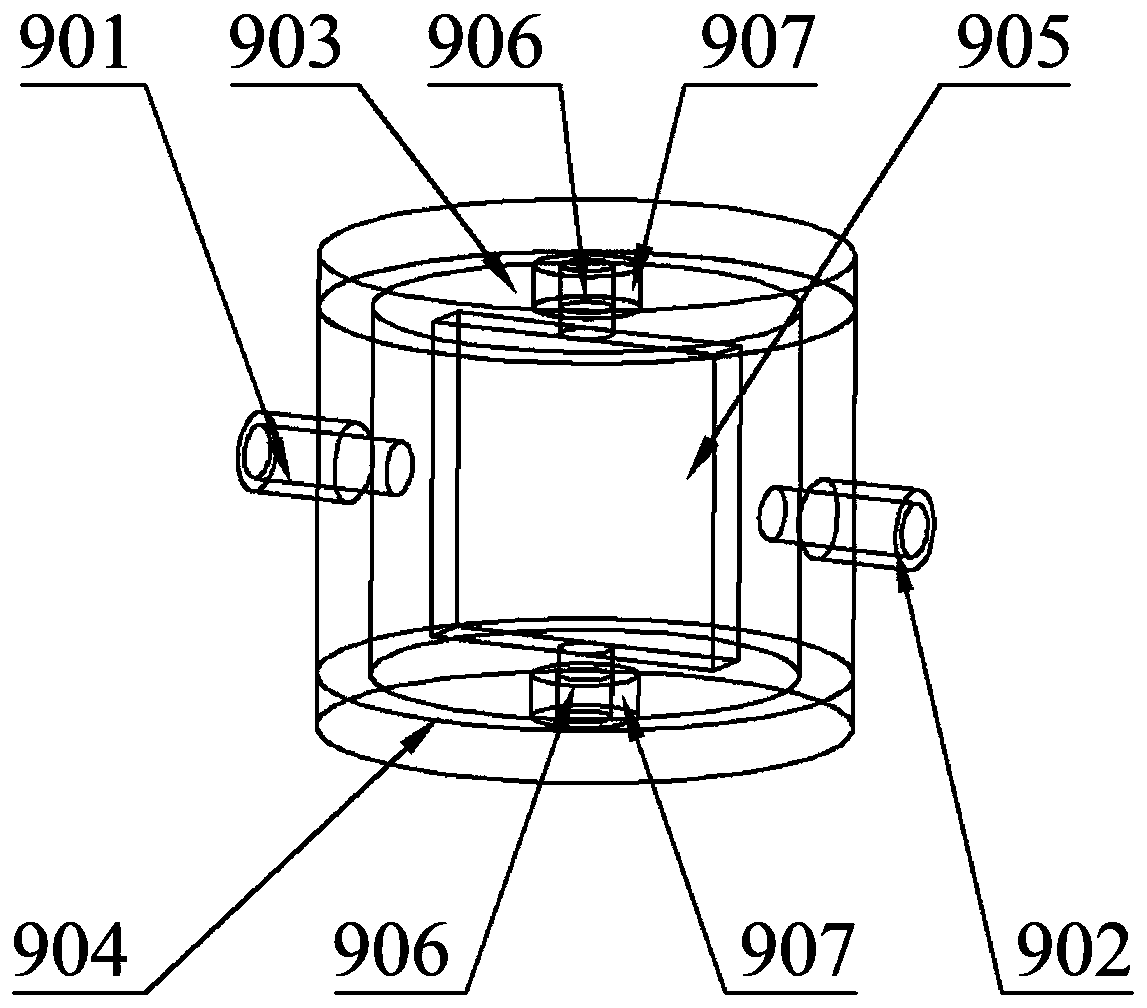

Concentration preparation device for mixed solution

InactiveCN104258780AGuaranteed ratioGuaranteed flow rateMixing methodsMixer accessoriesProcess engineeringProduction quality

The invention discloses a concentration preparation device for a mixed solution. The device comprises three solution storage devices and a solution mixing device, wherein the three solution storage devices are communicated with an input opening of the solution mixing device through respective pipelines; a flow meter and a proportion regulating valve are arranged on each pipeline; a flow meter is arranged on an output opening pipeline of the solution mixing device; the openness of the three proportion regulating valves is changed, so that the proportion of different solutions, entering the solution mixing device, in the three pipelines is further regulated. According to the invention, the proportioning is stable, and the mixed solution can be used for a long time after the proportion of the mixed solution is regulated; the production efficiency can be improved to the greatest extent, and meanwhile, the production quality is guaranteed; the production automation is realized, and the labor intensity of workers is alleviated; the device is convenient to operate and reliable to run.

Owner:HANGZHOU FANTENG TECH

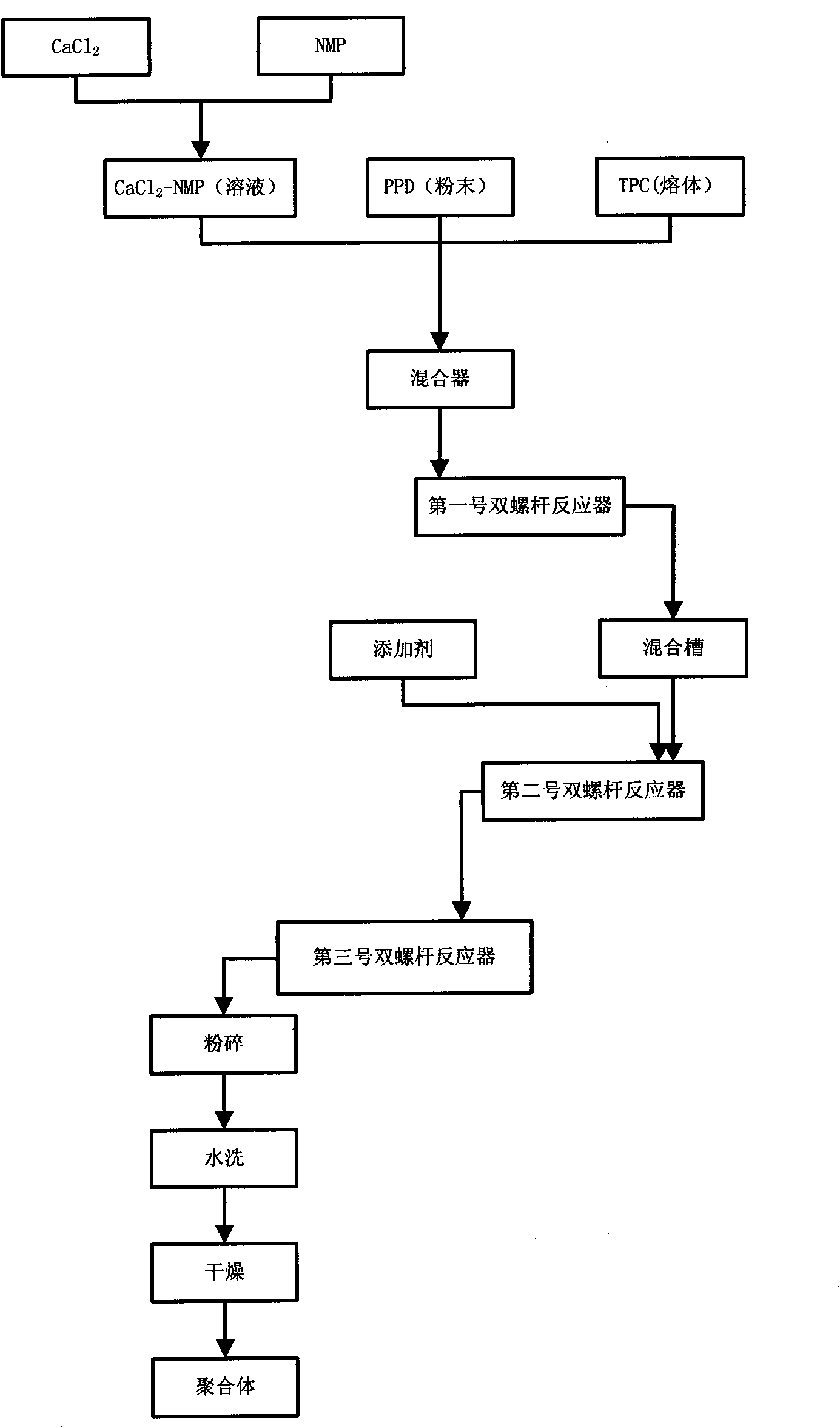

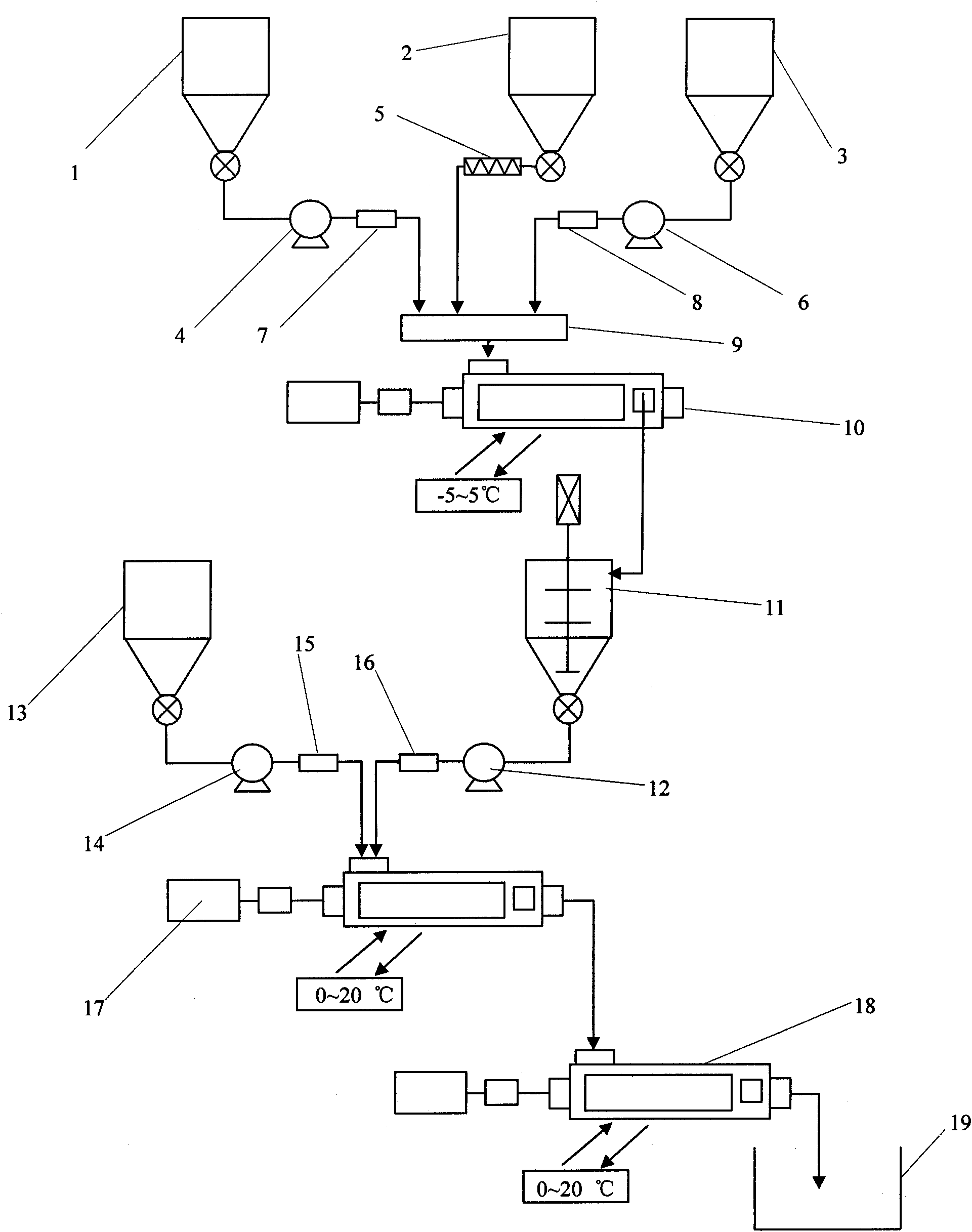

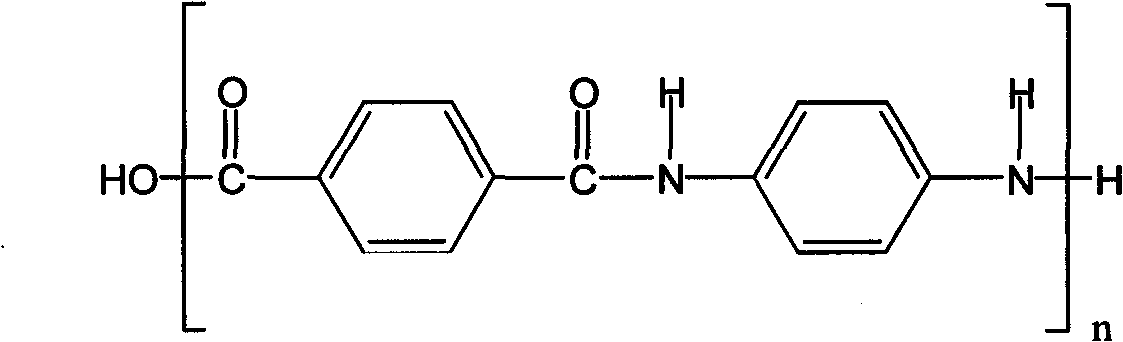

Device for continuous preparation of poly(p-phenylene terephthalamide) polymer and preparation method

ActiveCN102206339AMeet continuous and stable spinningContinuous and accurate meteringMonocomponent polyamides artificial filamentP-PhenylenediaminePhenylene

A device for continuous preparation of poly(p-phenylene terephthalamide) polymer and a preparation method belong to the field of polymer materials, and relate to the polymer material manufacturing technology. The invention is characterized in that: the poly(p-phenylene terephthalamide) polymer is prepared by using the preparation device and through the following steps: preparing a cosolvent-solvent system; proportionally and simultaneously adding the cosolvent-solvent, p-phenylenediamine and terephthaloyl chloride into a No.1 mixer, mixing and allowing the mixture to flow into a twin screw reactor; successively allowing the mixture to flow into a subsequent mixer and a No.2 twin screw reactor till a light-yellow breadcrumb-like mixture is extruded from a No.3 twin screw reactor, pulverizing the mixture, washing by water, and drying to obtain the poly(p-phenylene terephthalamide) polymer. The method of the invention can solve the problems of deepened color and decreased reactivity of p-phenylenediamine caused by long-term storage in a cosolvent-containing solvent; the combination of a plurality of twin screw reactors meets the mixing requirements of the polycondensation reaction at different stages and provides a logarithmic viscosity of above 6.5 dl / g; the performance requirements for industrial continuous preparation are met.

