Stirring equipment with adjustable angle of hot-air blowing turbulent flow

A technology of mixing equipment and hot air, used in mixer accessories, mixers, food science and other directions, can solve the problems of insufficient and thorough mixing of feed, low mixing efficiency, slow discharge speed, etc., to achieve complete dispersion of raw materials and improve mixing effect, effect that facilitates aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

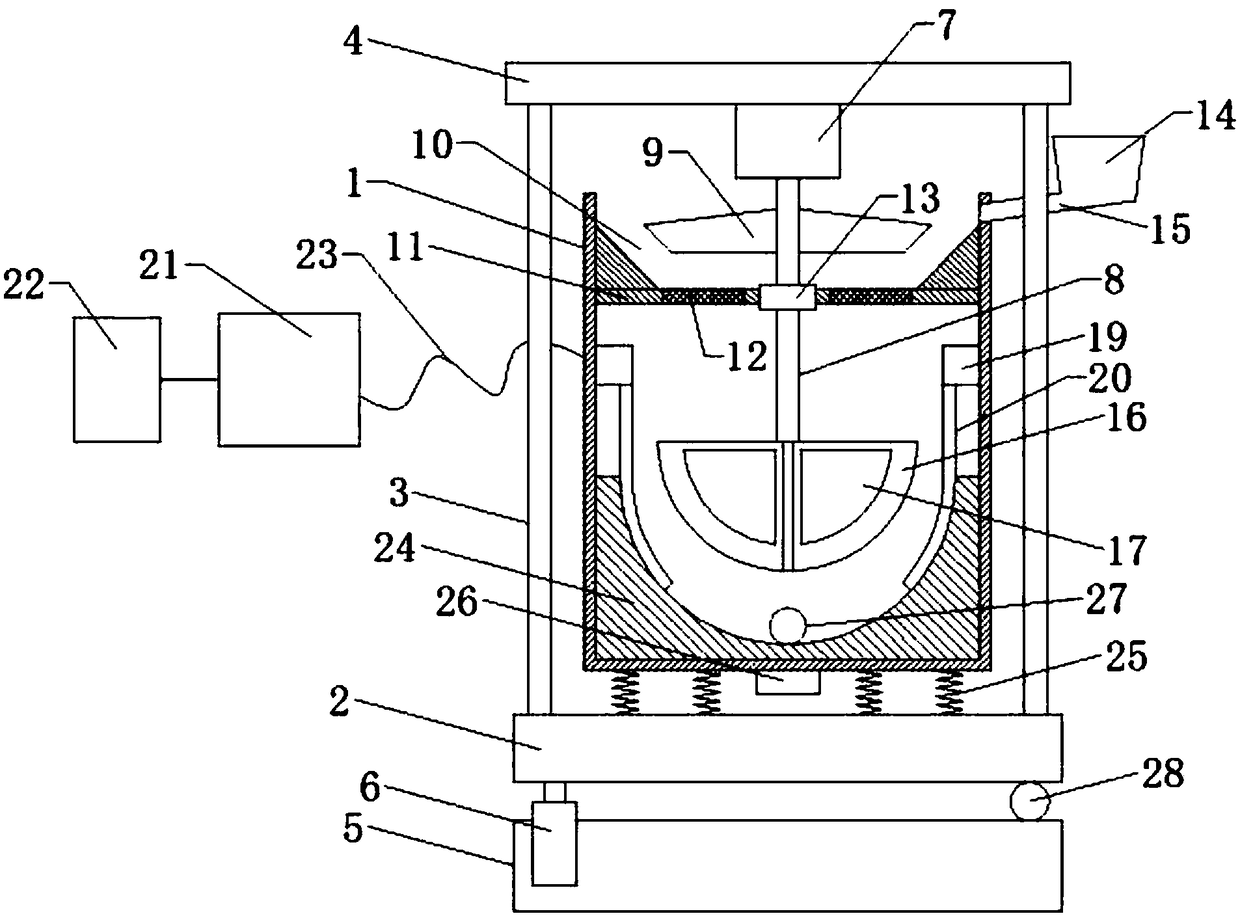

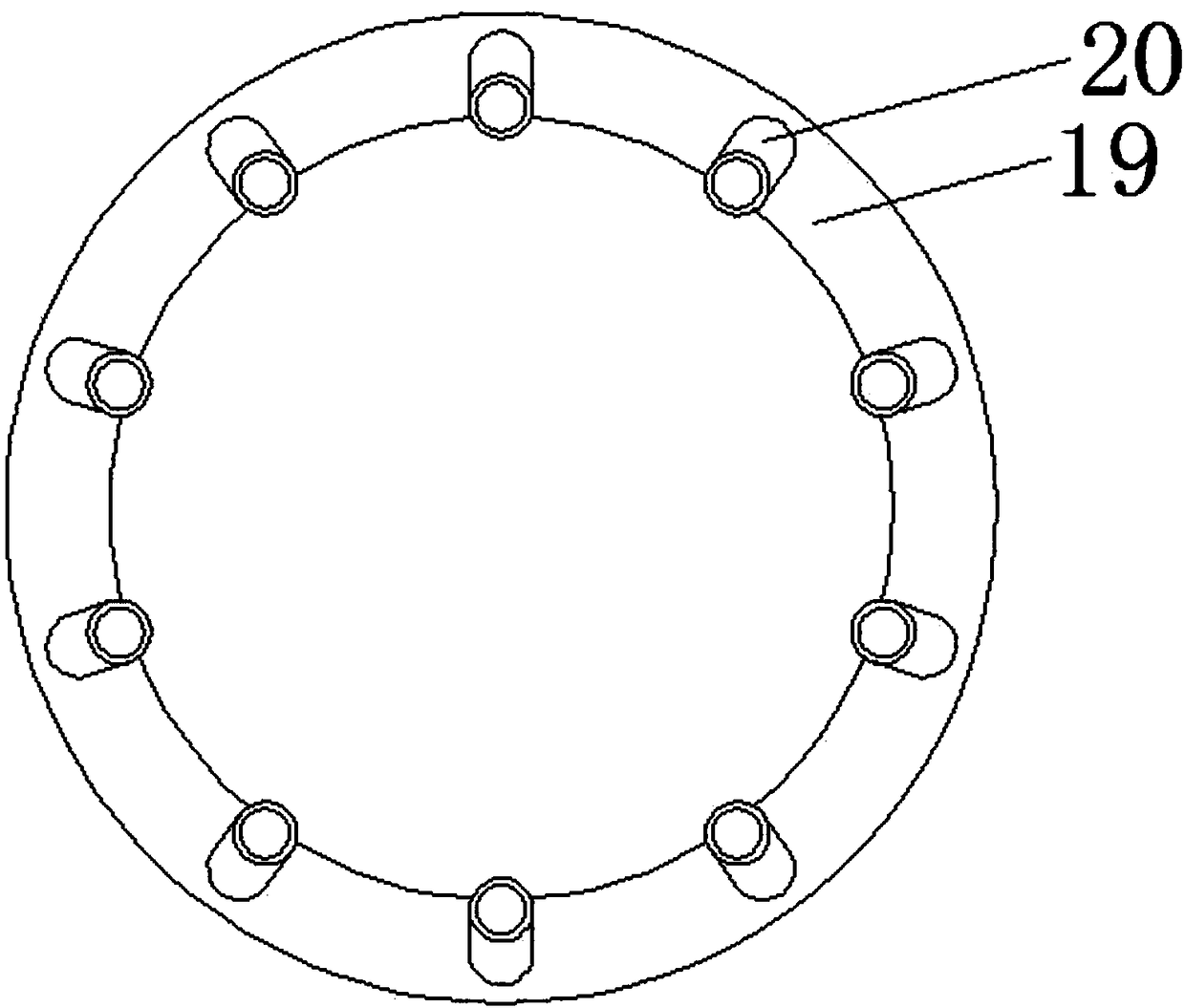

