Automatic shot blasting device for large steel tube or steel beam

A technology of shot blasting device and steel pipe, which is applied in the direction of abrasive feeding device, used abrasive processing device, abrasive, etc., which can solve the problem of unfavorable health of environmental operators, failure to meet standards and product quality requirements, shot blasting Problems such as poor uniformity of roughness value, etc., achieve the effect of improving production safety, low cost, and large internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

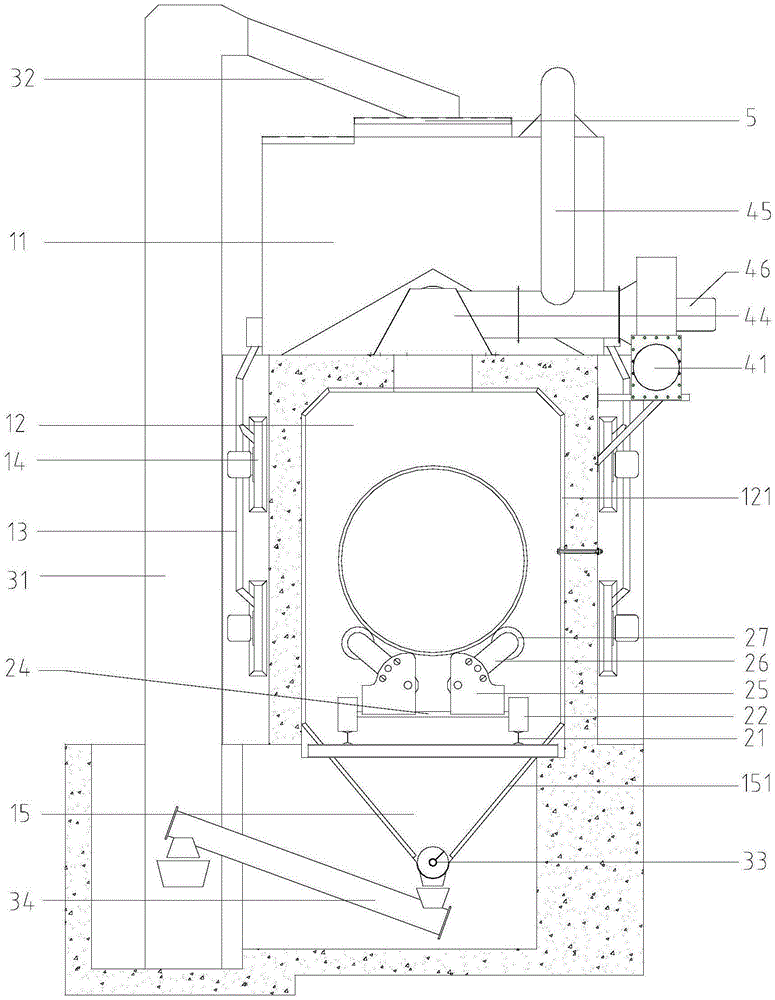

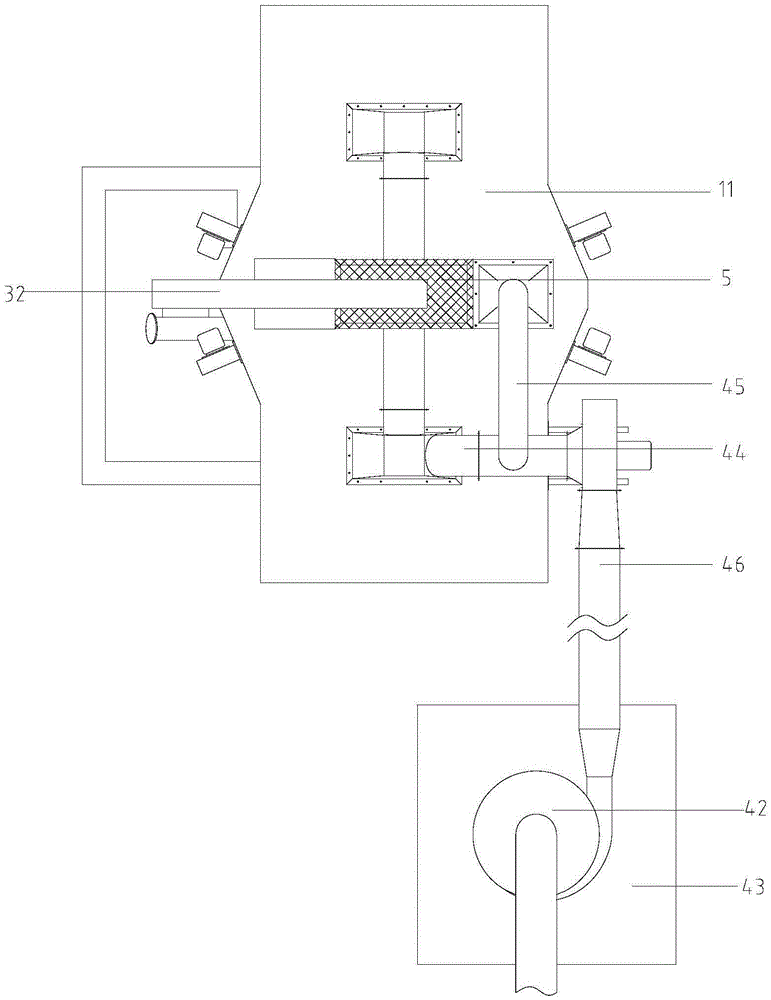

[0028] This embodiment has provided a kind of large-scale steel pipe steel girder automatic shot blasting device, has such as Figure 1-5 The structure shown includes shot blasting chamber, workpiece pushing vehicle system, circulating sand blasting system, and purification system.