Owner:上海舟汉纤维材料科技股份有限公司

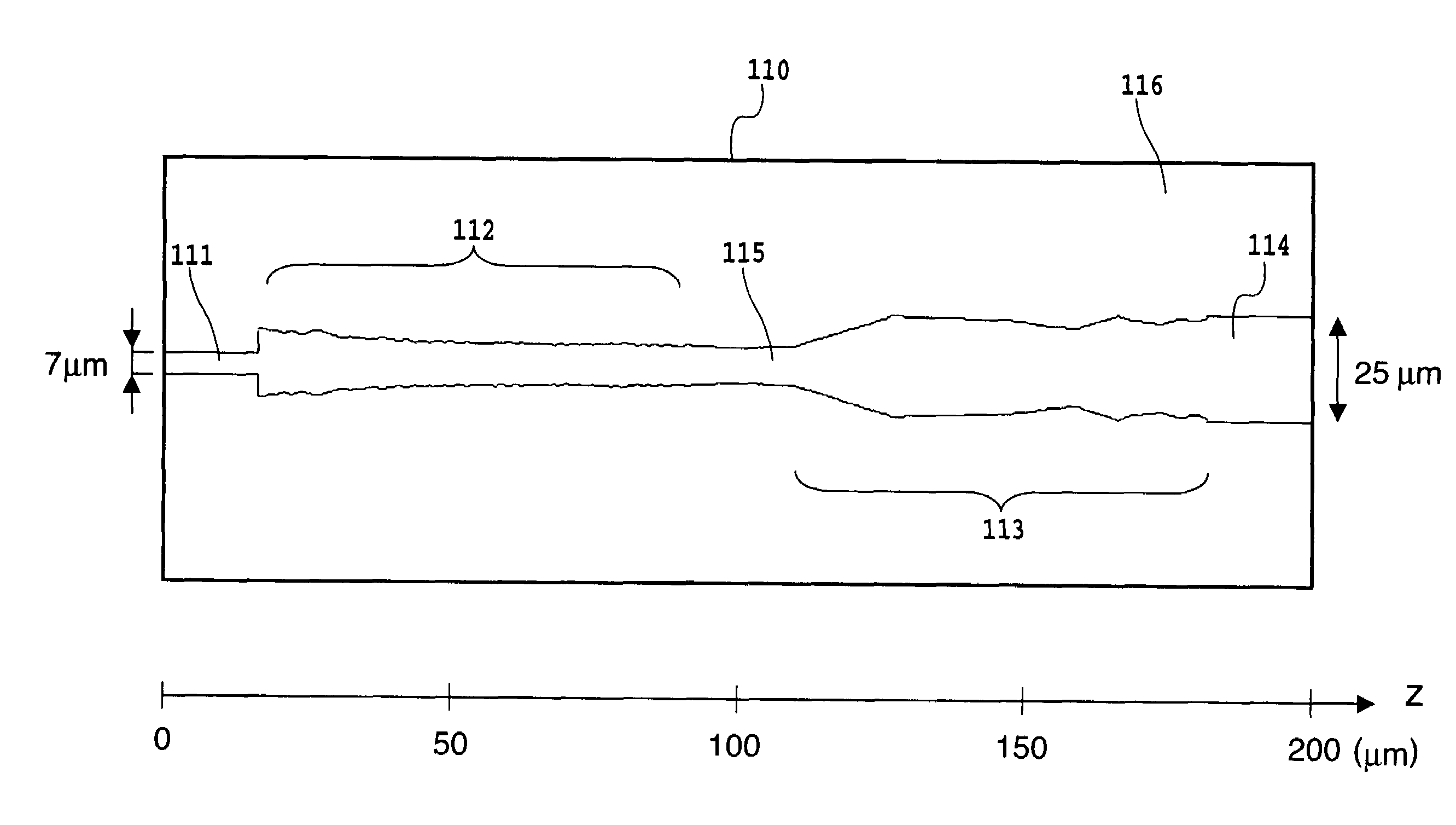

Planar Lightwave Circuit, Design Method for Wave Propagation Circuit, and Computer Program

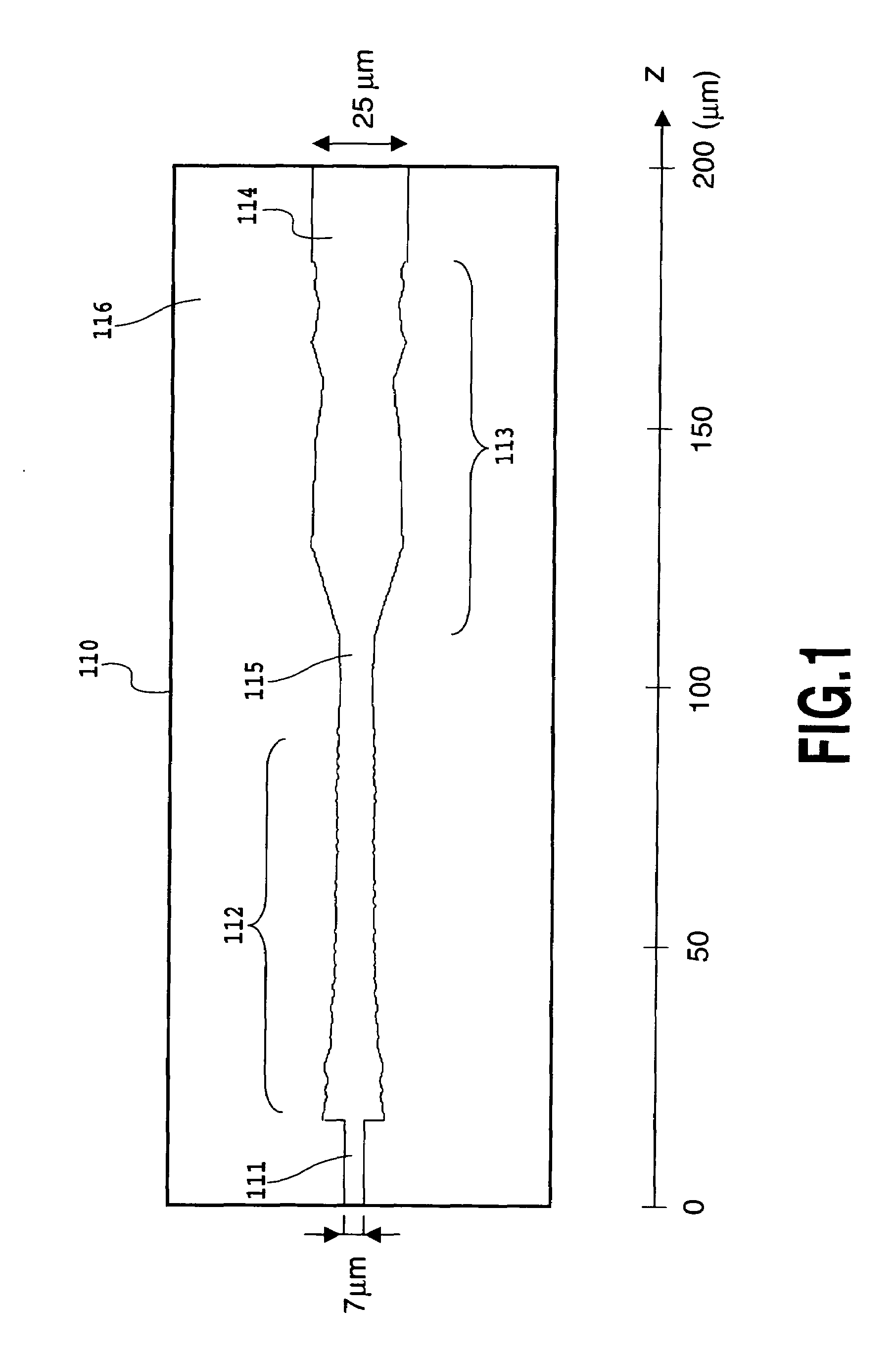

ActiveUS20080273829A1Reduce lossEasy to makeCoupling light guidesOptical waveguide light guideRadiation modeSignal light

A planar lightwave circuit is provided which can be easily fabricated by an existing planar-lightwave-circuit fabrication process, which can lower the propagation loss of signal light and which can convert inputted signal light so as to derive desired signal light. A planar lightwave circuit having a core and a clad which are formed on a substrate, has input optical waveguide(s) (111) which inputs signal light, mode coupling part (112) for coupling a fundamental mode of the inputted signal light to a higher-order mode and / or a radiation mode, or mode re-coupling part (113) for re-coupling the higher-order mode and / or the radiation mode to the fundamental mode, and output optical waveguide(s) (114) which outputs signal light. The mode coupling part or the mode re-coupling part is an optical waveguide which has core width and / or height varied continuously.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Raman signal detecting and analyzing system and method

The invention discloses a Raman signal detecting and analyzing system and method. The method comprises the following steps of: sending exciting light to a sample so as to generate a Raman signal; modulating the Raman signal through a plurality of optical filters and modulators, wherein the modulated Raman signal comprises two orthogonal components; calculating the intensity of the two components according to the first harmonic wave of the modulated Raman signal; and then determining the content of a specified analyte in the sample according to the ratio of the intensity of the two components.

