Sewage treatment dry powder wet agent adding device free of dust leakage and thorough in dispersion

A technology of sewage treatment and dosing device, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of flying dust, easy blockage of conveying pumps, and incomplete dispersion, and achieve complete dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

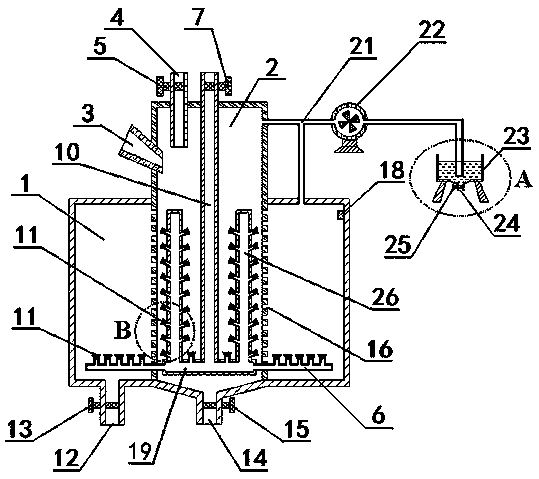

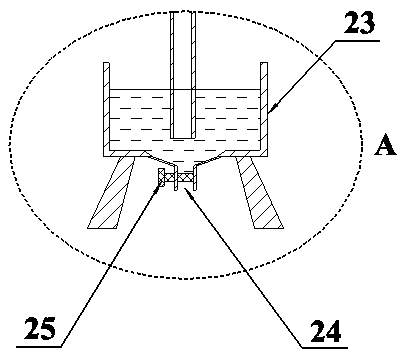

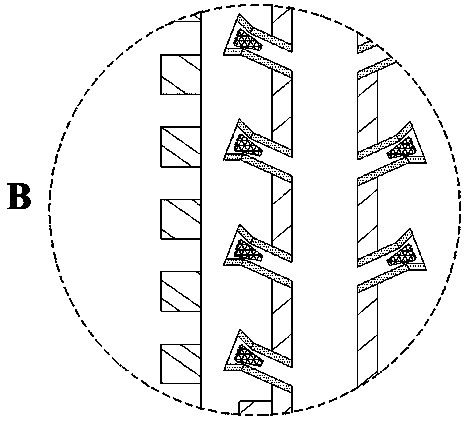

[0039] figure 1 It is a schematic diagram of the longitudinal section structure of Embodiment 1 of the present invention, figure 2 for figure 1 The enlarged schematic diagram of A in the middle, image 3 for figure 1 The enlarged schematic diagram of B in the middle, Figure 4 It is a top schematic view viewed from above for Embodiment 1, Figure 5 It is a schematic view of the lower part after removing the upper part and looking down on the lower part by taking the inner surface of the top of the liquid storage chamber as the section plane in Example 1, Figure 6 for Figure 5 The enlarged schematic diagram at C.

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a dry powder wet dosing device for sewage treatment with no dust leakage and more thorough dispersion, including a drug dissolution tank, a liquid storage chamber, an air stirring device, and an exhaust device;

[0041] The medicine dissolving tank is a closed...

Embodiment 2

[0060] Figure 7 It is a schematic diagram of the longitudinal section structure of Embodiment 2 of the present invention, Figure 8 It is a schematic diagram of Embodiment 2 of the present invention, taking the inner surface of the top of the liquid storage chamber as a section plane and then removing the upper part and looking down at the lower part.

[0061] Such as Figure 7 , Figure 8 As shown, a dry powder wet dosing device for sewage treatment with no dust leakage and more thorough dispersion, including a drug dissolution tank, a liquid storage chamber, an air stirring device, and an exhaust device;

[0062] The drug-dissolving tank is a closed cavity with a top and a bottom. A water inlet pipe and a first main air pipe pass through the top of the drug-dissolving tank and enter the inside of the drug-dissolving tank. The main gas delivery pipe is vertically located in the center of the top of the drug dissolution tank and is rotatably fixed to the top of the drug di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com