Patents

Literature

48results about How to "Uniform surface properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

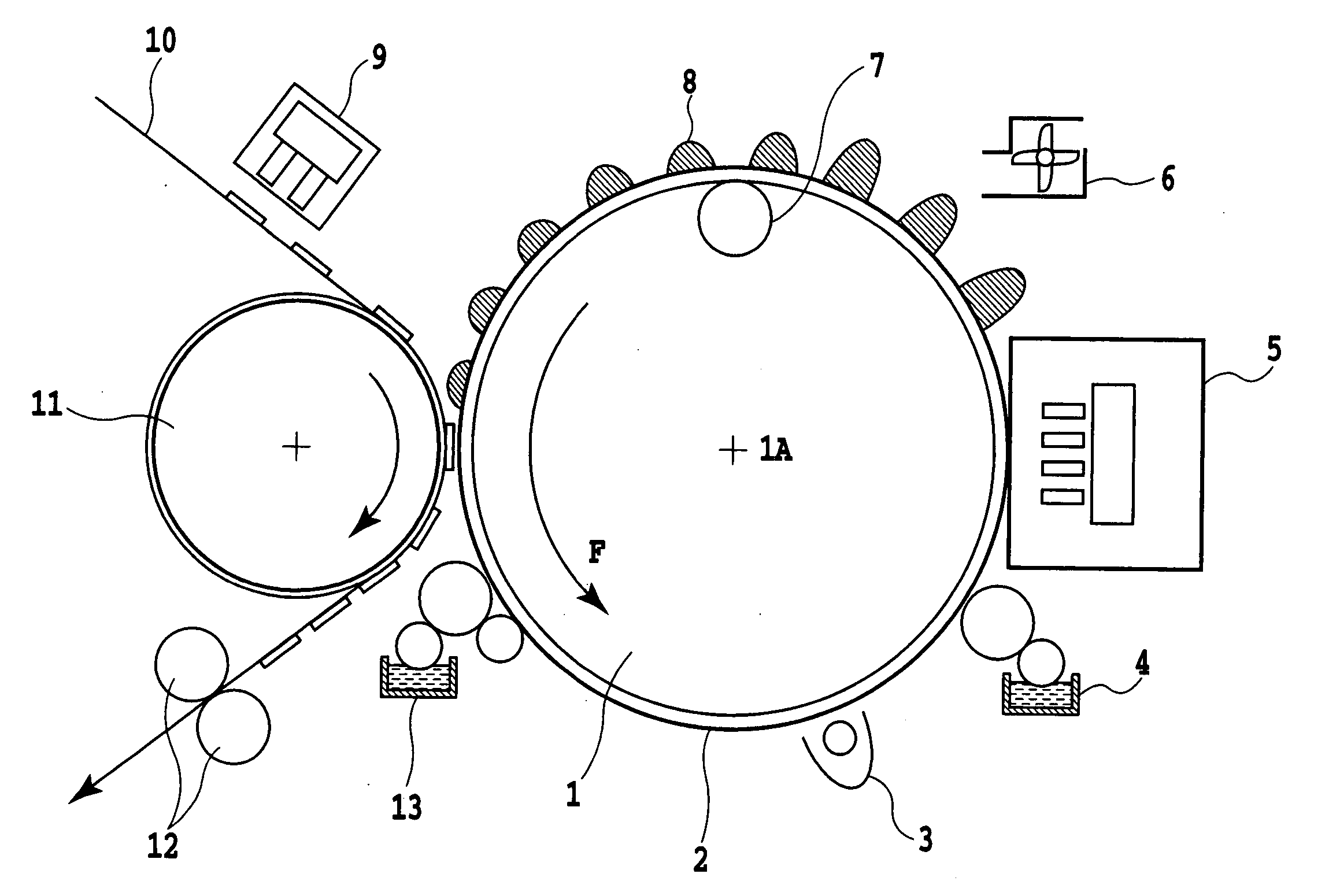

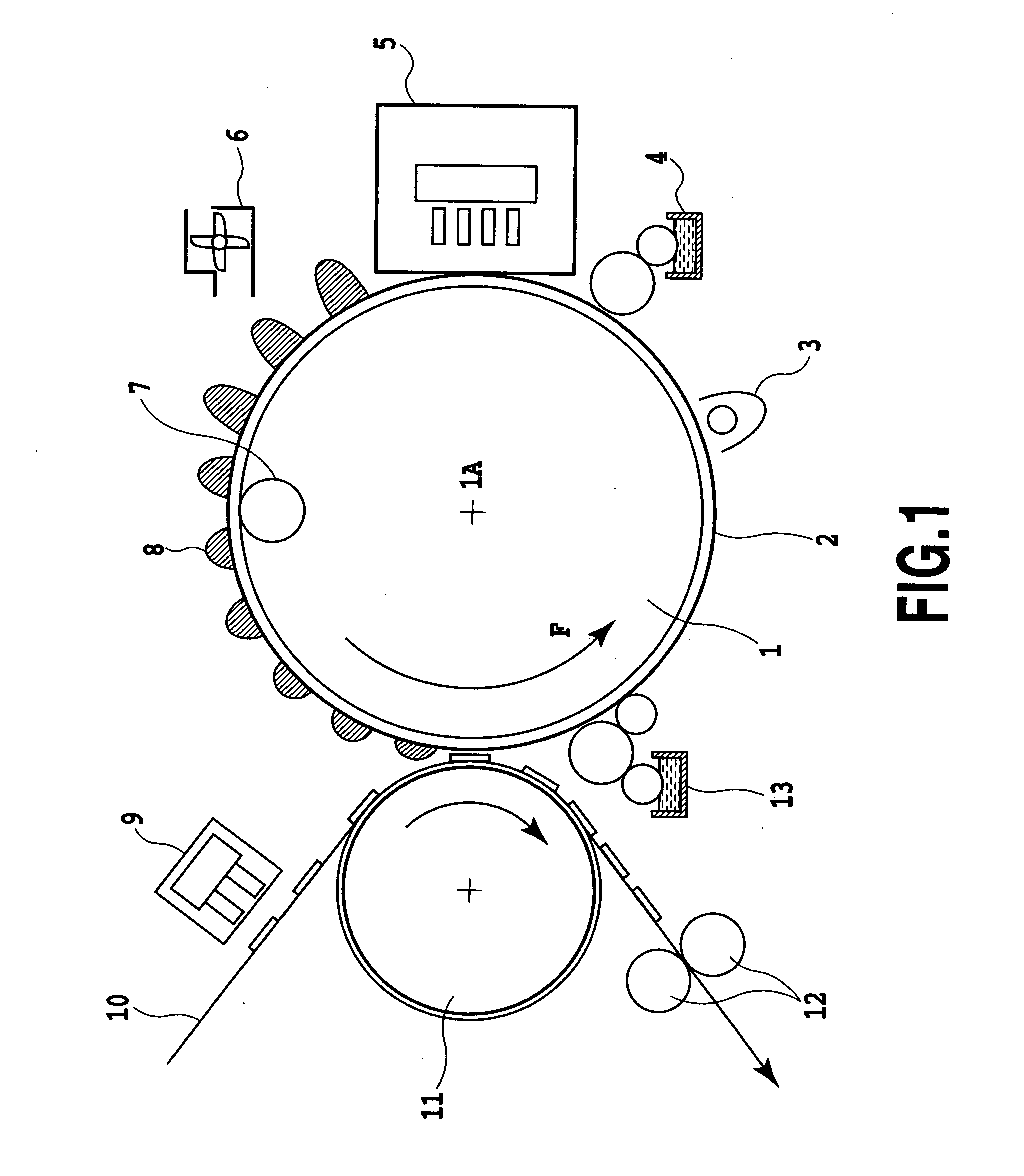

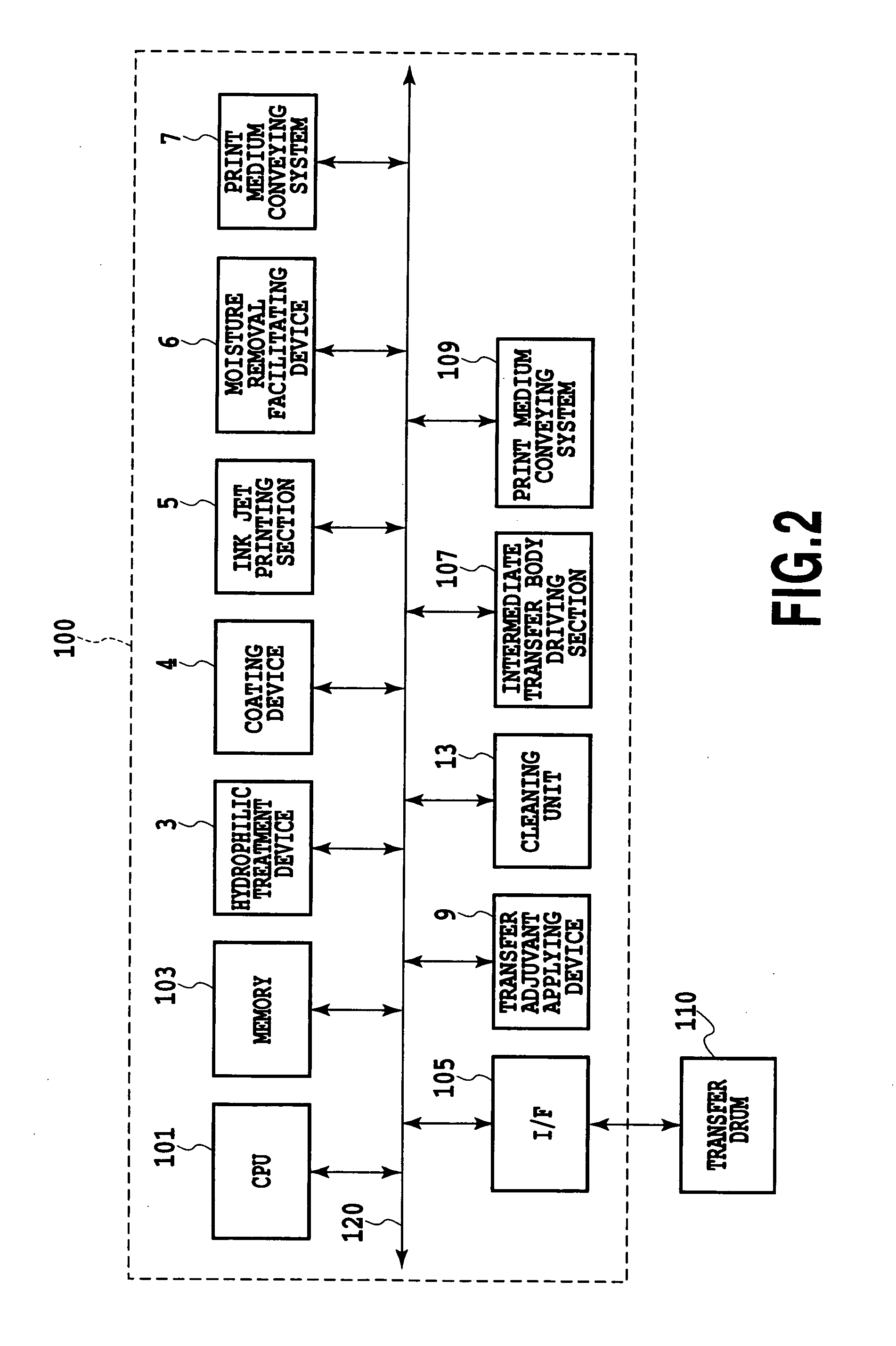

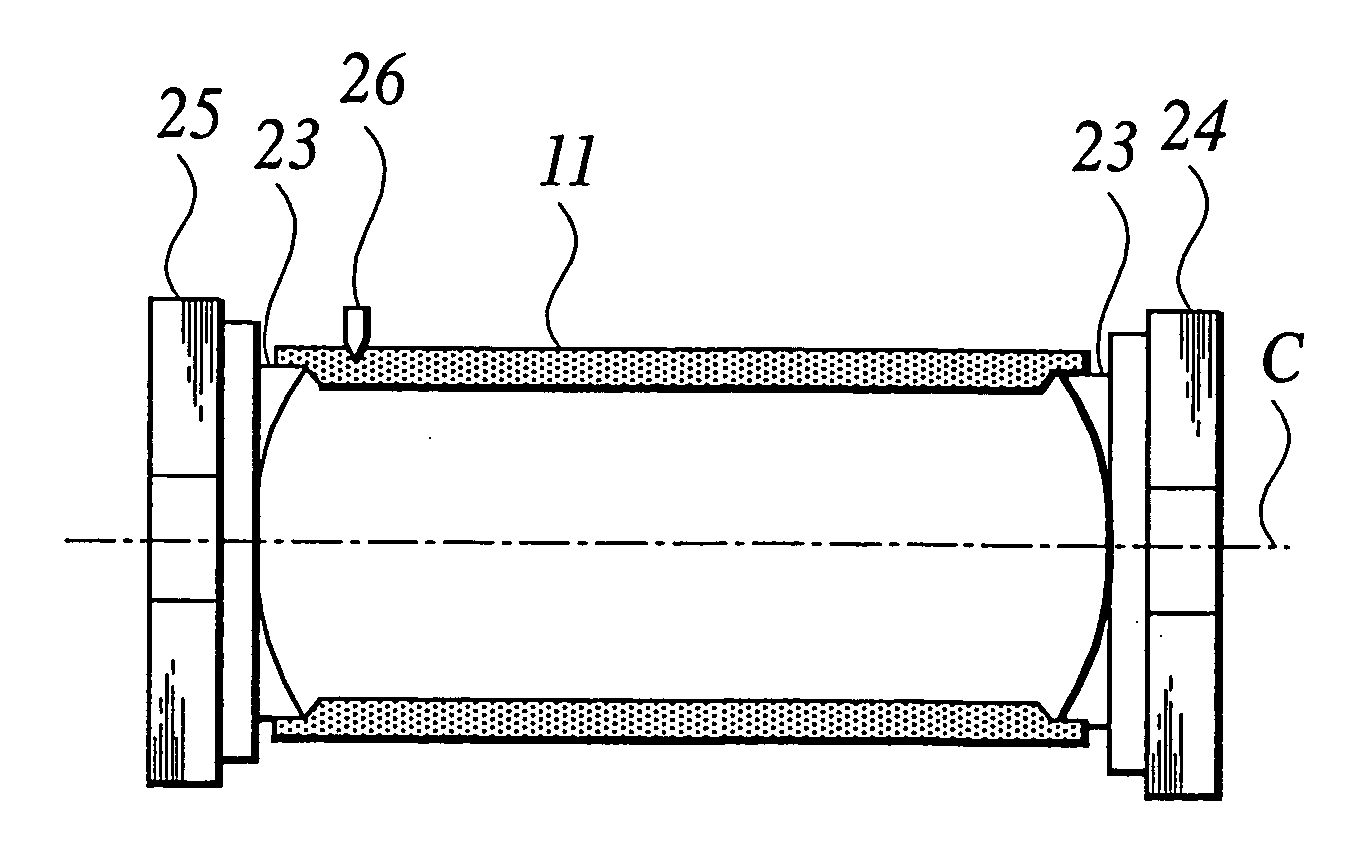

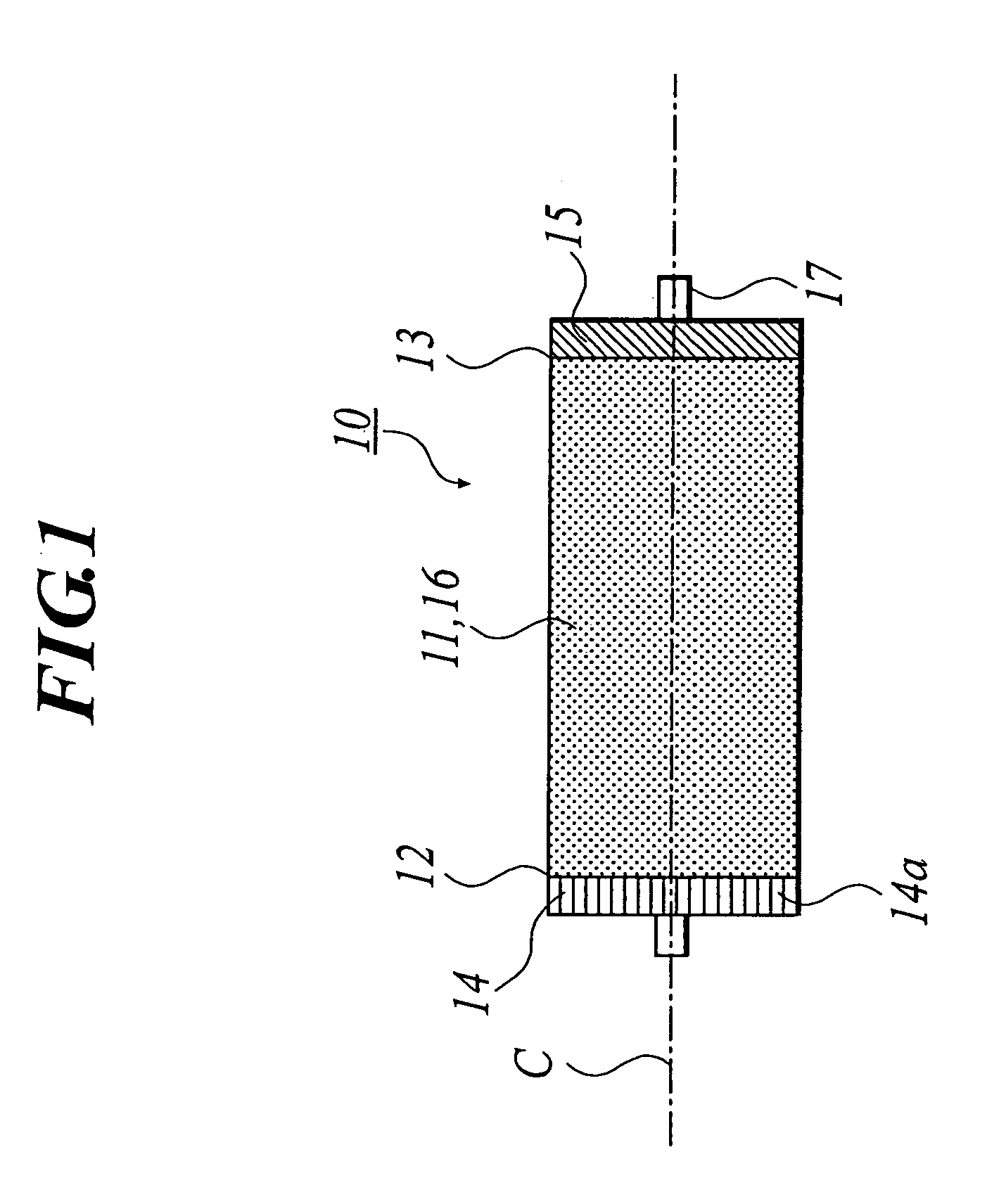

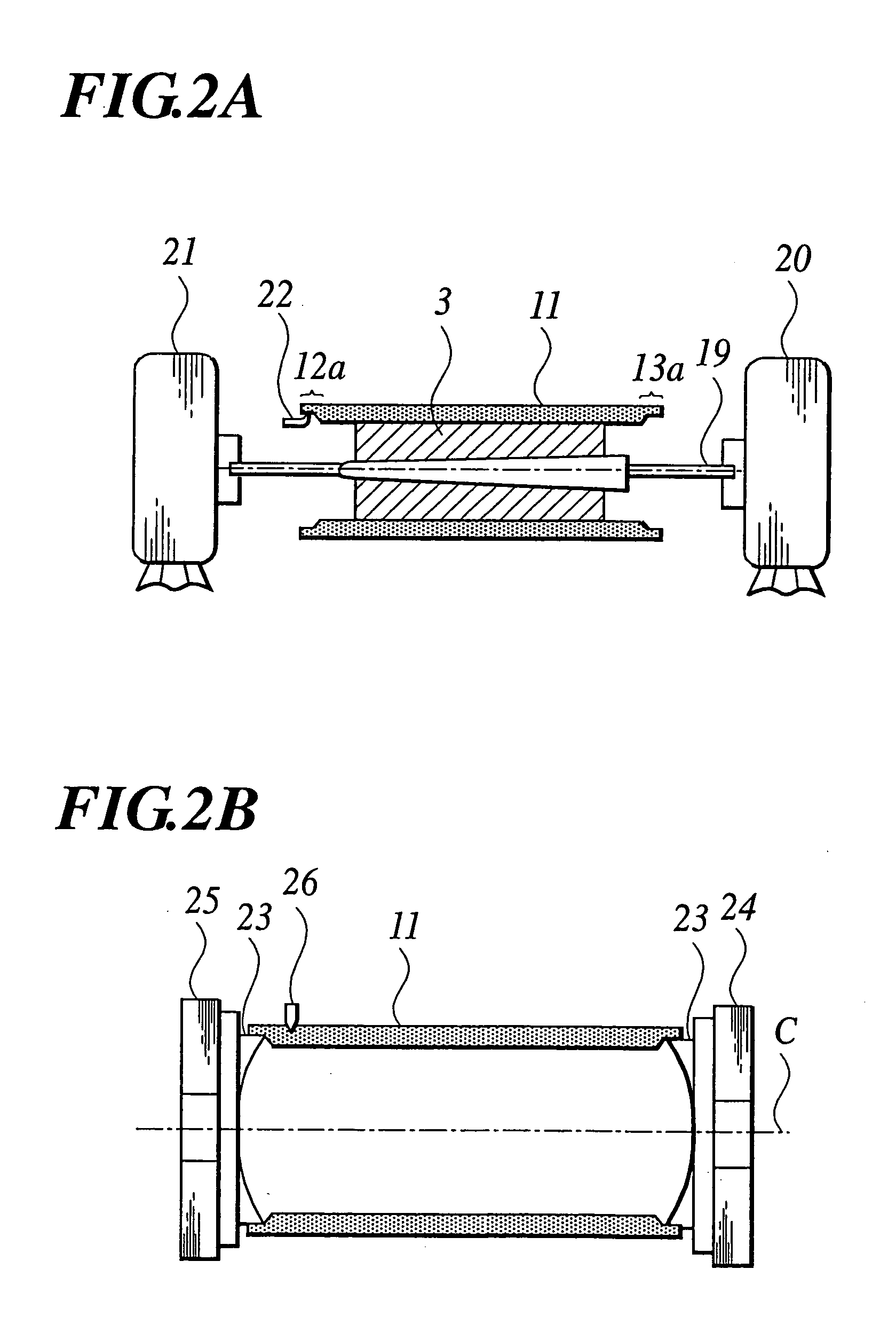

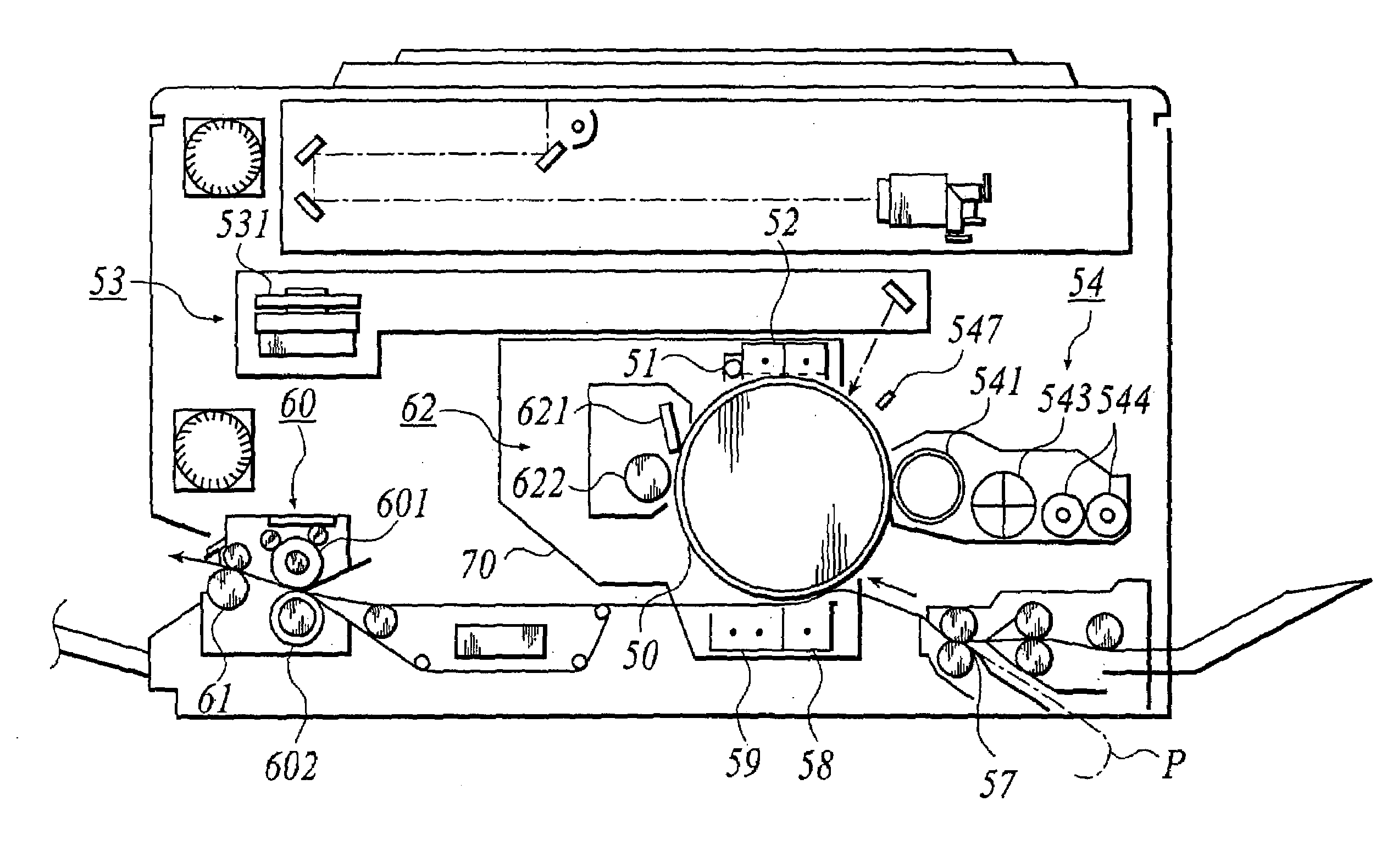

Method and apparatus for forming image

A method and apparatus for forming an image which can form a high-quality image on a great variety of print media regardless of the surface roughness or ink absorptivity of the print medium, without sacrificing the high degree of freedom of the ink jet printing system are provided. An ink jet printing section ejects ink to an intermediate transfer body to form an ink image on the intermediate transfer body. Before the ink image thus obtained is transferred to a print medium, an ink transfer adjuvant is applied to the print medium. Then, the ink image formed on the intermediate transfer body is transferred to the print medium to which the ink transfer adjuvant has been applied.