Owner:HONG KONG APPLIED SCI & TECH RES INST

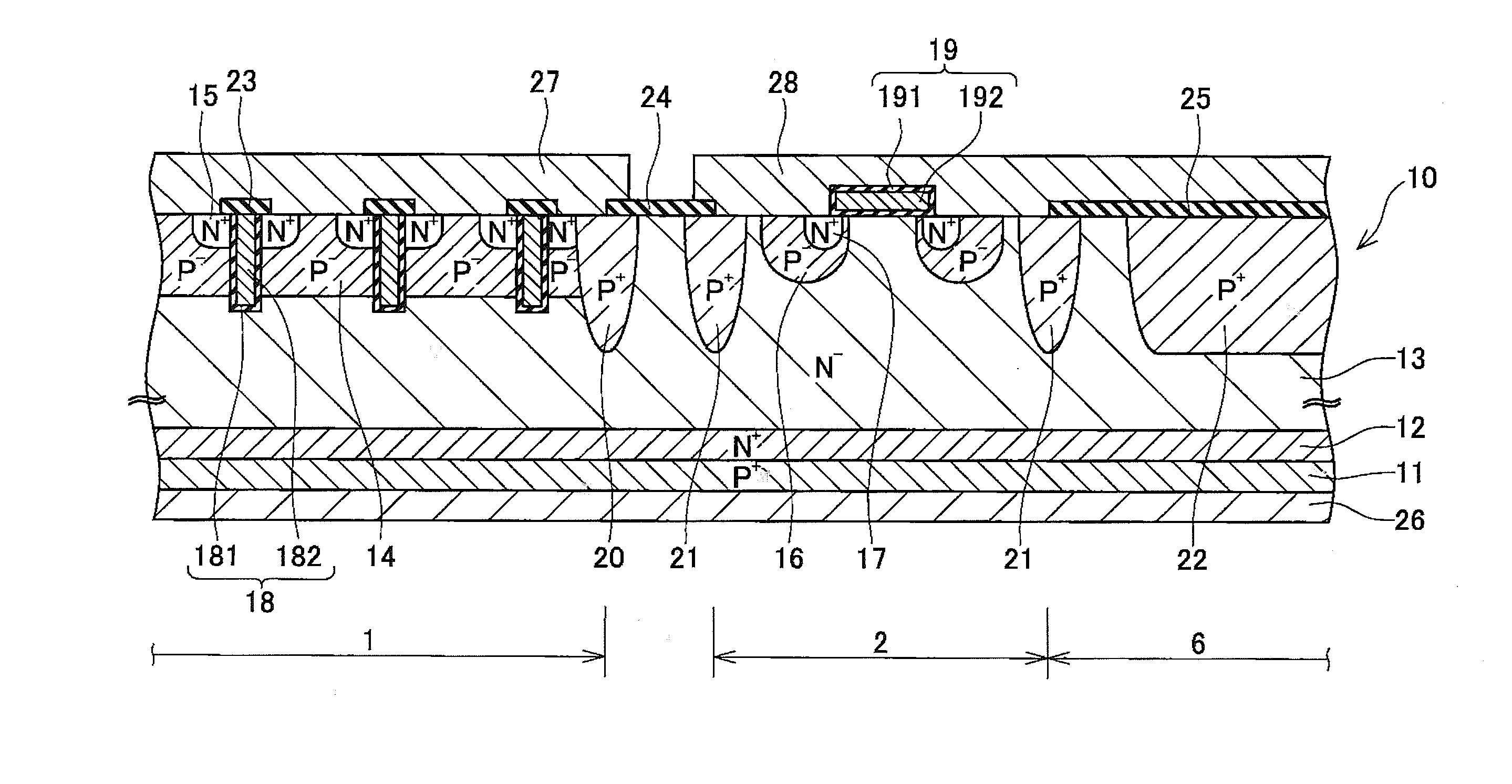

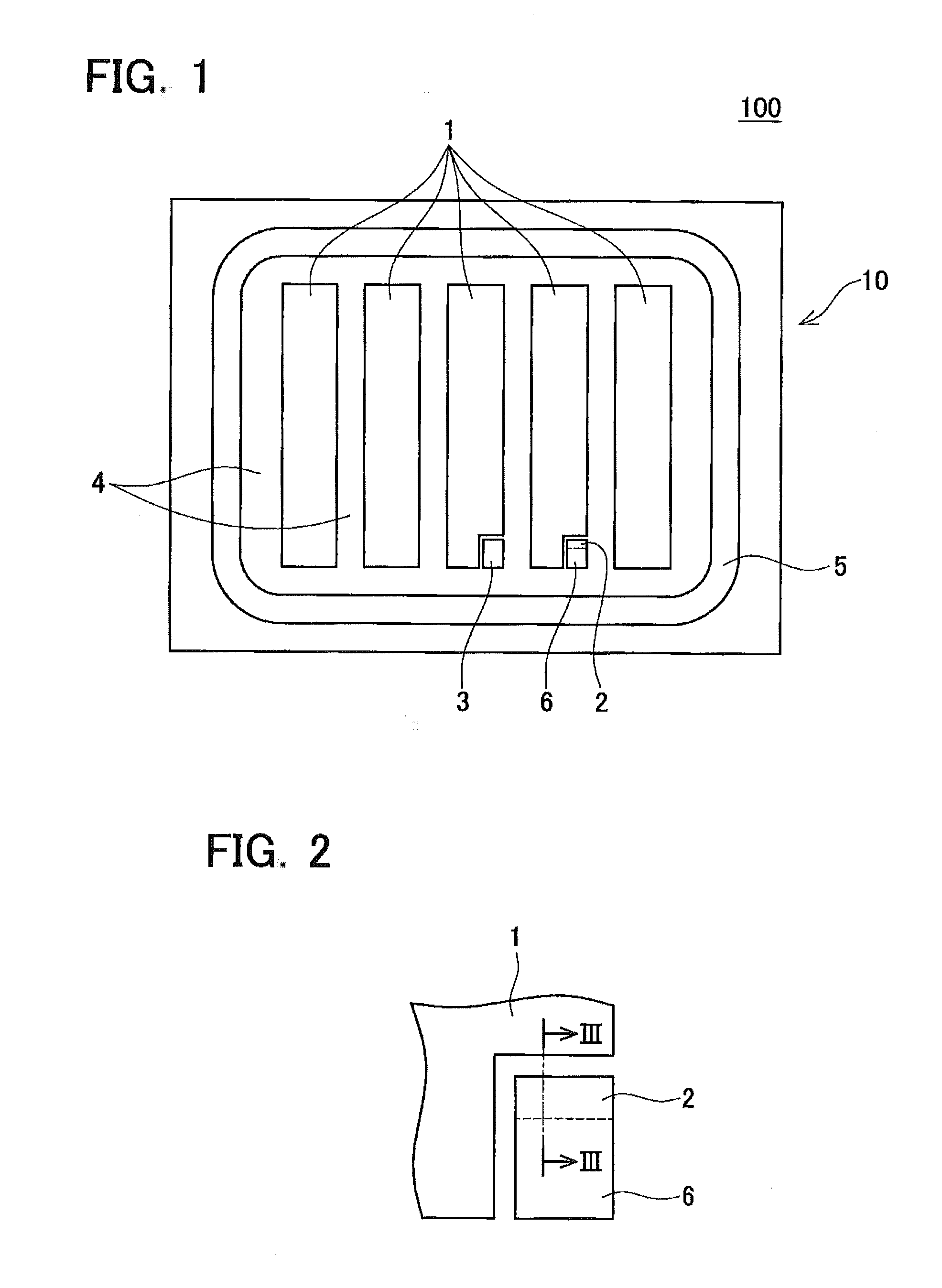

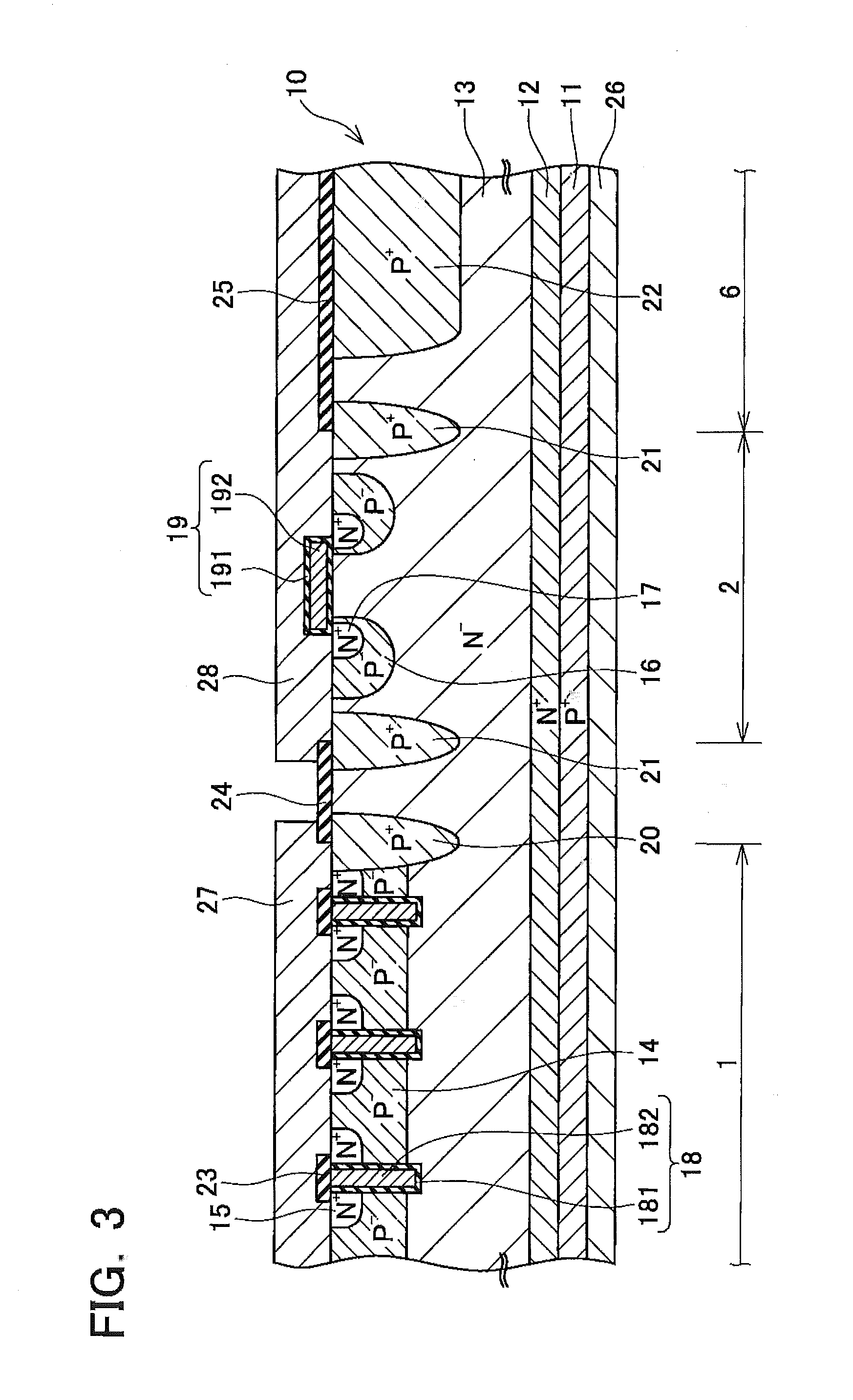

Semiconductor device

ActiveUS20120007139A1Suppress mutationAccurate detectionTransistorSolid-state devicesPower semiconductor deviceDevice material

The present teachings provides a bipolar semiconductor device comprising: a main cell region consisting of a trench gate type element region; and a sense cell region including a planar gate type element region.

Owner:TOYOTA JIDOSHA KK

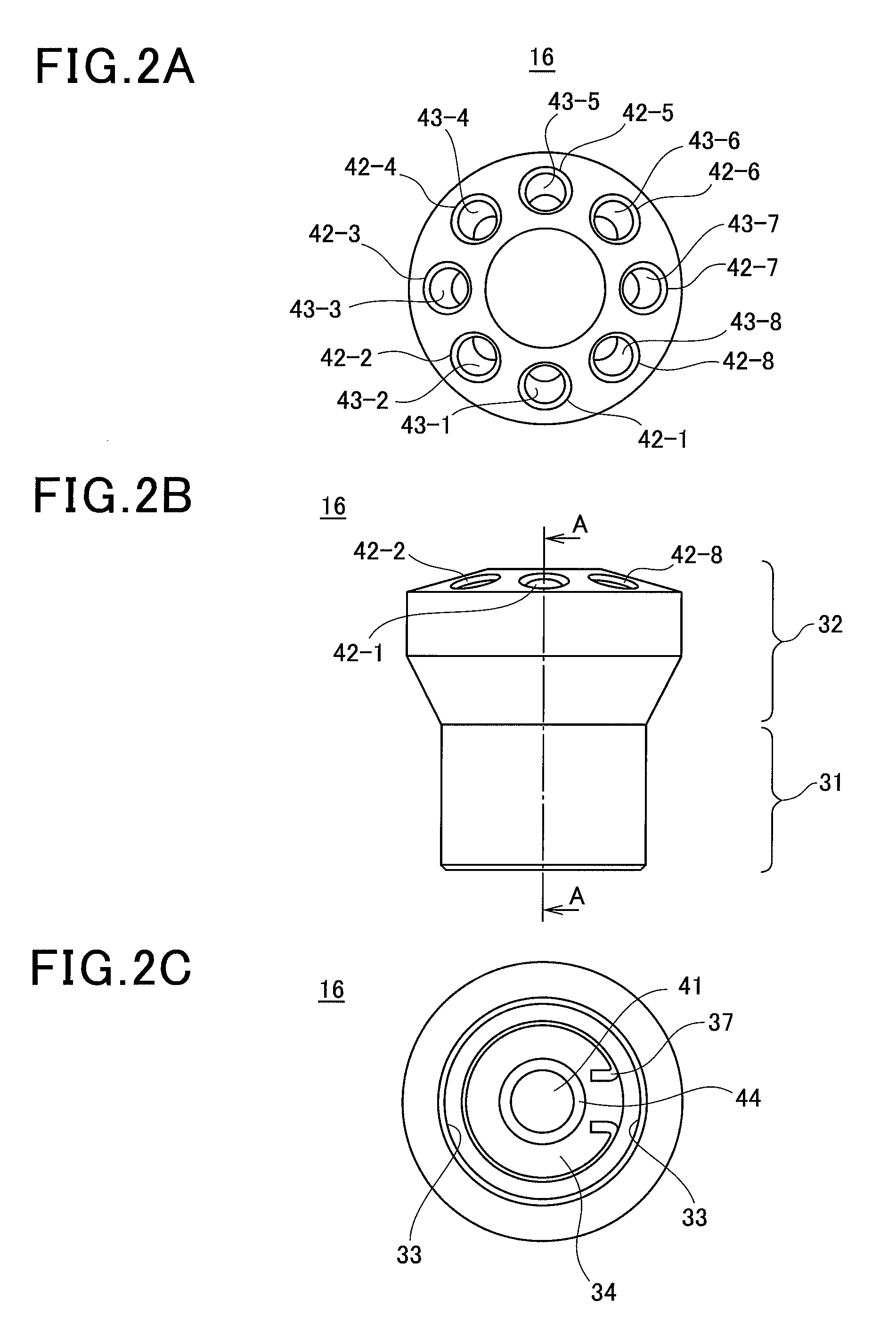

Refrigerant distributor

InactiveUS20100293980A1Reliably urgeReduce noiseDomestic cooling apparatusPipeline expansion-compensationRefrigerant distributionEngineering

A conical-shaped distributing member 41 is disposed in a refrigerant distributing portion 32 distributing refrigerant, an orifice 34 is disposed by being positioned at an axis 16X of the conical body, the orifice 34 is held by a stop ring 37, and the stop ring 37 urges the orifice 34 in a flow direction of the refrigerant.

