Preparation method of foundation make-up premix having minimal color difference

A premix and foundation technology, which is applied to medical preparations, body powders, and pharmaceutical formulations containing active ingredients, can solve the problems of limited improvement, no improvement in color difference control, and high price, and achieve uniform color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

[0071] In the present invention, by analyzing and deciphering many factors that affect the color difference of the foundation, a complete set of technological methods is finally formed to produce the foundation premix material with extremely small color difference, and then easily produce the foundation product with very small color difference. details as follows:

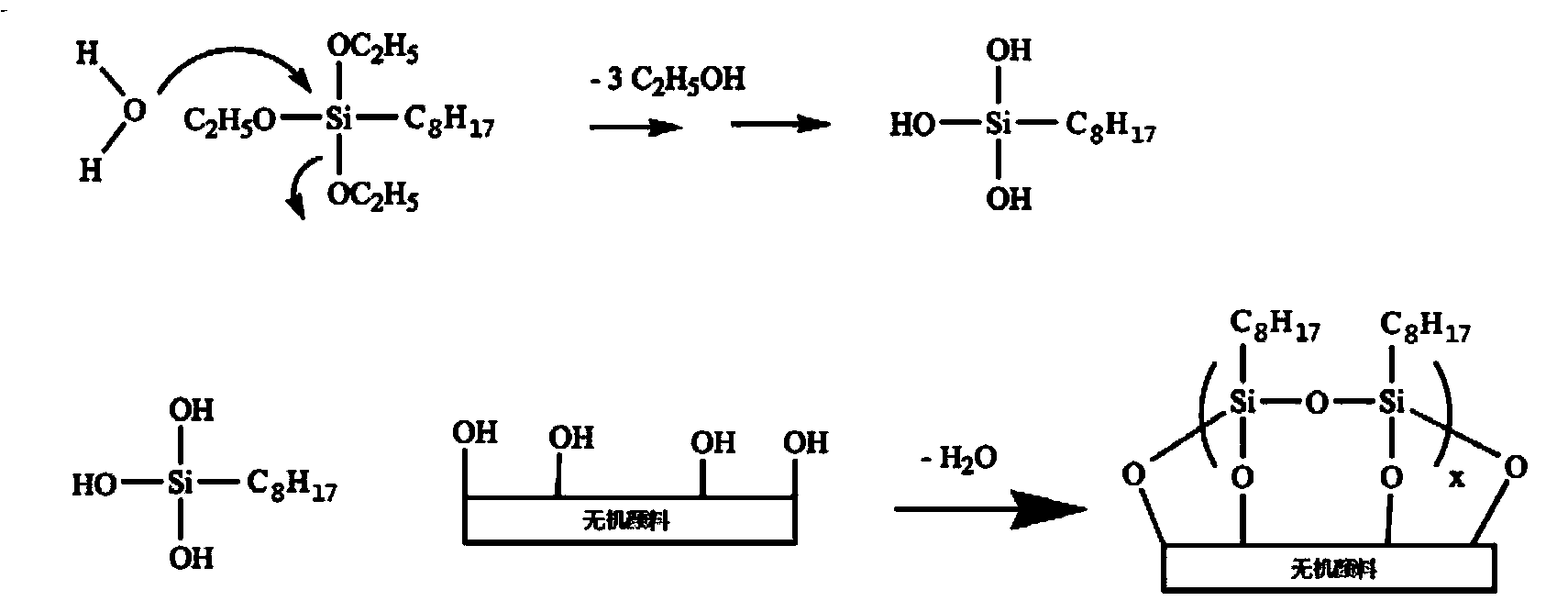

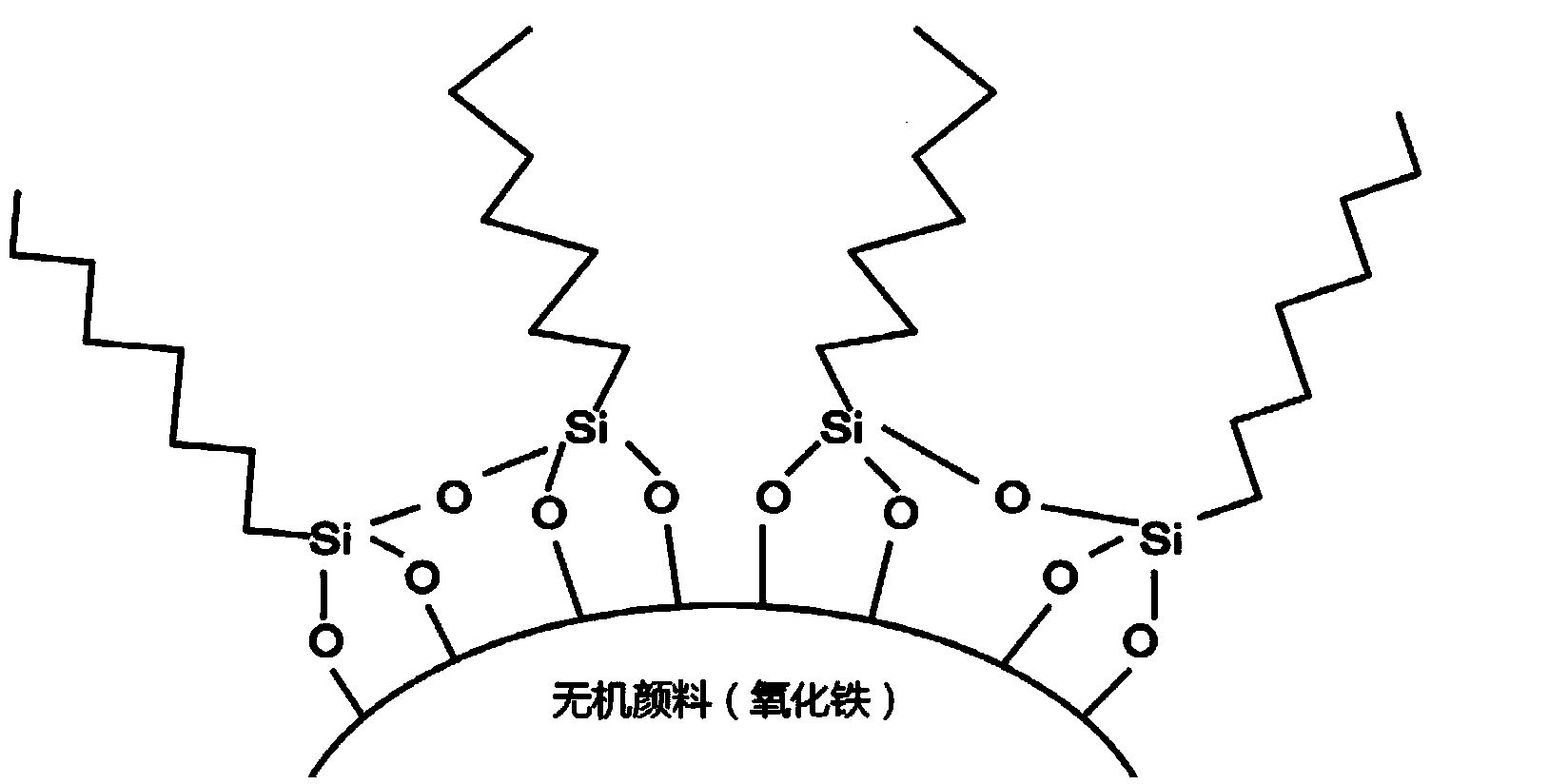

[0072] 1. Perform uniform surface treatment on various raw material powders of the foundation premix to make the surface properties tend to be consistent.

[0073] In order to ensure that various powders can be well dispersed in the dispersion medium or emulsification system, so as to control the color difference of foundation products, it is necessary to carry out uniform surface treatment on various powders. Various powders with very different physical and chemical properties tend to be consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com