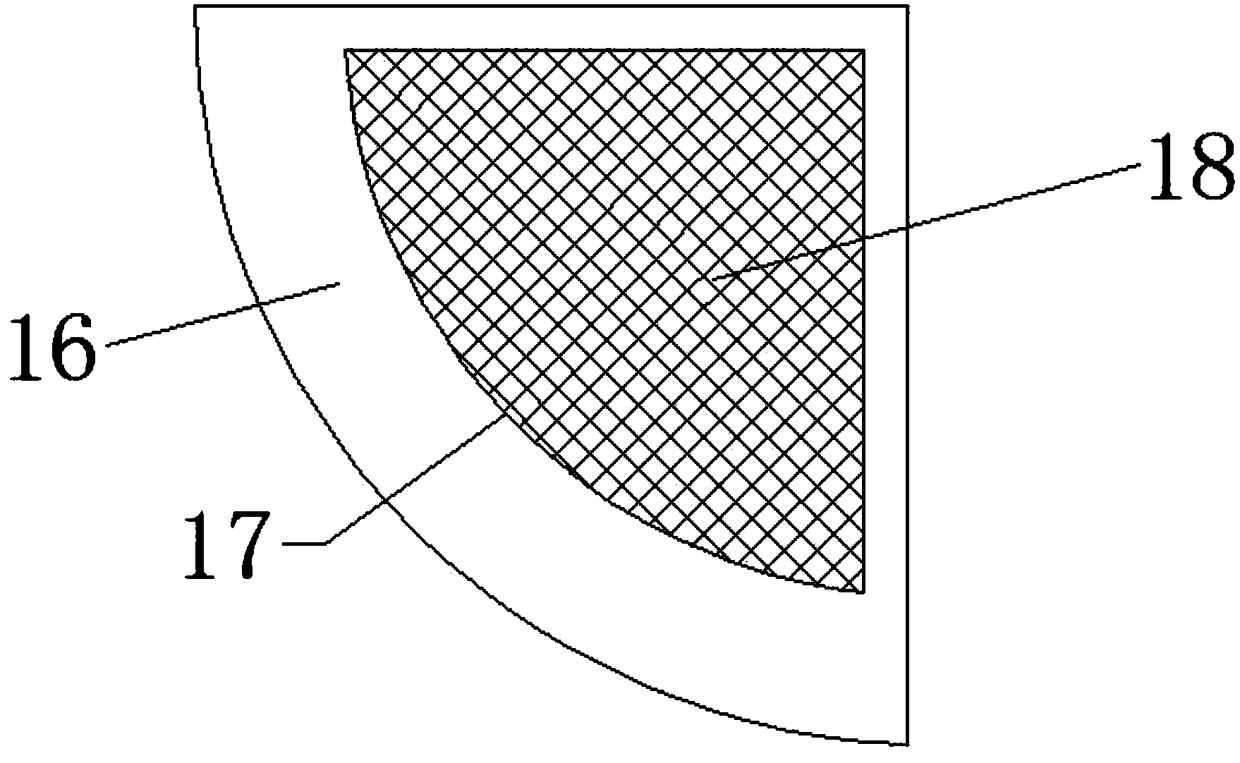

[0017] Please refer to the figure, in the embodiment of the present invention, a stirring device with an adjustable angle of hot air blowing and turbulence includes a cylinder 1, a base 2, a support rod 3, a top plate 4 and a motor 7; the four corners on the base 2 Vertical support rods 3 are fixed on the top, and the upper end of the support rods 3 is fixed with a horizontal top plate 4; Several springs 25 are connected, and the cylinder body 1 is supported by the springs 25. A vibrating motor 26 is fixedly installed on the bottom of the cylinder body 1, and the vibration motor 26 drives the cylinder body 1 to vibrate, so that the internal feed falls and shakes; A horizontal support seat 5 is arranged below, and one end between the base 2 and the support seat 5 is connected by a pin shaft 28 for rotation, specifically, the pin shaft 28 is plugged into the connection seat fixed on the base 2 and the support seat 5, Offer the pin hole in the connecting seat, connect it by the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com