Owner:CANON KK

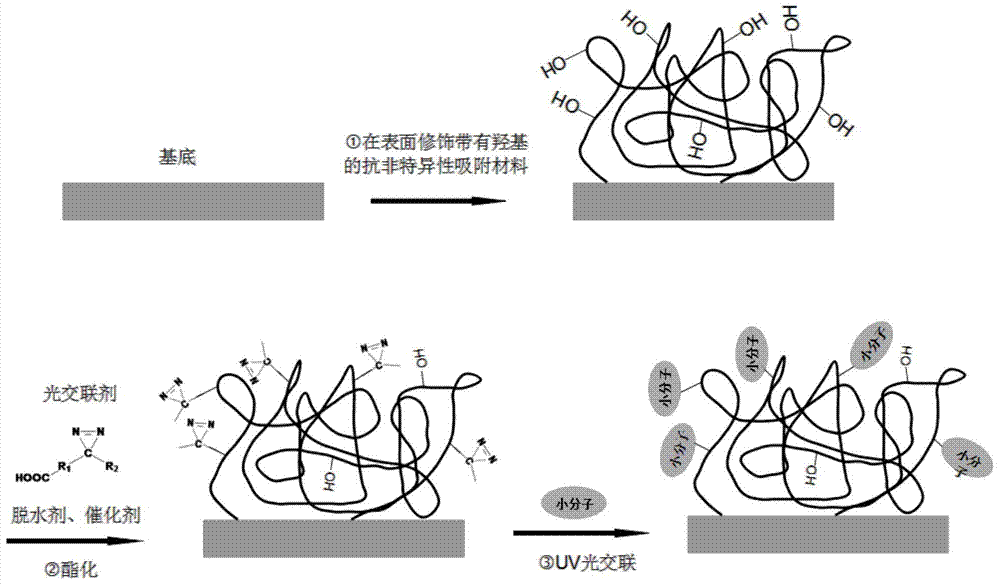

Small-molecule microarray and preparation method thereof

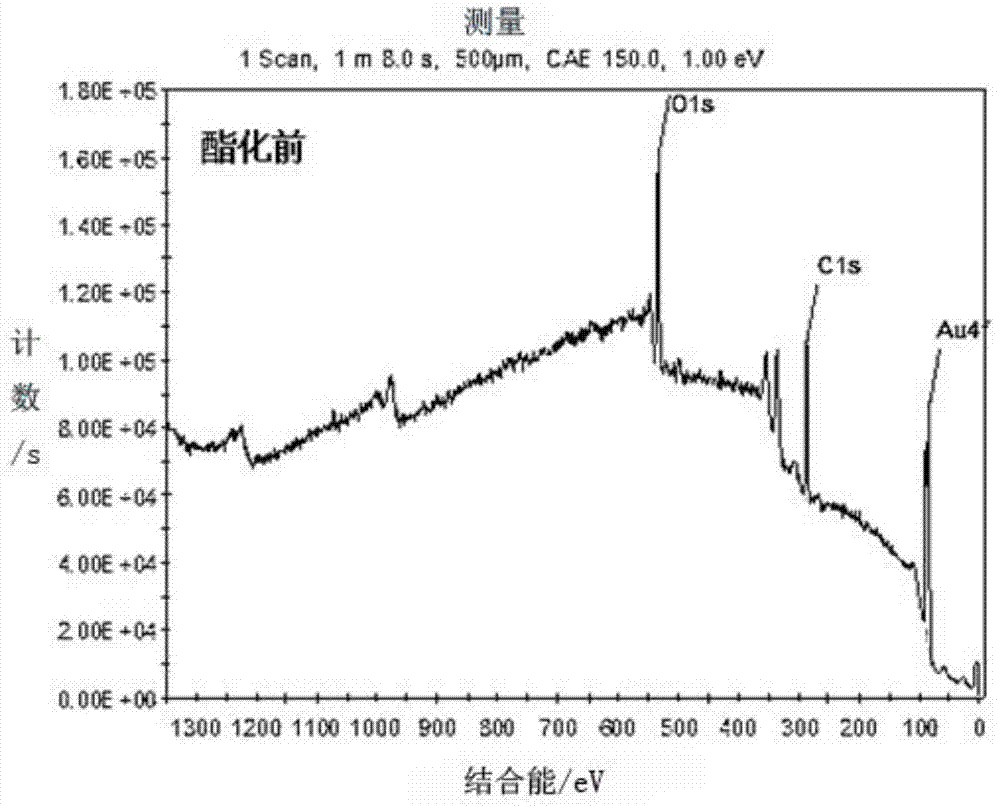

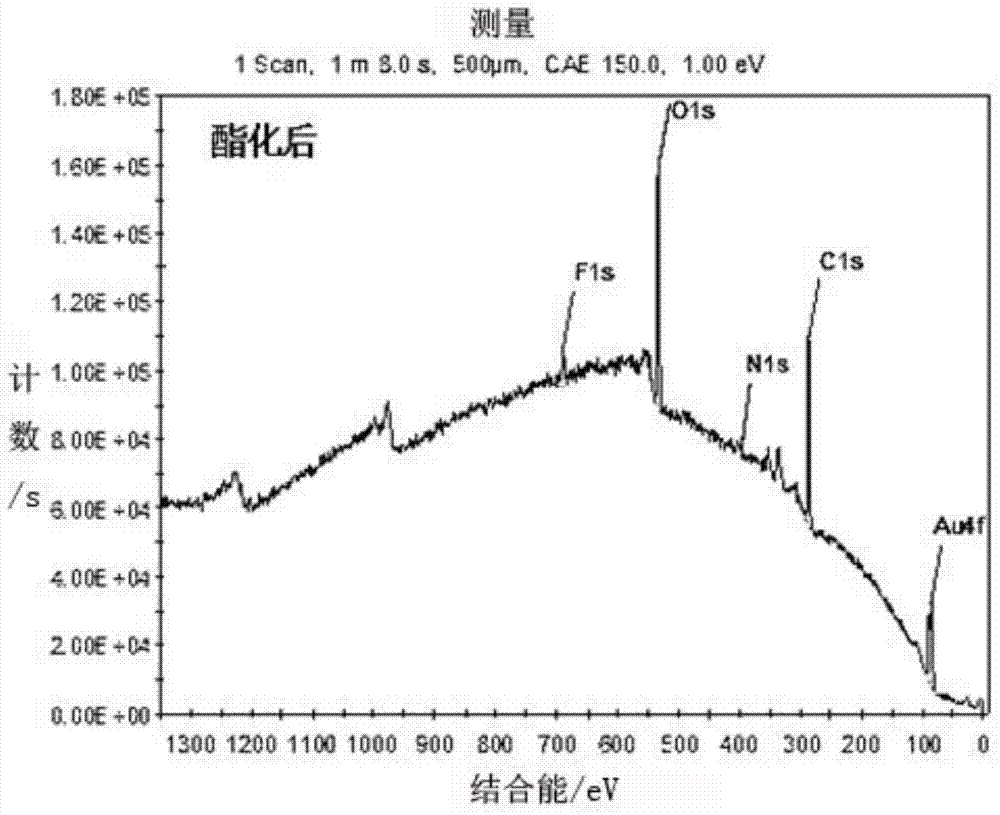

ActiveCN103792345AHigh resistance to non-specific adsorptionThe modification process is simple and convenientLaboratory glasswaresBiological testingHigh fluxEsterification reaction

The invention discloses a preparation method for a small-molecule microarray. The preparation method comprises the steps of bonding the hydroxyl terminal of a nonspecific adsorption resistance material modified on a chip substrate with the hydroxyl terminal of a small-molecule light crosslinking agent through an esterification reaction, and randomly fixing small molecules on the hydroxyl terminals through light crosslinking. By the adoption of a direct esterification mode, the small-molecule light crosslinking agent is quickly and efficiently coupled to the surface of the nonspecific adsorption resistance material; a chip modification process is simple and convenient and can be implemented under a normal temperature condition; therefore, the modification cost is reduced, and the modification efficiency is improved; a high detection signal is guaranteed; a non-reacted group still keeps high nonspecific adsorption resistance capacity, so that a background signal is reduced; the prepared small-molecule microarray is high in detection signal and low in background signal and can be used for mutual action between high-flux screened small-molecule medicaments and targets.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

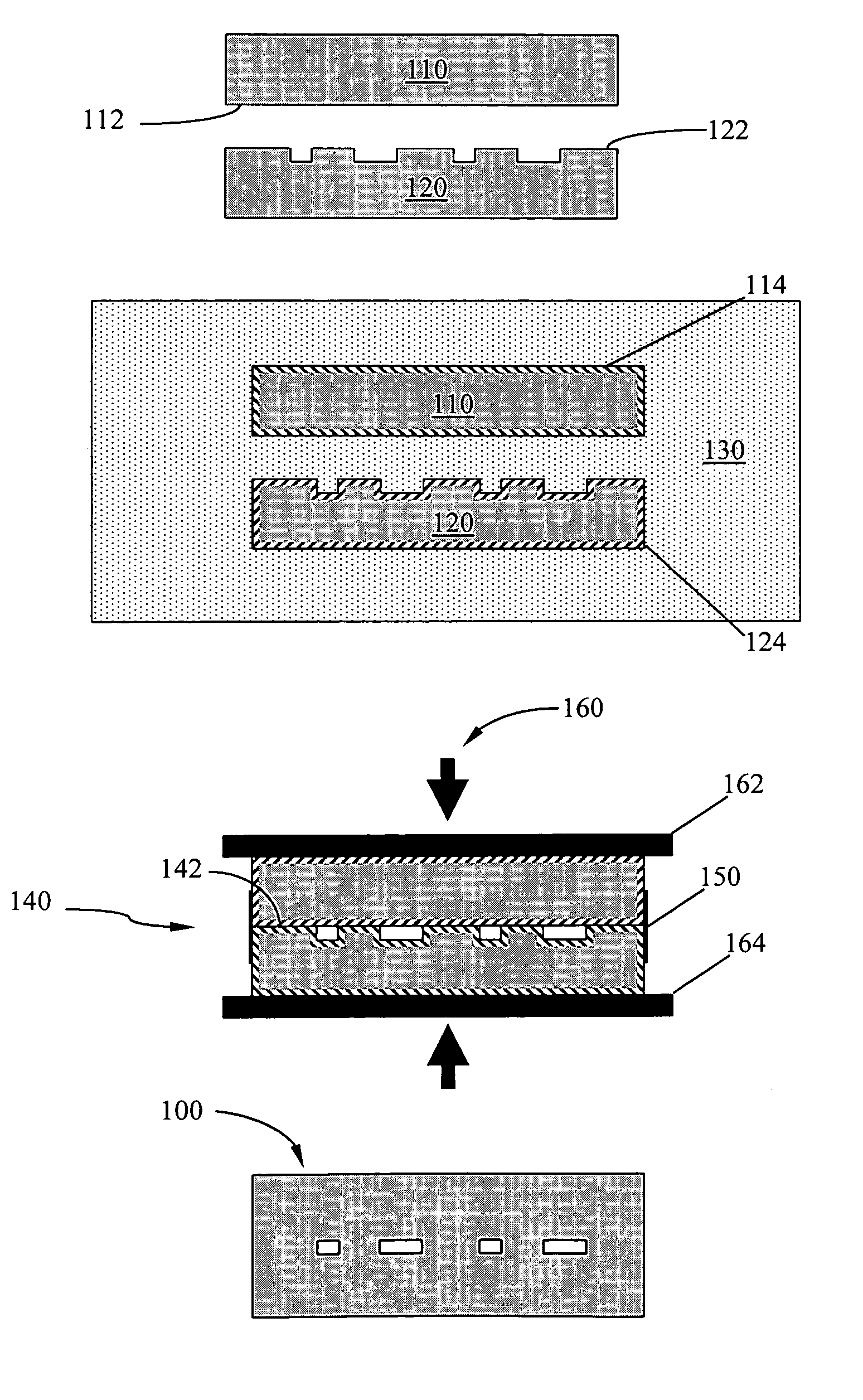

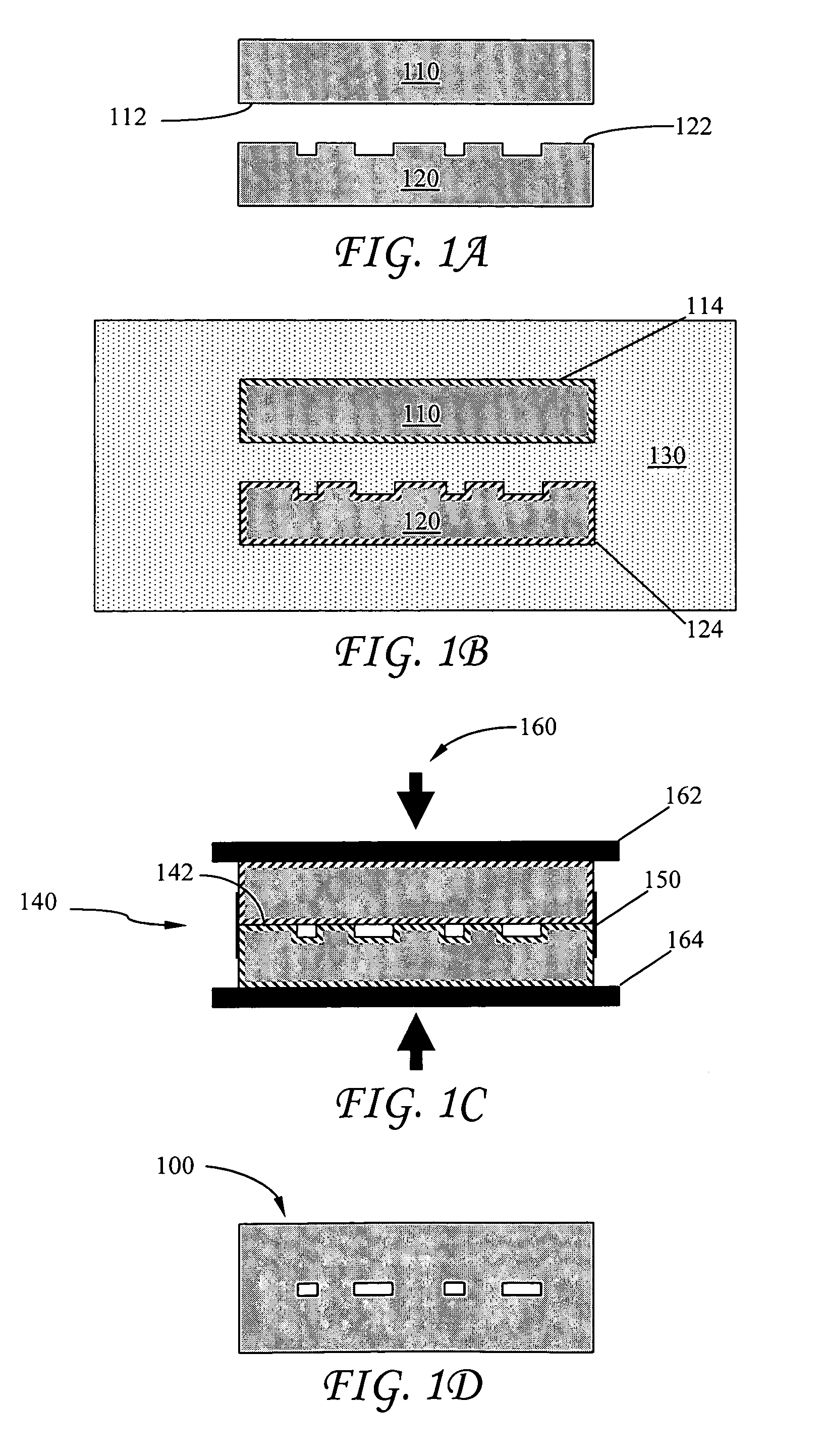

Bonding thermoplastic polymers

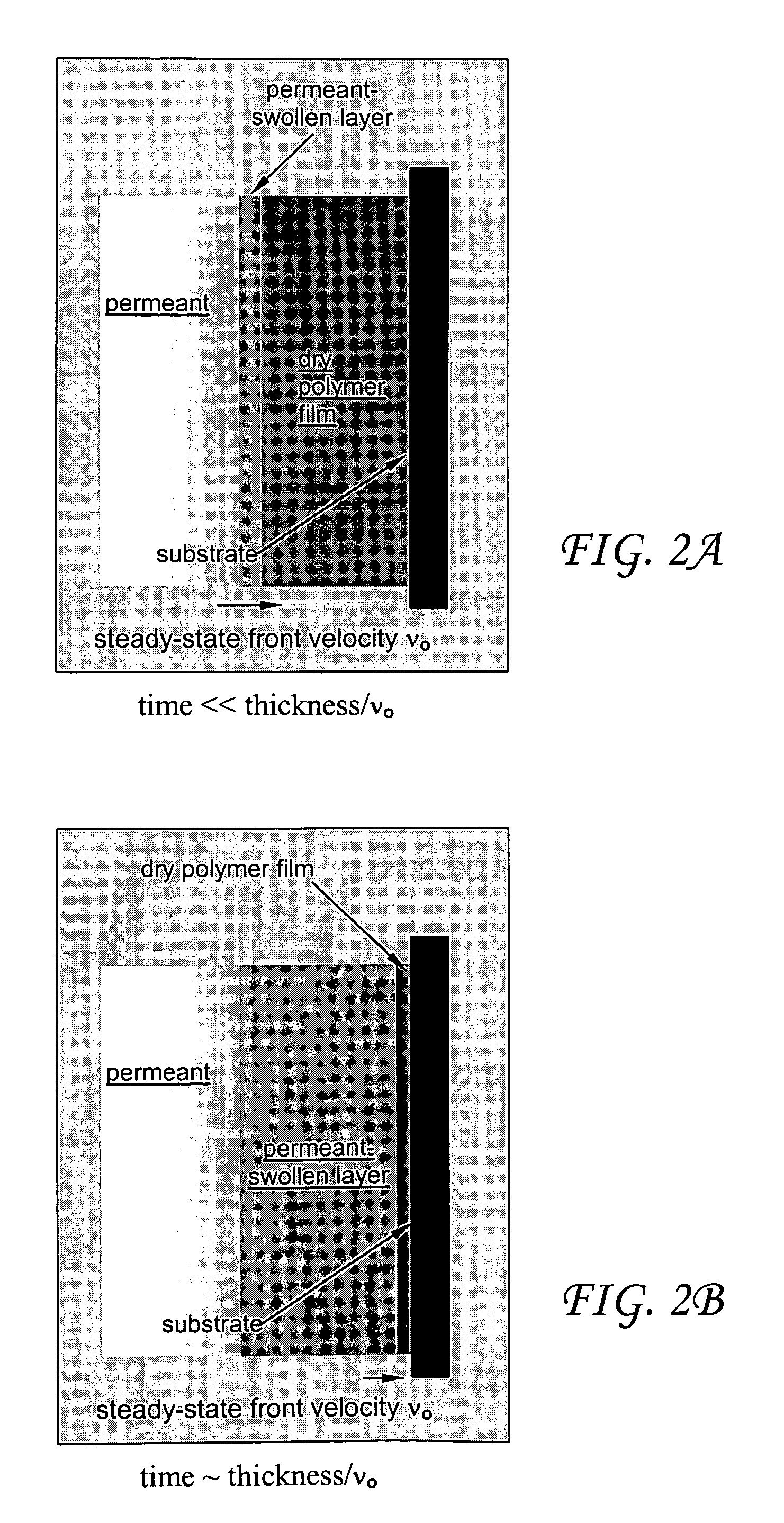

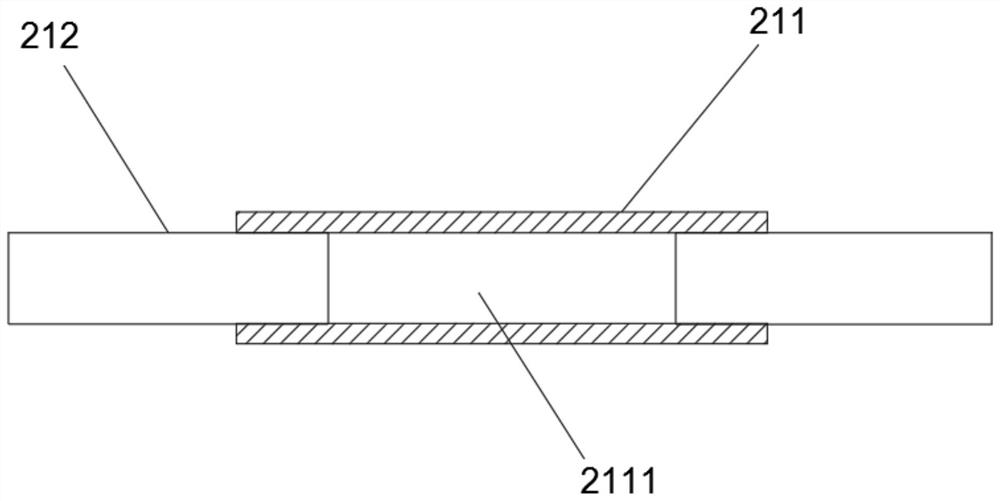

InactiveUS7390377B1UniformUniform surface propertiesMechanical working/deformationAdhesive processes with surface pretreatmentMicrometerThermosetting polymer

We demonstrate a new method for joining patterned thermoplastic parts into layered structures. The method takes advantage of case-II permeant diffusion to generate dimensionally controlled, activated bonding layers at the surfaces being joined. It is capable of producing bonds characterized by cohesive failure while preserving the fidelity of patterned features in the bonding surfaces. This approach is uniquely suited to production of microfluidic multilayer structures, as it allows the bond-forming interface between plastic parts to be precisely manipulated at micrometer length scales. The bond enhancing procedure is easily integrated in standard process flows and requires no specialized equipment.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

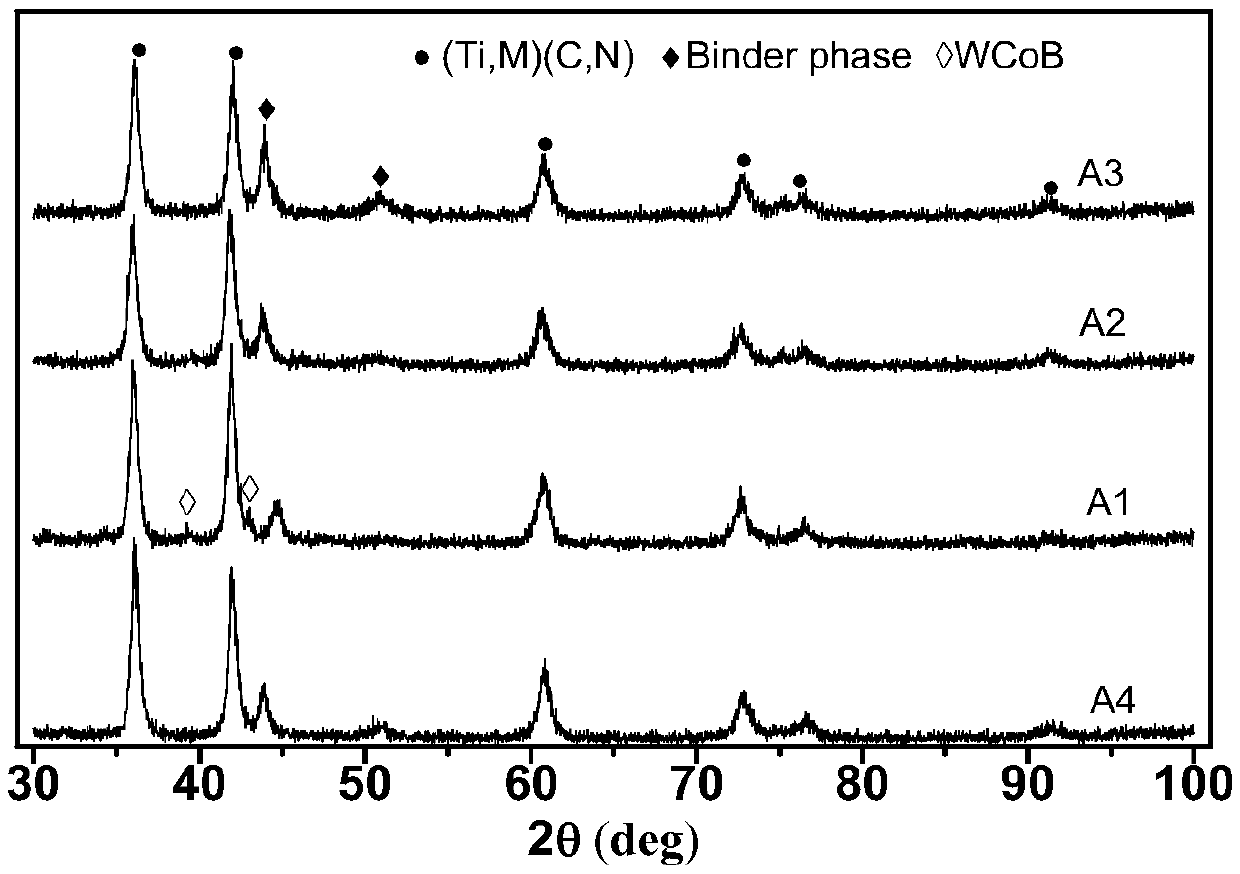

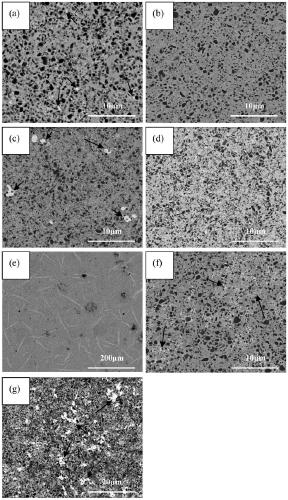

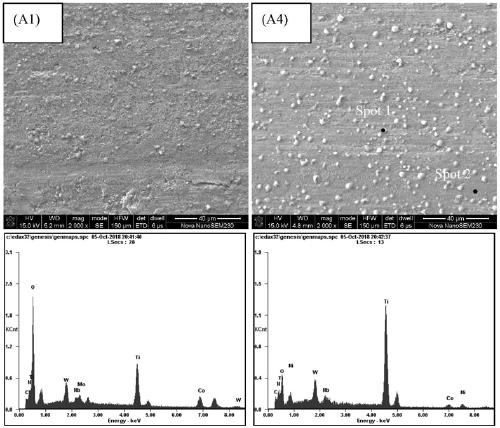

Ternary boride reinforced Ti-based (C,N) metal ceramic material and preparation method thereof

The invention discloses a ternary boride reinforced Ti-based (C,N) metal ceramic material and a preparation method thereof. The main preparation process comprises the following steps that Ti (C,N) metal ceramic raw material powder, carbide and nitride boride powder, binding phase raw material powder and binary boride powder are taken as raw materials, Ti-based (C,N) metal ceramic is prepared through the steps of ball milling mixing, drying, forming and sintering, wherein second phase ceramic particles generated by primary reaction are distributed in a binding phase of the metal ceramic material in a fine dispersion mode, the hardness and toughness of the metal ceramic material can be effectively improved through the phase. Compared with an existing technology for enhancing wear resistance,such as coating and surface treatment, the Ti-based (C,N) metal ceramic material prepared through the method has the advantages that the rockwell hardness reaches 91.5-94 HRA, the bending strength can reach 1800-2800 MPa, and the fracture toughness can reach 12-15 MPa.<-1 / 2>; and in addition, the depth of the grinding crack measured is reduced by about 70% compared with that of metal ceramic withthe same binding phase, and the friction coefficient is reduced by about 0.1.