Owner:SANYO ELECTRIC CO LTD

Method for synthesizing sulfur-containing silane coupling agent from sodium polysulfide

ActiveCN102875587AStable ratioImprove qualityGroup 4/14 element organic compoundsSilanesReaction temperature

The invention relates to a method for synthesizing a sulfur-containing silane coupling agent from sodium polysulfide, belonging to the technical field of organic chemistry. The method comprises the following steps: reacting sodium hydroxide and sulfur to prepare sodium polysulfide, and synthesizing the sulfur-containing silane coupling agent from the sodium polysulfide. The invention solves the problems of great product quality fluctuation and heavy environmental pollution in the sulfur-containing silane in the production of sodium polysulfide from sodium sulfide and sulfur, and the problem of high cost in the sodium polysulfide prepared from sodium metal and sulfur at present in China. Since the temperature is low in the whole reaction process, no sulfur is volatilized, no sulfur dioxide (SO2) gas due to contact oxidation of air is generated, thus, the environmental pollution is slight, and the produced sulfur-containing silane product has stable sulfur distribution. The invention has the advantages of low cost, high control stability, stable product quality and light color.

Owner:JINGZHOU JIANGHAN FINE CHEM

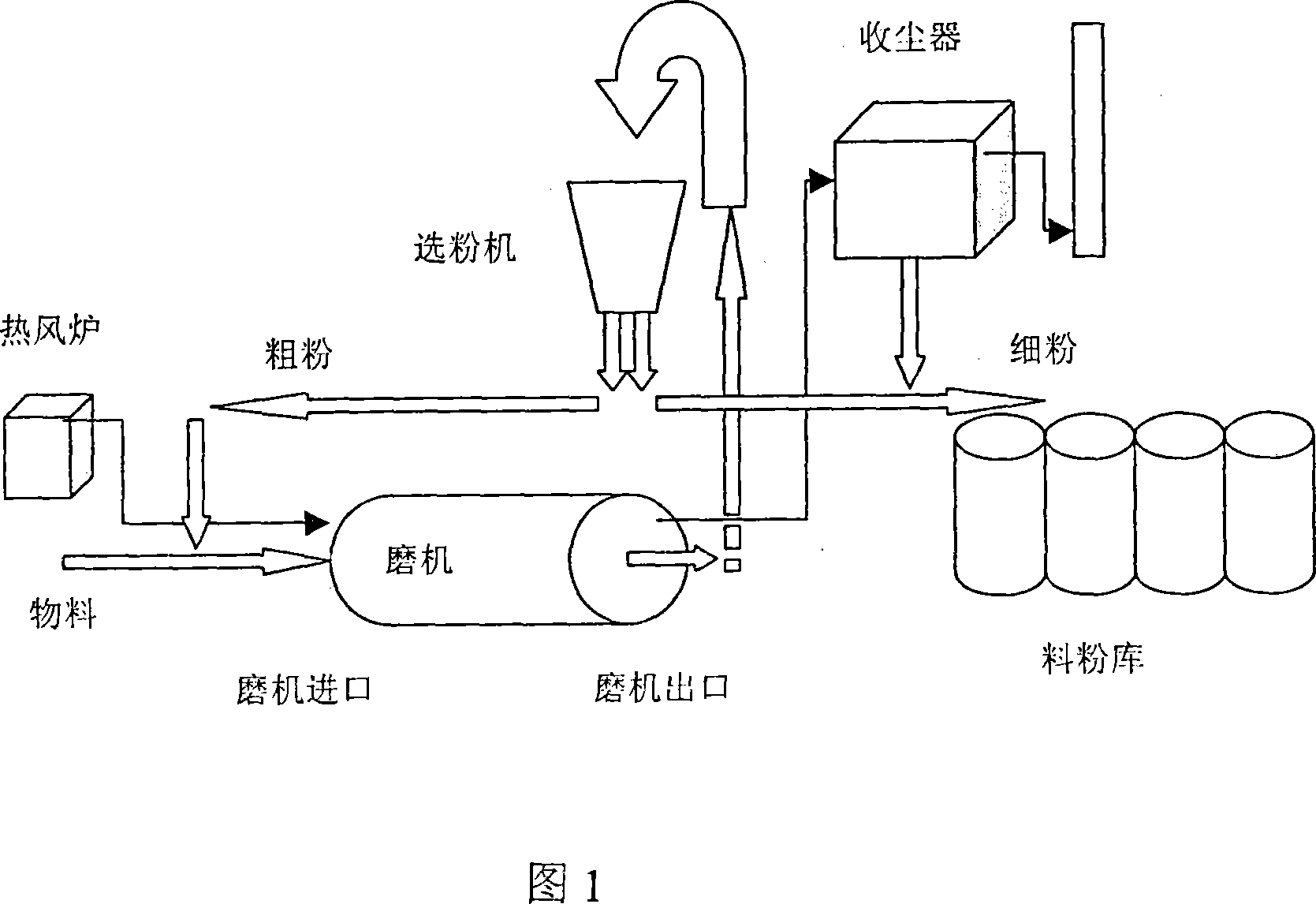

Cement raw meal mill automatic control method and control device

InactiveCN101125741ASimple structureGuaranteed uptimeCement productionProgramme control in sequence/logic controllersFrequency changerAutomatic control

The invention relates to an automatic control method of a mill during the production process of cement and a device thereof. The method is that: a program controller is adopted to control a plurality of links of material powder preparation; a milling sound monitoring instrument is used for monitoring the milling sound change during operation, a dust collector fan inverter is used for controlling the rotating speed, instrument used for detecting the wind pressure in the mill outputs wind pressure signals to the program controller, a controller is used for controlling fan frequency conversion, an inverter is used by a powder-choosing machine for controlling the rotating speed of a rotor of the powder-choosing machine and the program controller adjusts the rotor frequency conversion of the powder-choosing machine according to the input data; a hot blast stove is arranged in front of the mill to raise temperature in the mill and cause water content of the materials to be evaporated in the mill, a thermocouple is applied at the hot wind inlet in front of the mill to monitoring the temperature of the hot wind entering the mill and leading the temperature to rise to a standard that can evaporate water content of the materials in the mill. The invention has the advantages of simple structure, reliable operation, high testing precision, the running of the mill being timely and accurately monitored by operators in a control chamber, thus realizing manual monitoring, reducing labor intensity of workers, increasing output and reducing power consumption.

Owner:缪建通

Polyamide, synthesis method and application thereof, and polyamide product

The invention discloses a polyamide, a synthesis method and application thereof, and a polyamide product. The synthesis method comprises the following steps: feeding: proportionally adding dibasic acid monomer, diamine monomer and other reaction assistants into a reaction kettle; charging shielding gas into the reaction kettle until the pressure in the reaction kettle is 0.2-1.0 MPa, wherein the shielding gas contains 60-100 vol% of CO2; heating the reaction kettle to perform prepolymerization reaction on the mixture in the reaction kettle, discharging after the prepolymerization reaction is finished, drying the prepolymerization product, and carrying out solid-phase tackification to obtain the polyamide. The terminal amino content and terminal carboxyl content in the polyamide prepared by the synthesis method are low. The polyamide disclosed by the invention is applicable to a manufacturing material of electric and electronic equipment, automobile part, office supply or home supply. The invention also discloses a manufacturing material of electric and electronic equipment, automobile part, office supply or home supply.

Owner:KINGFA SCI & TECH CO LTD +2

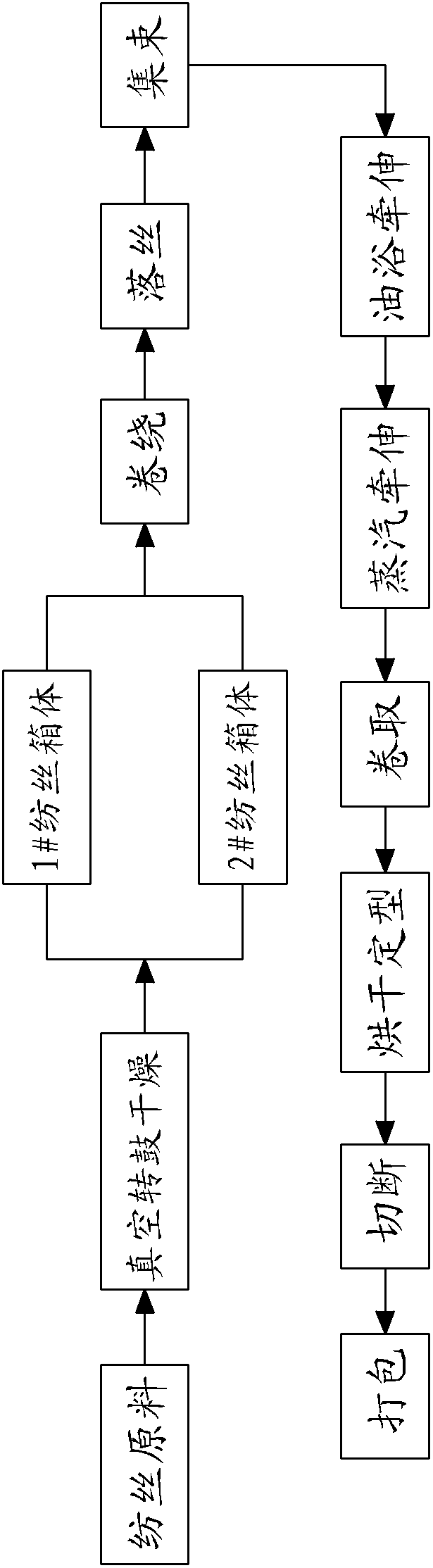

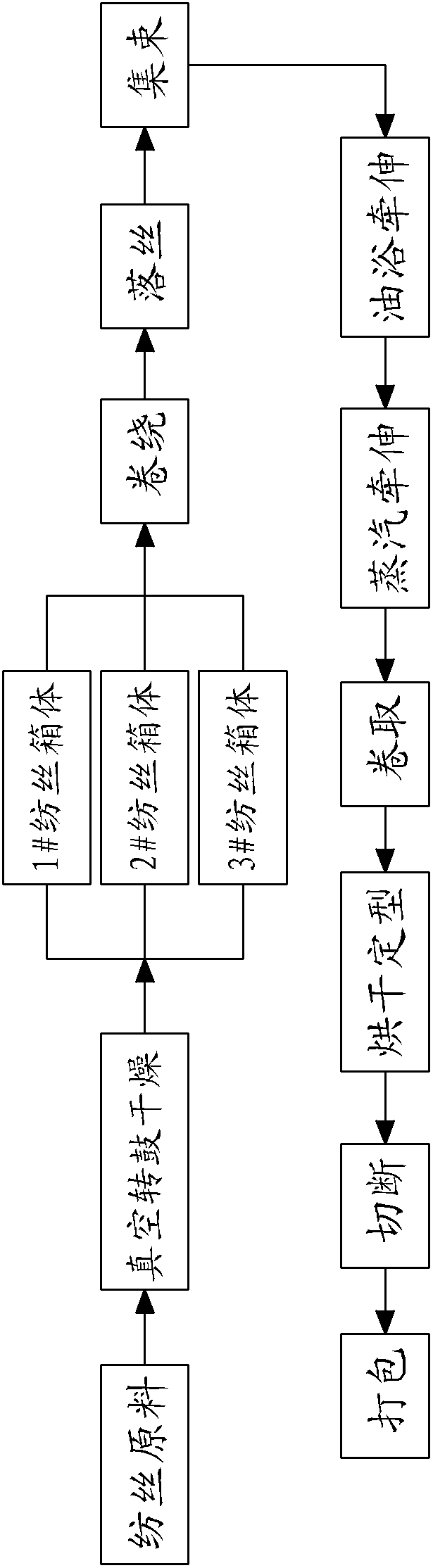

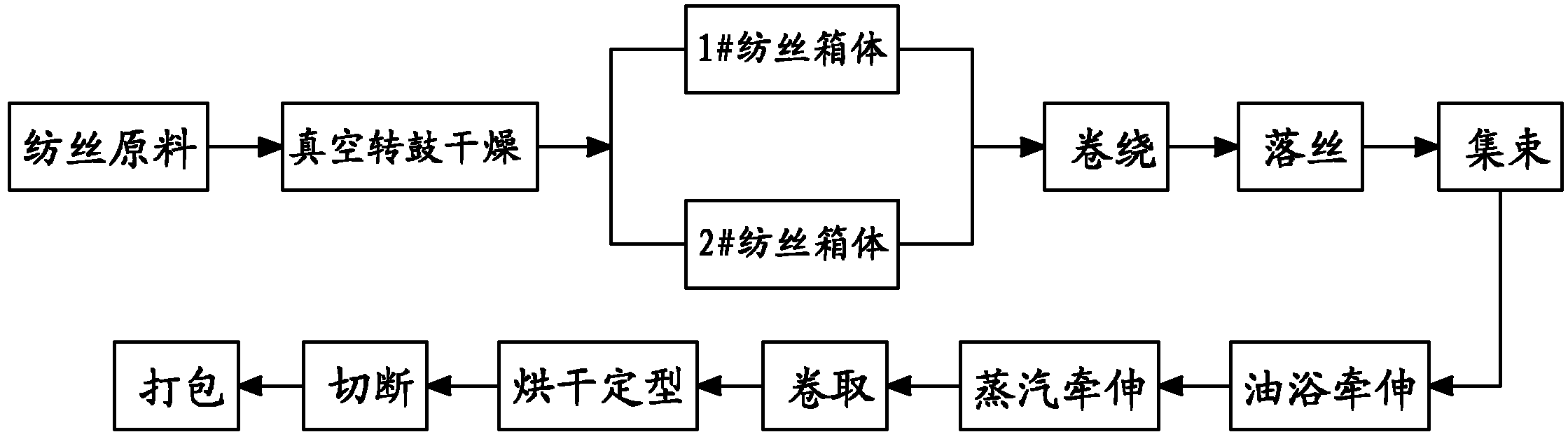

Method for preparing mixed regenerated polyester fibers special for non-woven material

ActiveCN102505177AStable ratioWell mixedArtificial filament heat treatmentMonocomponent polyesters artificial filamentPolyesterState of art

The invention discloses a method for preparing mixed regenerated polyester fibers special for a non-woven material. The method comprises the following steps of: mixing spinning raw materials such as bottle flakes, a chemical fiber friction material, a bubble material and a fluorescent brightener, drying by using a vacuum drum dryer, and performing melt spinning to obtain as-spun fibers with two or more kinds of fineness through two or more spinning box bodies of melt spinning equipment; winding, doffing and bundling the as-spun fibers in turn; drawing in an oil bath, drawing in steam, and reeling; and performing heat setting to prepare the mixed regenerated polyester fibers special for the non-woven material. Compared with the prior art, the method has the advantages that: the fibers produced by the method have two or more kinds of fineness, the raw materials are stably proportioned and uniformly mixed, the non-woven material can have good opening and mixing effects, and the technical index of the non-woven material can be effectively improved. The mixed fibers can be used for producing different styles of non-woven materials, work efficiency is improved, and production cost is reduced.

