Cement raw meal mill automatic control method and control device

An automatic control, cement raw meal technology, applied in cement production, sequence/logic controller program control, electrical program control, etc., can solve the problems of mechanical damage, many preparation links, and shortened service life of the powder separator. To achieve the effect of reducing labor intensity, high detection accuracy, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

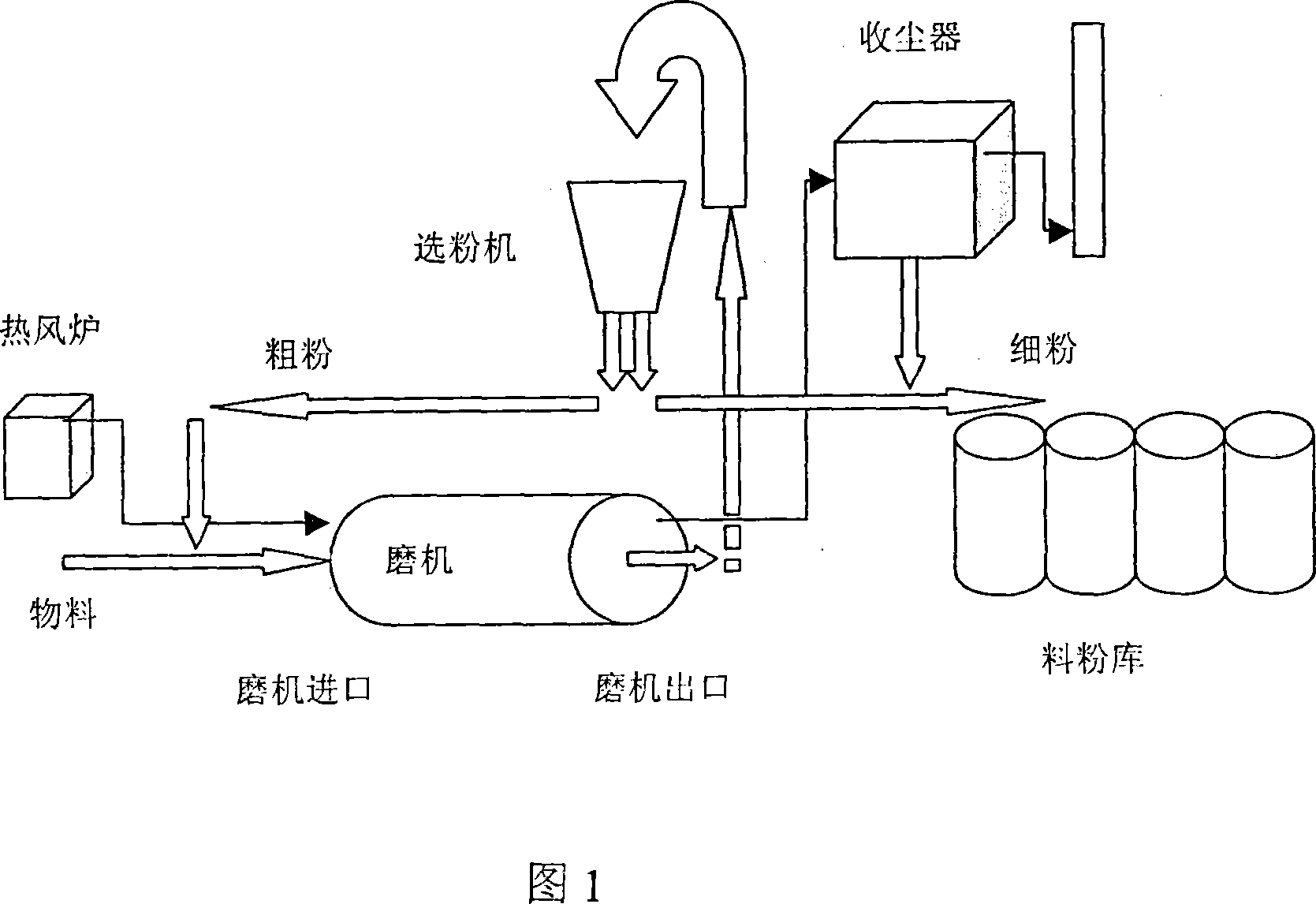

[0019] Referring to accompanying drawing 1, the method is to use a set of program controllers to control multiple links of raw meal preparation so as to integrate them into a raw meal mill automatic closed-loop control.

[0020] Use a set of grinding sound monitoring equipment to monitor the change of grinding sound during the operation of the mill, output the signal of grinding sound change to the program controller, and the program controller controls the feeding amount of the mill according to the change of grinding sound; according to the change of grinding sound of the mill Automatic control of the amount of material in the mill can keep the load of the mill or the amount of filling in the mill at a certain value or range, so that the output of the mill can reach the highest per hour, the unit power consumption is the lowest, and the energy-saving effect is the best, making the mill stable for a long time Run in the best working condition to prevent empty grinding and full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com