Owner:CENT SOUTH UNIV

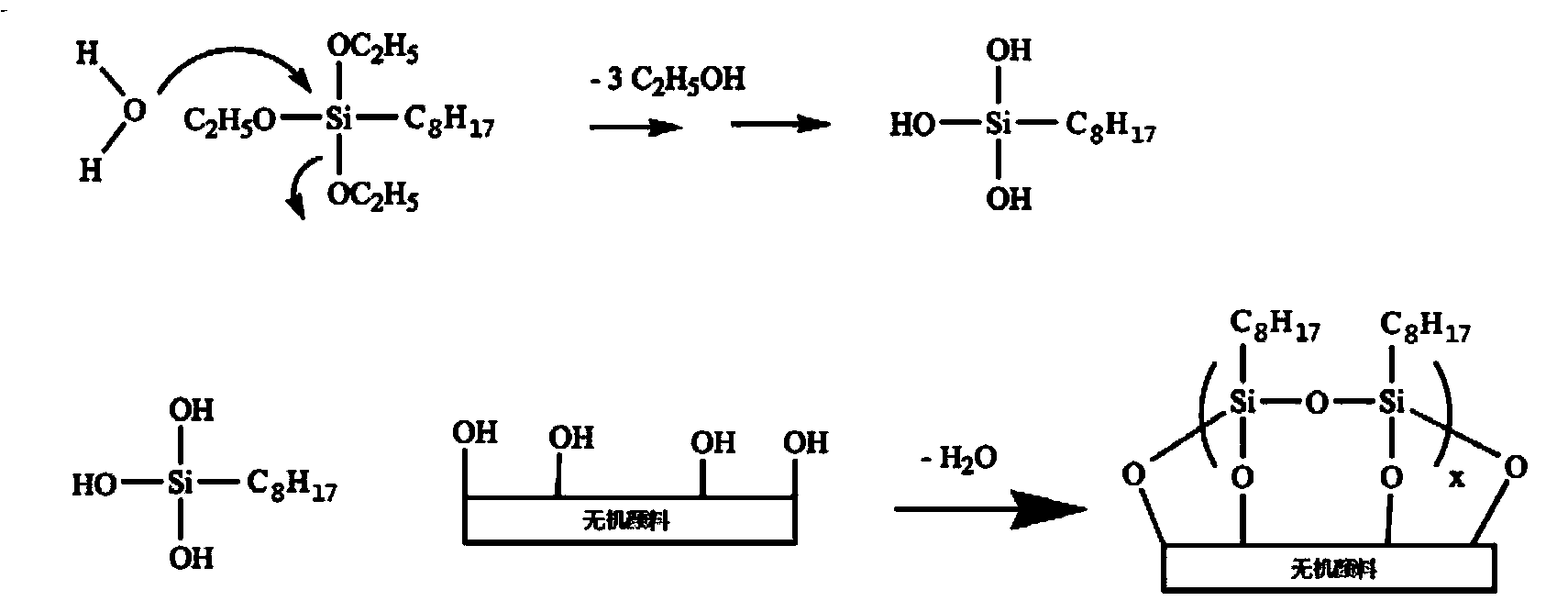

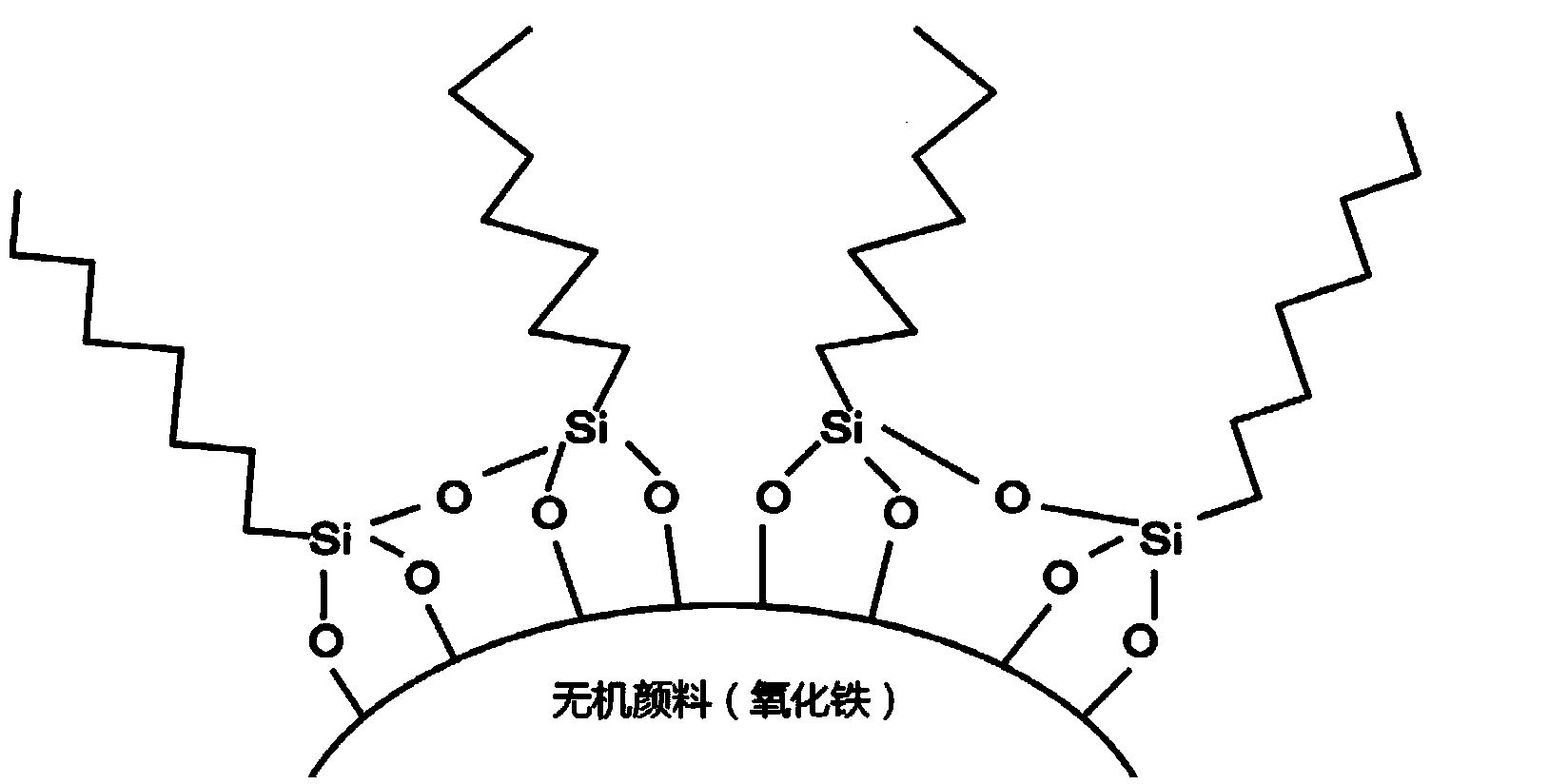

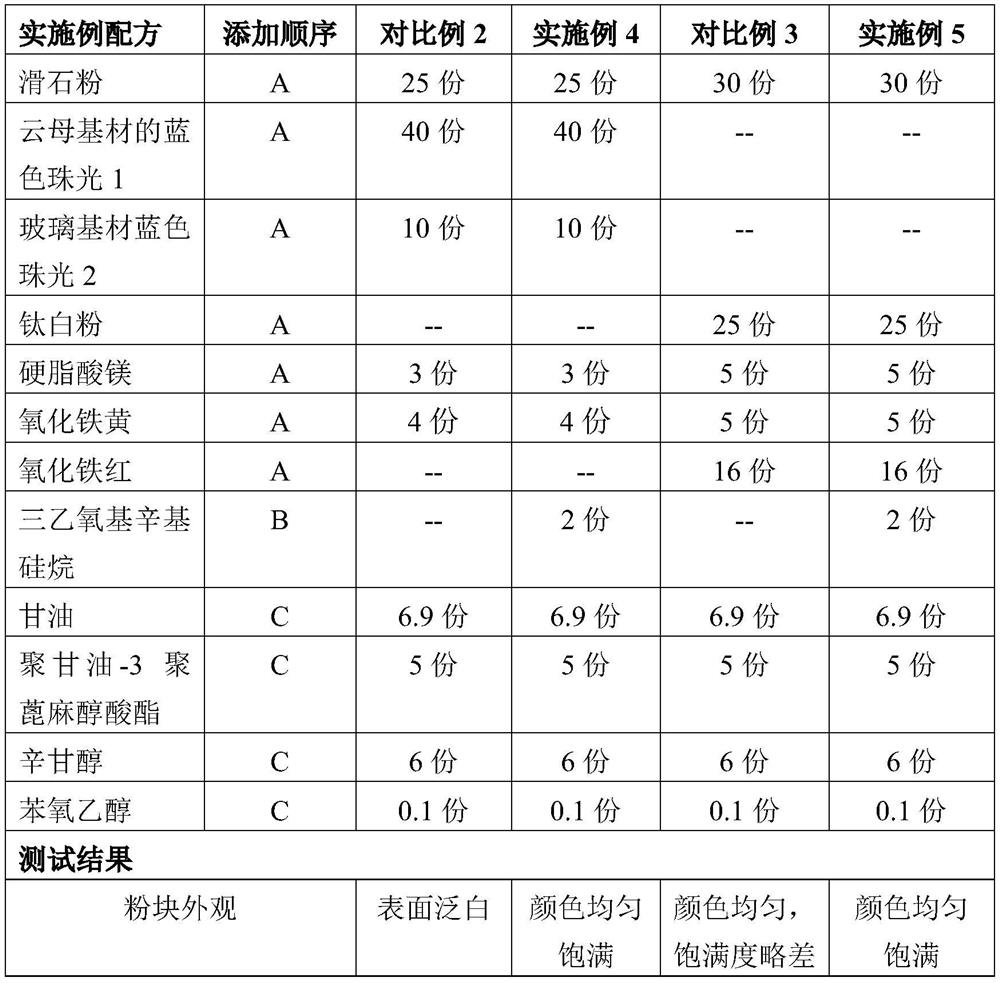

Preparation method of foundation make-up premix having minimal color difference

ActiveCN104055684AUniform surface propertiesEvenly distributedCosmetic preparationsBody powdersEmulsionEngineering

The invention relates to a preparation method of a foundation make-up premix having minimal color difference, which comprises the following steps: (1) performing unified surface treatment on various raw material powder of the foundation make-up premix, and ensuring that the surface properties tend to be consistent; (2) uniformly stirring the treated raw material powder at a high speed to obtain the foundation make-up premix, performing subsequent treatment on the foundation make-up premix mixed by a high-speed stirrer through an airstream smashing method, and ensuring that the powder is uniformly dispersed; (3) measuring the color difference; (4) performing color mixing; and (5) monitoring the color difference, and ensuring that the color difference of the foundation make-up premix delta Ecmc is less than 0.8. According to the invention, the magnitude of the color difference is quantitatively analyzed in a digitization manner by means of an instrument; unified surface treatment is performed on various powder, so that unified surface properties are achieved, thereby ensuring that the powder can be uniformly dispersed and distributed in a dispersion medium or emulsion system; the airstream smashing method is adopted, thereby ensuring that the powder is thoroughly dispersed without bonding and accumulation phenomena; and the color of each batch of premix is comprehensively ensured to be uniform and consistent.

Owner:SHANGHAI CO FUN BIOTECH

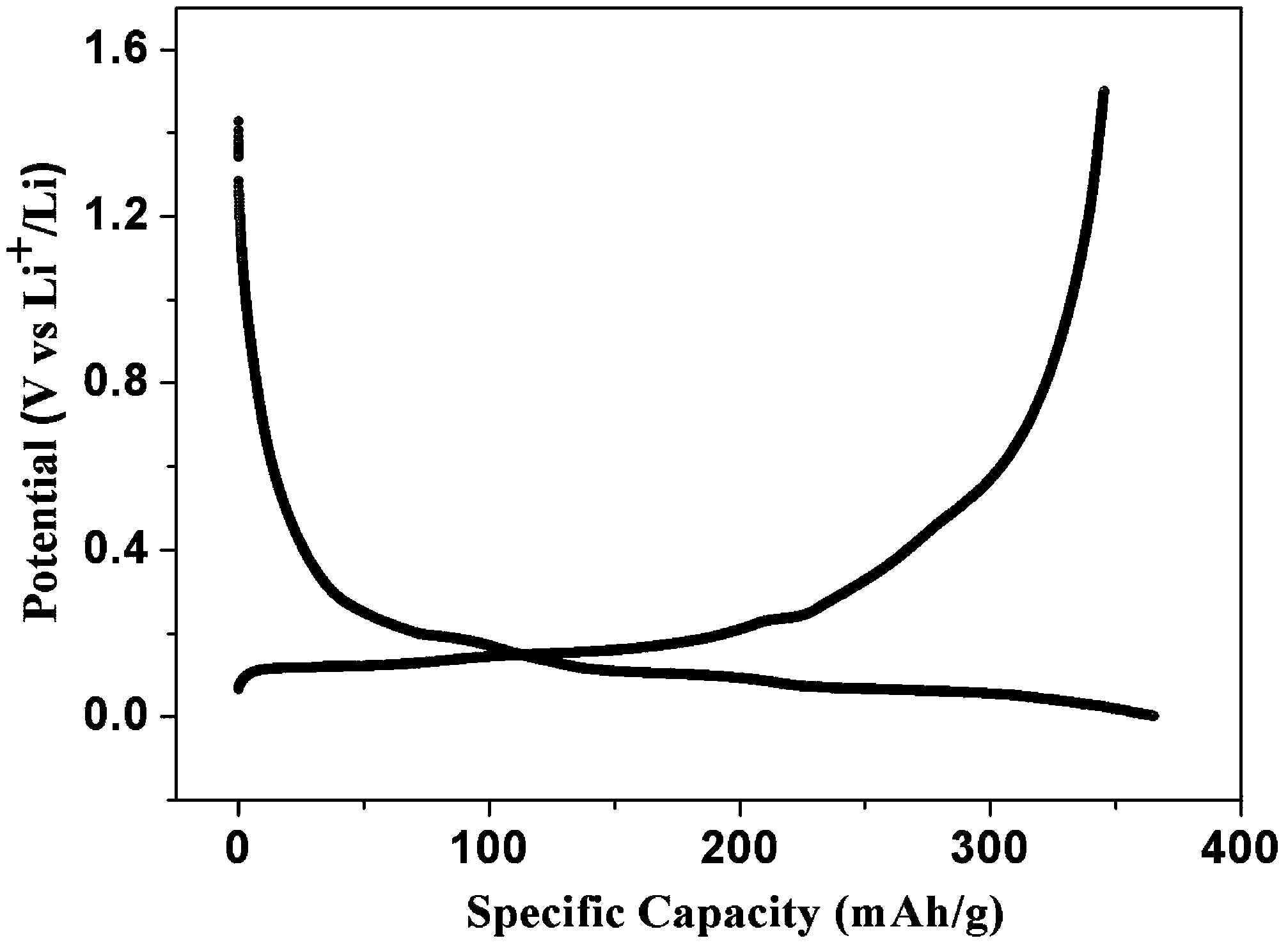

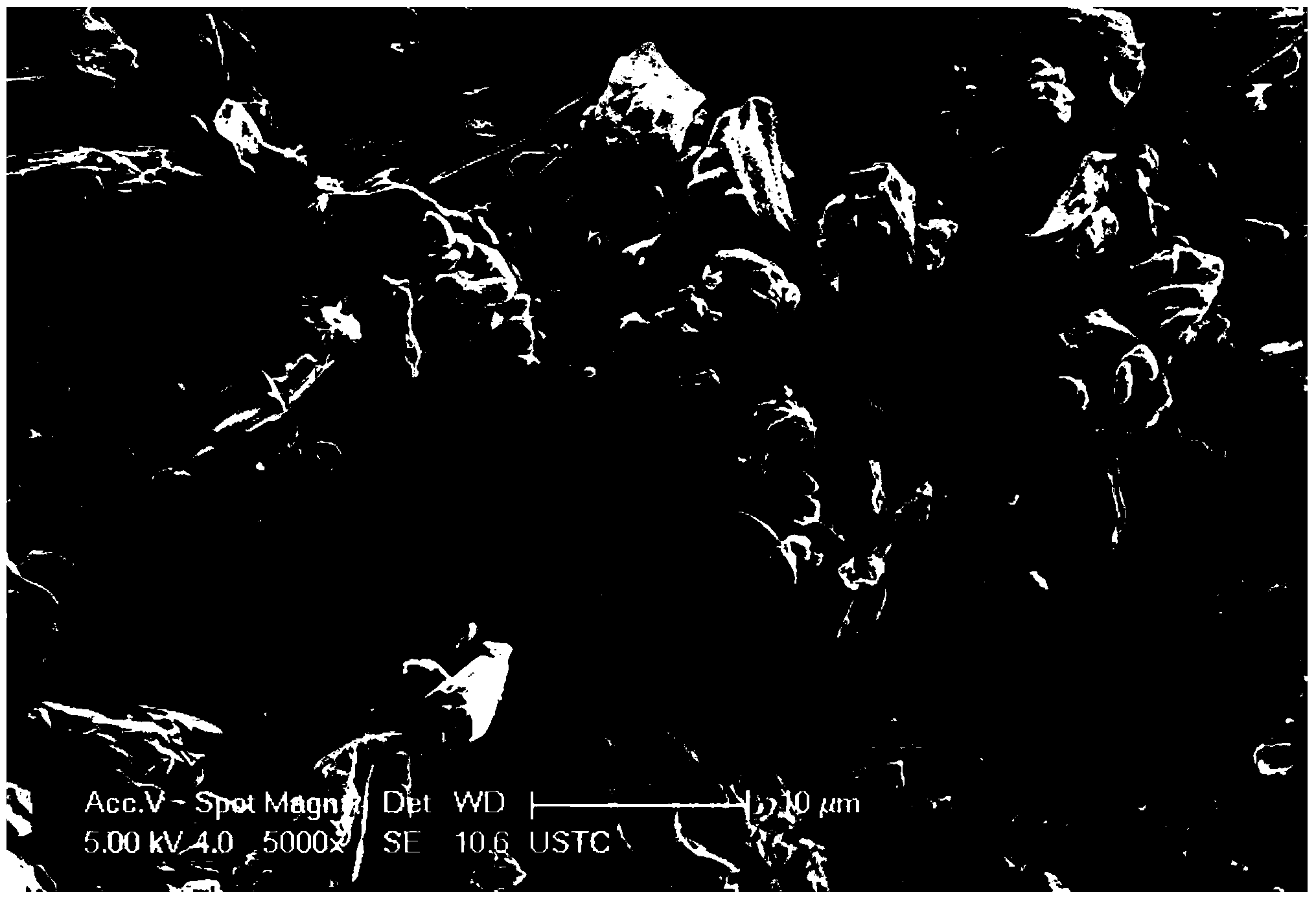

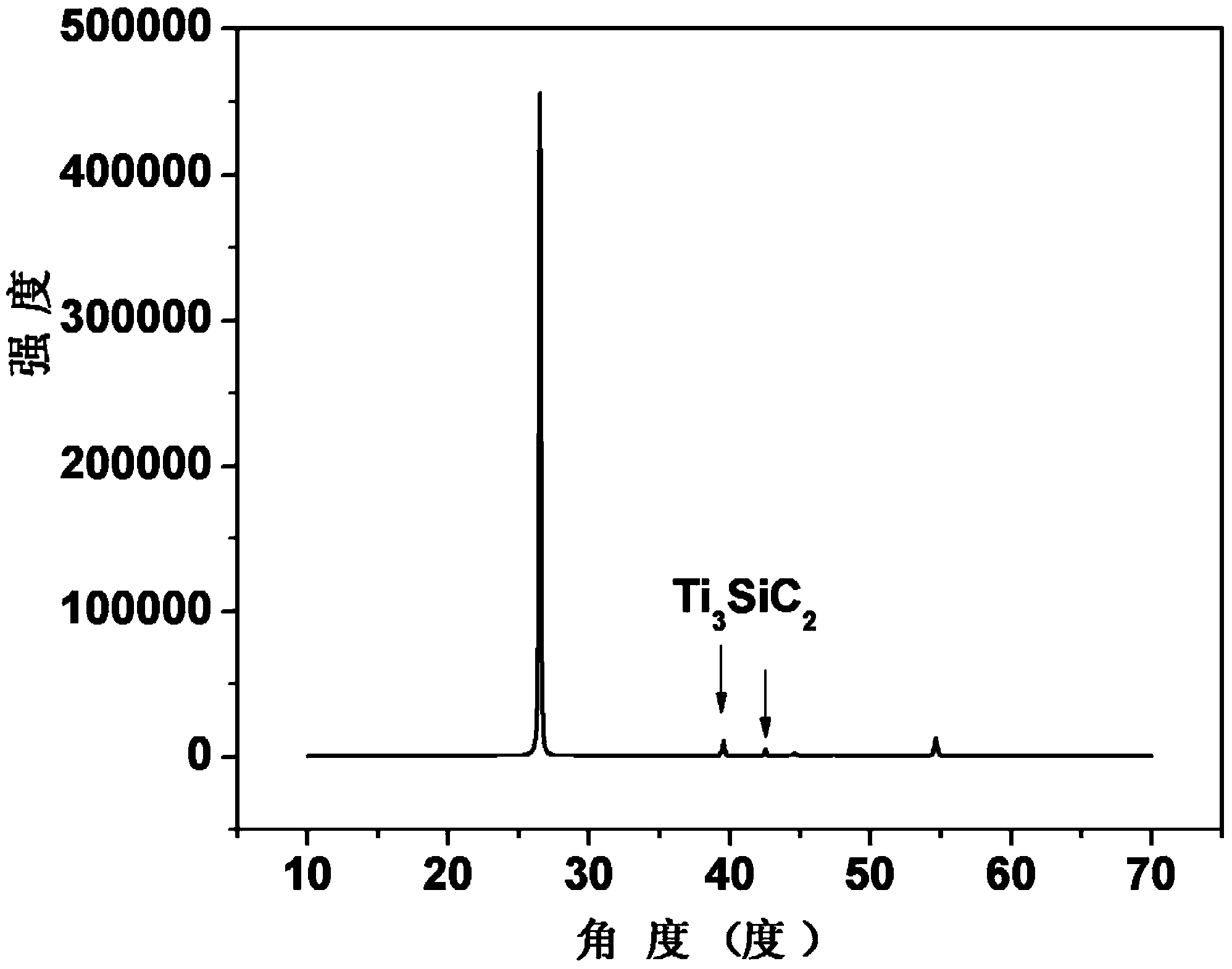

Modified lithium ion battery graphite negative material and preparation method thereof

ActiveCN103928684ASimple processEasy to implementCell electrodesSecondary cellsNew energyLithium-ion battery

