Patents

Literature

54results about How to "Uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

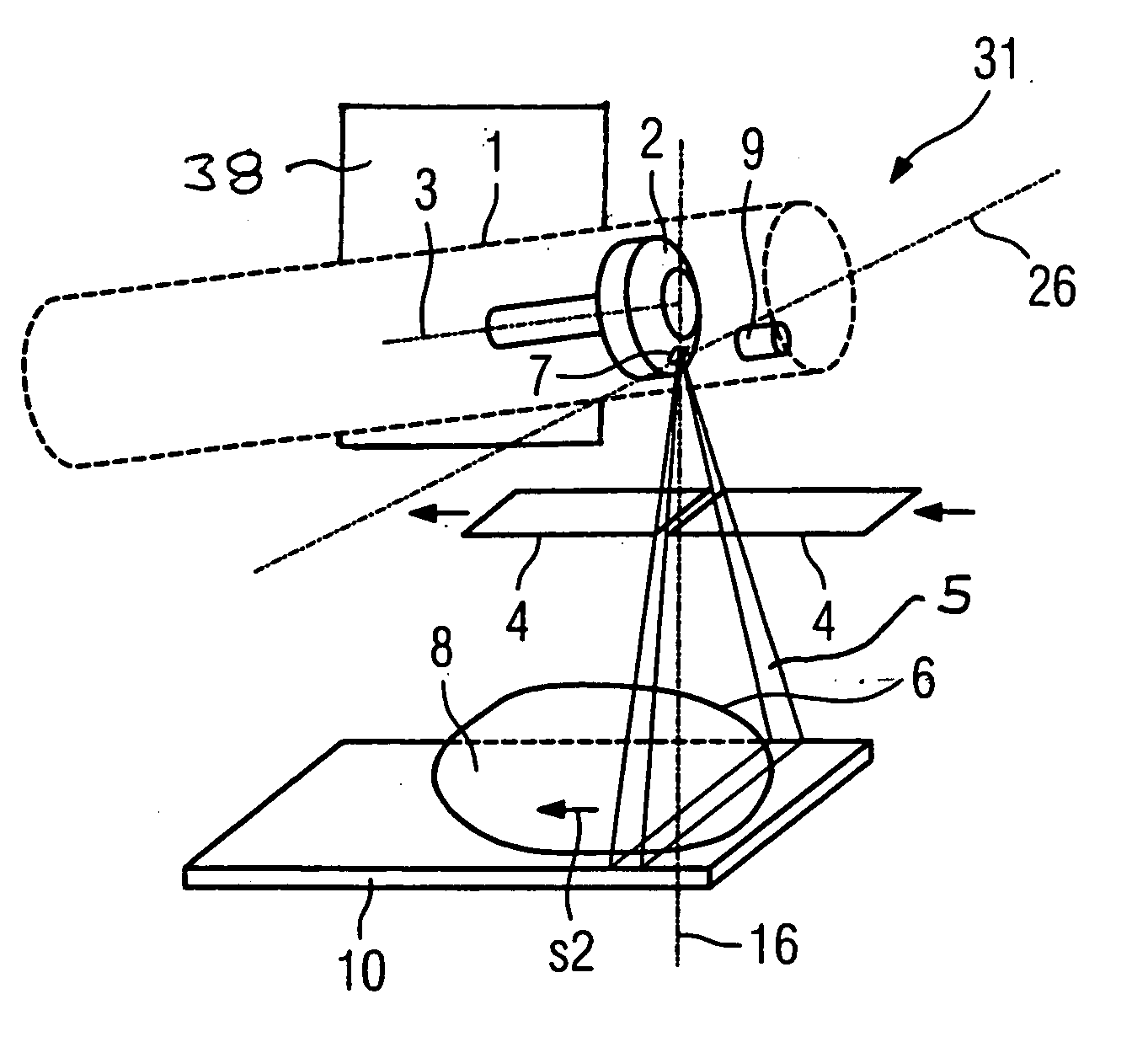

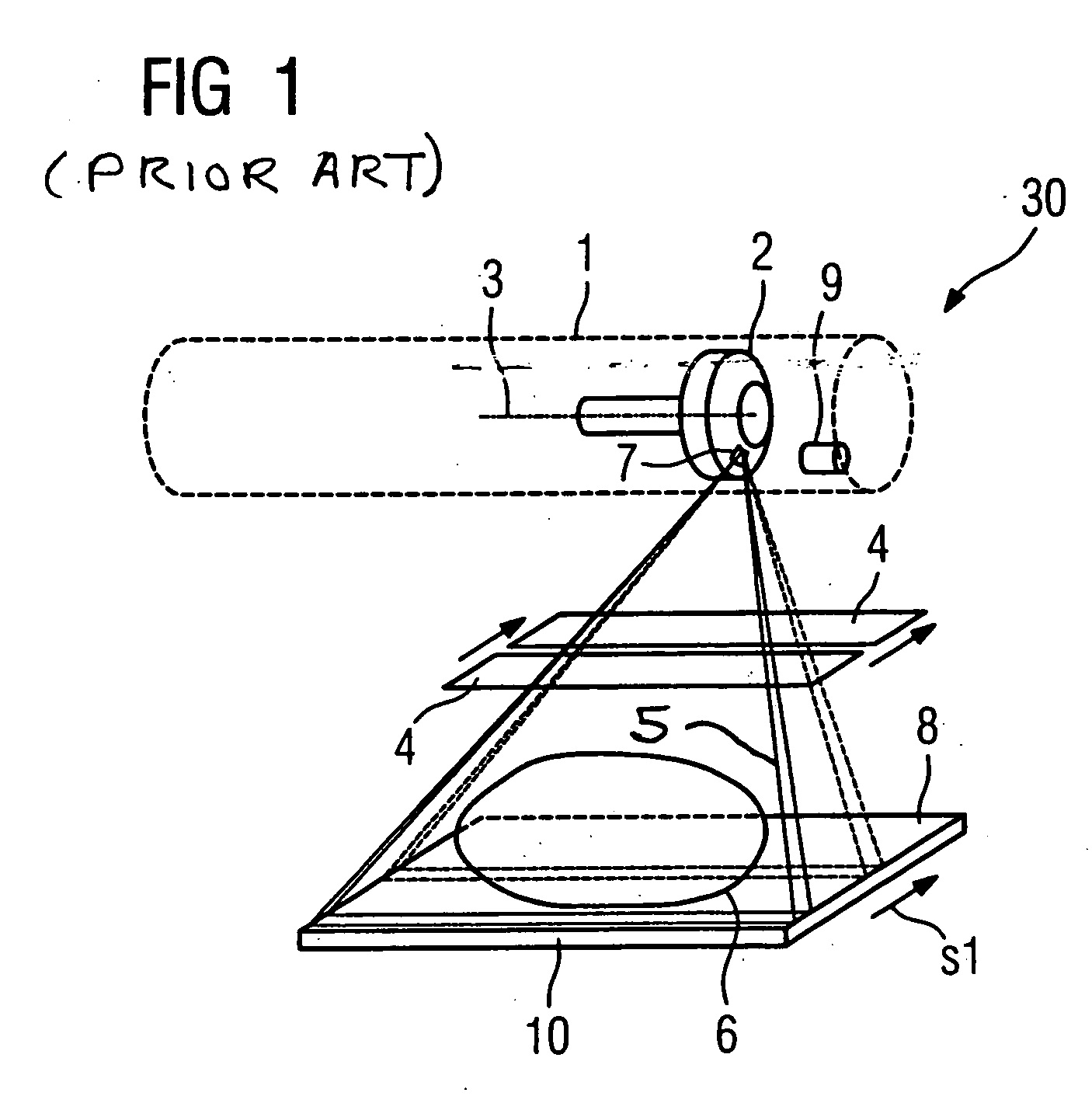

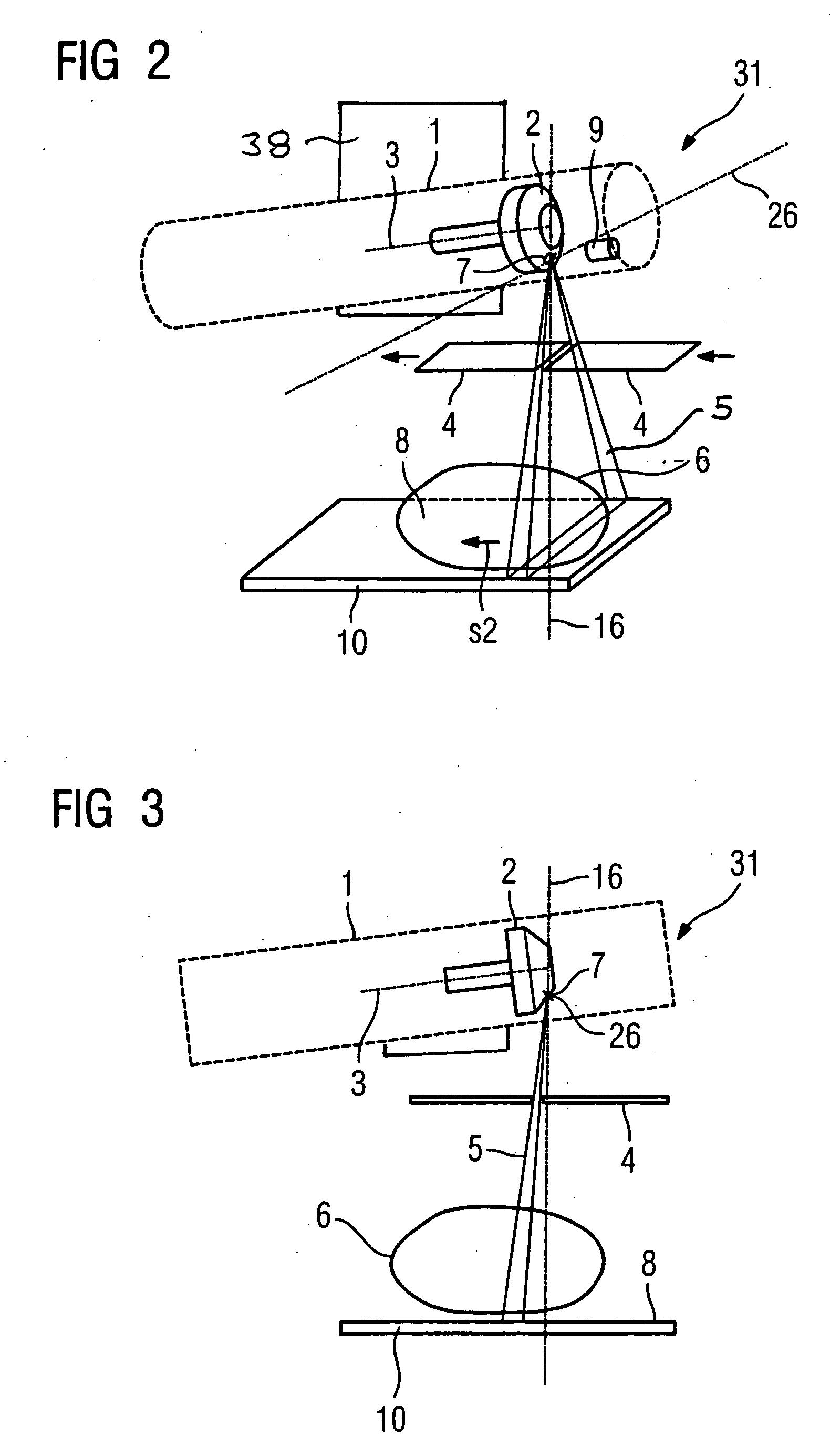

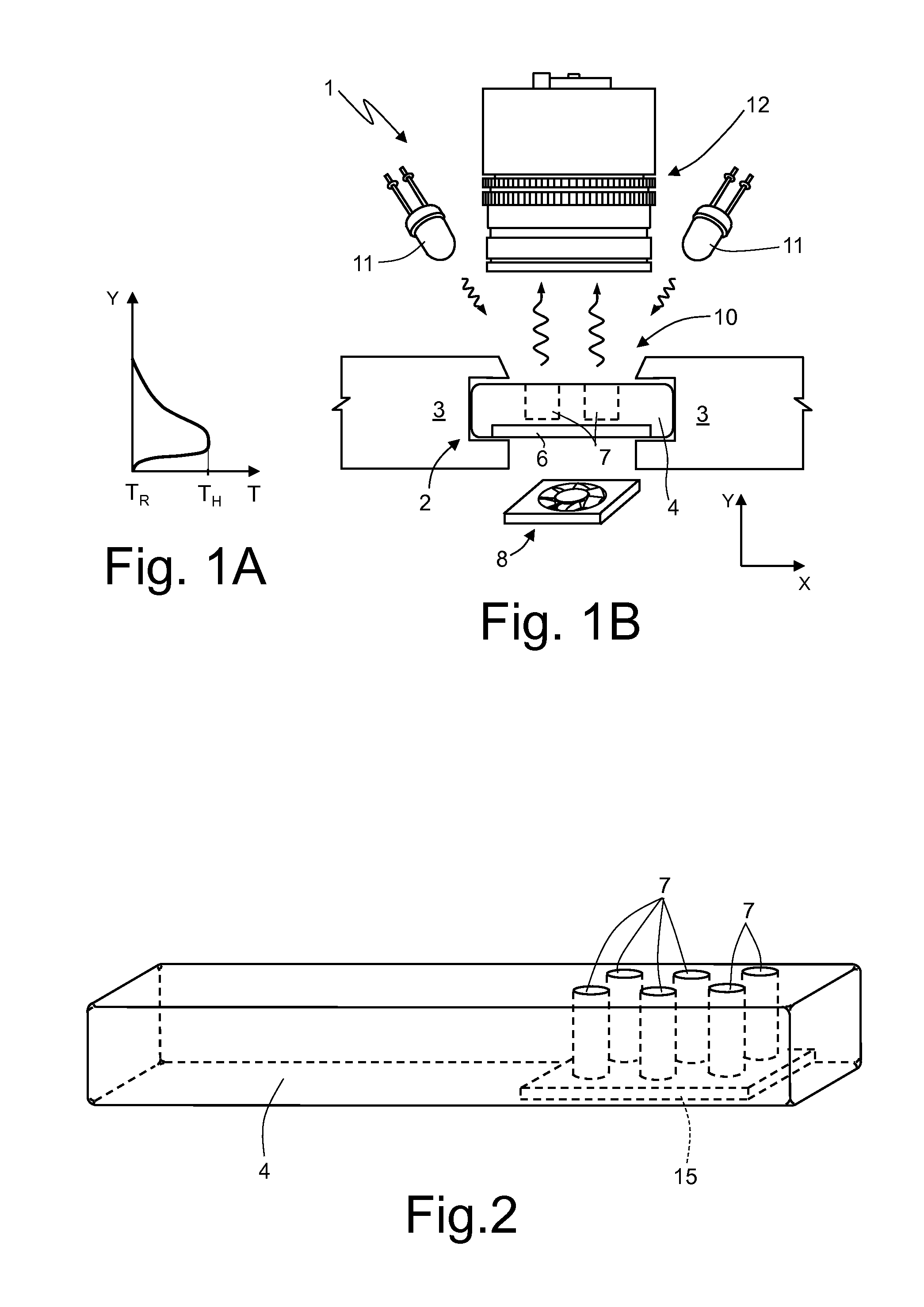

X-ray device that emits an x-ray beam with a scanning-like movement

InactiveUS20060034426A1Quality improvementLow-cost mannerX-ray tube electrodesHandling using diaphragms/collimetersRotational axisImage resolution

An x-ray device includes an x-ray tube for generation of an x-ray emanating from a focal spot of a rotary anode rotatable around a rotation axis and a slit-shaped diaphragm for generation of a fan-shaped x-ray beam that is gated from the x-ray and emission is moved through an examination region in the manner of a scan. To improve the image resolution, the fan-shaped x-ray beam can be moved over the examination region essentially in the direction of the rotational axis of the rotary anode by tilting the x-ray tube on the focal spot, with the x-ray tube being tilted on the focal spot so that the fan-shaped x-ray beam is always gated from the region of the overall emitted x-ray beam having the highest-image resolution or the highest image definition in the movement through the examination region.