Owner:福建鑫华股份有限公司

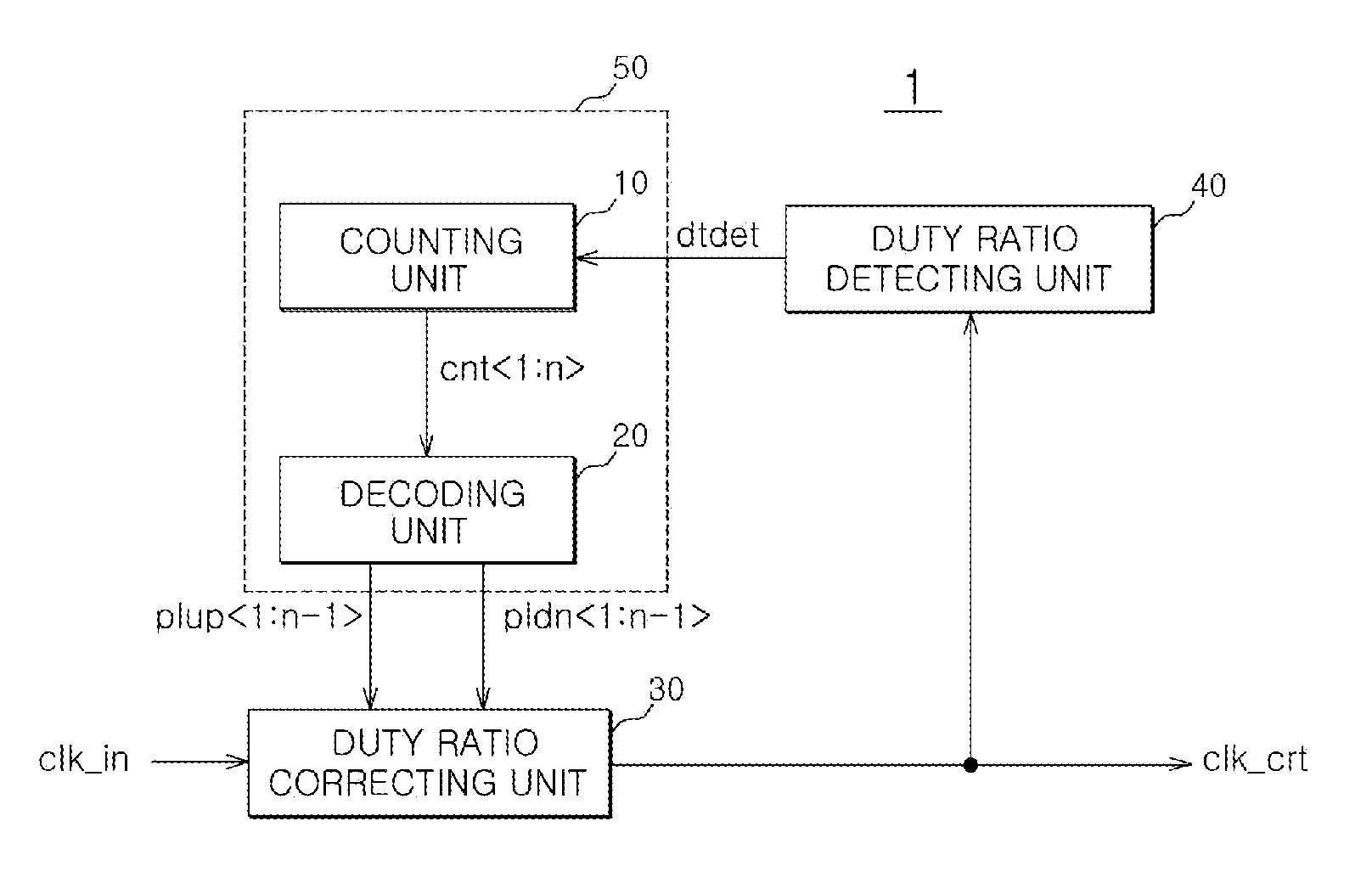

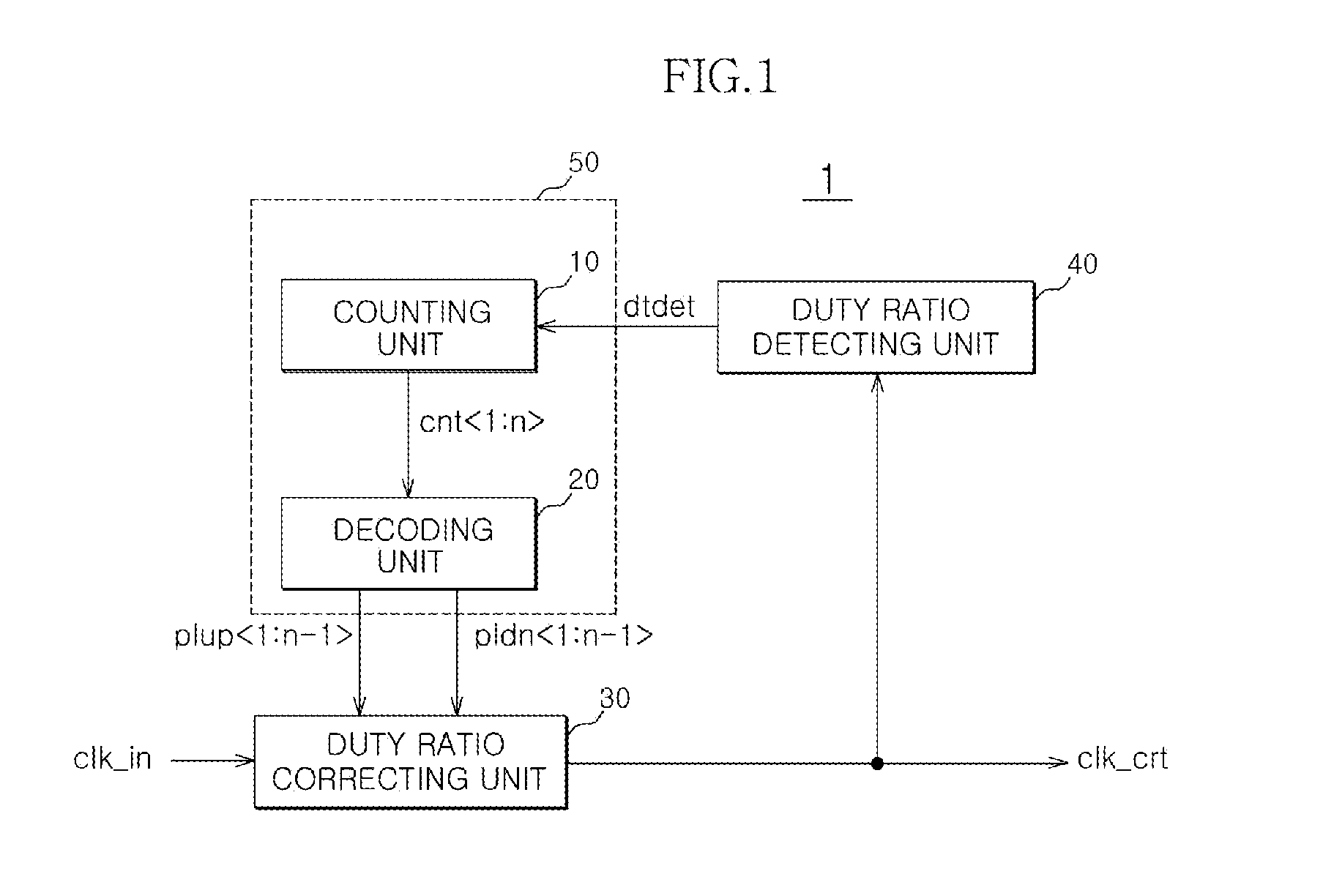

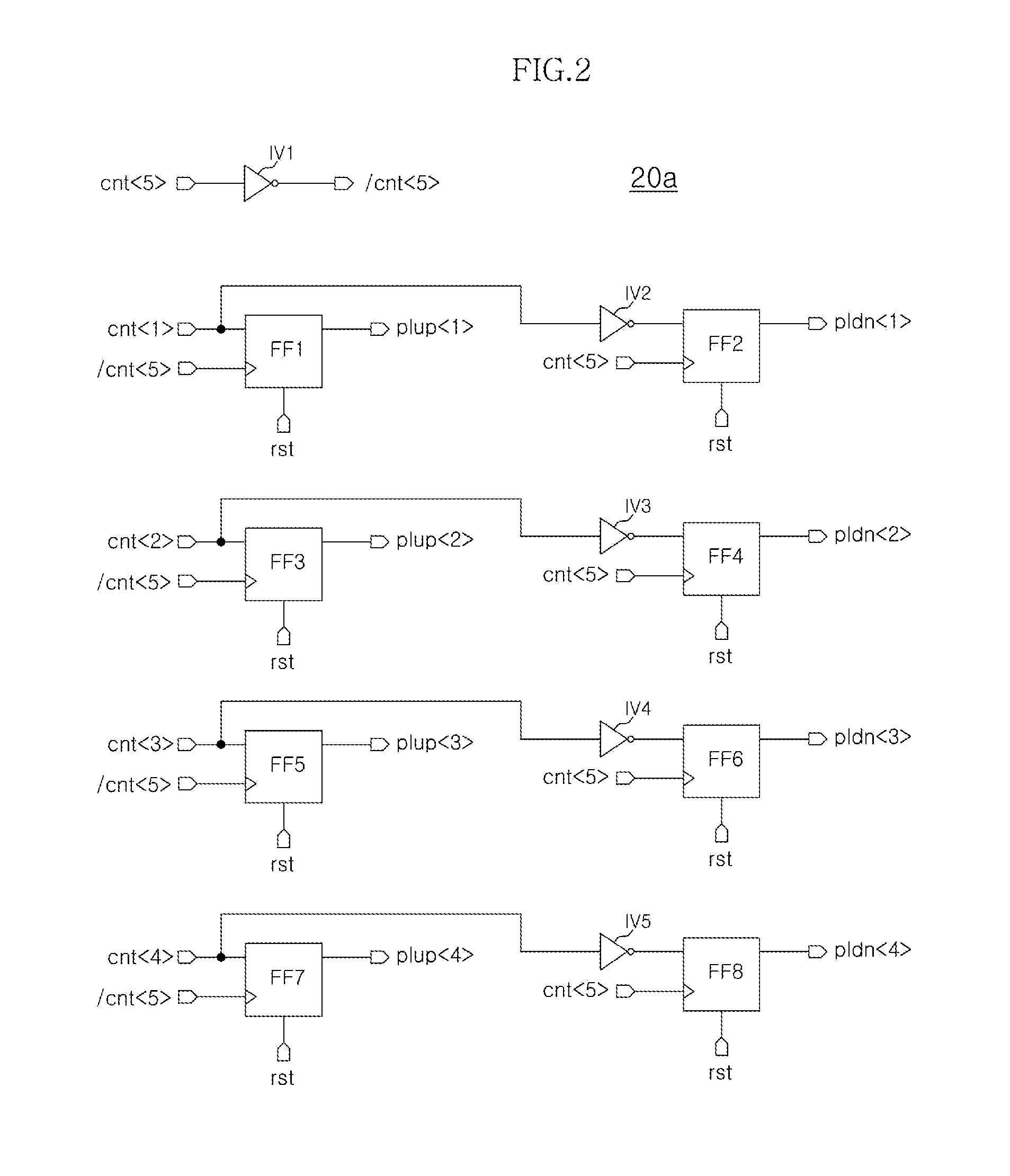

Duty cycle correcting circuit and method of correcting a duty cycle

ActiveUS20090295446A1Enhanced signalStable ratioPulse automatic controlDigital storageControl signalEngineering

A duty cycle correcting circuit includes a duty ratio control unit configured to alternately change logical values of a plurality of bits of a pull-up control signal and a plurality of bits of a pull-down control signal in response to a duty ratio detection signal, a duty ratio correcting unit configured to adjust driving abilities of a first driver and a second driver in response to the plurality of bits of the pull-up control signal and the plurality of bits of the pull-down control signal to output a correction clock signal, and a duty ratio detecting unit configured to detect a duty ratio of the correction clock to generate the duty ratio detection signal.

