Assistant gap nailing machine

A nailing machine and slot technology, applied in nail dispensers, packaging, manufacturing tools, etc., can solve the problems of people's trouble, can't nail well, can't meet people's needs, etc., to achieve convenient nailing, meet the needs of use, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

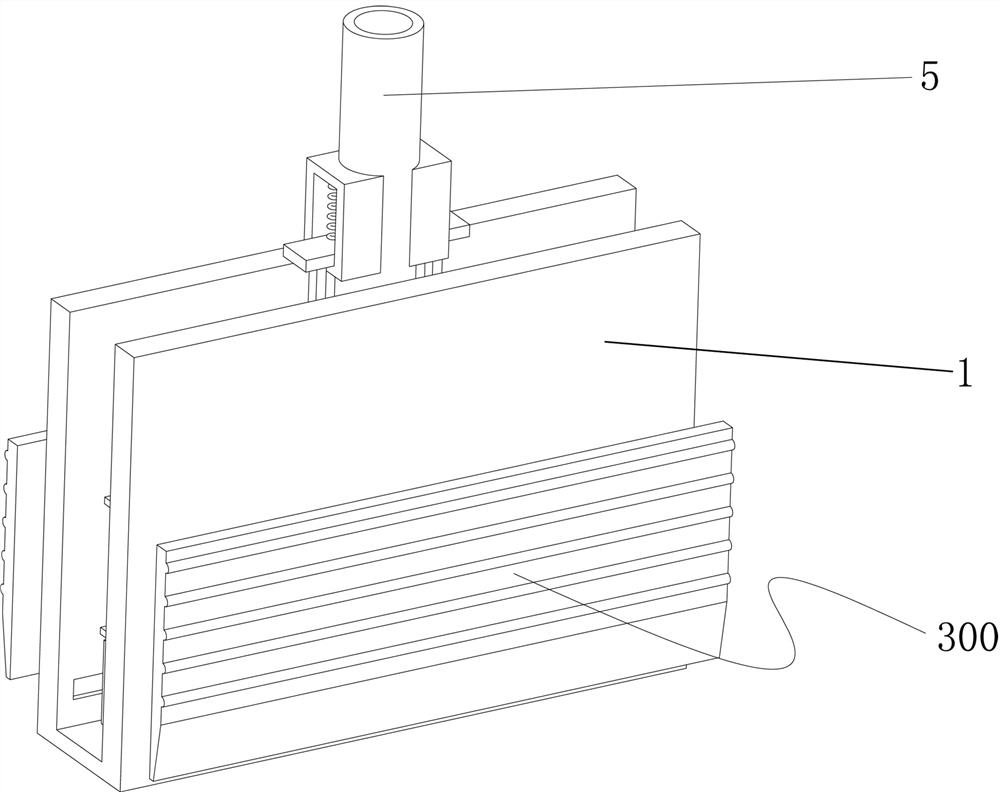

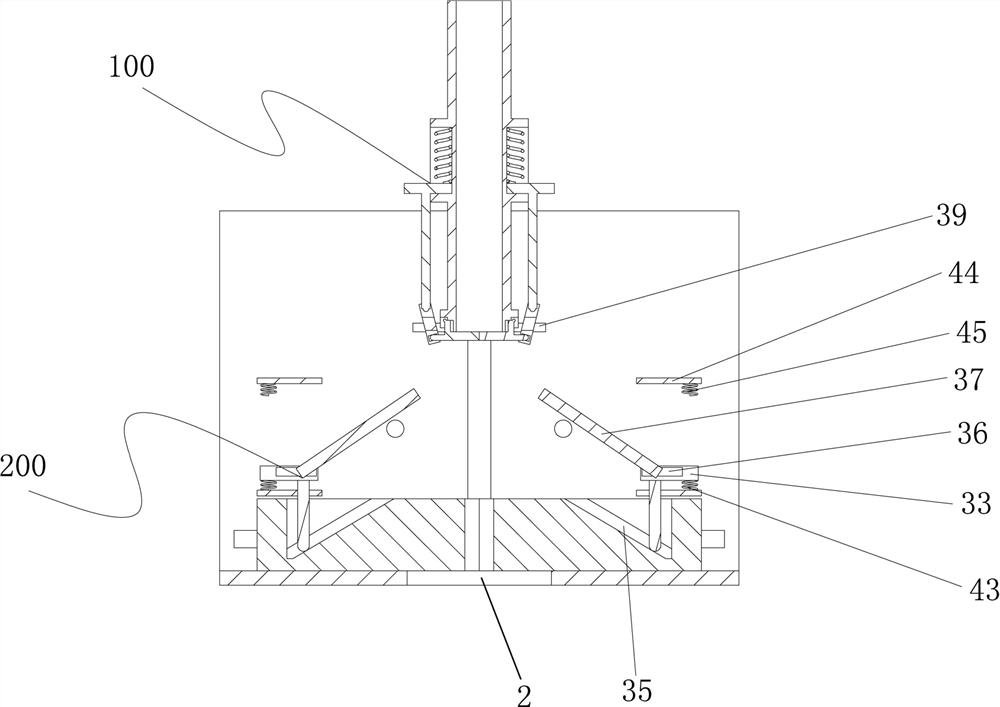

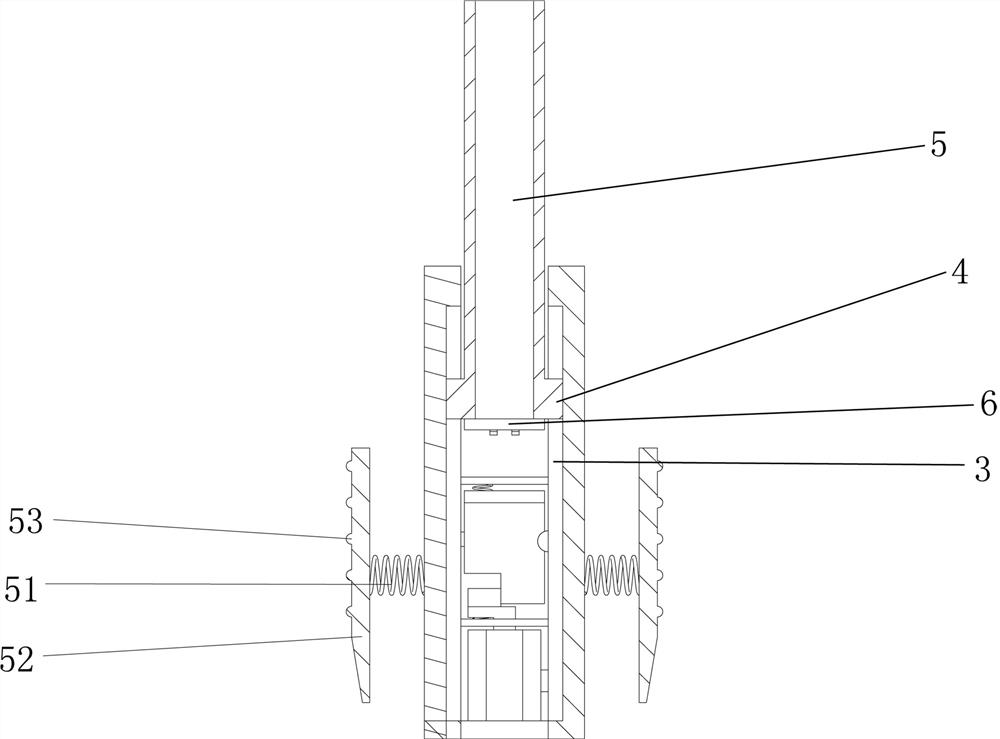

[0018]The present invention will be further described below in conjunction with the description of the drawings and specific implementations:Figure 1 to 4The auxiliary gap nailing machine shown includes a U-shaped block 1, a through hole 2 penetrates through the bottom of the U-shaped block 1, and a second symmetrical structure is provided on the inner wall of the U-shaped block 1 above the through hole 2. A vertical chute 3, a first guide block 4 is movably provided in the first vertical chute 3, and a cylinder 5 capable of inserting nails is connected between the first guide blocks 4, and The opening of the lower end of the cylindrical barrel 5 is symmetrically hinged with a flap 6, and a control mechanism 100 capable of controlling the opening of the flap 6 to open or close the opening at the lower end of the cylindrical barrel 5 is provided on one side of the cylindrical barrel 5. The inner wall of the U-shaped block 1 is located The cylindrical barrel 5 is provided with symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com