The invention discloses a modified lithium ion battery graphite negative material and a preparation method thereof, and belongs to the fields of an electrochemical material and a new energy source. The surface of the modified lithium ion battery graphite negative material is coated with a Ti2SiC2 conductive network. The method comprises the following steps: weighing a titanium source, a silicon source and graphite; adding a dispersing agent and carrying out ball-milling or ultrasonic mixing treatment under the protection of inert gas, and then drying; and sintering the dry material under the protection of a mixed atmosphere of hydrogen and inert gas. The modified lithium ion battery graphite negative material is smooth in surface, uniform in surface property, and high in electronic conductivity. by a surface cladding layer, direct contact of a graphite negative electrode and electrolyte is effectively weakened and the corrosion of the electrolyte is alleviated; the titanium, silicon and carbon surface cladding layer is good in chemical stability and conductivity, a stable crystal structure can be effectively kept in the repeated charge and discharge processes, the electrical conductivity is obviously improved, and the first coulombic efficiency, the rate capability and the cycle performance are obviously improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

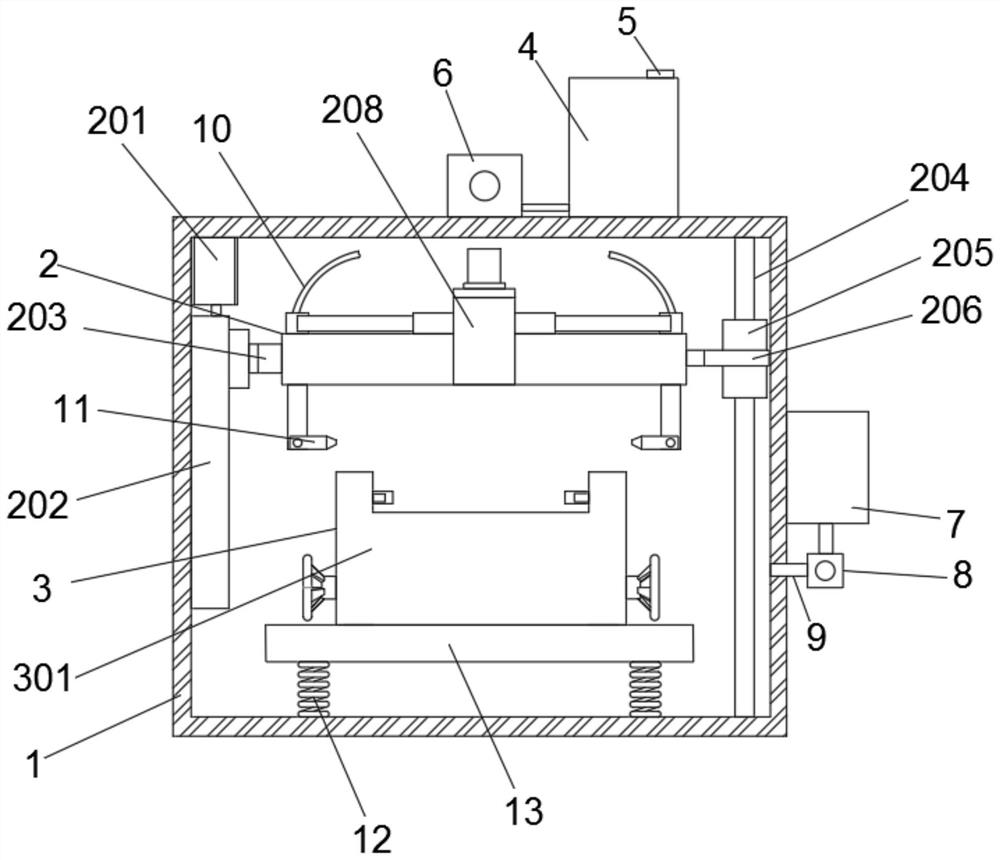

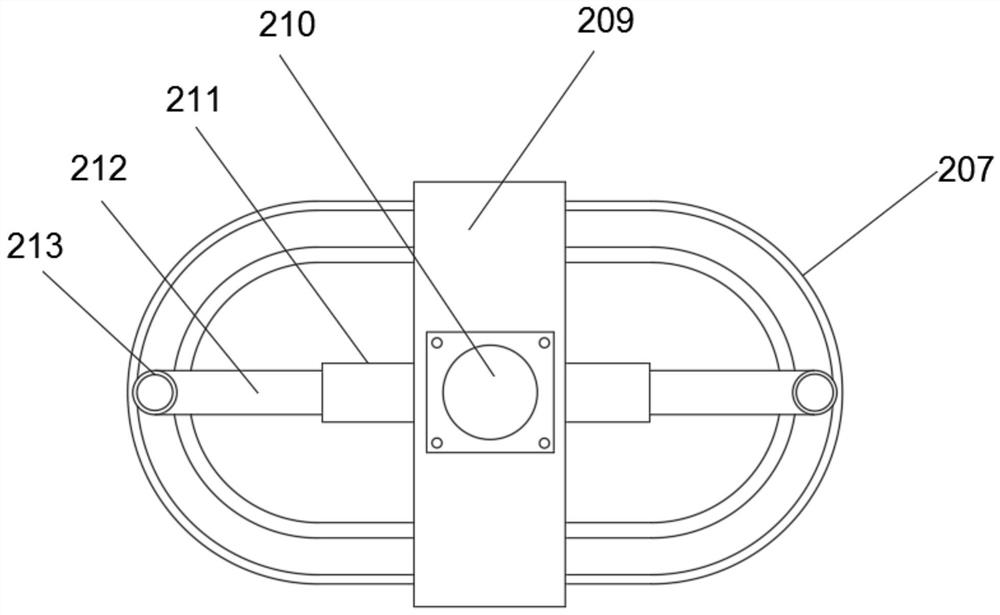

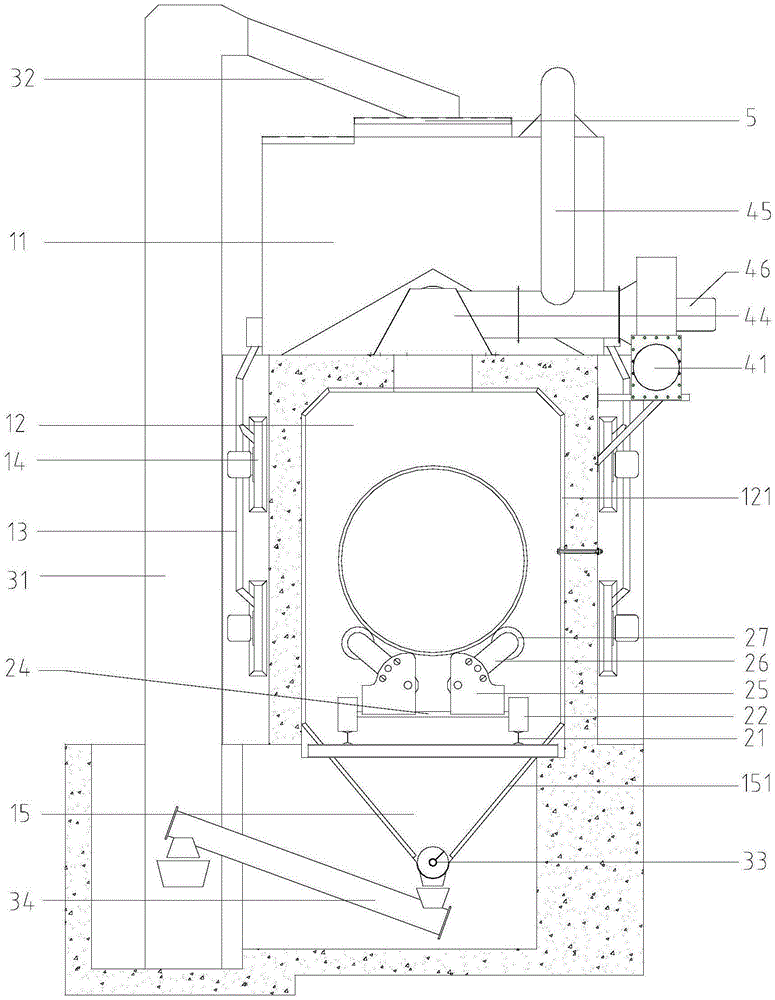

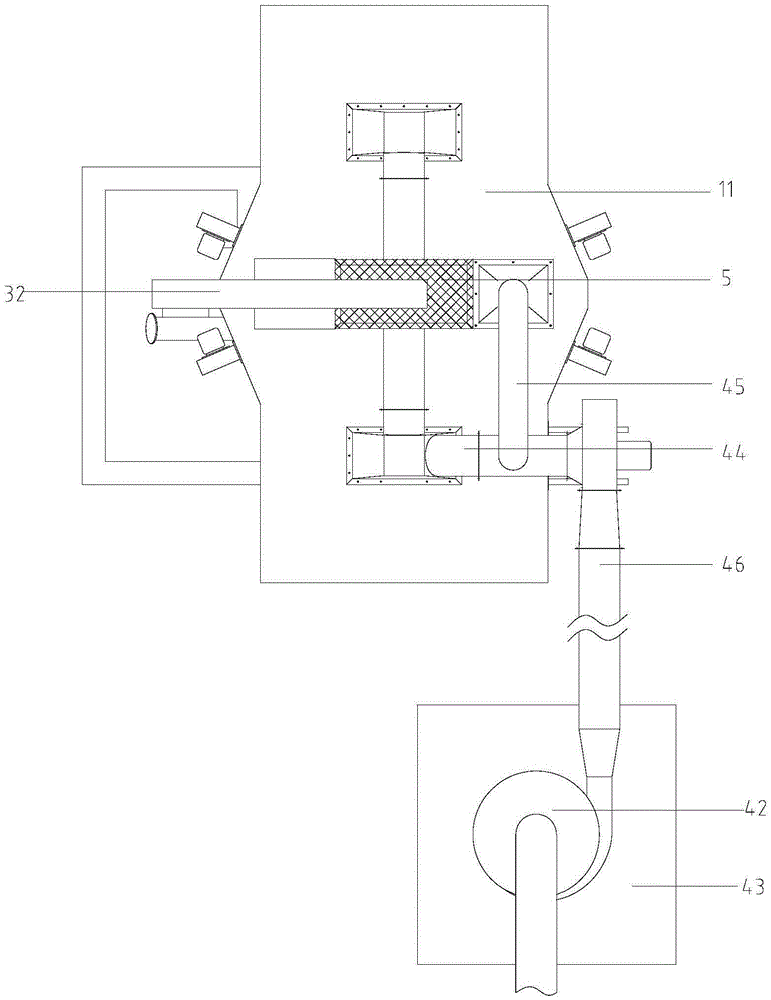

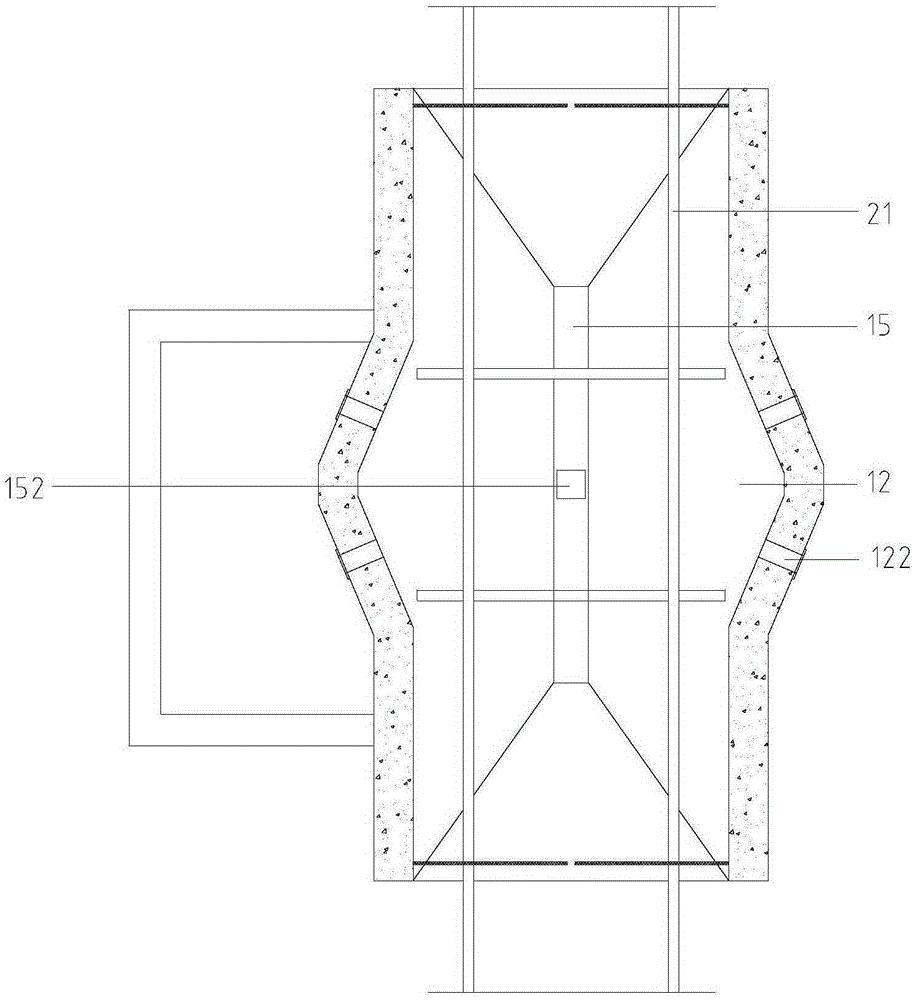

Mildew-proof and corrosion-proof spraying device for wicker product and using method thereof

InactiveCN111774223AThe spraying effect is even and smoothReduce the occluded areaLiquid surface applicatorsCoatingsAgricultural engineeringEngineering

The invention discloses a mildew-proof and corrosion-proof spraying device for a wicker product and a using method thereof. The mildew-proof and corrosion-proof spraying device comprises a box body, aspraying adjusting device and a spraying clamping device, wherein the spraying adjusting device is arranged inside the box body, and the spraying clamping device is arranged right below the sprayingadjusting device. A spraying annular guide rail is arranged, a rotary sleeve rod is in sliding fit with an extendable sliding rod, and meanwhile, a lead screw module is arranged to drive the sprayingannular guide rail to do lifting motion, automatic all-dimensional spraying on the wicker product is achieved, and the symmetrically-arranged spraying clamping device can be adjusted according to thewidth of the wicker product, and a handle hanging lug of the wicker product is clamped so that the shielded area of the wicker product can be reduced, the spraying coverage rate is increased, oil mistis collected after spraying is completed, harm to personnel and the environment is prevented, the whole device is simple and compact in structure, all-around mildew-proof and corrosion-proof sprayingcan be automatically carried out on the wicker product, the labor intensity of workers is reduced, and the production efficiency is improved.

Owner:安徽宏润工艺品有限公司

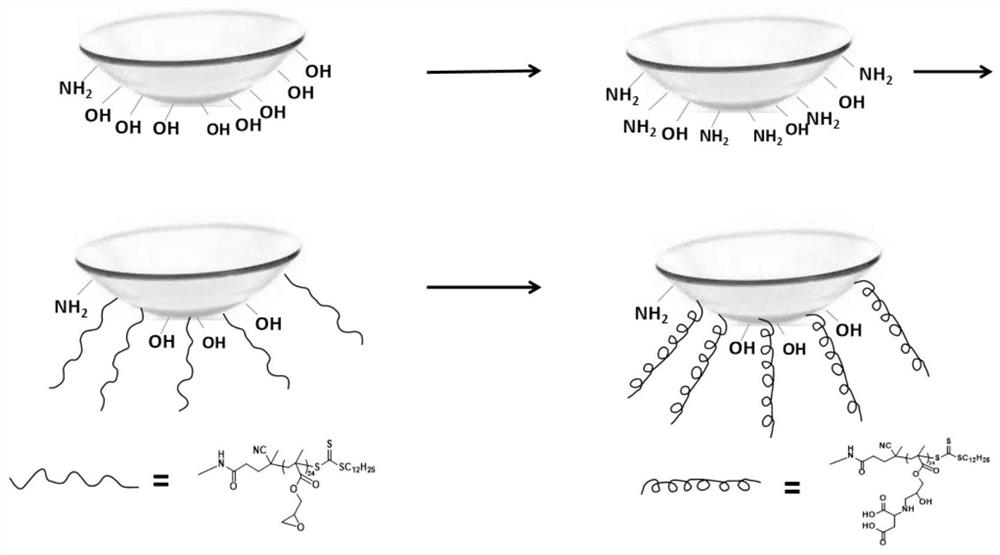

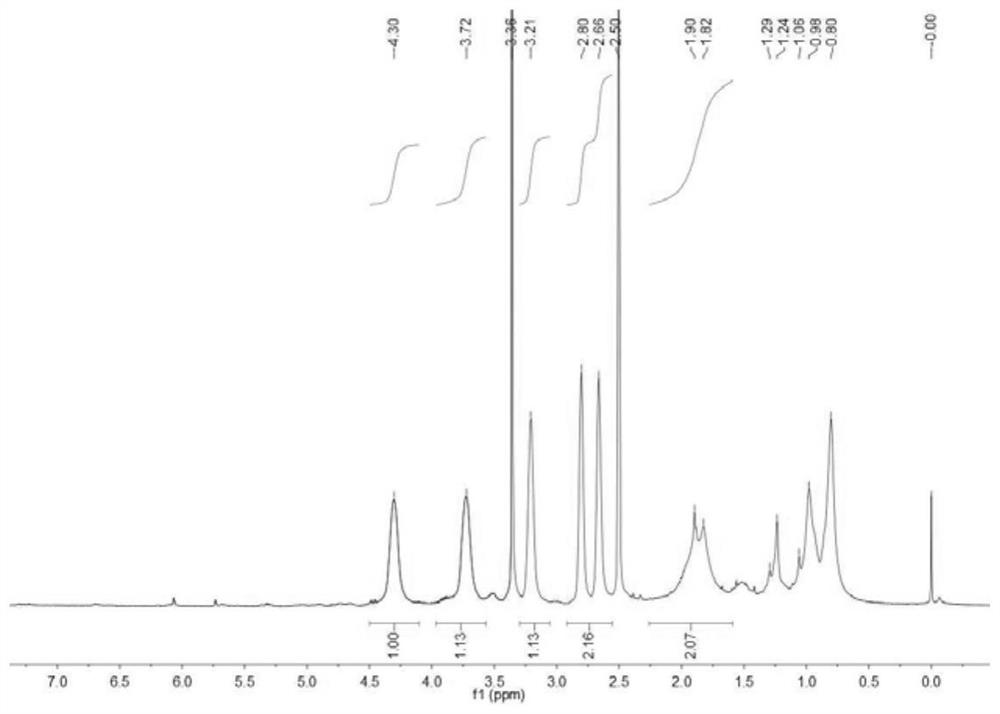

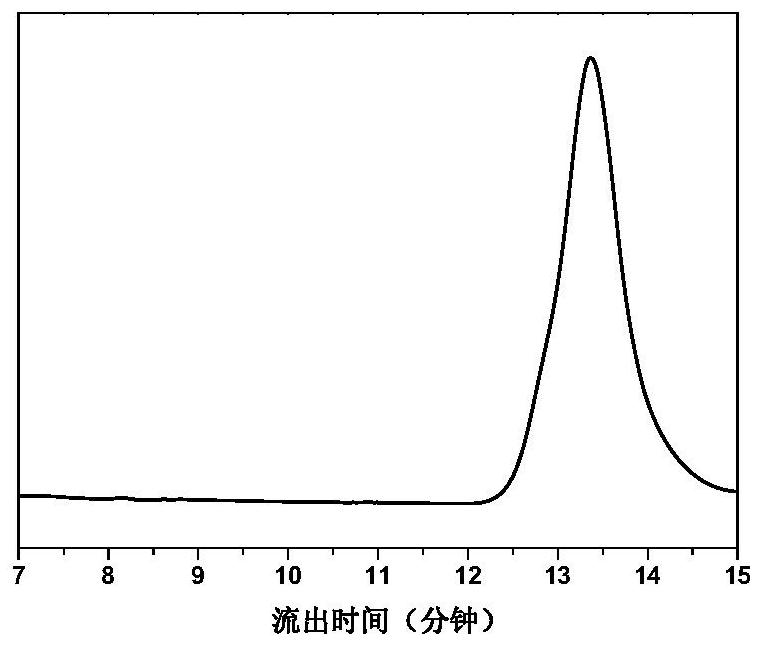

Surface polymer brush modified hydrogel material as well as preparation method and application thereof

ActiveCN112625253AIncrease moisture contentImprove hydrophilicityOptical partsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a preparation method of a surface polymer brush modified hydrogel material. Beta-hydroxyethyl methacrylate (HEMA) is used as a main monomer to prepare cross-linked hydrogel, and the physical and chemical properties of the hydrogel are changed by adding a third component. Then, hydroxyl on the surface of the hydrogel is activated into amino, the amino is coupled to carboxyl at the tail end of polyglycidyl methacrylate (PGMA) prepared through reversible addition-fragmentation chain transfer (RAFT) free radical polymerization, and a polymer chain is grafted to the surface of the hydrogel. Further, the surface of the hydrogel is modified with functional molecules through the reaction of small molecules with amino groups and epoxy groups in the PGMA. Through a post-modification method, the surface of the hydrogel is modified with a layer of functional polymer brush, and the length of the polymer brush can be adjusted through the RAFT polymerization reaction feeding ratio. On the basis of keeping the water content and mechanical properties of the hydrogel, the surface properties of the hydrogel are changed, and the protein adsorption resistance is improved.

Owner:NANJING 3H MEDICAL PROD CO LTD

Lacquer painting processing composition, lacquer painting processing method and lacquer painting mending method

InactiveCN101591510AUniform surface propertiesAqueous dispersionsPolishing compositions with abrasivesMohs scale of mineral hardnessLacquer

Owner:3M INNOVATIVE PROPERTIES CO

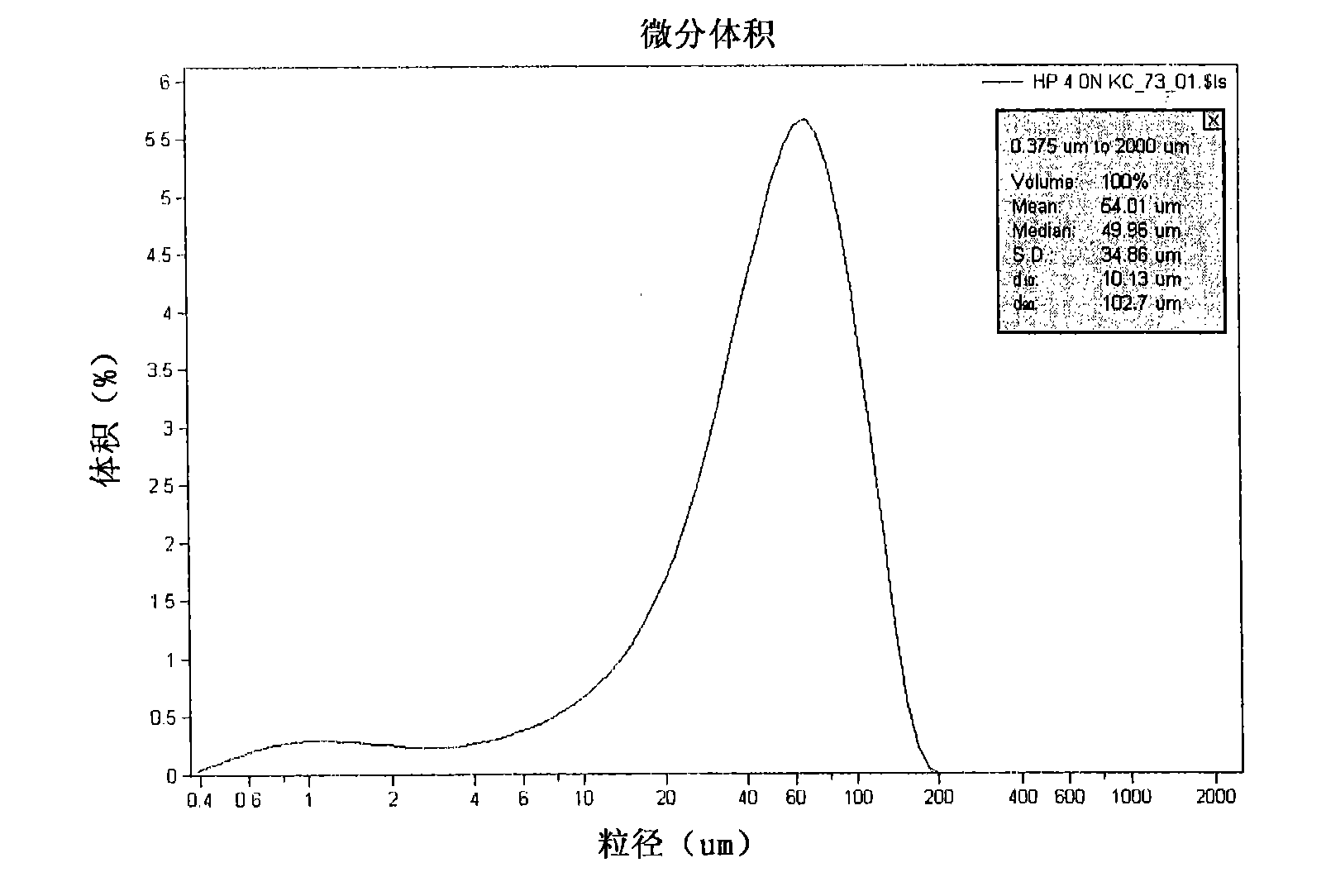

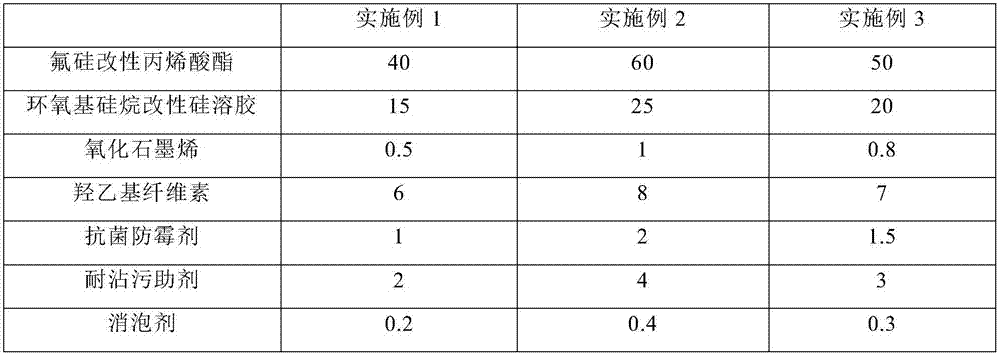

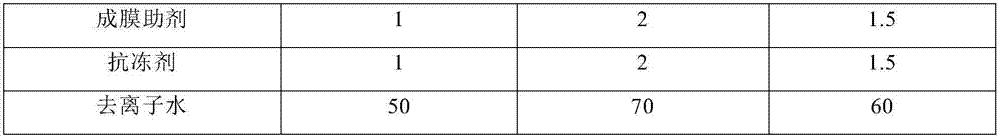

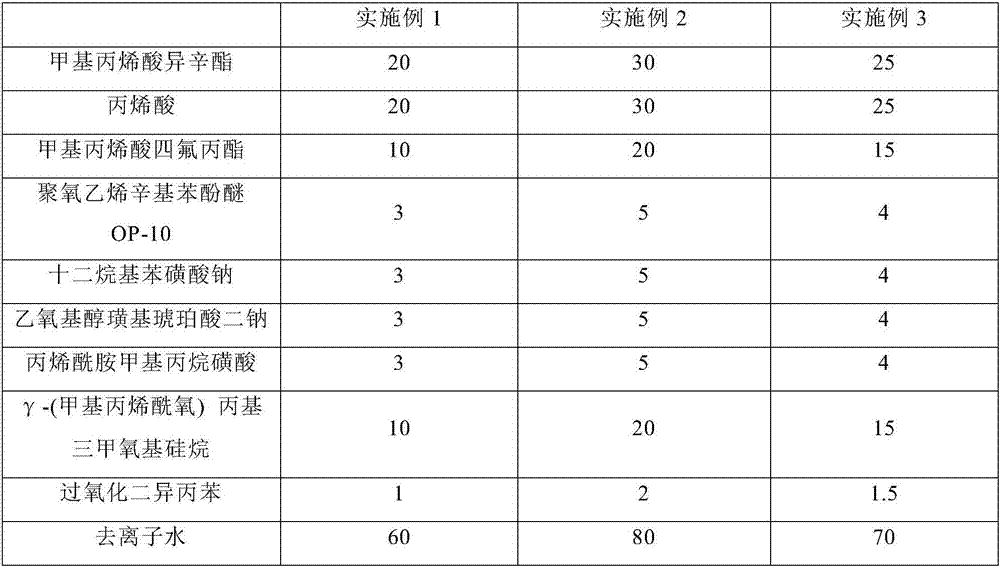

Method for preparing high-performance fluorine-silicon modified finish-coat paint