Owner:SK HYNIX INC

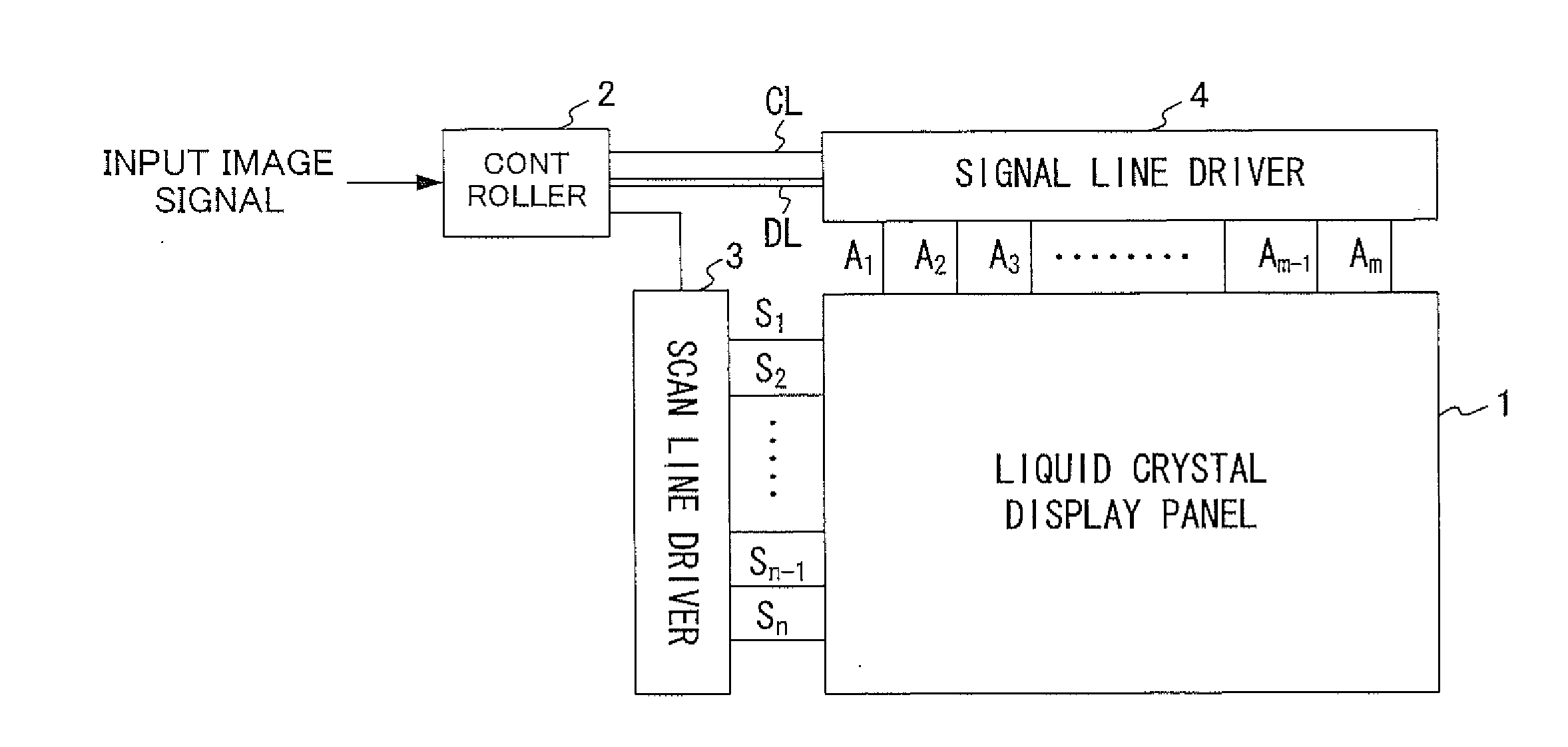

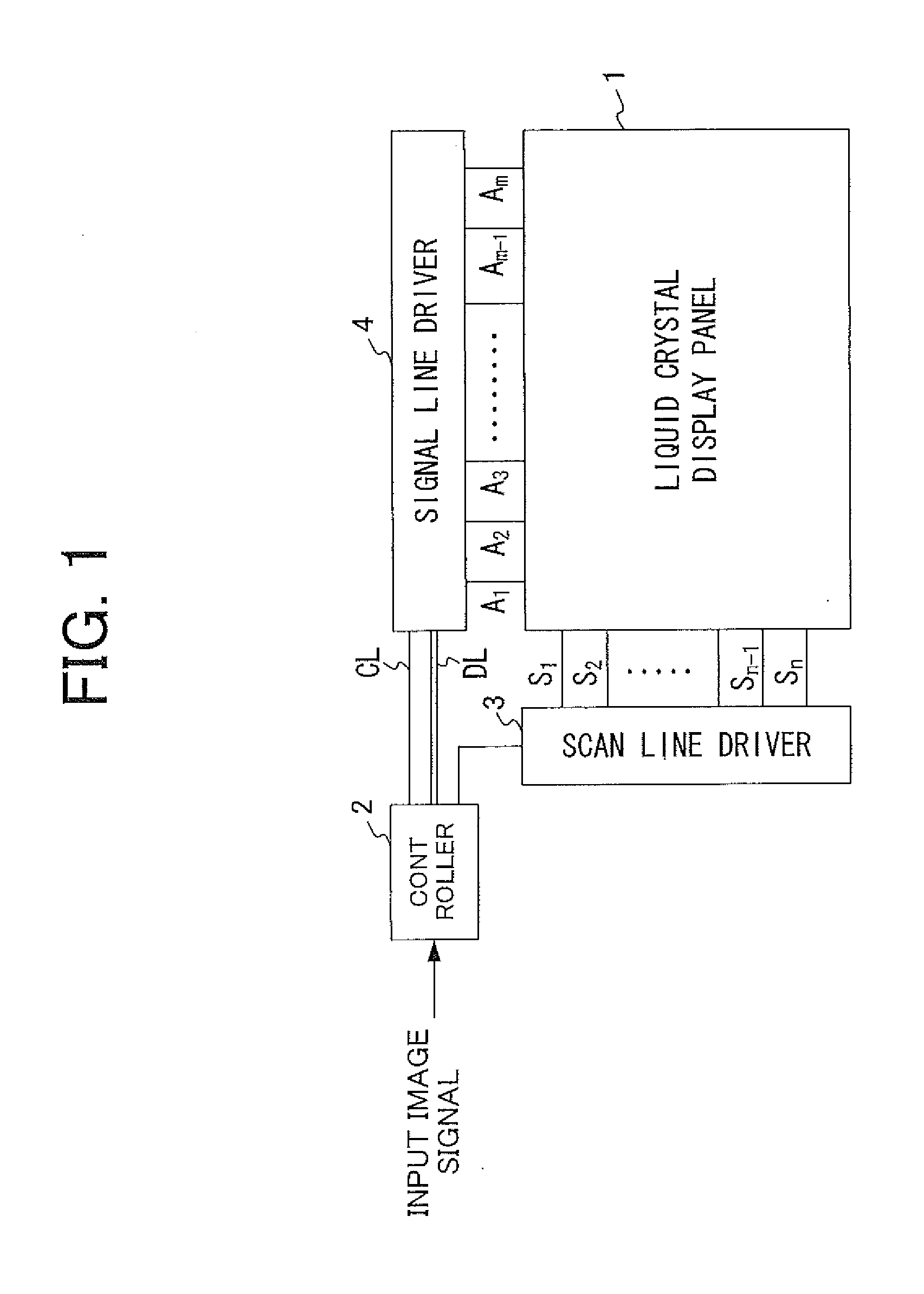

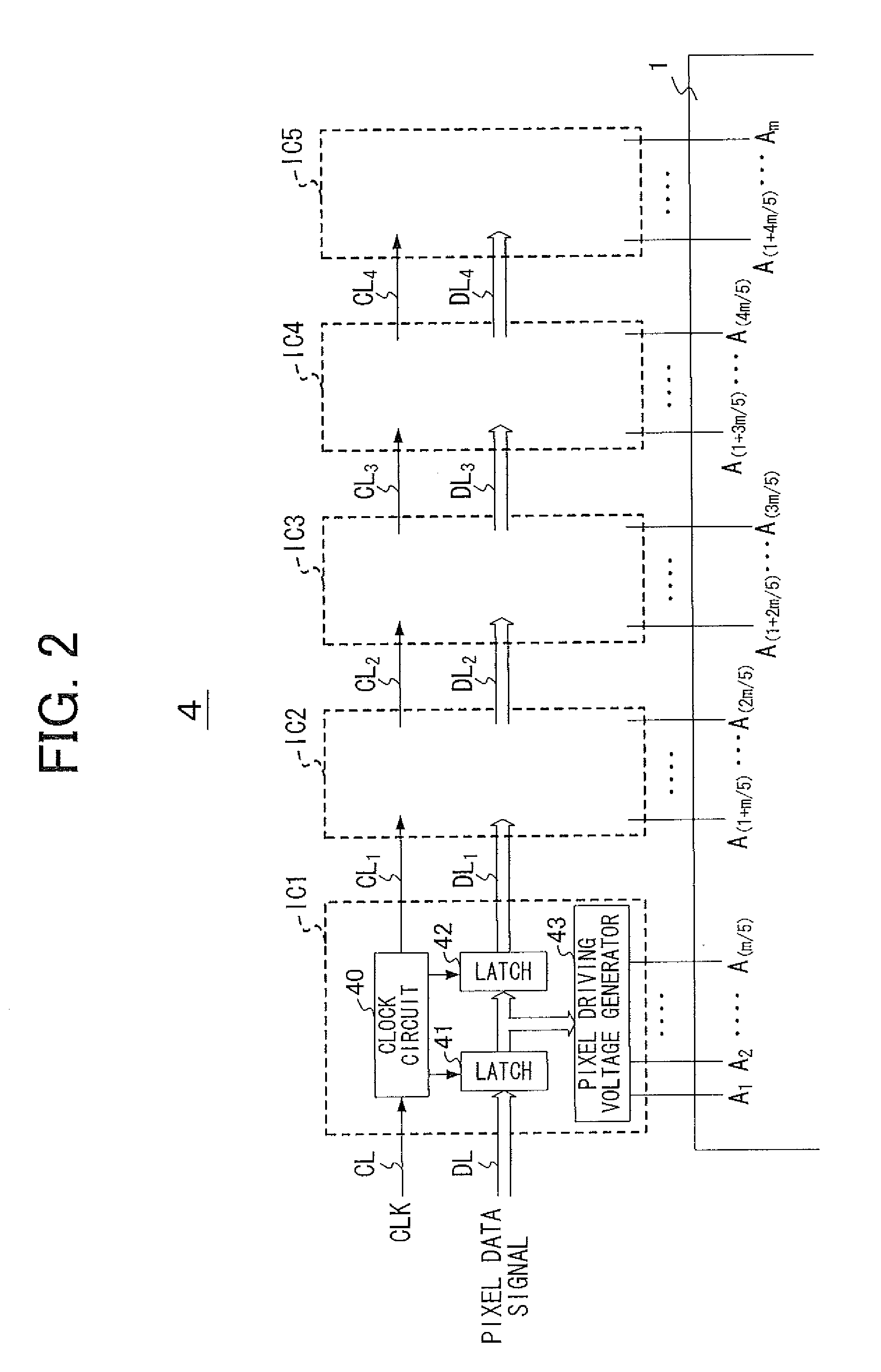

Display panel driving device

ActiveUS20120081349A1Increase power consumptionIncrease consumptionCathode-ray tube indicatorsInput/output processes for data processingEngineeringImage signal

A display panel driving device has a signal line driver. The signal line driver applies a pixel driving voltage based on an input image signal to each signal line of a display panel at a timing corresponding to a clock signal. The signal line driver is divided into a plurality of driver chips connected in cascade by the clock line. The display panel driving device supplies a clock signal through the driver chips. The duty ratio of the clock signal is stabilized when the clock signal passes through the driver chips, without leading to an increase in power consumption and in manufacturing costs.

Owner:LAPIS SEMICON CO LTD

Pharmaceutical bottom fertilizer granule for preventing cotton sprout plant diseases and insect pests

InactiveCN101016219AGood insecticidal effectImprove nutritional conditionsBiocideAnimal repellantsAdjuvantPotassium

The invention discloses a drug substrate fertilizer particle agent to prevent cotton seeding pest, which is characterized by the following: adopting nitrogen, phosphor, potassium or composite fertilizer as carrier; allocating imidacloprid, thiram, triazole ketone and adjuvant according to certain proportion; making the drug particle agent; modifying the nourishing condition and seeding growing environment; reinforcing pest-proof and growing property.

