Buffering type dust removing and impurity removing device for grain

A grain and screw feeding device technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of low efficiency of dust removal, dust and grain impurities can not be effectively treated, grain feeding Excessive volume and other problems, to achieve the effect of controllability, easy discharge, and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. The components of the embodiments of the invention generally described and illustrated in the figures herein may be arranged and designed in a variety of different configurations.

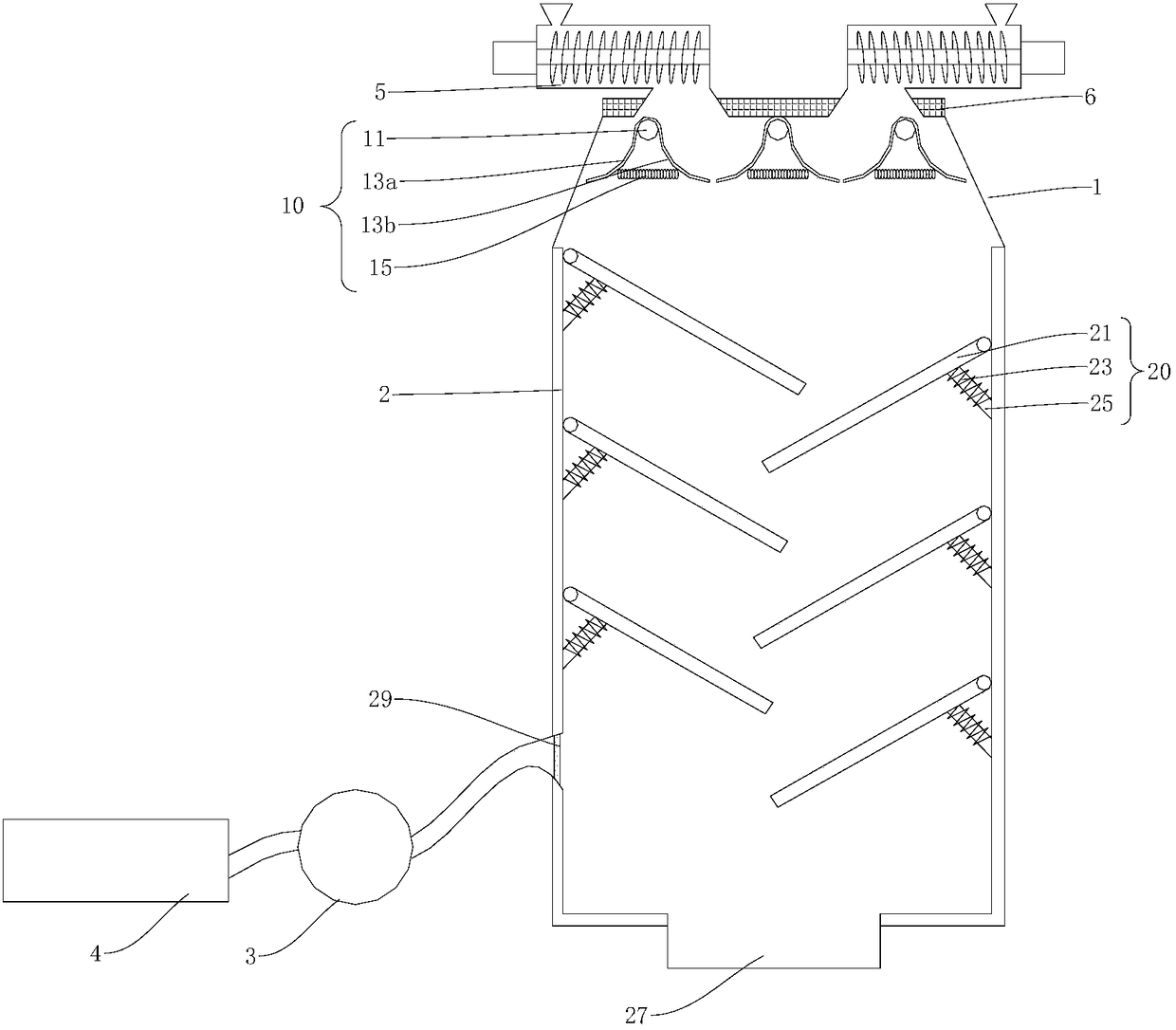

[0016] Please refer to figure 1 , the present embodiment provides a buffer type grain dust removal device, which mainly includes a feeding mechanism 1, a housing 2, an air pump 3, a dust storage device 4 and a screw feeding device, the screw feeding device, the feeding mechanism 1 and the housing The bodies 2 are connected sequentially from top to bottom. The screw feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com