InactiveCN107502119AStrong adhesionImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceEpoxy

The invention discloses a method for preparing high-performance fluorine-silicon modified finish-coat paint. The method is simple in process, low in manufacturing cost, safe, environment-friendly and suitable for industrial production. Fluorine-silicon modified acrylate serves as a main raw material and is excellent in film-forming property, high in adhesive force and excellent in hydrophobic property; epoxy silane modified silica sol is capable of improving the film surface performance and excellent in dispersity and realizes film surface performance uniformity; due to the addition of graphene oxide, the adhesive force, flexibility, impact resistance, water resistance, salt fog resistance and hardness of the finish-coat paint can be greatly improved; the antibacterial mildew preventive adopts traditional Chinese herbal medicine extract and is safe, environment-friendly, non-toxic and excellent in antibacterial property; the stain-resistant assistant contributes to improving the stain resistance of the finish-coat paint film; and the finish-coat paint disclosed by the invention has the adhesive force reaching the level 2, has a static contact angle of 110-120 degrees between the coating and water, has good flexibility and impact resistance and excellent hydrophobic property, water resistance, salt fog resistance and stain resistance, does not contain any volatile organic compound and is safe, environment-friendly, antibacterial, mildew-proof and long in service life.

Owner:苏州振振好新型建材科技有限公司

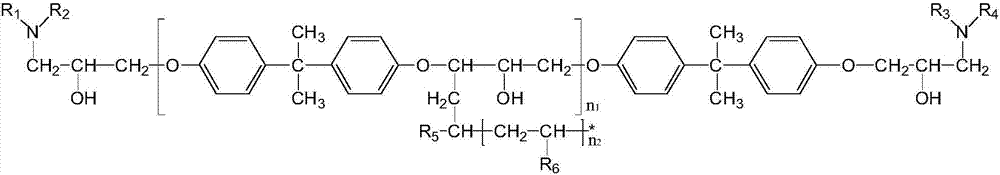

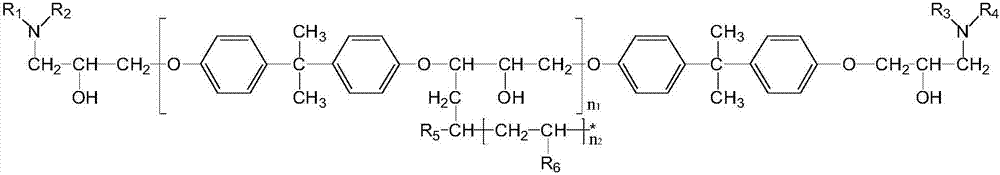

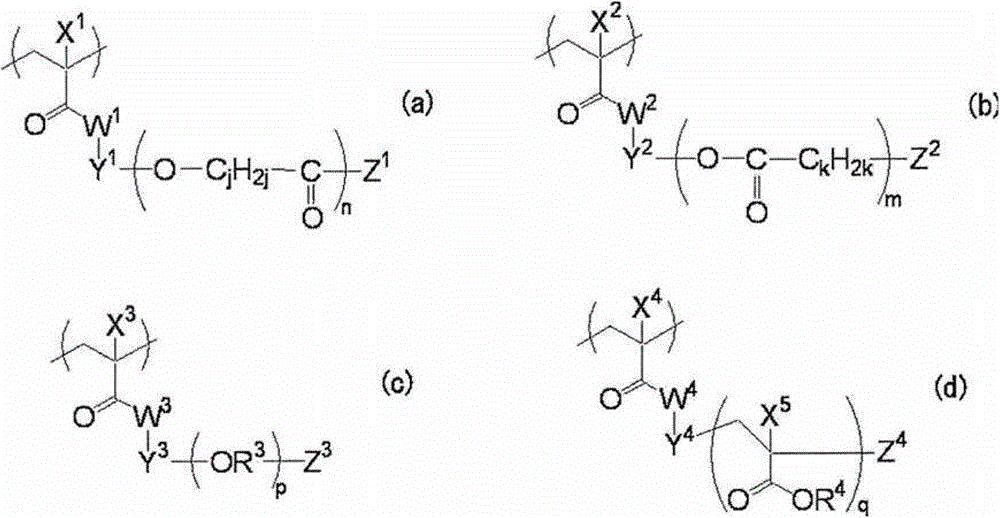

Epoxy resin surface-coated with hydrophilic coating and preparation method and application thereof

The invention discloses epoxy resin surface-coated with a hydrophilic coating. The bonding mode between the hydrophilic coating and an epoxy resin layer is chemical crosslinking. The epoxy resin layer is cured epoxy resin surface-grafted with a hydrophilic polymer. The structural formula is as shown in the specification. In the formula, R1-R4 are connection points with other epoxy resin chain structures; R5-R6 are hydrophilic monomer polar groups; and n1 and n2 are natural numbers, n1 is less than or equal to 10 and greater than or equal to 1, and n2 is less than or equal to 50,000 and greater than or equal to 1. According to the method of the invention, harsh surface cleaning or coating of an intermediate bonding layer is not adopted. Through crosslinking, the cured epoxy resin surface-grafted with the hydrophilic polymer and the subsequently-coated hydrophilic coating are bonded firmly, thus achieving the purpose of firmly bonding the hydrophilic coating to the surface of an epoxy resin substrate. Different ionic monomers can be selected as a homopolymer or copolymer monomer of the hydrophilic coating. Sources of the raw materials are wide, and the hydrophilic coating with uniform surface property can be prepared.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

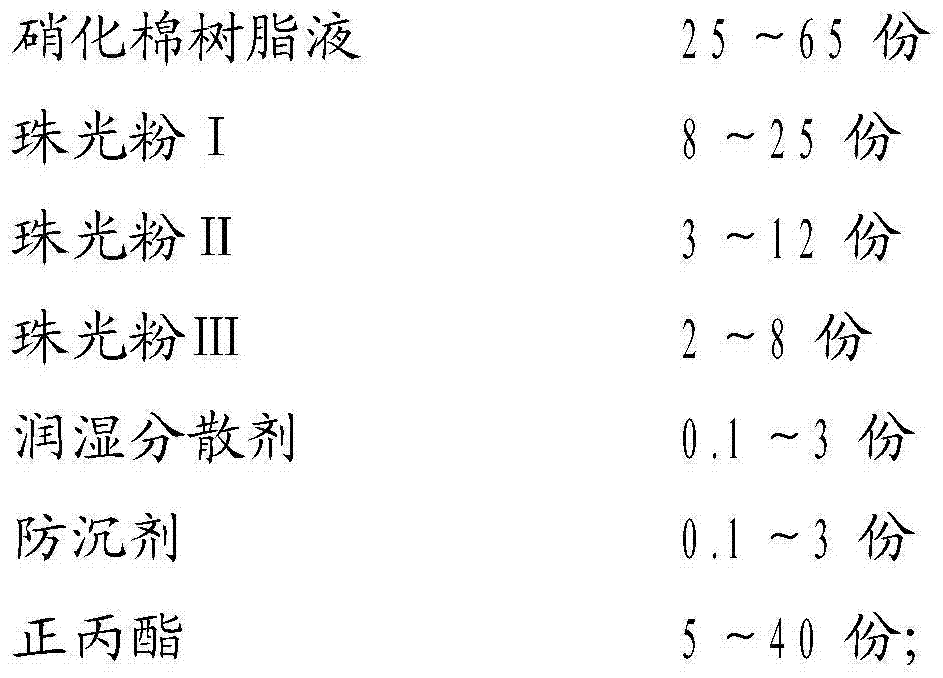

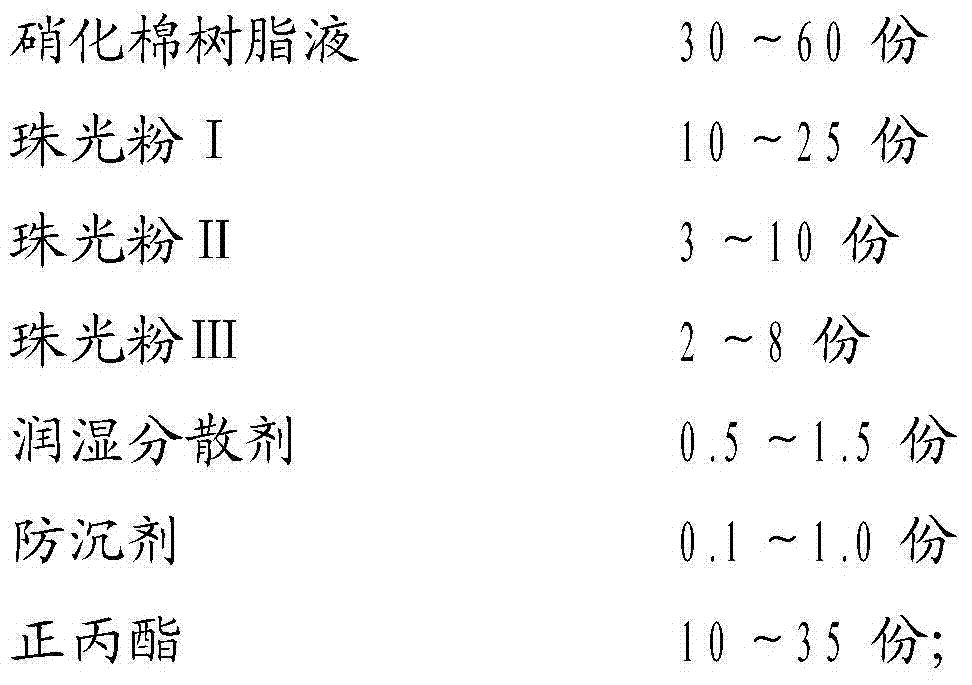

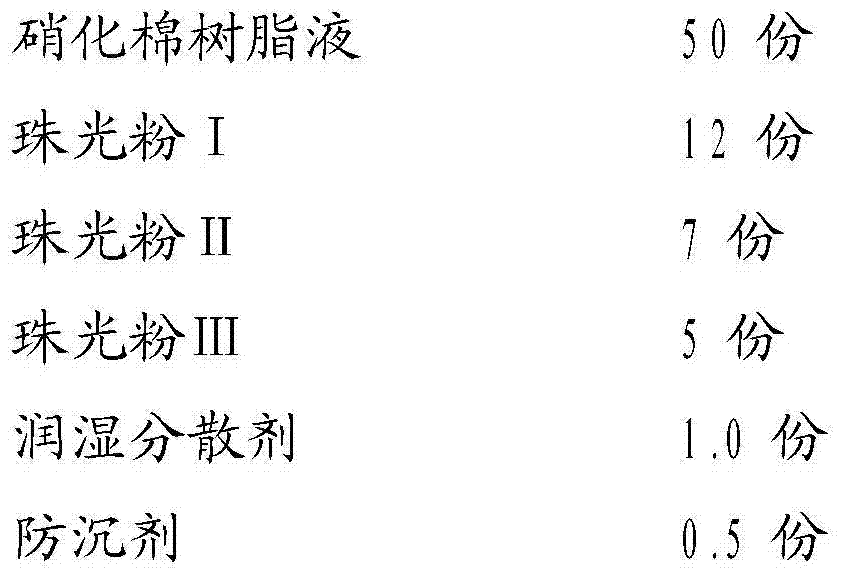

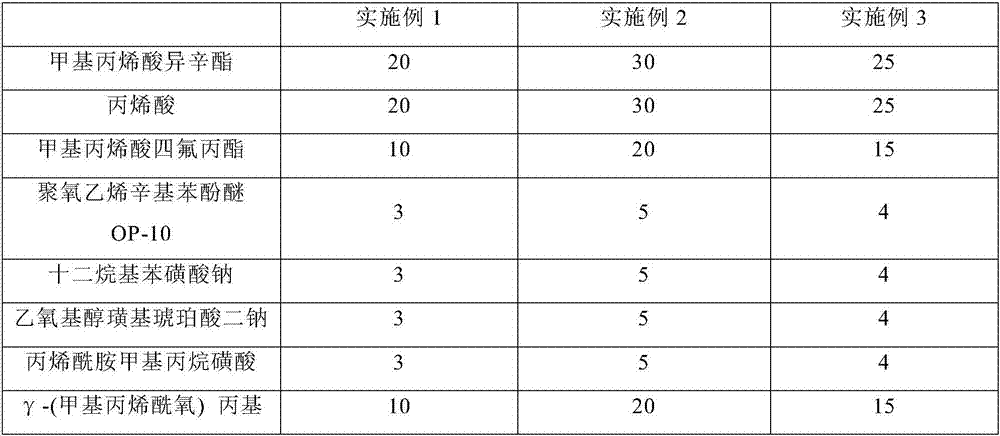

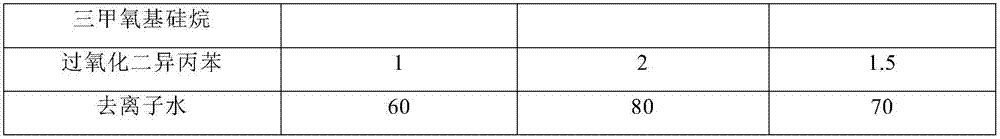

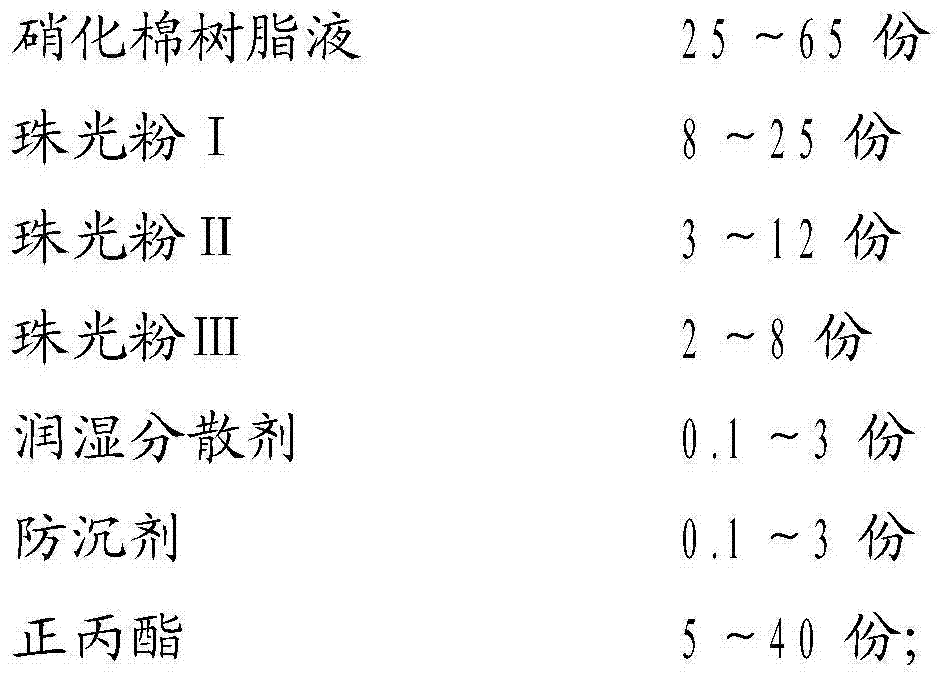

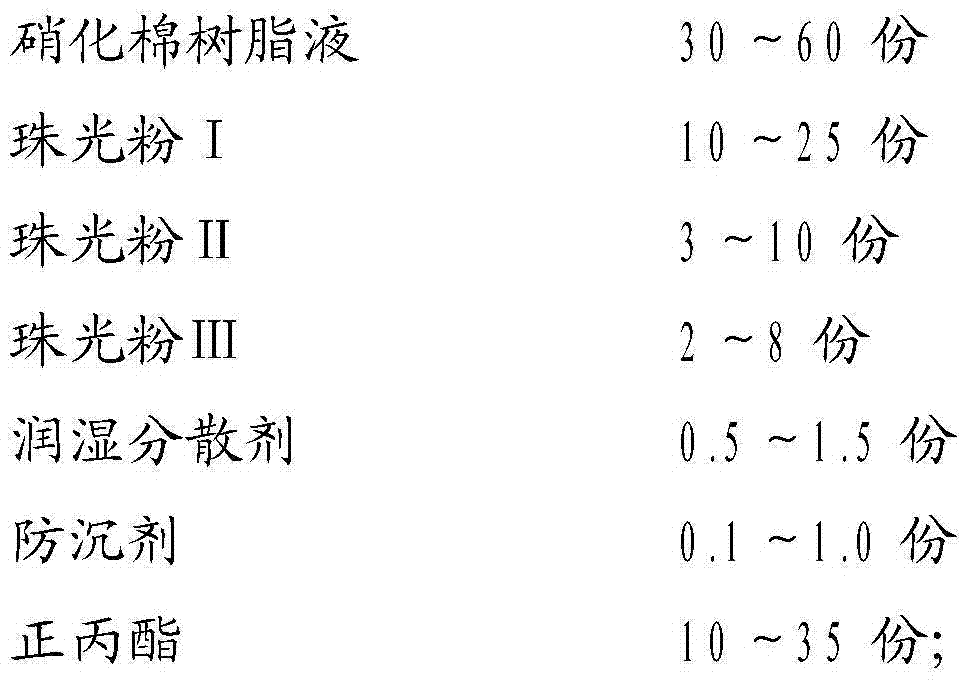

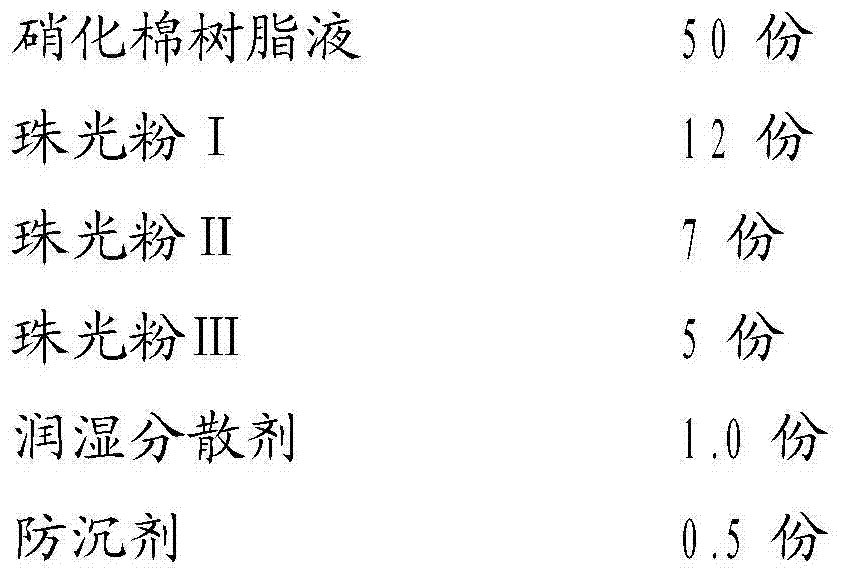

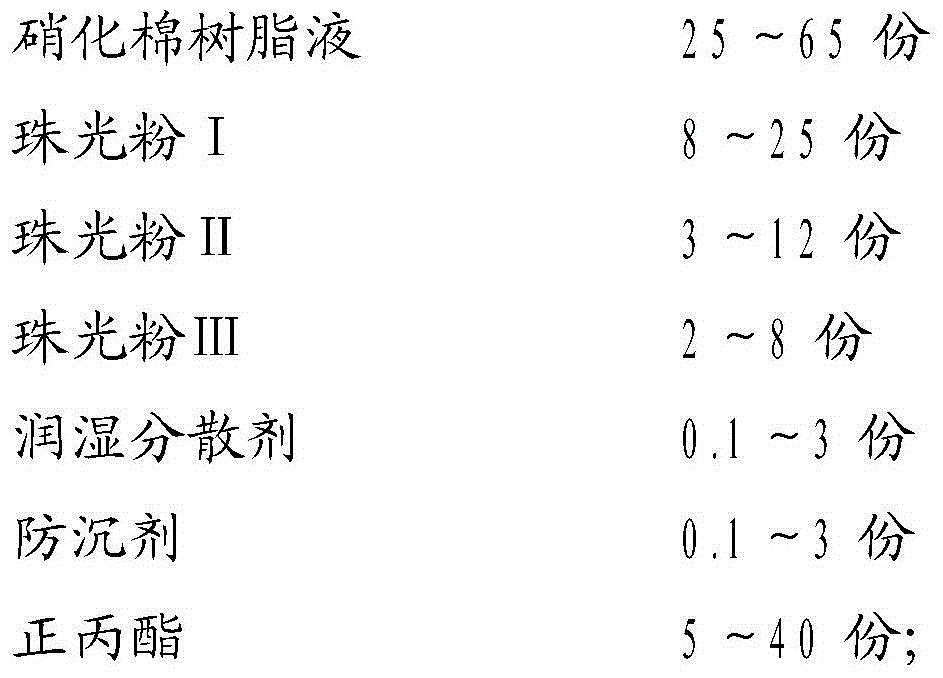

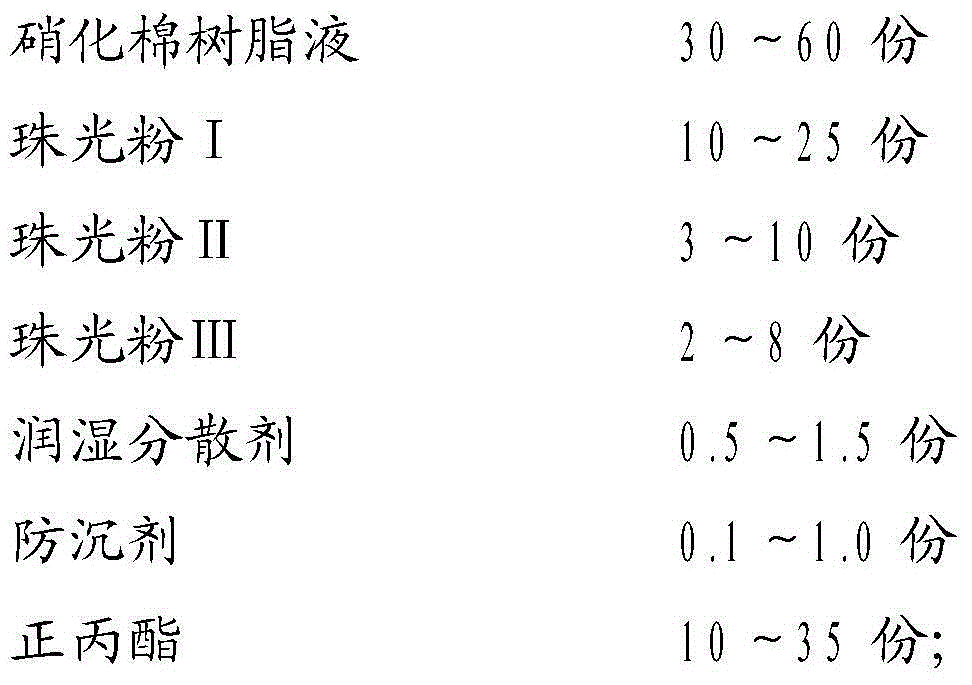

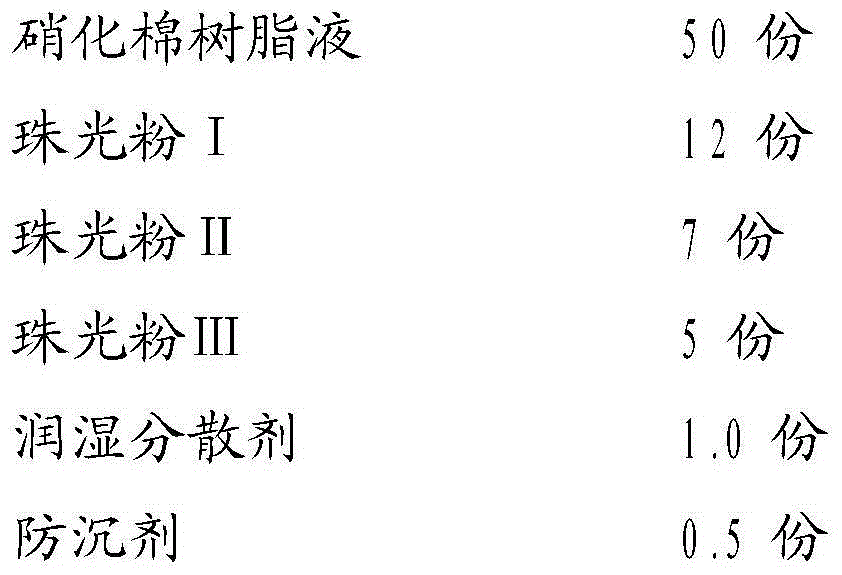

Pearlescent ink, and preparation method and printing method thereof

InactiveCN103773105AAdaptableGood surface effectInksOther printing apparatusWettingMaterials science

The invention discloses a pearlescent ink which is especially used for intaglio printing of light-color substrates. The pearlescent ink is mainly prepared from the following raw materials in parts by weight: 25-65 parts of nitrocellulose resin liquid, 8-25 parts of pearlescent powder I, 3-12 parts of pearlescent powder II, 2-8 parts of pearlescent powder III, 0.1-3 parts of wetting and dispersing agent, 0.1-3 parts of anti-settling agent and 5-40 parts of n-propyl ester. Correspondingly, the invention also discloses a preparation method of the pearlescent ink and a printing method of the pearlescent ink. The pearlescent ink can satisfy the requirements for intaglio printing on light-color substrates, and has favorable printing effect.