Owner:HUBEI NONGBEI CHEM IND

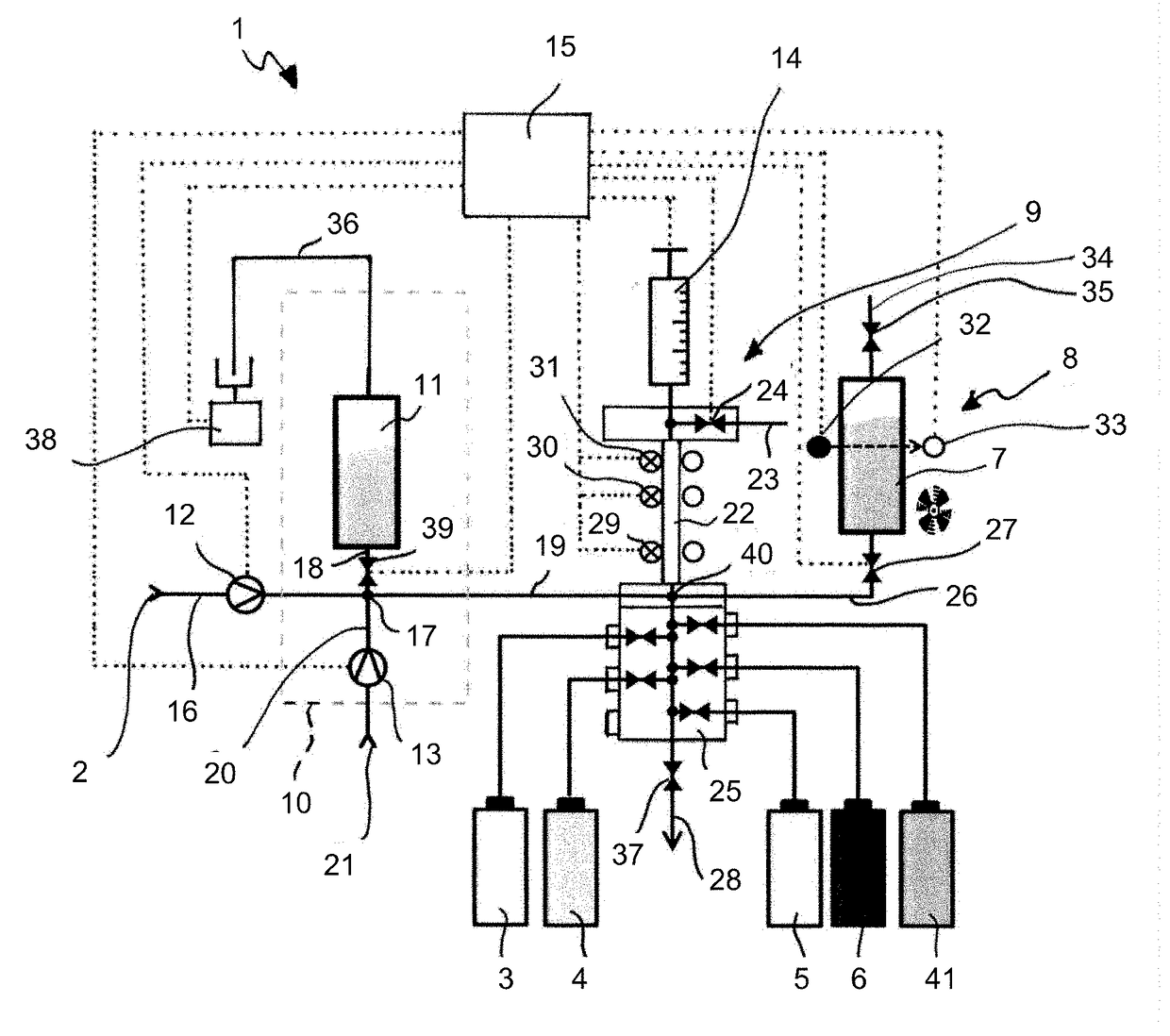

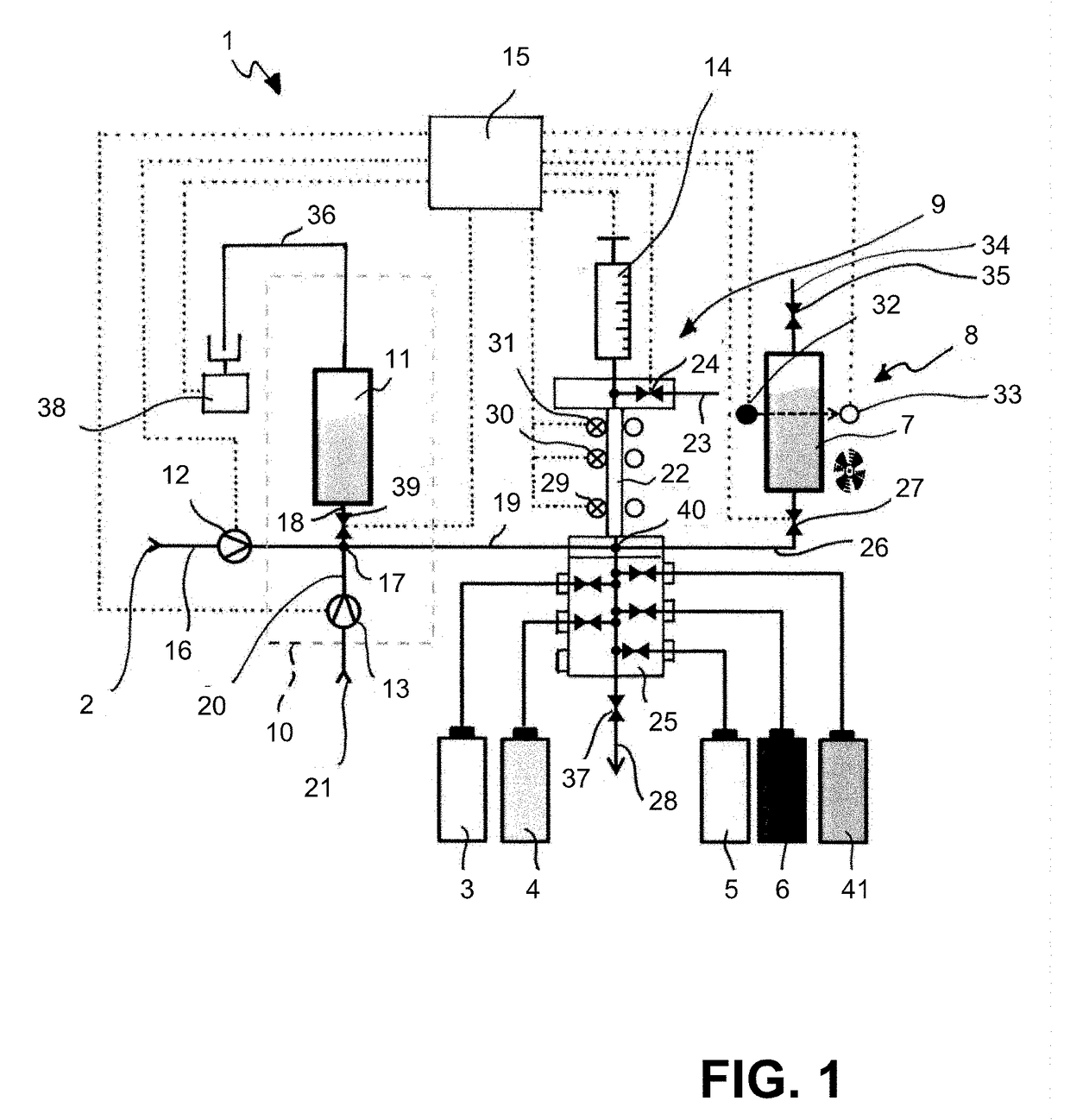

Automatic analyzer and method

ActiveUS20170285054A1Stable dilution ratioStable ratioMaterial analysisPreparing sample for investigationControl systemBiomedical engineering

The present disclosure relates to an automatic analyzer for determining a parameter of a sample fluid, including a dosing device comprising at least one dosing chamber, a first fluid flow path connecting a sample receiving vessel to the dosing chamber via a first pump, a tank containing a dilution medium, a second fluid flow path connecting the tank to the dosing chamber via a second pump, a measuring cell in communication with the dosing chamber via a third fluid flow path via a third pump, and a measuring and control system connected to and configured to control the pumps, wherein the first, second, and third fluid flow paths can selectively be blocked or unblocked by at least one valve unit and the measuring and control system is configured to control the at least one valve unit to block or unblock the first, second, and third flow paths.

Owner:ENDRESSHAUSER CONDUCTA GMBHCO

Method for preparing and using shift drive agent of reversed phase latex of polyacrylamide

InactiveCN101003726AIncrease concentrationGood dispersionDrilling compositionEmulsionPolymer science

This invention discloses a method for preparing polyacrylamide reverse phase emulsion profile control agent. The method comprises: preparing organic crosslinker, preparing polyacrylamide reverse phase emulsion, and preparing polyacrylamide reverse phase emulsion profile control agent. When used, 0.8-2% polyacrylamide reverse phase emulsion profile control agent is mixed with 400-3500 mg / L phase-reverse agent and oil field wastewater at 30-45 deg.C, and filled into the oil layer through a water-injection well. The phase-reverse gelation time is 2-15 days, and the gel viscosity is higher than 5000 MPa.s.

Owner:中国石化股份胜利油田分公司孤岛采油厂

Solution bubble removal device and coating machine

InactiveCN107754381AImprove efficiencyStable ratioLiquid surface applicatorsLiquid degasification regulation/controlEngineeringExhaust pipe

The invention provides a bubble removal device for a polyimide solution. The device comprises a first tank, a second tank and an ultrasonic generator, wherein the second tank is arranged in the firsttank; the ultrasonic generator is arranged on the first tank; the volume of the second tank is smaller than that of the first tank; a first containing chamber and a second containing chamber which arenot connected with each other are respectively formed in the first tank and the second tank; the first containing chamber is filled with water; the second containing chamber is filled with a solution; and a liquid outlet pipe, a liquid inlet pipe and an exhaust pipe communicated with the second containing chamber are respectively arranged on the second tank. The invention further provides a coating machine. The coating machine comprises the bubble removal device for the polyimide solution, wherein the liquid outlet pipe is connected with a solution pipeline of a coating nozzle; and the liquidinlet pipe is connected with a storage tank. Compared with the prior art, the bubble removal device for the polyimide solution is capable of removing bubbles in the polyimide solution, so that the bubble removal time can be shortened, and time needed by the process is greatly reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

