High-performance fluorosilicone modified finish-coat paint

A technology of fluorosilicon modification and finishing paint, which is applied in the direction of biocide-containing paint, antifouling/underwater paint, coating, etc. Whitening and other problems, to achieve good dispersion, strong adhesion, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

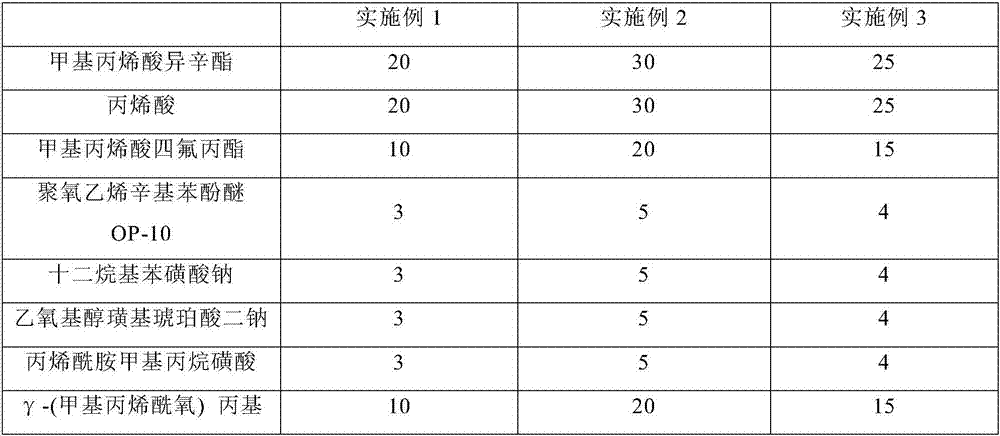

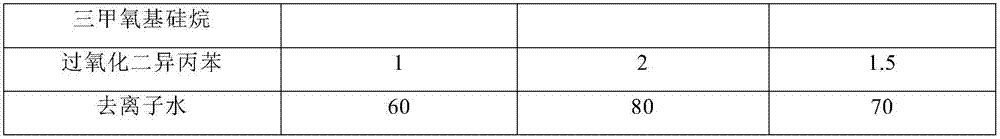

Embodiment 1

[0031] A high-performance fluorosilicon-modified finish paint, the preparation method of the fluorosilicon-modified acrylate is the preparation of isooctyl methacrylate, acrylic acid, tetrafluoropropyl methacrylate, polyoxyethylene octylphenol ether OP -10. Mix sodium dodecylbenzenesulfonate and deionized water evenly, add dicumyl peroxide, heat up to 80°C, keep warm for 8 minutes, then add disodium ethoxylated alcohol sulfosuccinate and acrylamide formaldehyde Sodium propane sulfonate was mixed evenly, cooled to 30°C, then added ammonia water to adjust the pH of the system to 7, filtered and cooled to room temperature to obtain material A; add material A and γ-(methacryloyloxy)propyltrimethoxysilane Add N,N dimethylethanolamine to deionized water to adjust the pH of the system to 8, raise the temperature to 60°C, stir for 40 minutes, and discharge to obtain fluorosilicon-modified acrylate.

[0032] The epoxy silane modified silica sol includes the following components by weig...

Embodiment 2

[0040]A high-performance fluorosilicon-modified finish paint, the preparation method of the fluorosilicon-modified acrylate is the preparation of isooctyl methacrylate, acrylic acid, tetrafluoropropyl methacrylate, polyoxyethylene octylphenol ether OP -10. Mix sodium dodecylbenzenesulfonate and deionized water evenly, add dicumyl peroxide, heat up to 90°C, keep warm for 12 minutes, then add disodium ethoxylated alcohol sulfosuccinate and acrylamide formaldehyde Sodium propane sulfonate was mixed evenly, cooled to 40°C, then added ammonia water to adjust the pH of the system to 8, filtered and cooled to room temperature to obtain material A; add material A and γ-(methacryloyloxy)propyltrimethoxysilane Add N,N dimethylethanolamine to deionized water to adjust the pH of the system to 10, raise the temperature to 70°C, stir for 80 minutes, and discharge to obtain fluorosilicon-modified acrylate.

[0041] The epoxy silane modified silica sol includes the following components by wei...

Embodiment 3

[0049] A high-performance fluorosilicon-modified finish paint, the preparation method of the fluorosilicon-modified acrylate is the preparation of isooctyl methacrylate, acrylic acid, tetrafluoropropyl methacrylate, polyoxyethylene octylphenol ether OP -10. Mix sodium dodecylbenzenesulfonate and deionized water evenly, add dicumyl peroxide, heat up to 85°C, keep warm for 10 minutes, then add disodium ethoxylated alcohol sulfosuccinate and acrylamide formaldehyde Sodium propane sulfonate was mixed evenly, cooled to 35°C, then added ammonia water to adjust the pH of the system to 7.5, filtered and cooled to room temperature to obtain material A; add material A and γ-(methacryloyloxy)propyltrimethoxysilane Add N,N dimethylethanolamine to deionized water to adjust the pH of the system to 9, raise the temperature to 65°C, stir for 60 minutes, and discharge to obtain fluorosilicon-modified acrylate.

[0050] The epoxy silane modified silica sol includes the following components by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com