Owner:惠州市立美特环保油墨有限公司

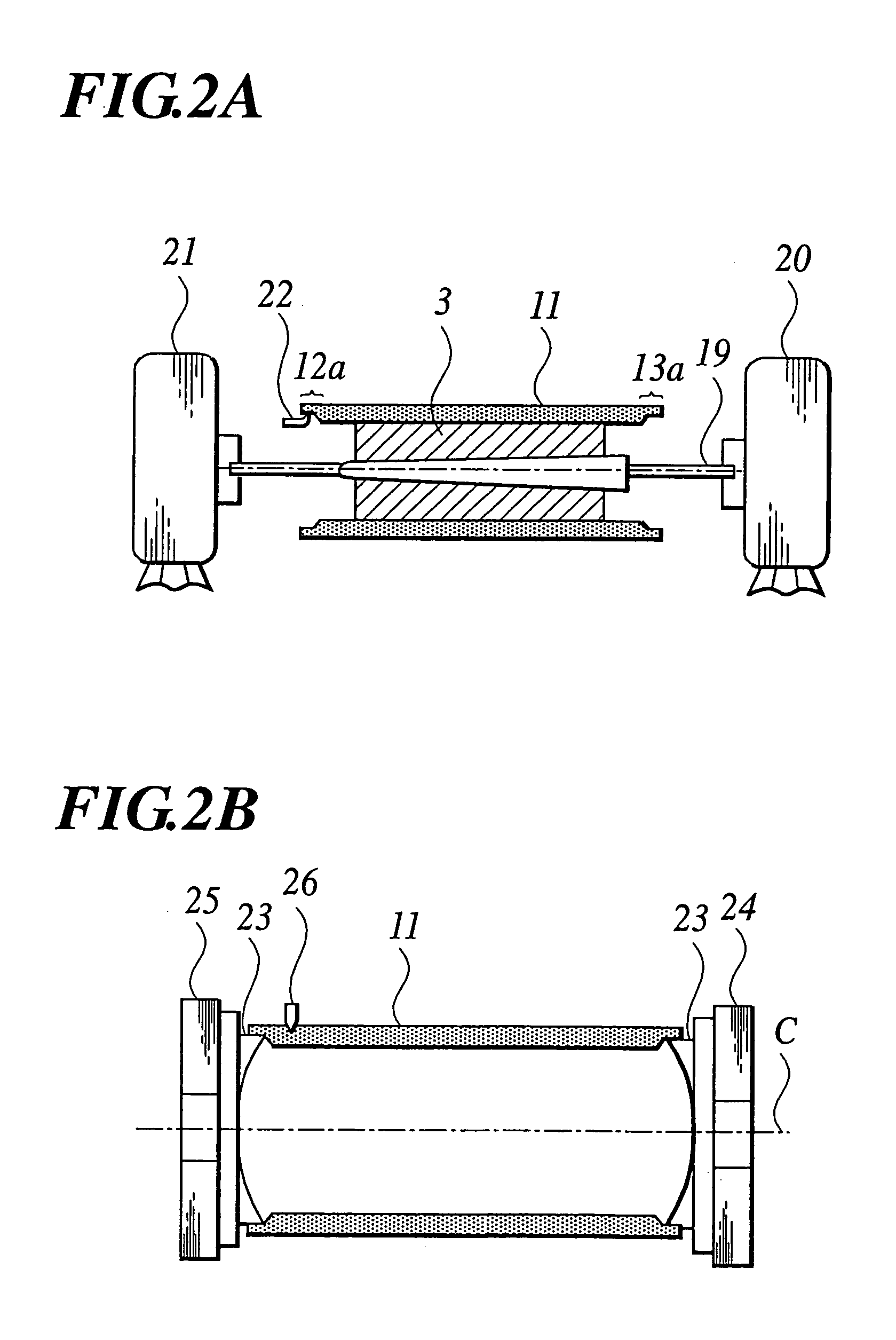

Automatic shot blasting device for large steel tube or steel beam

InactiveCN105328583ALarge inner spaceAvoid dust pollution to the environmentAbrasive feedersAbrasive machine appurtenancesSteel tubeSurface finishing

The invention discloses an automatic shot blasting device for a large steel tube or steel beam. The automatic shot blasting device comprises a shot blasting chamber, a workpiece pushing car system, a circulating sand blasting system and a purification system, wherein the shot blasting chamber comprises a sand blasting chamber which is provided with a channel allowing a workpiece to pass through; the workpiece pushing car system is arranged along the workpiece channel of the sand blasting chamber; the circulating sand blasting system comprises an auger conveying component, a steel shot hoister and a sand-sliding pipe; the purification system comprises an air pipe, a fan, a cyclone separator and a dust removing chamber. The inner space of the sand blasting chamber of the automatic shot blasting device is large and particularly suitable for surface treatment for the large steel tube or steel beam. The automatic shot blasting device can prevent dust from polluting the environment, greatly reduce steel shot loss and relieve labor intensity and has the advantages of being small in pollution, low in cost and capable of improving production safety. The workpiece pushing car system drives the workpiece to automatically rotate, uniform effects on all the surfaces of the workpiece are guaranteed, nonuniformity of roughness values is reduced, and the product quality is guaranteed.

Owner:ANHUI JIXI JIADE STEEL STRUCTURE

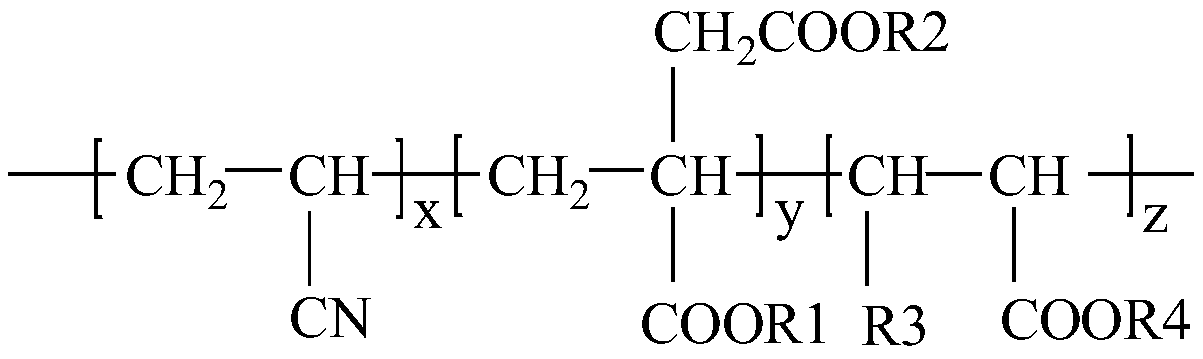

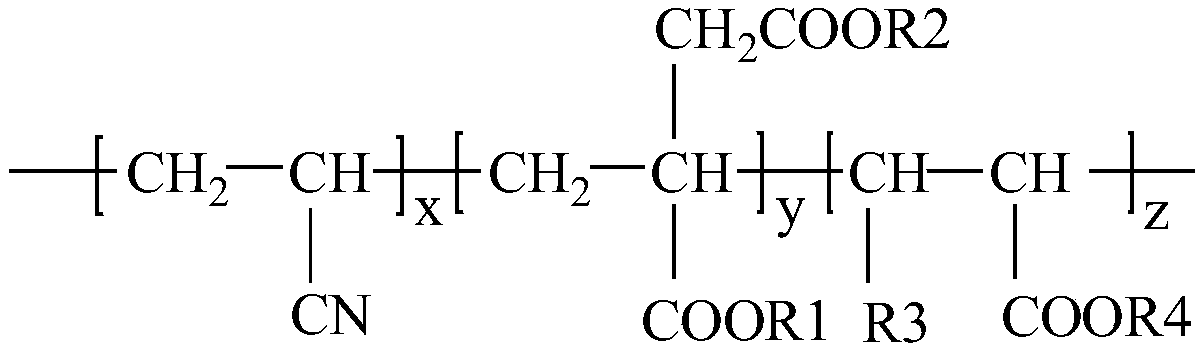

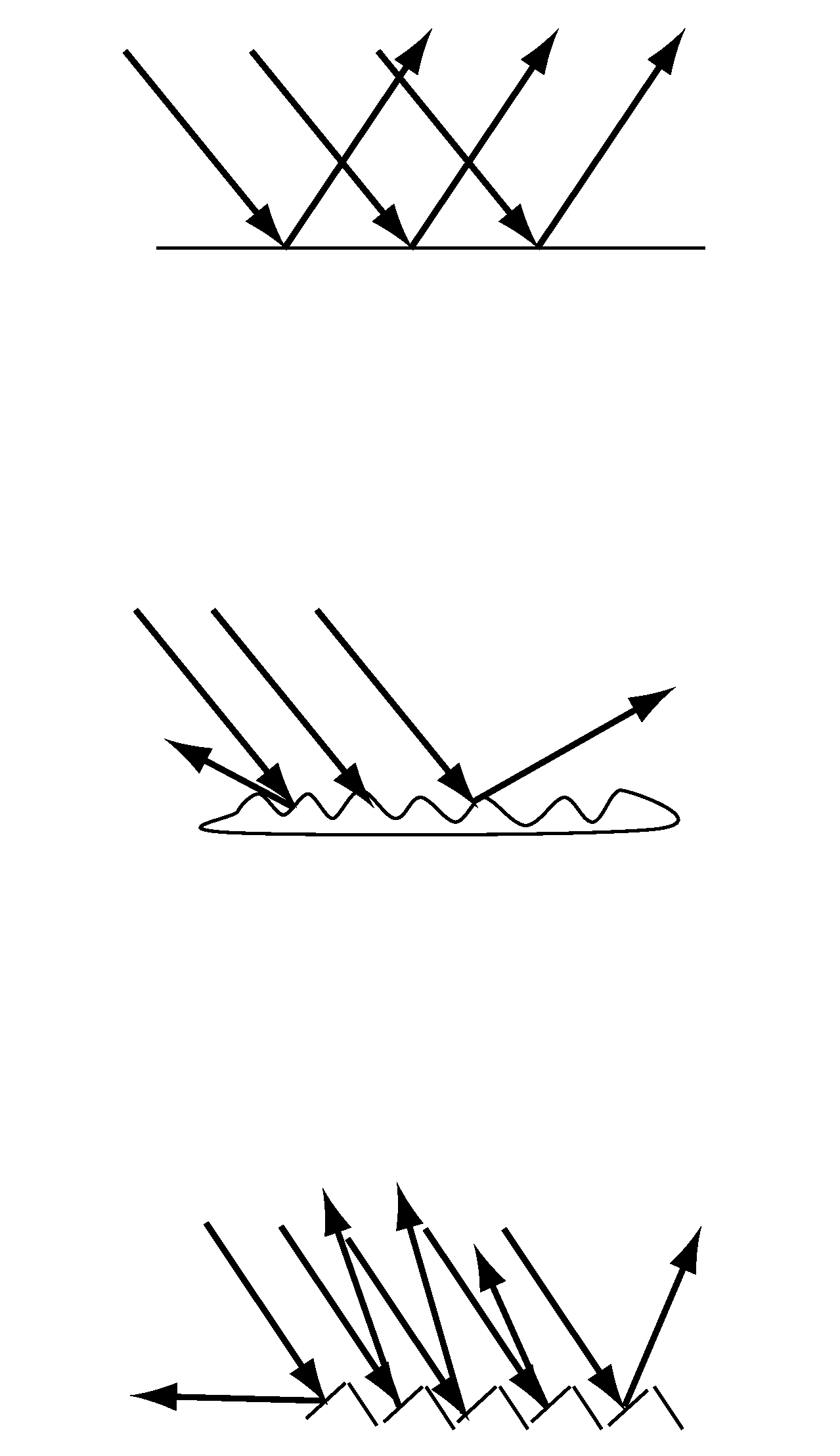

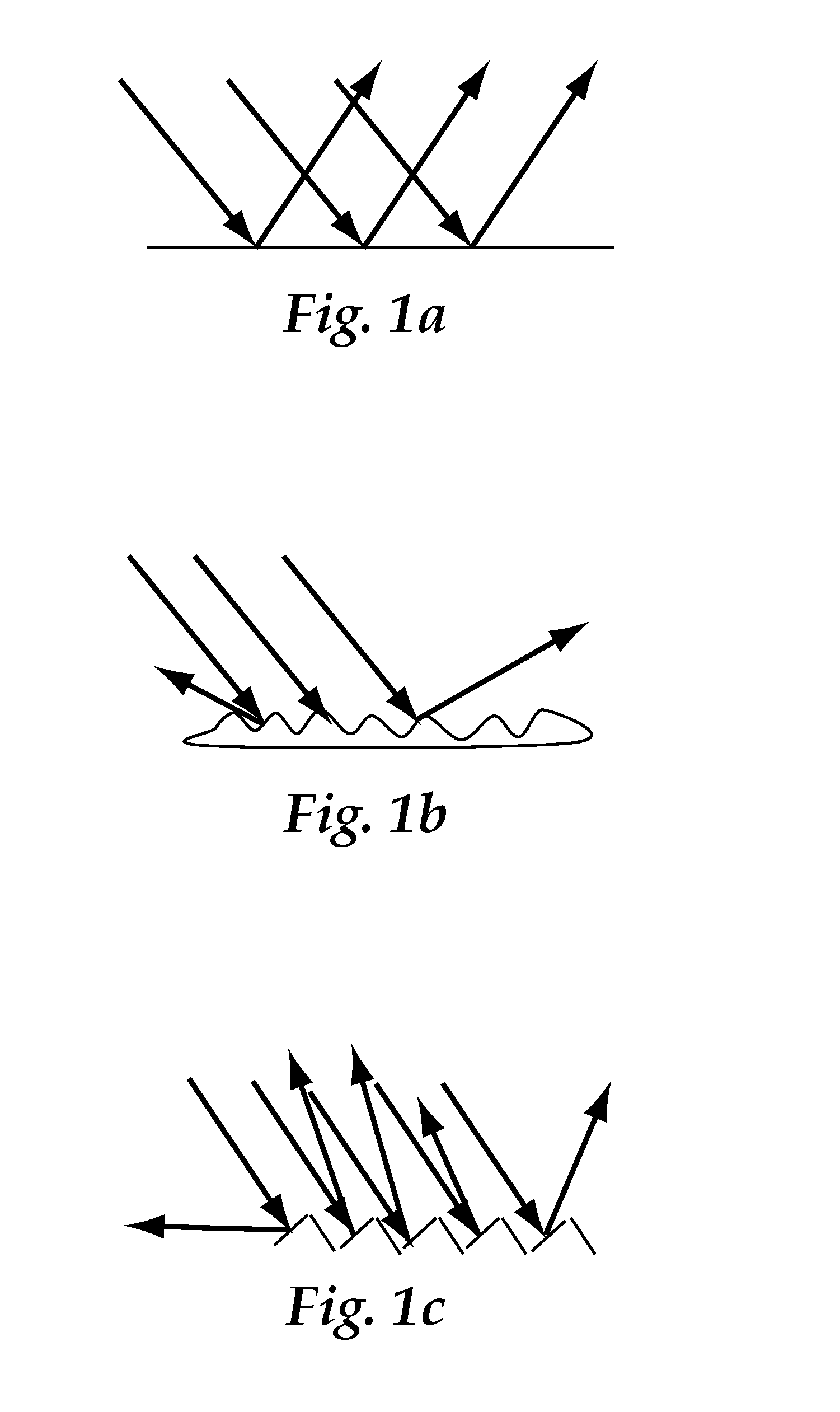

Anti-dazzle glass processing method and anti-dazzle glass

The invention relates to an anti-dazzle glass processing method and anti-dazzle glass and discloses the anti-dazzle glass processing method. The method comprises the following steps: S1, providing a silicon resin material and a glass substrate; S2, spraying the silicon resin material to the surface of the glass substrate by a low pressure atomizing spray gun to form a silicon resin film which is a coarse film; and S3, roasting the glass substrate at 200-400 DEG C for 20-80 minutes. The method can effectively avoid conditions of lines and uneven thicknesses and the like of the glass and is free from environmental pollution, and the glass has high glossiness and high transmittance.

Owner:SHENZHEN SANXIN JMT GLASS

Image forming method

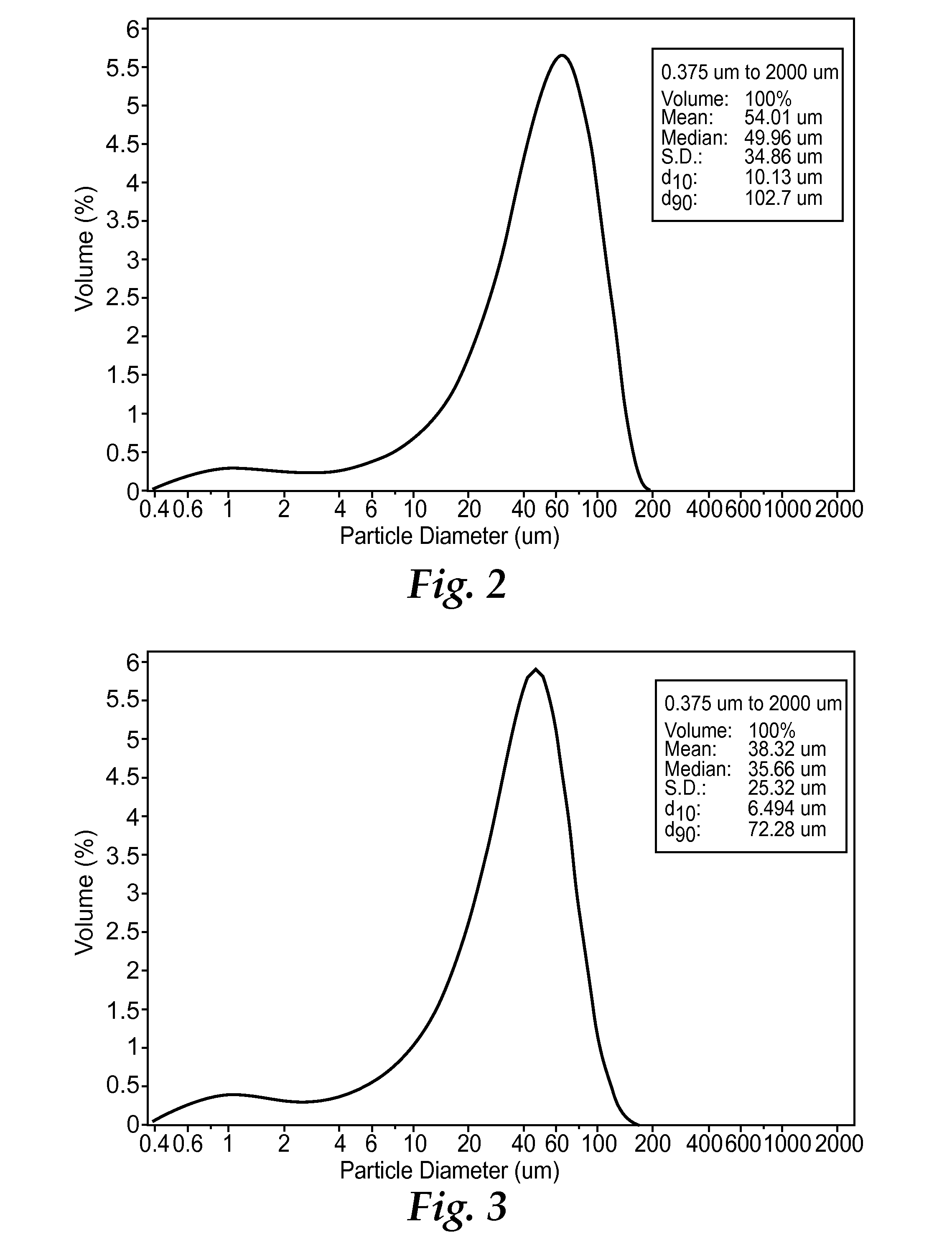

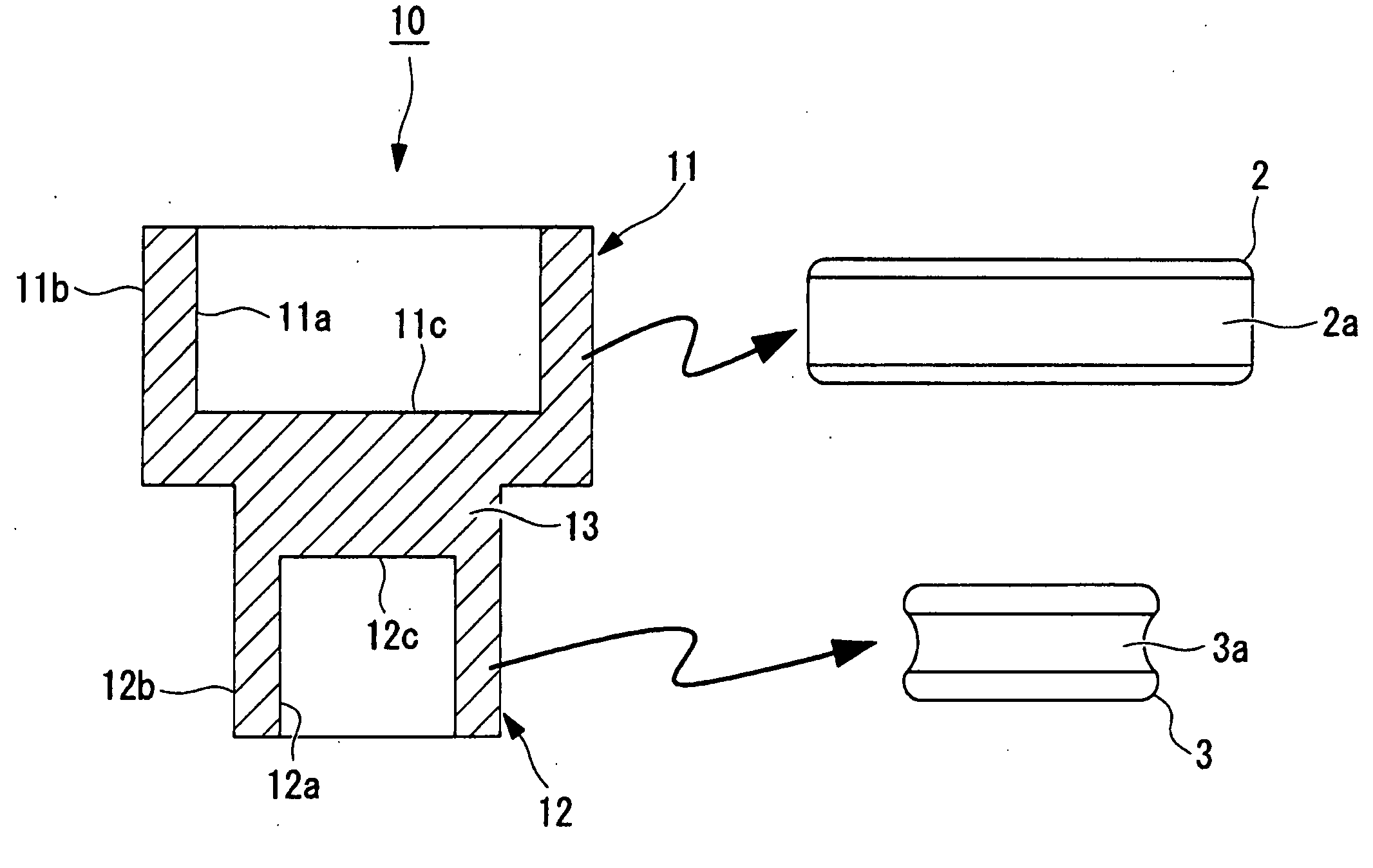

InactiveUS20050208415A1High quality electrophotographicUniform surface propertiesElectrographic process apparatusDevelopersLatent imageEngineering

An image forming method having: developing a latent image formed on a cylindrical electrophotographic photoreceptor having a cylindricity of 5 to 40 μm, with a developer comprising a toner which comprises a ratio Dv50 / Dp50 of a 50% volume particle diameter Dv50 to a 50% number particle diameter Dp50 of 1.0 to 1.15, a ratio Dv75 / Dp75 of a cumulative 75% volume particle diameter from a largest volume particle diameter Dv75 to a cumulative 75% number particle diameter from a largest number particle diameter of Dp75 of 1.0 to 1.20, and toner particles having a particle diameter of 0.7×Dp50 or less in an amount of 10 percent by number or less.