Owner:SIEMENS AG

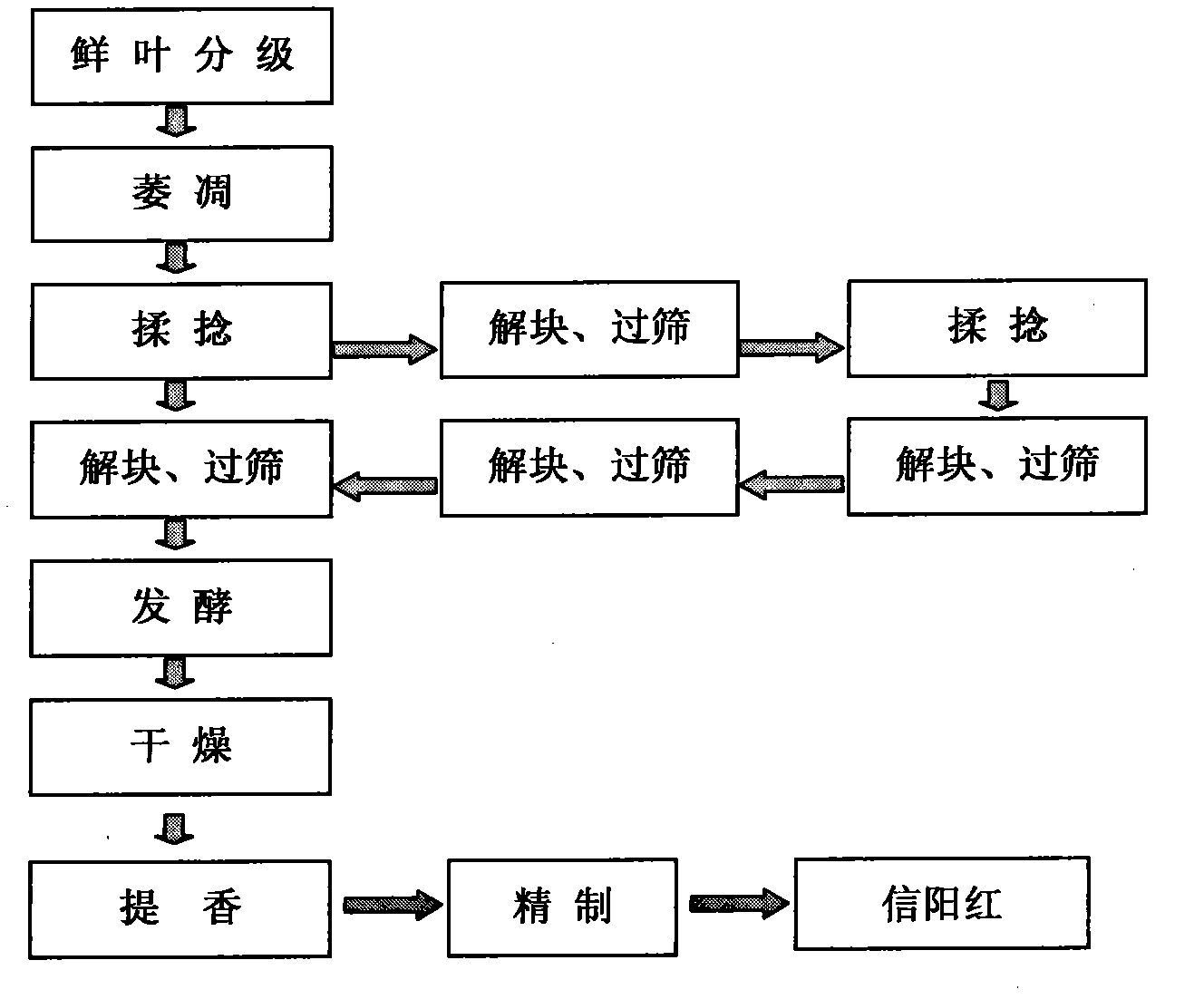

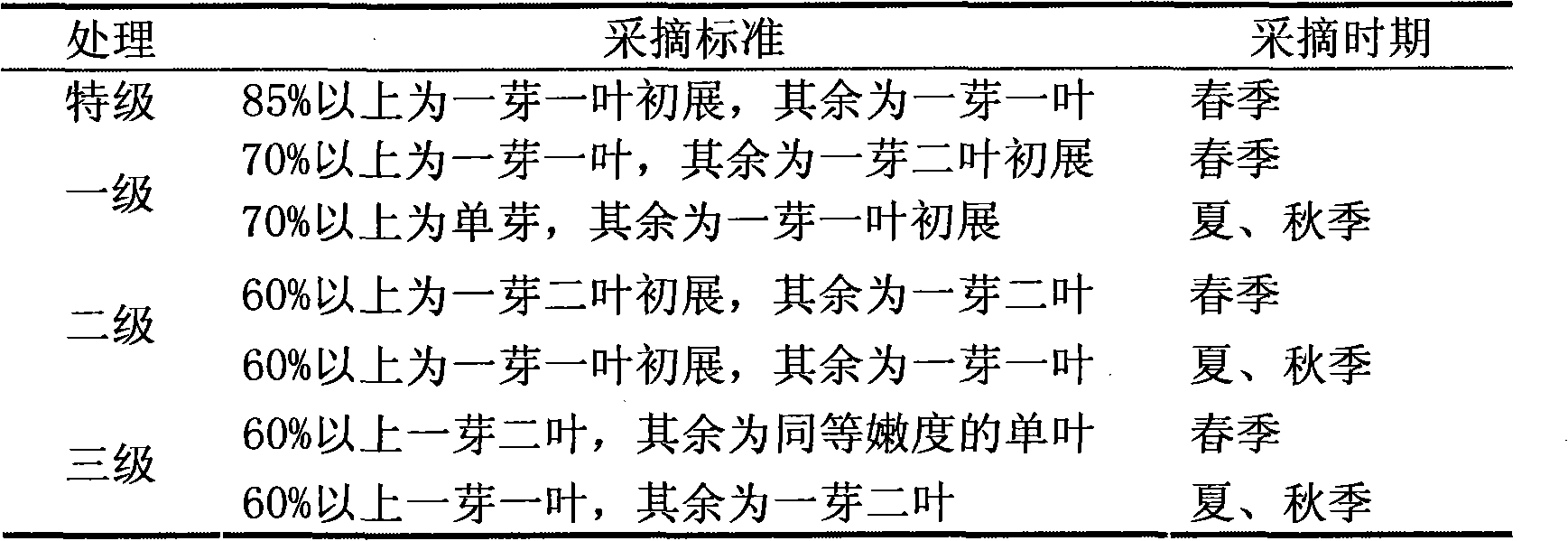

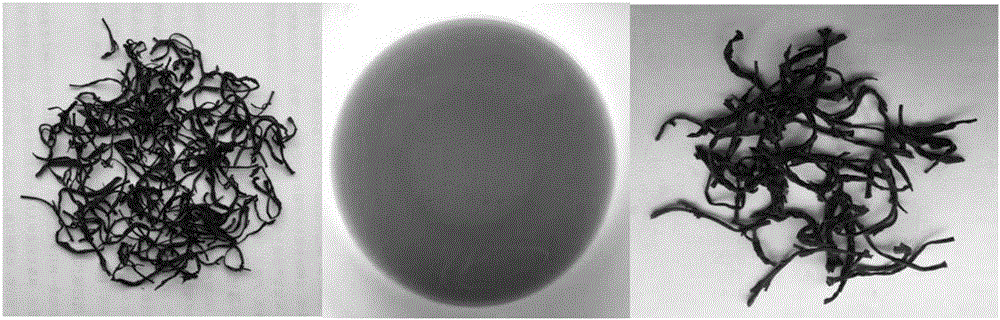

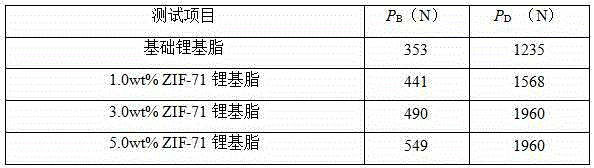

Xinyang red black tea processing technique

The invention relates to a Xingyang red black tea processing technique. The technique comprises the following parameters: wilting temperature: 25-30 DEG C; humidity: 60-70%; wilting time: 6-7 h; twisting machine rotating speed: 55-60 r / min; 2-3 times of twisting, each for 30 min; amount of tea feed: 30-35 kg; unravel machine rotating speed: 35 r / min; sieve pore size: 6#; 2-3 times of unravelling;temperature in a fermentation chamber: 2-7 DEG C; humidity in the fermentation chamber: 96%; tea spread thickness: 10 cm; oxygen supply amount: 5 L / min; fermentation time: 4.5 h; initial drying temperature: 115 DEG C; initial drying time: 20 min; re-drying temperature: 75 DEG C; and re-drying time: 30 min. The processing technique of the invention is unique, and the quality of the made black tea is excellent: the appearance of the product is fat and tender and compact, the peak of the tea is gold and the tea has bright luster; the endoplasm aroma of the tea has rich green flavour; the taste of the tea is mellow and sweet; the tea liquor is brilliantly red; and the root of the tea leaf is soft and green, has many sprouts and a colour of brilliant red.