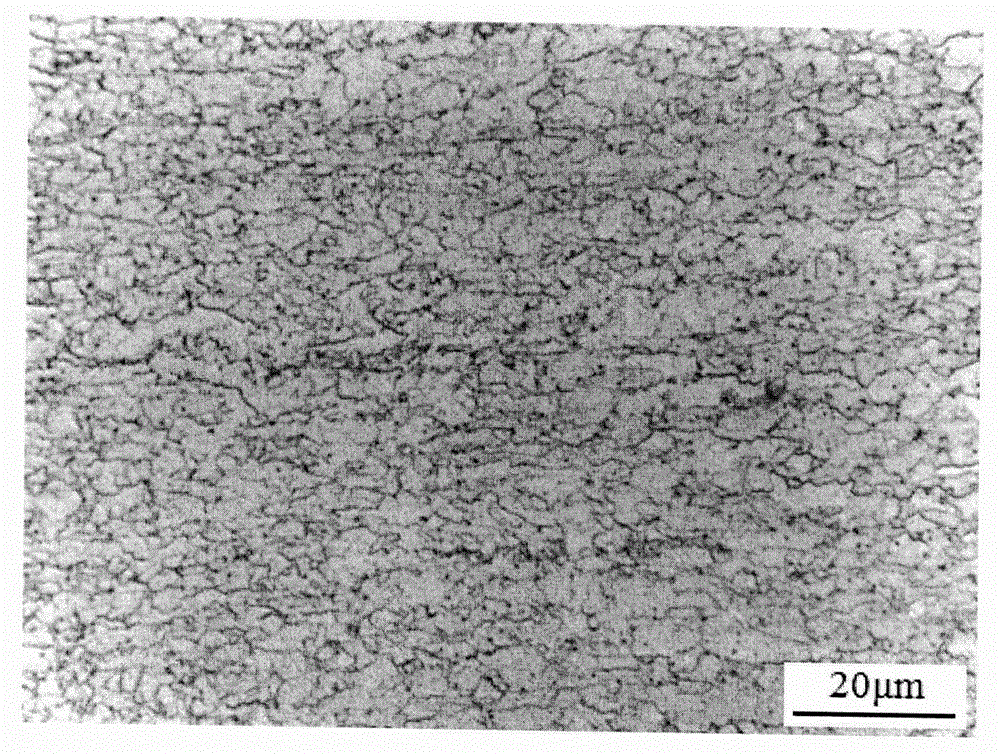

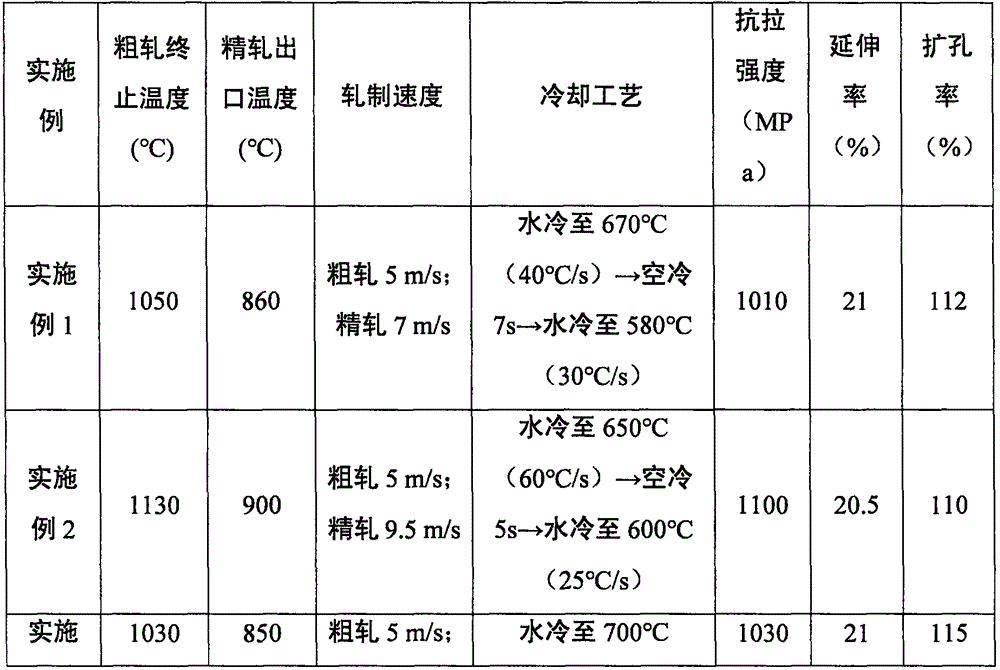

Hot-rolled pickled steel strip with high broaching performance and production method thereof

The invention discloses a hot-rolled pickled steel strip with high broaching performance and a production method thereof, and belongs to the technical field of steelmaking. The hot-rolled pickled steel strip comprises the following chemical components by mass percent: 0.03% to 0.1% of C, 0.1% or fewer of Si, 0.5% to 1.5% of Mn, 0.02% or fewer of P, 0.006% of fewer of S, 0.05% or fewer of Nb, 0.1% or fewer of Ti, 0.15% or fewer of Mo and 0.1% to 0.4% of Re, and the balance being Fe and unavoidable impurities. An internal microscopic structure of the hot-rolled pickled steel strip is ferrite. The production method comprises the steps of molten iron pretreatment, smelting, casting, hot rolling, cooling, reeling, levelling and pickling, a three-stage cooling mode of water cooling, air cooling and water cooling is adopted, and constant-speed rolling is controlled. According to the obtained hot-rolled pickled steel strip, the tensile strength is larger than or equal to 980 MPa, the broaching rate lambda is larger than or equal to 110%, the elongation is larger than or equal to 20%, and the surface quality of the steel strip is excellent.

Owner:SHOUGANG CORPORATION +1

Deodorizing method through composite deodorant cooperated with washing deodorizing tower

ActiveCN105435279AInhibitionReduce generationGas treatmentDispersed particle separationDeodorantPulp and paper industry

The invention relates to the fields of deodorant application, and especially relates to a deodorizing method through a composite deodorant cooperated with a washing deodorizing tower. The method comprises preparing the deodorant, installing equipment, adding the deodorant, preparing a spraying liquid and spraying. The invention aims at providing the deodorizing method through the composite deodorant cooperated with the washing deodorizing tower. The efficient deodorant is prepared and is cooperated with the washing deodorizing tower for usage, cyclic spraying utilization of the deodorant is realized, and also the deodorant can be sprayed and form tiny particles, and the deodorant can be fully reacted with stink molecules, and thus extremely good deodorizing effect is reached, and also the usage amount of the deodorant can be furthest saved.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

MEMS probe card and method of manufacturing same

InactiveUS20110169517A1Stable resistance ratioEasy to useElectrical measurement instrument detailsManufacture of electrical instrumentsElectrical resistance and conductanceElectrical conductor

Provided are a micro-electro-mechanical system (MEMS) probe card and a method for manufacturing thereof. The MEMS probe card includes a substrate provide with a via hole filler conductor or a via hole filled with the resistor, the resistive film formed on the via hole and the substrate, the insulating film and the resistive film formed on the resistive film and the substrate, and the electrode formed on the substrate to cover the insulating filmAs such, by means of a micro-electro-mechanical system (MEMS) probe card and a method for manufacturing thereof, the precise resistance value can be obtained and used for the semiconductor IC and others in the event of significant change in power.

Owner:TOP ENG CO LTD

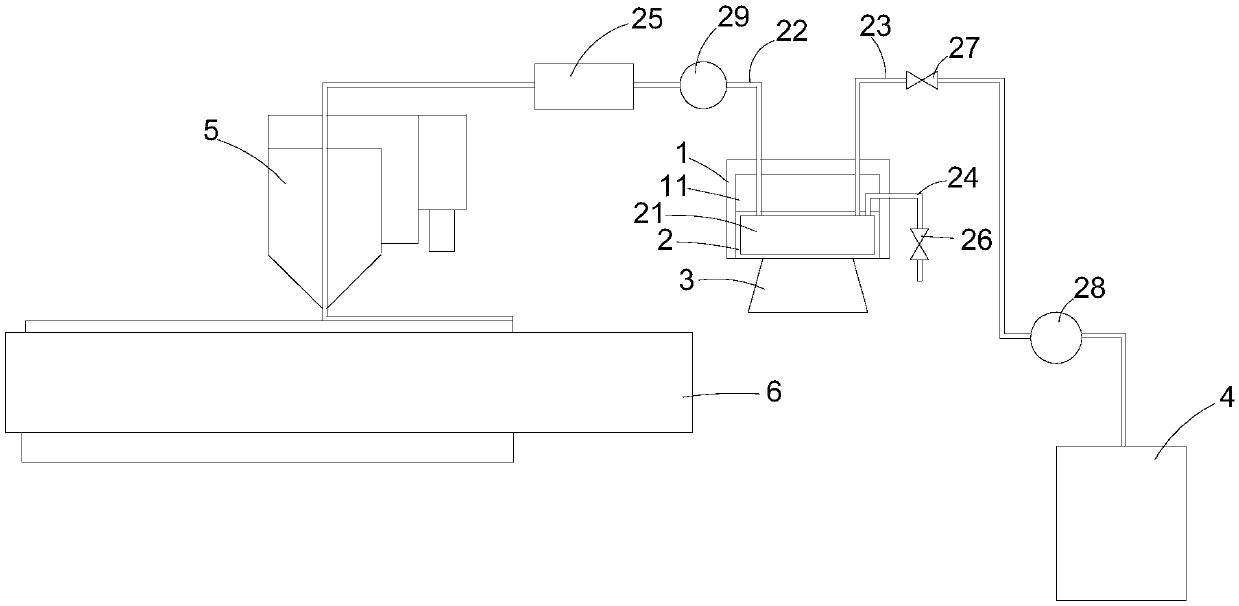

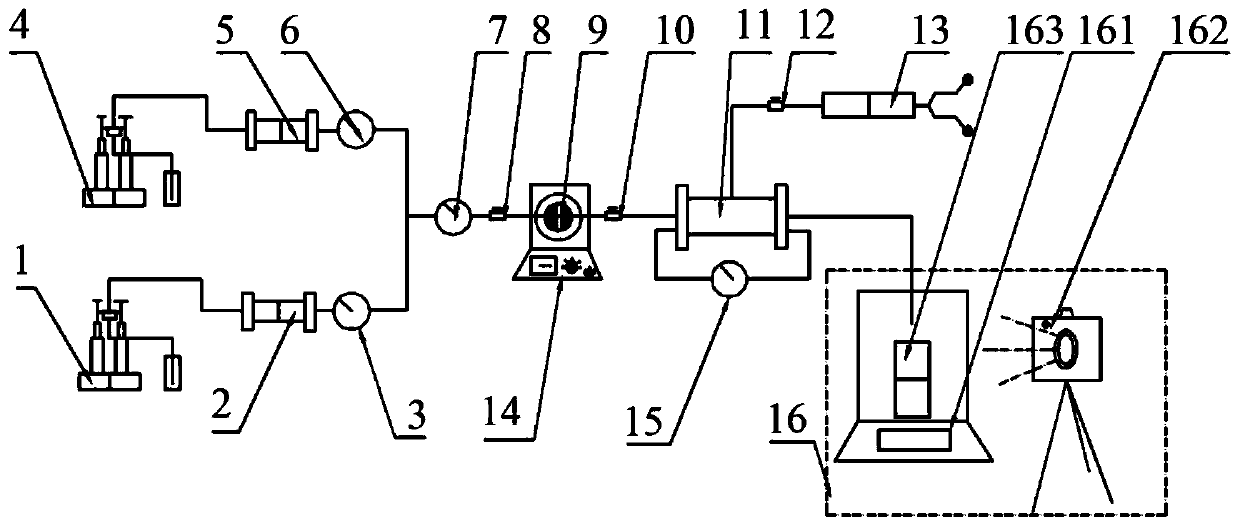

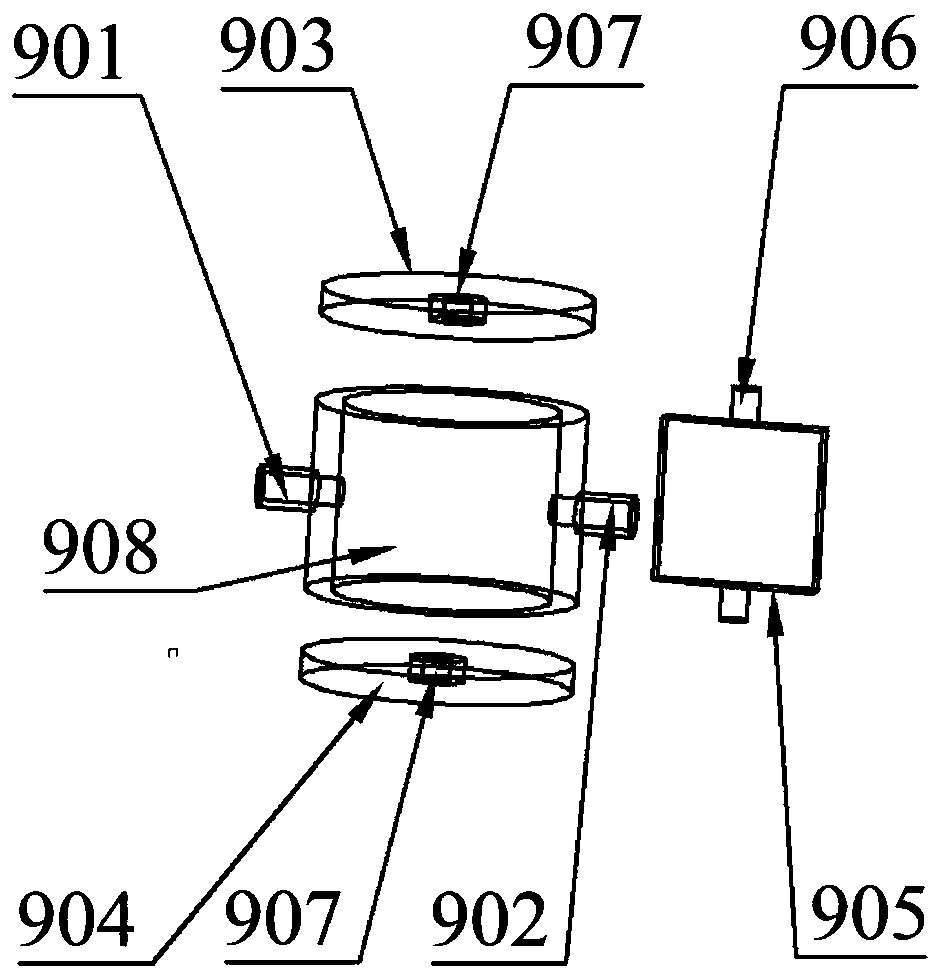

Test device and test method for oil-water relative permeability curve

PendingCN110160932AReduced measurement timeImprove measurement accuracySurface/boundary effectPermeability/surface area analysisWater productionOil water

The invention discloses a test device and test method for an oil-water relative permeability curve. The method comprises the steps of stirring and mixing oil and water by an oil-water uniform mixer, collecting a production liquid at interval, measuring mass and volume, and calculating oil-production speed, water-production speed and oil-water relative permeability to obtain the oil-water relativepermeability curve of a core. According to the oil-water relative permeability curve test method by a steady-state method, the oil and the water can be fully mixed in advance by a high-speed stirringeffect of the oil-water uniform mixer, so that the proportion of the oil and water which are injected into the core is more uniform and stable, the true moving state of the oil and water can be more accurately reflected, and the measurement time is shorted; and moreover, by the method, the metering of experiment data is more accurate, the accuracy is higher, and meanwhile, the method more conformsto reality by employing long core with relatively large size to perform simulation experiment in an oil deposit room.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com