Owner:KONICA MINOLTA INC

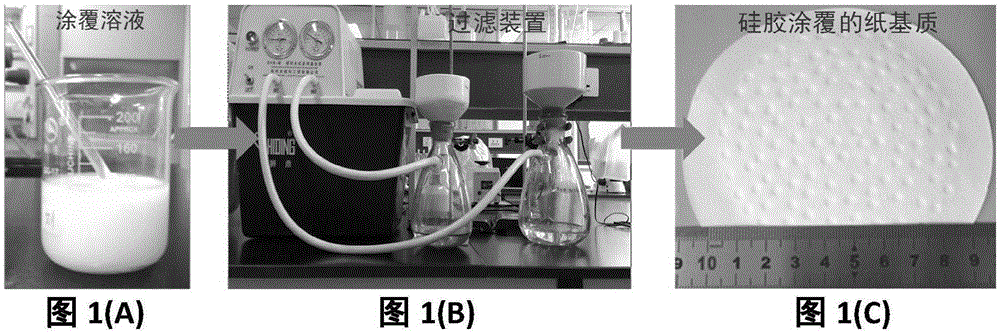

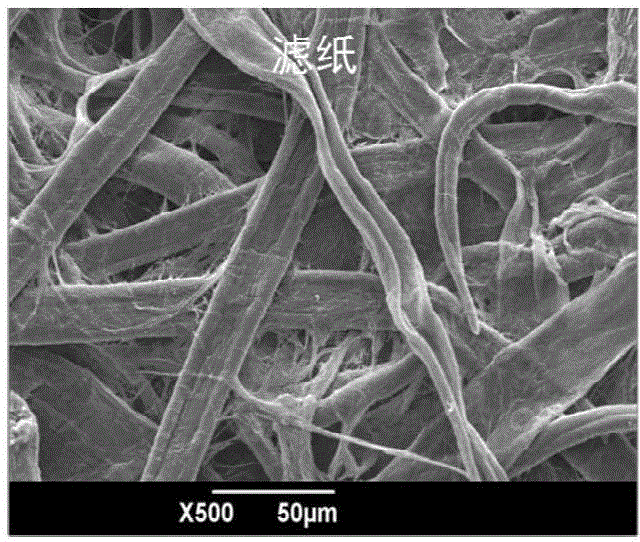

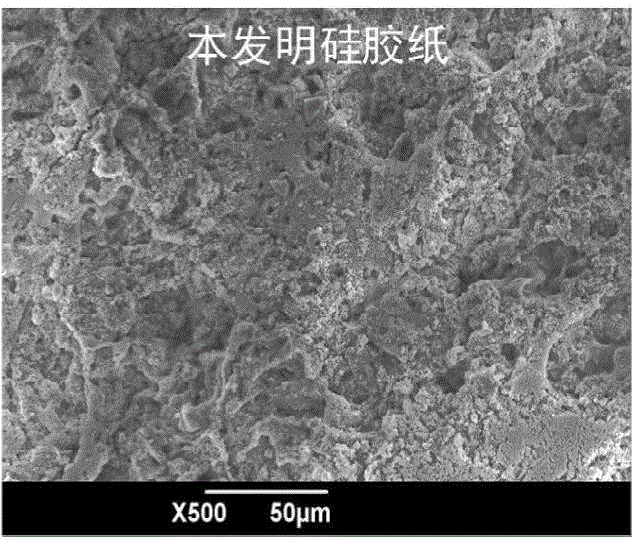

Method for coating paper substrate with silicon dioxide directly

InactiveCN105200849AMild preparation conditionsEasy to operateCoated paper substrateCoatingsCarbon nanotubeFiltration - action

The invention relates to a method for coating a paper substrate with silicon dioxide directly. Under normal temperature and pressure, a binding agent containing starch is completely dissolved in deionized water, and silicon dioxide is added to prepare a solution with uniformly dispersed coating materials; the surface of the paper substrate is uniformly coated with the solution with uniformly dispersed coating materials with a suction filtration coating method, and the surface of the paper substrate is uniformly coated with one layer of silicon dioxide particles under the bonding action of the binding agent of the starch and the like and the suction filtration action of a suction filtration pump; according to the method, the surface of the paper substrate can also be uniformly coated with other oxide particles, carbon nanotubes, polymer materials, metal powder and the like; the method has the advantages that the operation is simple and convenient, raw materials are easy to obtain, the equipment is simple, the prepared paper surface properties are uniform, mass production is easy, the preparation process is green and environment-friendly and the like.

Owner:XI'AN PETROLEUM UNIVERSITY

Image forming method

InactiveUS7183035B2Uniform surface propertiesDevelopersElectrographic process apparatusLatent imageEngineering

An image forming method having: developing a latent image formed on a cylindrical electrophotographic photoreceptor having a cylindricity of 5 to 40 μm, with a developer comprising a toner which comprises a ratio Dv50 / Dp50 of a 50% volume particle diameter Dv50 to a 50% number particle diameter Dp50 of 1.0 to 1.15, a ratio Dv75 / Dp75 of a cumulative 75% volume particle diameter from a largest volume particle diameter Dv75 to a cumulative 75% number particle diameter from a largest number particle diameter of Dp75 of 1.0 to 1.20, and toner particles having a particle diameter of 0.7×Dp50 or less in an amount of 10 percent by number or less.

Owner:KONICA MINOLTA INC

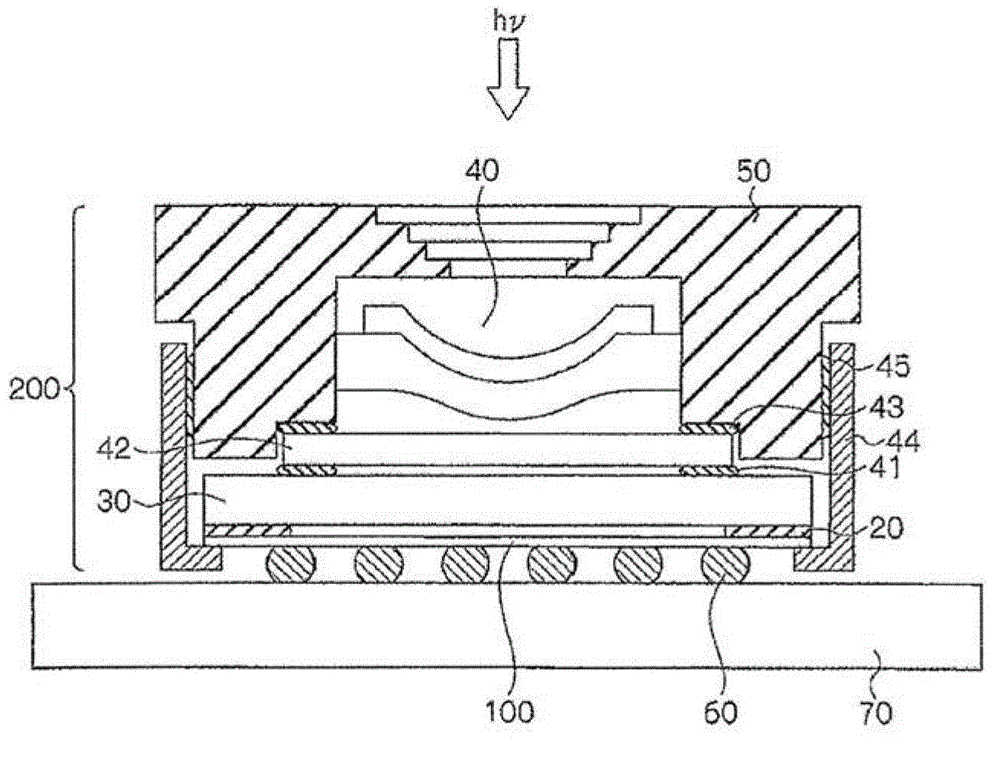

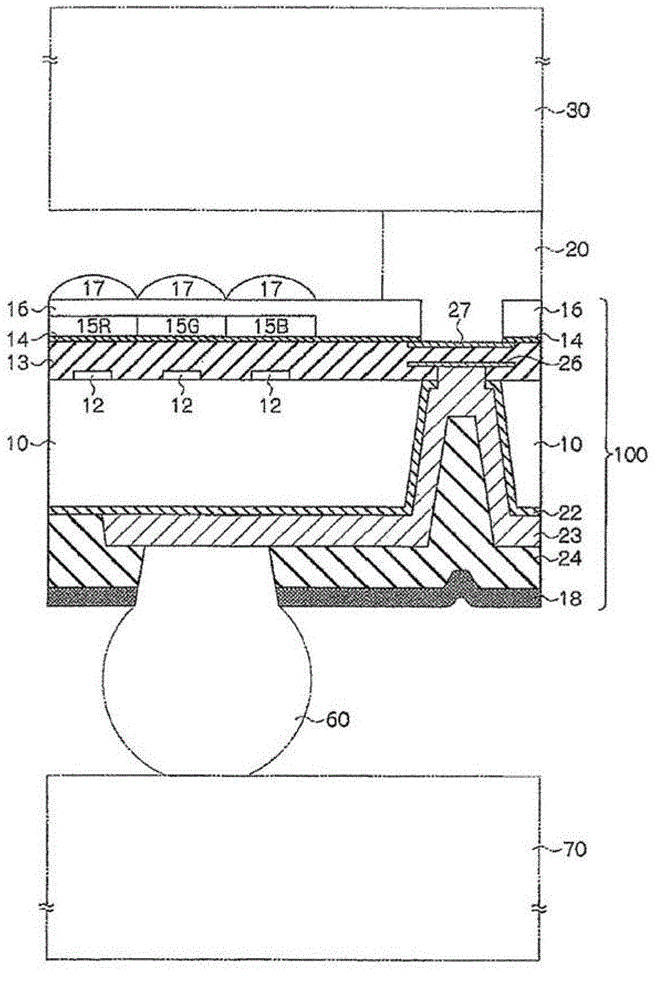

Light-shielding composition, method for producing a light-shielding composition, solder resist, method for forming a pattern, and solid-state imaging device

ActiveCN103339537AUniform surface propertiesImprove surface propertiesCircuit optical detailsSolid-state devicesResistMaterials science

The invention provides a light-shielding composition which has suitability for thick film formation, provides a film having an excellent coating uniformity, has thickness uniformity on uneven surface, and has an excellent light-shielding property of light in an infrared region. The light-shielding composition includes: (A) any one of a light-shielding particle or a light-shielding dye; (B) a first filler having a particle diameter of from 100 nm to 3,000 nm, the particle diameter being a maximum value in a particle diameter distribution of the first filler; and (C) a second filler having a particle diameter of from 5 nm to 90 nm, the particle diameter being a maximum value in a particle diameter distribution of the second filler.

Owner:FUJIFILM CORP

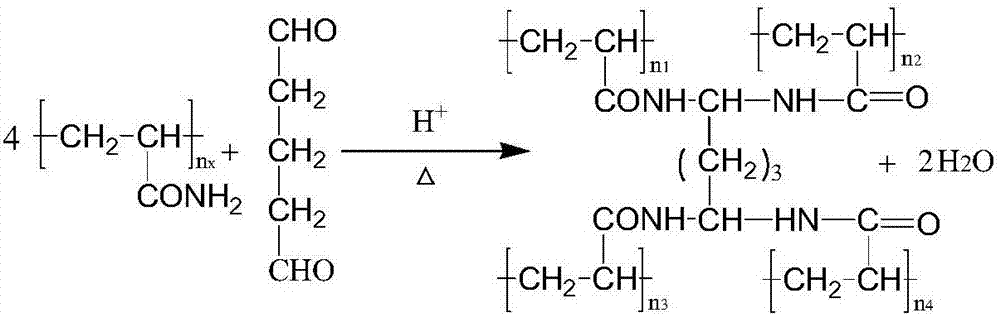

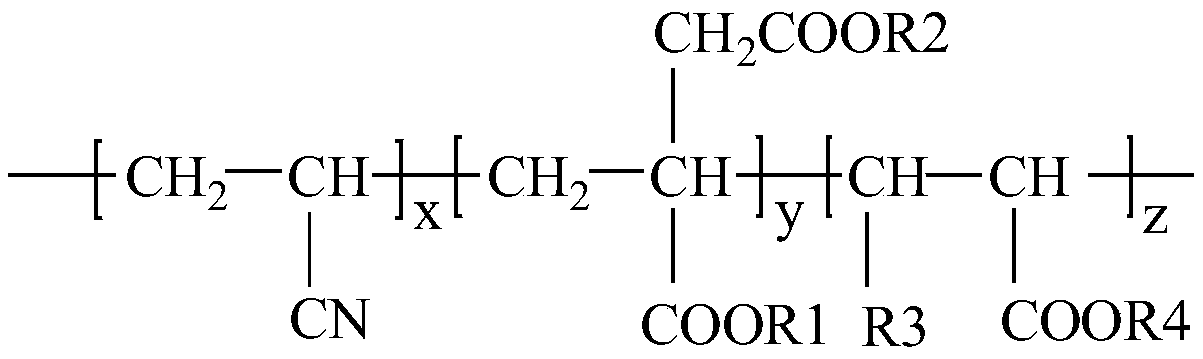

Method of preparing polyacrylonitrile-based carbon raw fibers by dry-wet method

ActiveCN110592728AChange the convergence methodImprove uniformityArtificial filament washing/dryingFibre chemical featuresAcrylonitrileSolvent

The invention particularly relates to a method of preparing polyacrylonitrile-based carbon raw fibers by a dry-wet method. Firstly, dimethyl sulfoxide is used as a solvent, a spinning dope of an acrylonitrile binary or ternary copolymer is prepared, and then oblique spinning, solidification, water washing and hot drawing, air drying, oiling and drying, steam drawing, and relaxation and setting areconducted to prepare the polyacrylonitrile-based carbon raw fibers. By adopting the method of preparing the polyacrylonitrile-based carbon raw fibers by the dry-wet method, a control method of a drysection is simplified, the uniformity of the fibers is improved, the problem of sticking is overcome, and the uniformity of oiling is improved by air-drying. The method of preparing the polyacrylonitrile-based carbon raw fibers by the dry-wet method has a simple process, easy process control and high production efficiency, and can be used for continuously preparing uniform and stable high-performance polyacrylonitrile-based carbon raw fibers. The general formula of the copolymer adopted by the method of preparing the polyacrylonitrile-based carbon raw fibers by the dry-wet method is shown as follows.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

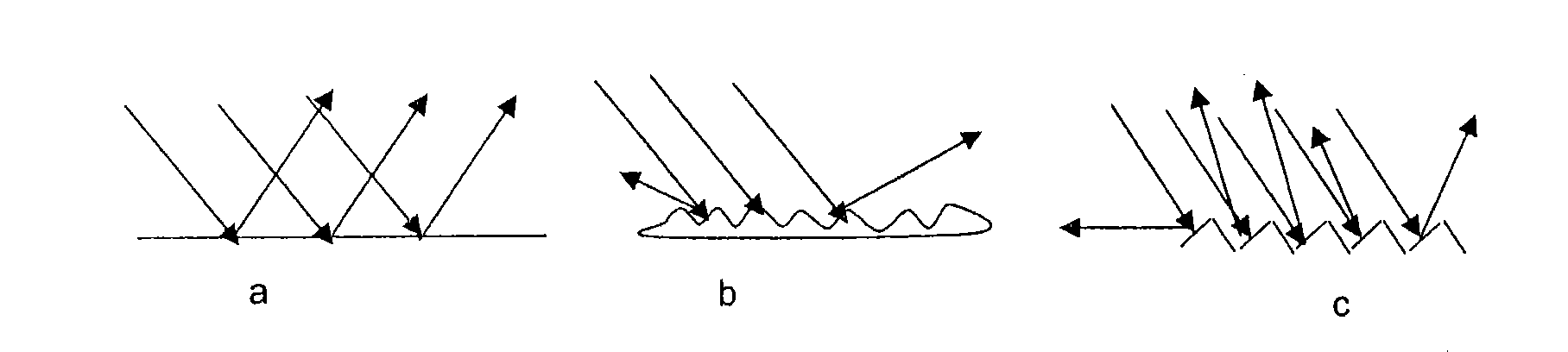

Painted surface treating composition, a painted surface treating method and a painted surface patching method

InactiveUS20110203185A1Reduce glossUniform surface propertiesPigmenting treatmentOther chemical processesHardnessMohs scale of mineral hardness

This invention provides a painted surface treating composition which includes a dispersion medium and an abrasive dispersing in the dispersion medium, and said abrasive has an average particle diameter of 12-55 μm and a Mohs' hardness of 5.5-6. A painted surface treating method and a painted surface patching method using this painted surface treating composition are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

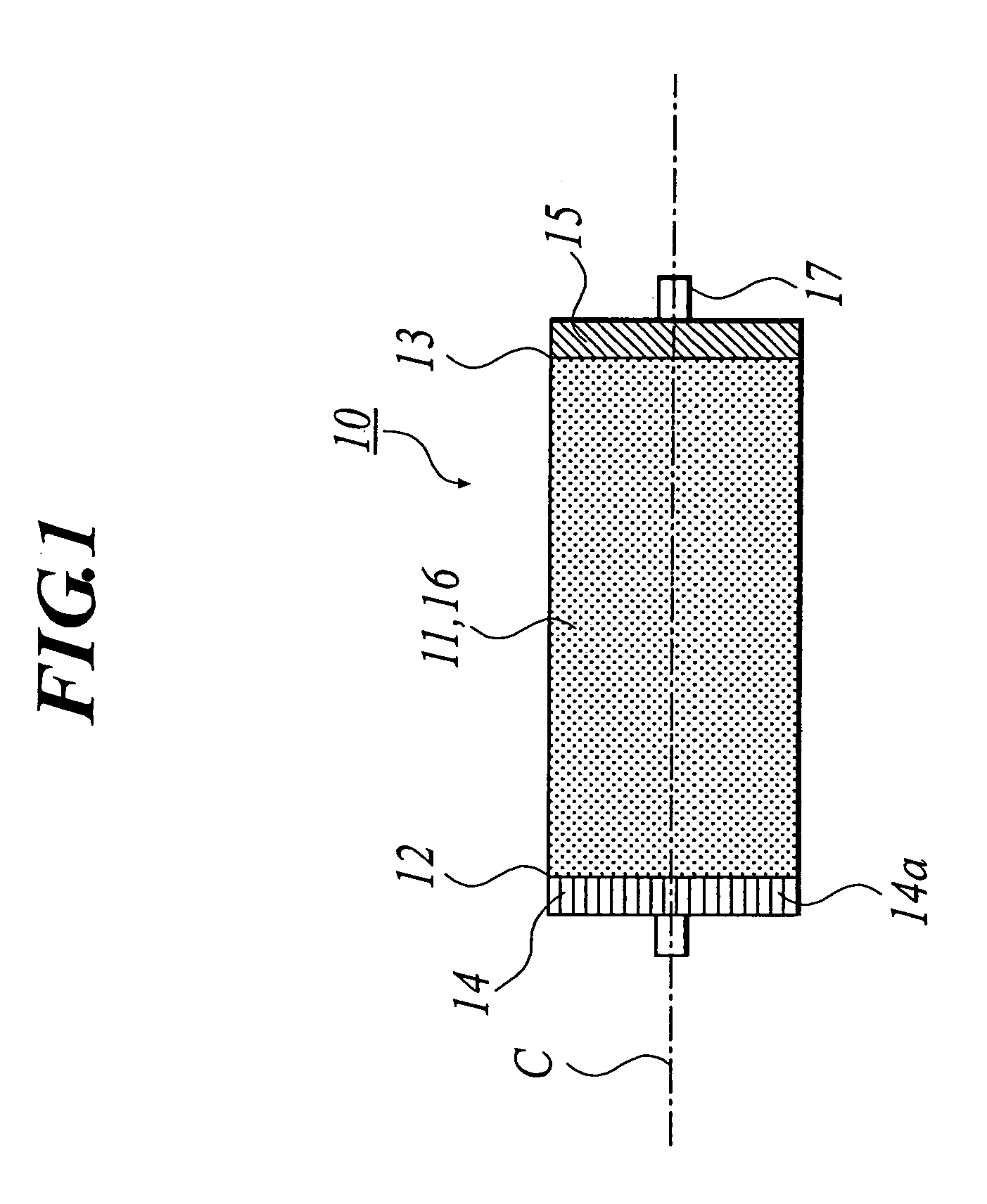

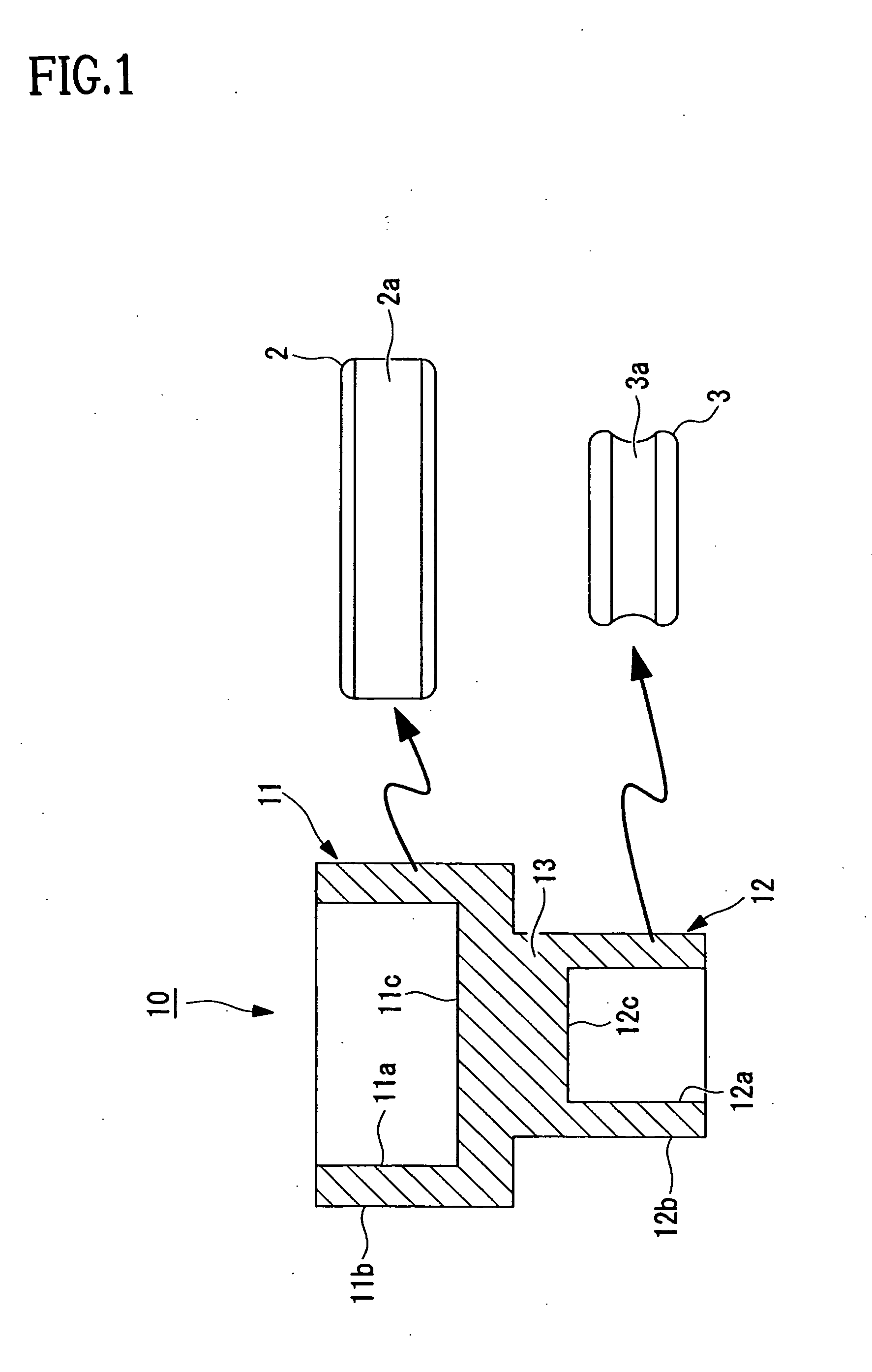

Blank for a ring member of a bearing, manufacturing method for the same,manufacturing method for a ring member of a mearing, and bearing

ActiveUS20090257700A1Improve accuracyPrecise rotationSemiconductor/solid-state device detailsBall bearingsTarget surfaceCarbide

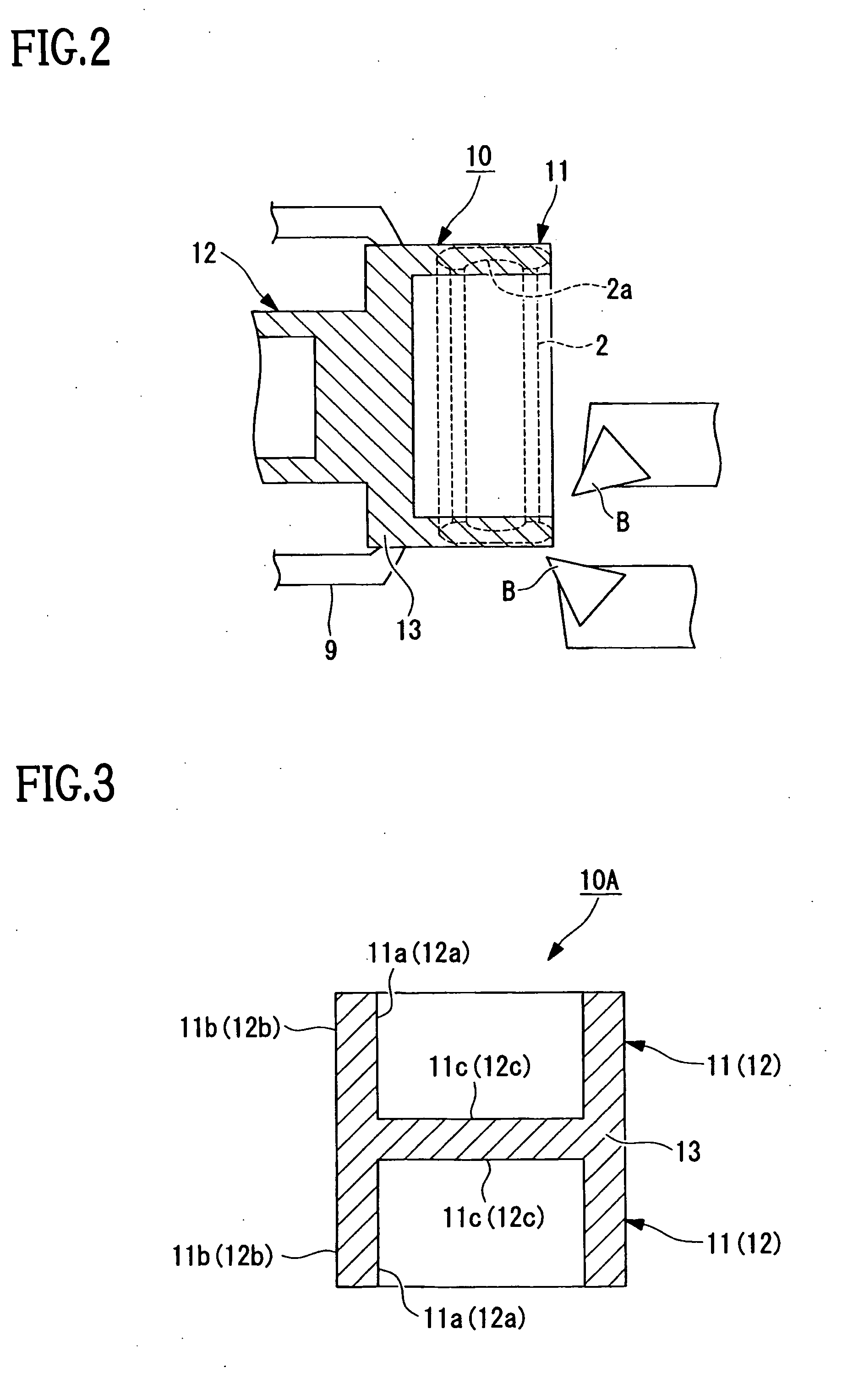

Provided is a blank structure for a ring member of a bearing in which a cut target surface after stainless steel is forged has uniform surface characteristics, and highly accurate cutting processing is enabled. A blank (10), which is processed to an outer race (2) and an inner race (3) of a bearing, includes: a cylindrical portion (11, 12) formed by forging a stainless-steel material, and having an inner circumferential surface (11a, 12a) and an outer circumferential surface (11b, 12b) entirely being surface eutectic carbides fragmented beds; and a clamp portion (13) provided to one end portion side of the cylindrical portion (11, 12).