[0029] The shot blasting chamber includes a sand storage box 11, a sand blasting chamber 12, a sand delivery pipe 13 and a shot blasting head 14, wherein:

[0030] The whole of the sand storage box 11 is an inverted M shape, and its size is 500-800mm wide, 2500-3000mm long, and 1500-2000mm high. The wall thickness is 4-8mm, and the slope at the bottom is inclined at an upward angle of 30°-60° so that the steel grit slides to both sides; The hole reserved on the side is installed with the electromagnetic dispensing valve as described below;

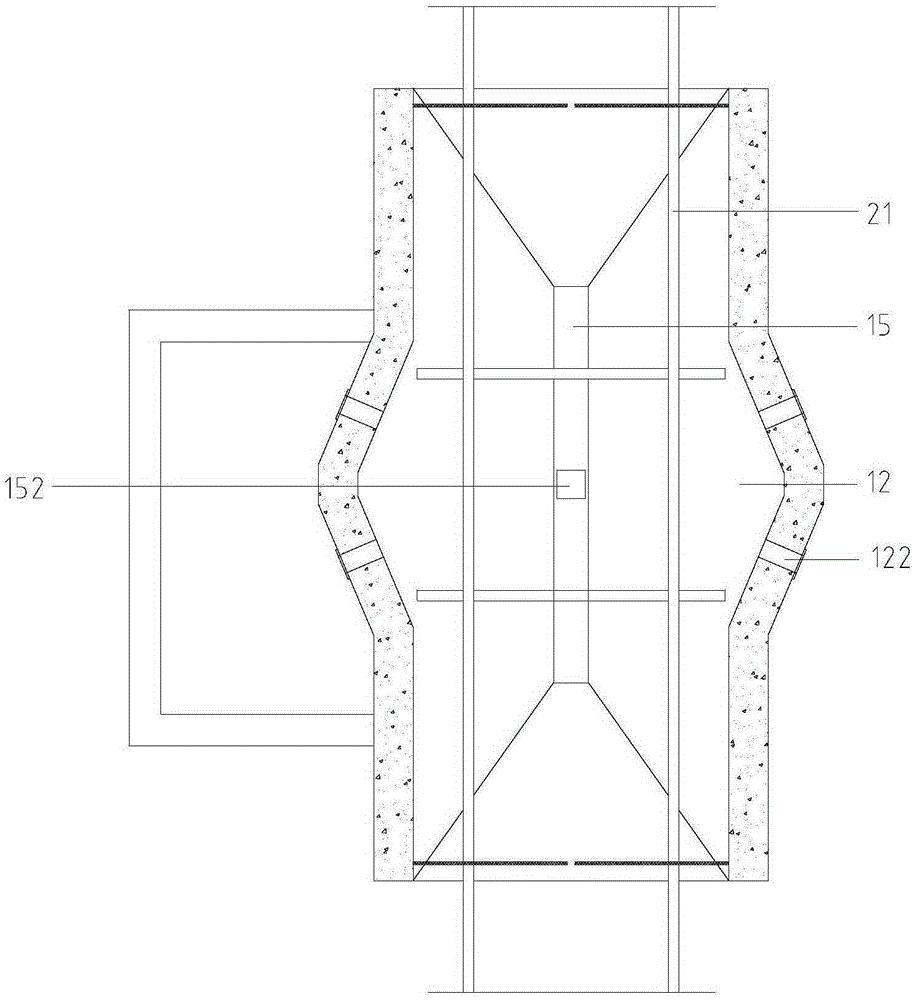

[0031] The sandblasting chamber 12 is cast from reinforced concrete, with a cross-section width of 1.5-2.0m, a height of 2.5-3.0m, a length of 3.5-4.5m, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com