Owner:SEIKO INSTR INC

Preparation method of hydrophobic surface on ceramic material

The invention relates to a preparation method of a hydrophobic surface on a ceramic material, wherein the preparation method mainly includes a SiO2 gel preparing process, a dip-coating process and a silanization reaction process. The preparation method includes steps of: 1) adding ammonia water and tetraethoxysilane to an ethanol solution to perform a reaction for preparing SiO2 sol; 2) aging theSiO2 sol for 12-48 h; 3) placing the ceramic material in the SiO2 sol solution to perform dip-coating and pulling; 4) gelatinizing the coating layer and treating the coating layer at 20-100 DEG C for1-5 h; 5) adding a solvent to trichlorosilane, as a coupling agent, to prepare a trichlorosilane solution with concentration being 2-10 mmol / L; 6) performing a reaction to the dip-coated ceramic material in the trichlorosilane solution and drying and aging the ceramic material for 1-24 h at temperature range of 50 to 150 DEG C, thus forming the hydrophobic surface on the ceramic material, even achieving ultra-hydrophobicity. The method is simple in operation. The hydrophobic surface has uniform surface performance and has good thermal stability, anti-acid / alkali performance and anti-impact property.

Owner:TIANJIN UNIV

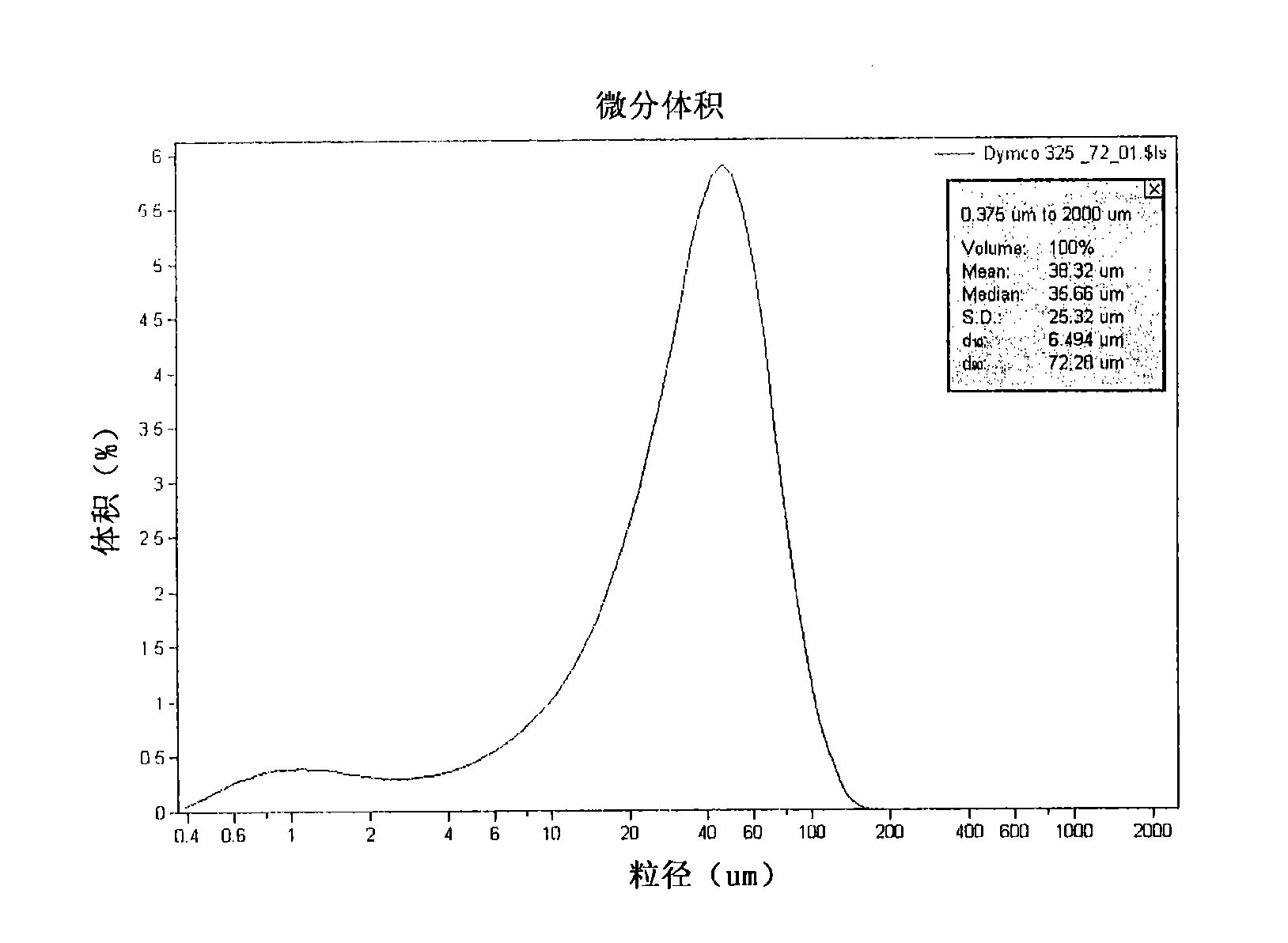

High-performance fluorosilicone modified finish-coat paint

InactiveCN107513296AStrong adhesionImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesDispersityEpoxy

The invention relates to high-performance fluorosilicone modified finish-coat paint. Fluorosilicone modified acrylate is taken as a main raw material, the film-forming property is excellent, the adhesive force is high and the hydrophobic property is excellent; the epoxy silane modified silica sol is adopted for improving the surface property of the film coating, the dispersity is excellent and the surface performance of the film is uniform; the graphene oxide is added, so that the adhesive force, flexibility, shock resistance, water tolerance, salt resistance and hardness of the finish-coat paint can be greatly promoted; an anti-microbial mildew preventive is selected from a Chinese herbal medicine extracting solution, is safe, environment-friendly and nontoxic and has excellent sterilizing property; a stain-resistant additive is beneficial to the promotion of stain resistance of the finish-coat paint; the finish-coat paint provided by the invention has the advantages of adhesive force reaching up to level 2, static contact angle of 110-120 degrees between a film and water, high flexibility, excellent shock resistance, high hydrophobicity, water resistance, salt resistance, stain resistance, no volatile organic compound, safety, environmental protection, anti-microbial and mold-proof effects and long service life.

Owner:苏州振振好新型建材科技有限公司

Pearlescent ink, and preparation method and printing method thereof

ActiveCN103773106AAdaptableSolve the phenomenon of "faintness"InksOther printing apparatusMaterials scienceWetting

The invention discloses a pearlescent ink which is especially used for intaglio printing of light-color substrates. The pearlescent ink is mainly prepared from the following raw materials in parts by weight: 25-65 parts of nitrocellulose resin liquid, 8-25 parts of pearlescent powder I, 3-12 parts of pearlescent powder II, 2-8 parts of pearlescent powder III, 0.1-3 parts of wetting and dispersing agent, 0.1-3 parts of anti-settling agent and 5-40 parts of n-propyl ester. Correspondingly, the invention also discloses a preparation method of the pearlescent ink and a printing method of the pearlescent ink. The pearlescent ink can satisfy the requirements for intaglio printing on light-color substrates, and has favorable printing effect.

Owner:惠州市立美特环保油墨有限公司

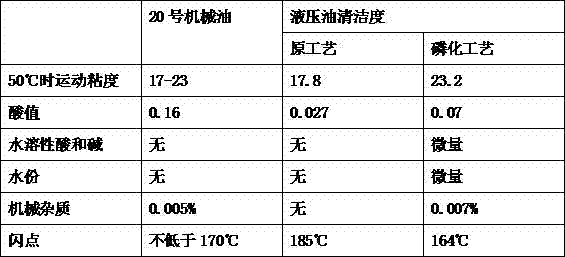

Anti-corrosion preprocessing method of engineering machinery oil tank

InactiveCN107460471AUniform thicknessCorrosion resistance exceedsMetallic material coating processesPretreatment methodFuel tank

The invention discloses an anti-corrosion preprocessing method of an engineering machinery oil tank. The method comprises the following steps: after the steps of degreasing, derusting, phosphating treatment and passivation treatment, saponification is performed on the oil tank, so that the thickness of a phosphating layer on the surface of the oil tank is uniform, wherein the thickness of the phosphating layer is 2-3 microns, and the surface of the phosphating layer is in the color of bright silver. The surface performance of the oil tank changes after phosphatization, the corrosion resistance is enhanced, and the quality is stable. The corrosion resistance of a rust-proof phosphating film is far beyond the corrosion resistance of an oxidation film of a metal part, and the size of the rust-proof phosphating film does not change, mainly because part of the metal is dissolved in a phosphating solution during formation of the phosphating film, the oil tank cannot be oxidized or corroded in the follow-up use process, no oxidation impurities exist in an oil liquid, and the cleanliness of the oil liquid is obviously improved.

Owner:安徽雷萨重工机械有限公司

Pearlescent ink, and preparation method and printing method thereof

ActiveCN103773106BAdaptableSolve the phenomenon of "faintness"InksOther printing apparatusMaterials scienceWetting

The invention discloses a pearlescent ink which is especially used for intaglio printing of light-color substrates. The pearlescent ink is mainly prepared from the following raw materials in parts by weight: 25-65 parts of nitrocellulose resin liquid, 8-25 parts of pearlescent powder I, 3-12 parts of pearlescent powder II, 2-8 parts of pearlescent powder III, 0.1-3 parts of wetting and dispersing agent, 0.1-3 parts of anti-settling agent and 5-40 parts of n-propyl ester. Correspondingly, the invention also discloses a preparation method of the pearlescent ink and a printing method of the pearlescent ink. The pearlescent ink can satisfy the requirements for intaglio printing on light-color substrates, and has favorable printing effect.

Owner:惠州市立美特环保油墨有限公司

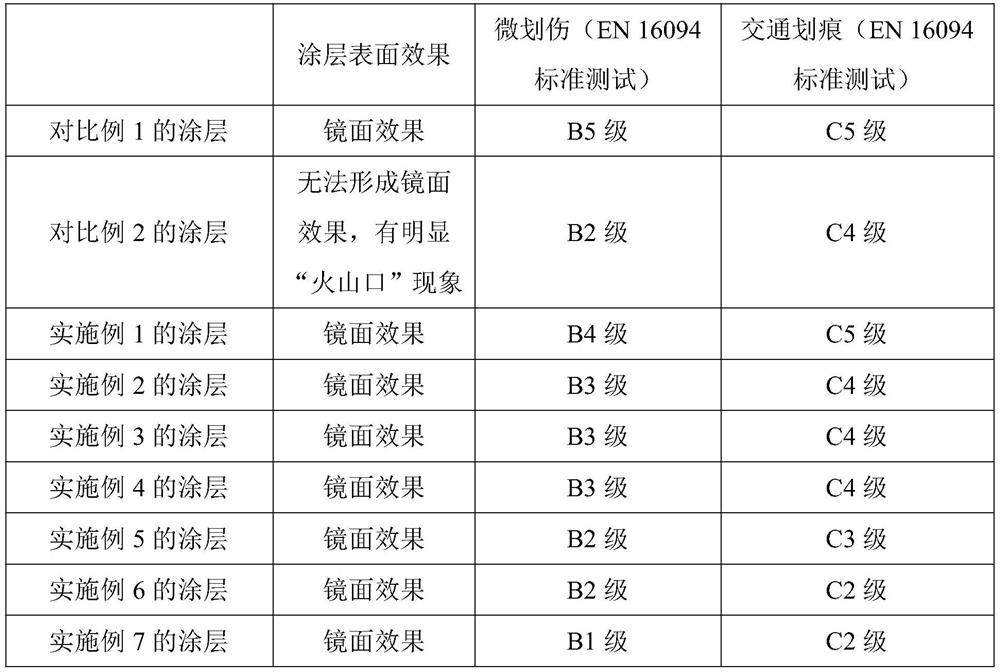

Preparation process of radiation curing coating, radiation curing coating and application of radiation curing coating

PendingCN113546829AStrong toleranceUniform effectPretreated surfacesPolyurea/polyurethane coatingsCeramic tilesMirror plane

The invention discloses a preparation process of a radiation curing coating, which comprises the following steps: (1) coating a carrier film with a radiation curing coating A and carrying out radiation curing to obtain a pre-coated film; (2) coating a radiation curing coating B on a substrate, then pasting the pre-coating film on the radiation curing coating B, and enabling the coating surface of the pre-coating film to be in contact with the radiation curing coating B to obtain a coating precursor; and (3) performing radiation curing on the coating precursor, and removing the carrier film to obtain the radiation curing coating. The invention also provides a radiation curing coating prepared by the radiation curing coating process and an application of the radiation curing coating. The preparation process disclosed by the invention has the advantages of strong tolerance to a construction environment, no oxygen inhibition influence, no consumption of radiation curing energy by the carrier film, no limitation on the addition amount of an inorganic functional filler and good mirror surface effect, and can be used for preparing a mirror surface coating with micro-scratch resistance reaching B1 level and traffic scratch resistance reaching C2 level so as to achieve the effect of replacing ceramic tiles and marble.

Owner:HUNAN BANFERT NEW MATERIALS TECH

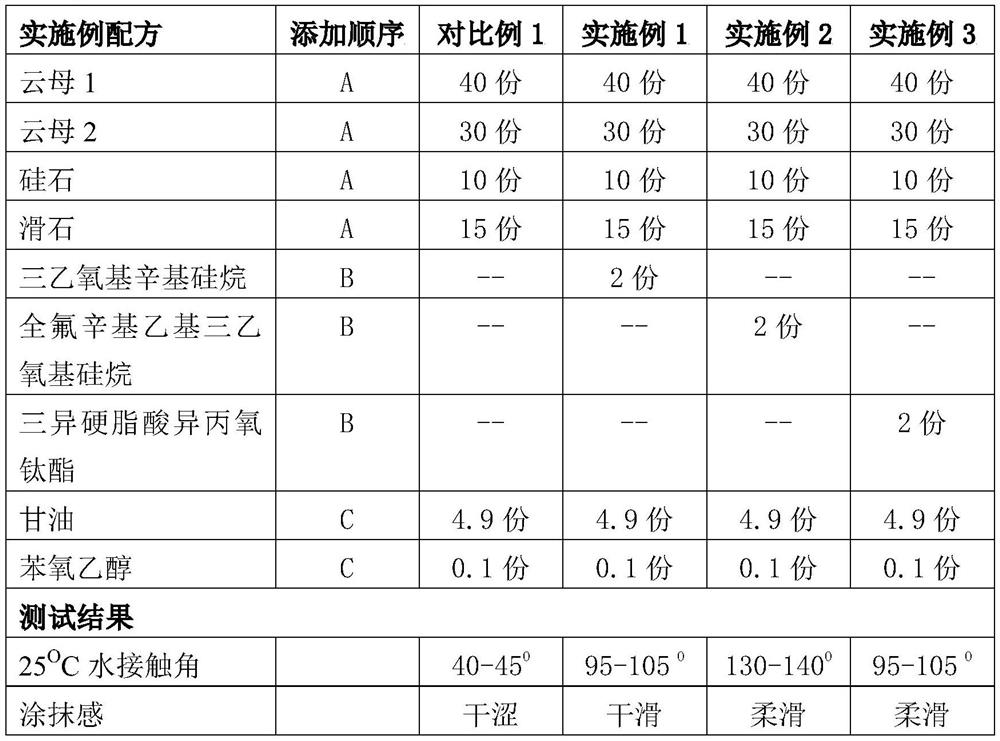

Hydrophobic modification method for powder composition and cosmetic containing same

PendingCN114681342AUniform surface propertiesGood compatibilityCosmetic preparationsMake-upPolymer sciencePolymer chemistry

The invention provides a method for simultaneously carrying out surface hydrophobic modification on a powder composition by using a physical or chemical method in the presence of a hydrophobizing agent, and a cosmetic containing the hydrophobically modified powder composition. According to the method, surface hydrophobic modification is simultaneously carried out on a powder composition formed by pre-mixing a plurality of powders with different types, shapes, colors and particle sizes in the presence of a hydrophobizing agent, so that each component of the composition has a hydrophobic surface. The surface water contact angle of the powder composition modified by the method is greater than 90 degrees, and the powder composition has smooth and soft surface touch feeling and more gorgeous surface effect and can be endowed with good use feeling.

Owner:SHANGHAI CHUANGYUAN COSMETICS

Preparation method of SBA-15 immobilized angiotensin converting enzyme

ActiveCN106701731AIncrease loadImprove stabilityOn/in inorganic carrierPeptidasesAngiotensin-converting enzymeMolecular sieve

The invention provides a preparation method of an SBA-15 immobilized angiotensin converting enzyme (ACE). A mesoporous molecular sieve SBA-15 chelated with zinc ions is used as a carrier and an angiotensin converting enzyme is used as an immobilization object, and the carrier and the immobilization object are subjected to adsorption and bonding effects to obtain the SBA-15 immobilized angiotensin converting enzyme. In a product obtained by the method, the ACE is immobilized in pore channels of the zinc ion chelated mesoporous molecular sieve SBA-15 and an outer surface of the molecular sieve. According to the preparation method, an immobilization process for preparing the Zn-SBA-15 immobilized ACE is simple and the stability of the product is good; and compared with a free enzyme, the prepared Zn-SBA-15 immobilized ACE has better temperature and pH (Potential of Hydrogen) stability.

Owner:DALIAN POLYTECHNIC UNIVERSITY

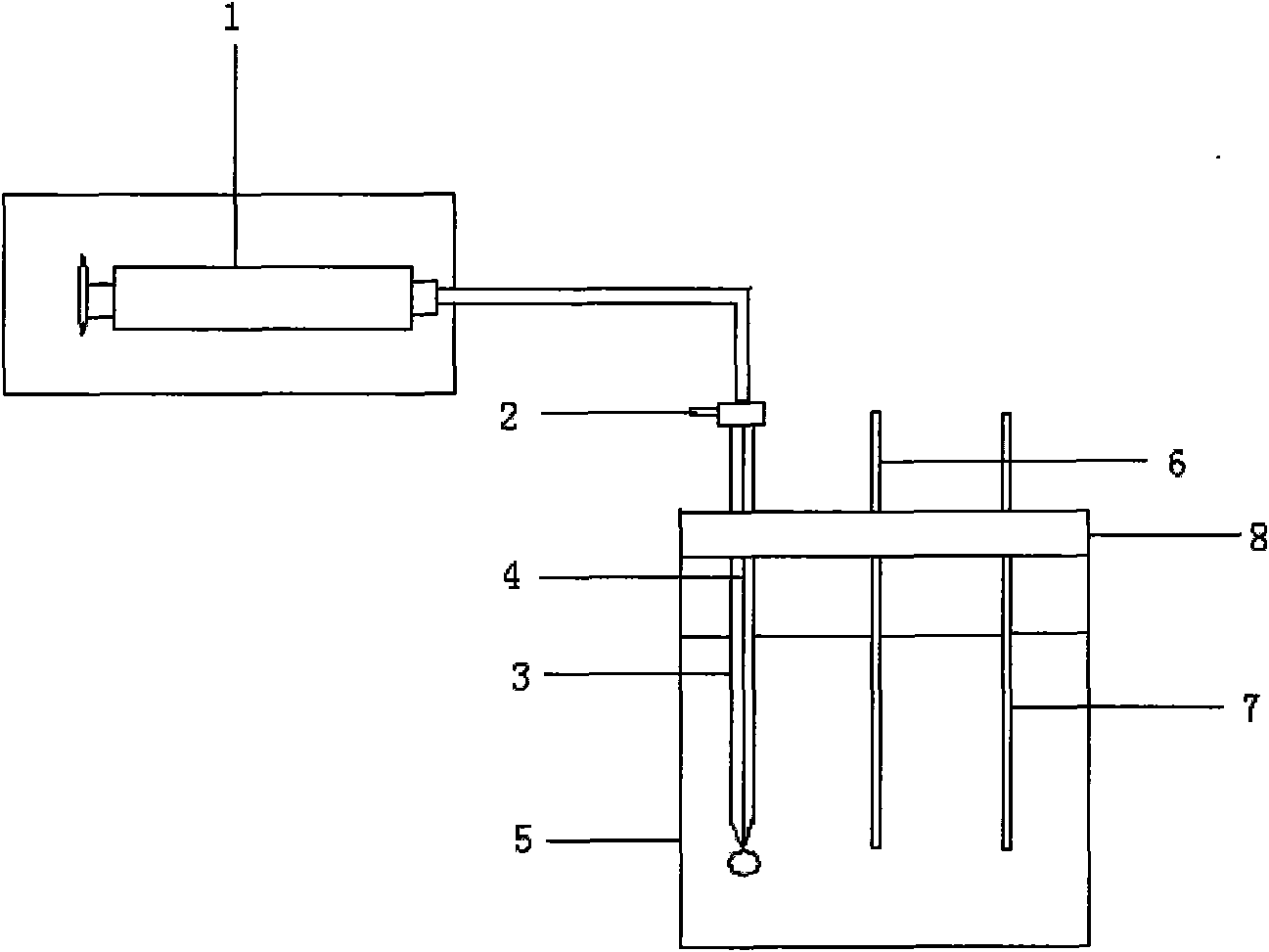

Chemical dropping electrode and method for monitoring pH value in solution

InactiveCN101620199AAvoid pollutionUniform surface propertiesMaterial electrochemical variablesElectrically conductiveSyringe

The invention relates to a chemical dropping electrode and a method for monitoring a pH value in solution in the field of environmental monitoring. The electrode comprises a flowing syringe, a stainless steel joint, a glass burette, a conductive wire, a liquid storing groove, a Pt pole, an Ag / AgCl pole and a pole frame, wherein the flowing syringe is connected with the glass burette by the stainless steel joint; the conductive wire is inserted into the glass burette; one end of the conductive wire is connected to the stainless steel joint, and the other end of the conductive wire is in tangent with an outlet of the glass burette; the glass burette, the Pt pole and the Ag / AgCl pole are positioned on the pole frame; and the pole frame is arranged on the liquid storing groove. The method for monitoring a pH value by the electrode comprises the following steps: absorbing 1, 2-dichloroethane into the flowing syringe; controlling the amount of liquid drop at the top end of the glass burette; and detecting the pH value. The invention has simple and convenient operation and high stability and sensitivity.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com