Owner:信阳市浉河区茶叶办公室

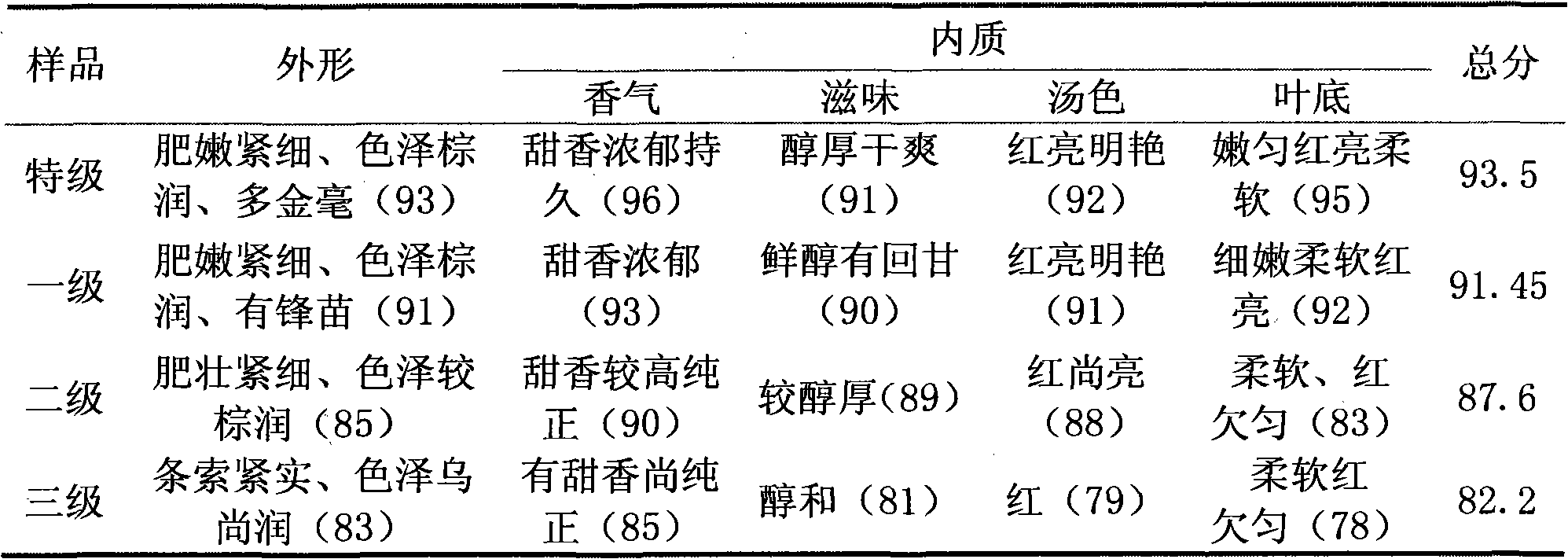

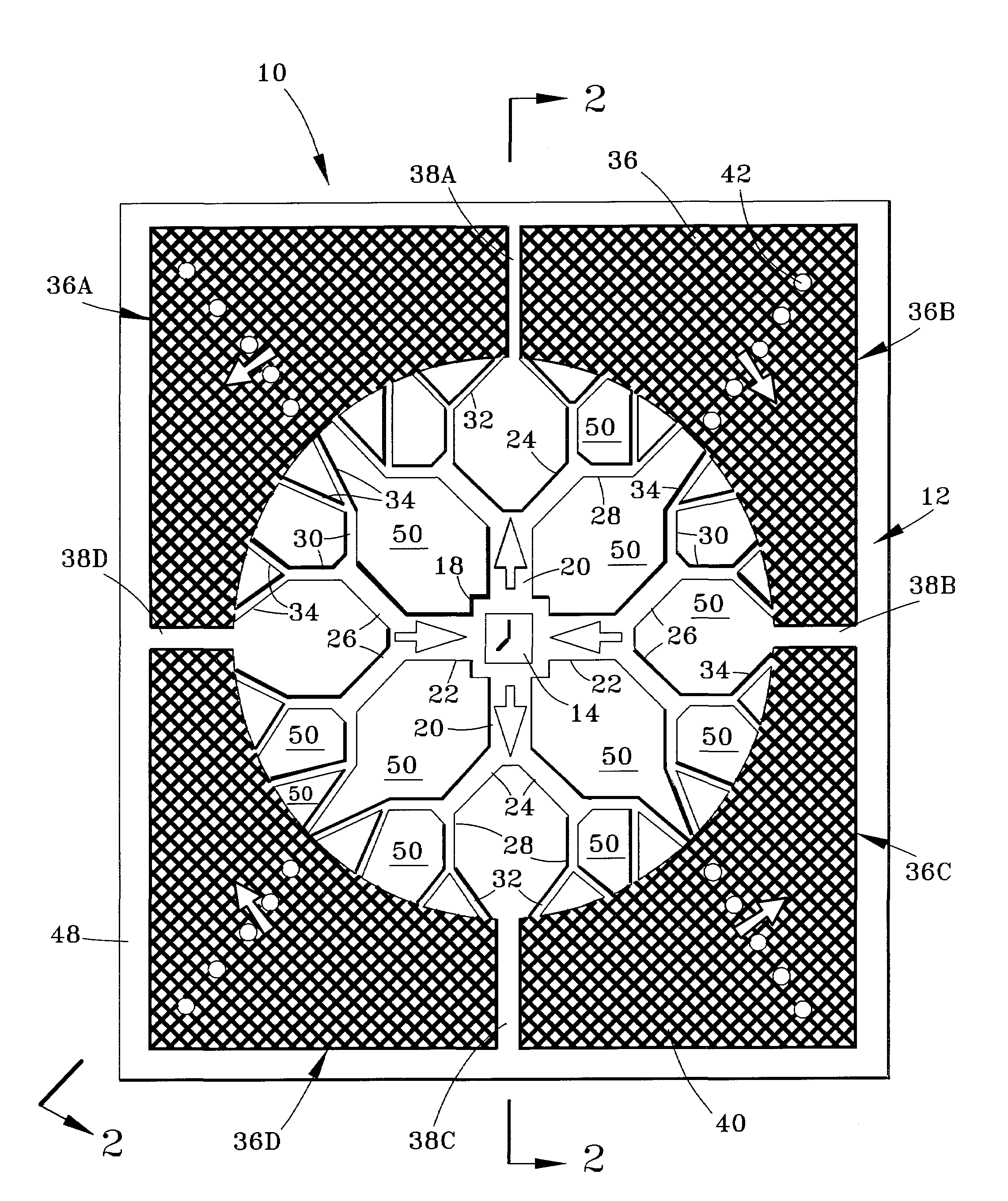

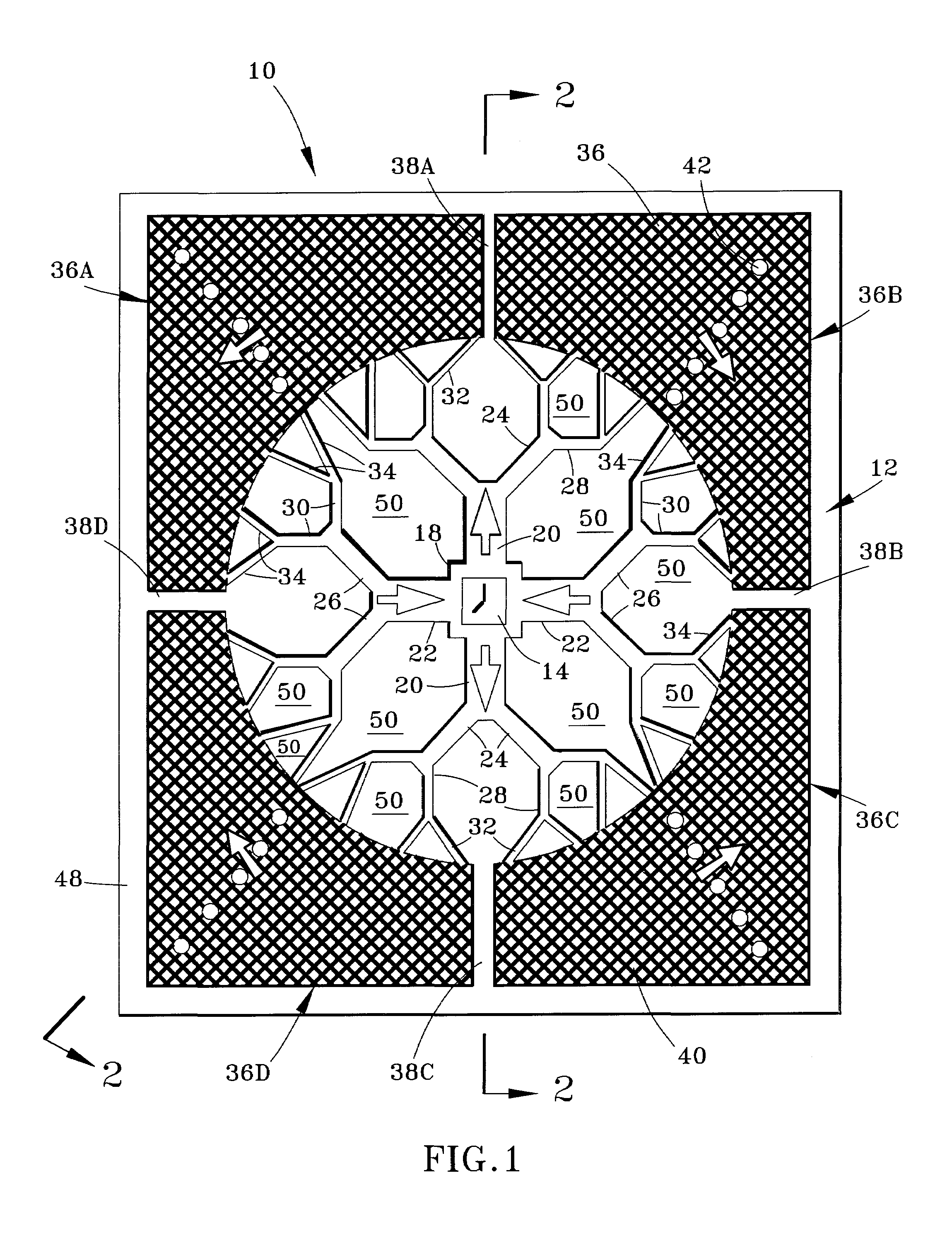

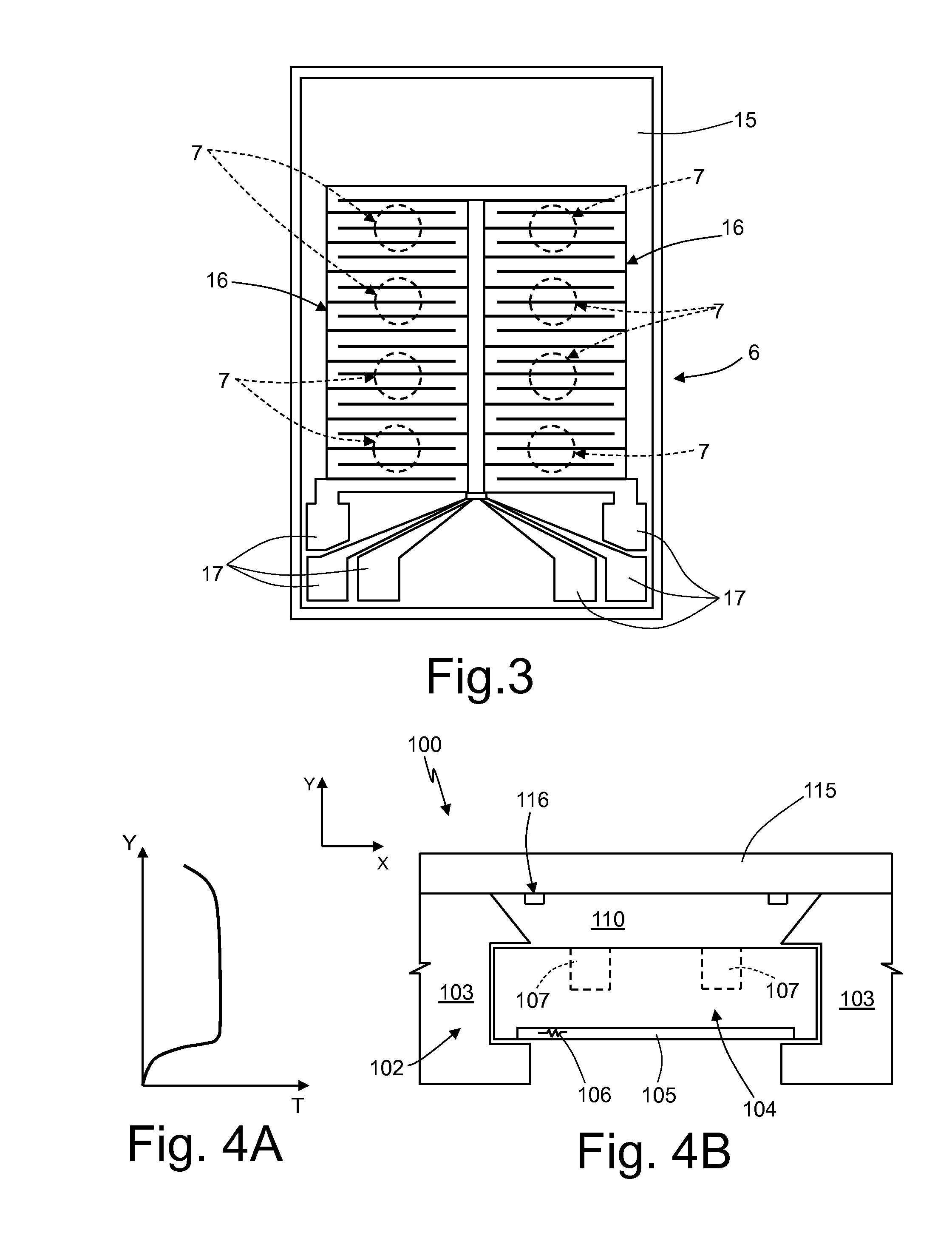

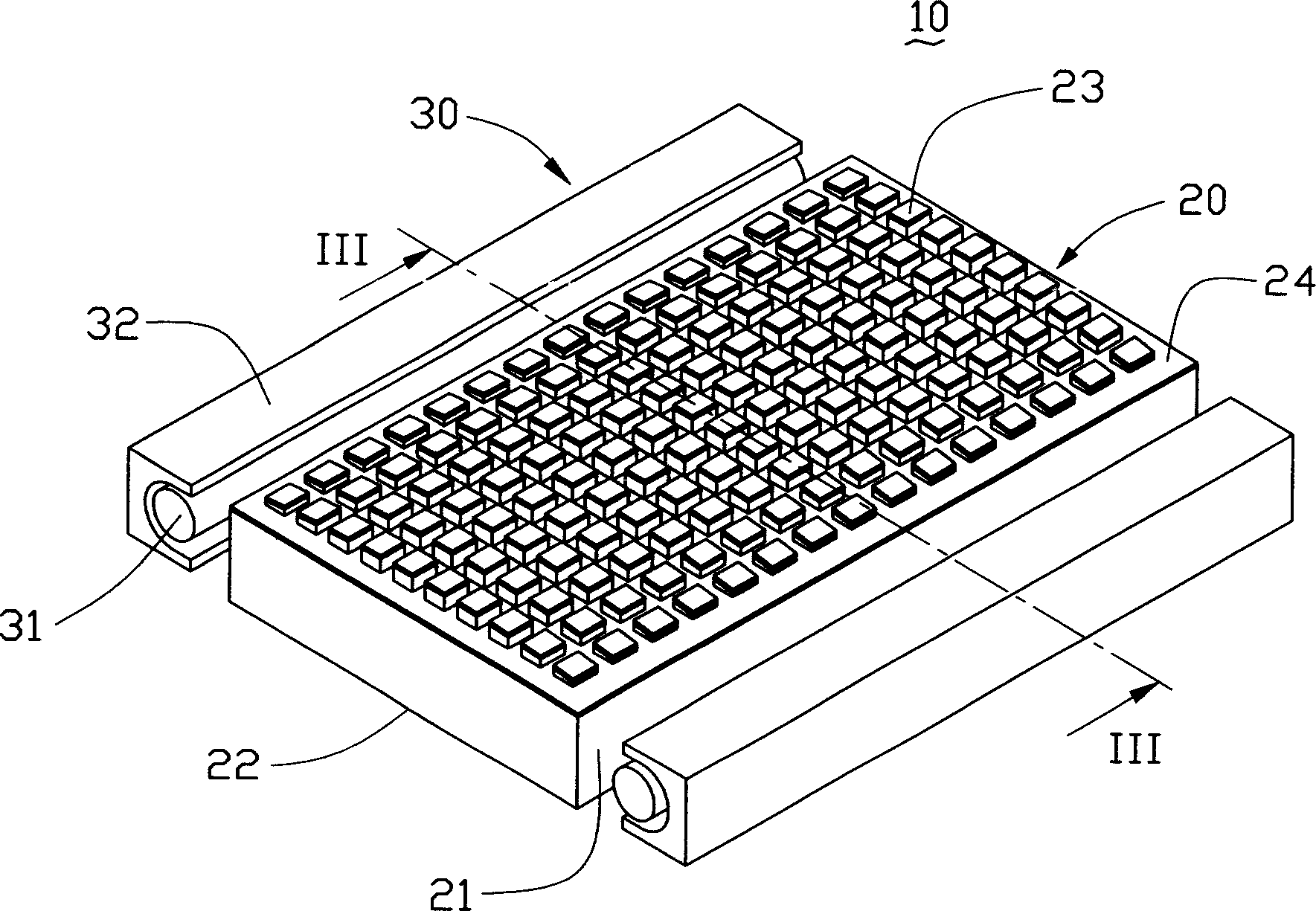

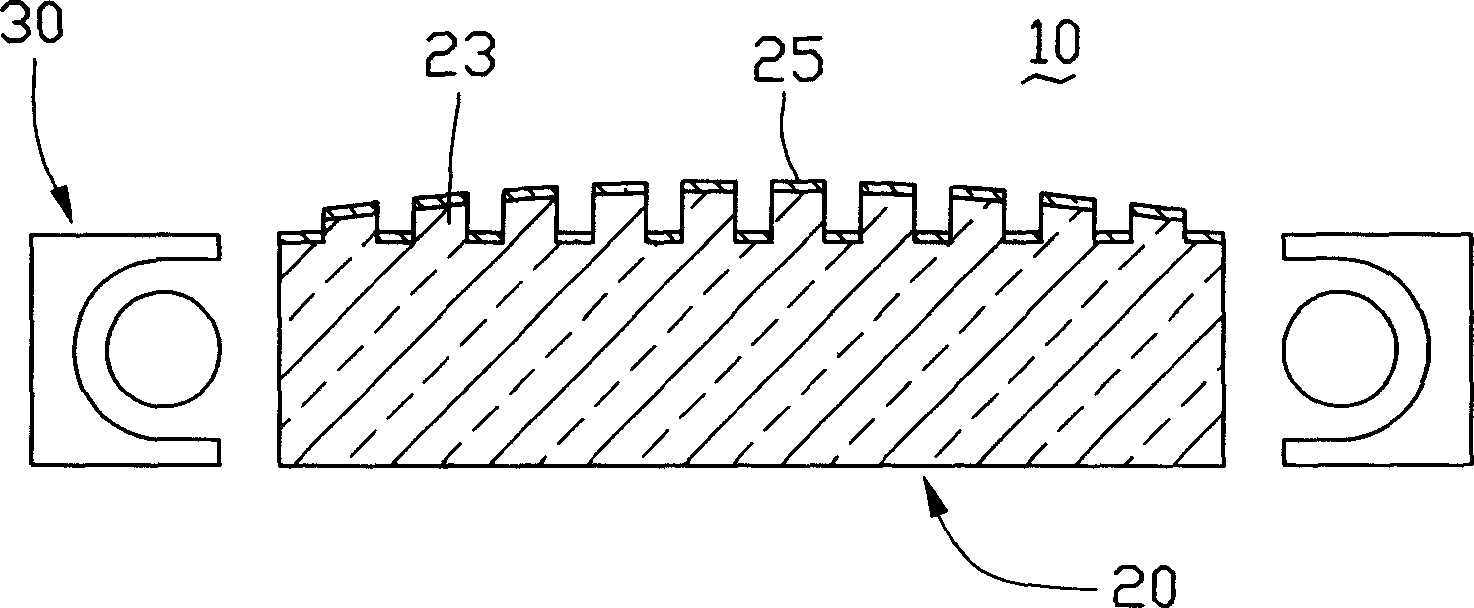

Cooling device for an electronic component

InactiveUS20080115916A1UniformAvoid bottlenecksSemiconductor/solid-state device detailsHeat exhanger conduitsEngineeringElectronic component

A cooling device for cooling an electronic component. The device has an enclosure adapted to contain a liquid coolant. The enclosure has an internal channel system comprising a cavity adjacent the electronic component, a first group of arborizing channels adapted to carry the liquid coolant away from the cavity, a second group of arborizing channels adapted to carry the liquid coolant to the cavity, and a plenum fluidically connecting the first and seconds groups of arborizing channels. Each group of arborizing channels has a parent branch and multiple successive sets of daughter branches with successively smaller cross-sectional areas, wherein the sum of the cross-sectional areas of the daughter branches of any set is approximately the same as that of its parent branch. Distal sets of the daughter branches are most distant from the cavity, fluidically connected to the plenum, and have the smallest cross-sectional areas of the daughter branches.

Owner:NYTELL SOFTWARE LLC

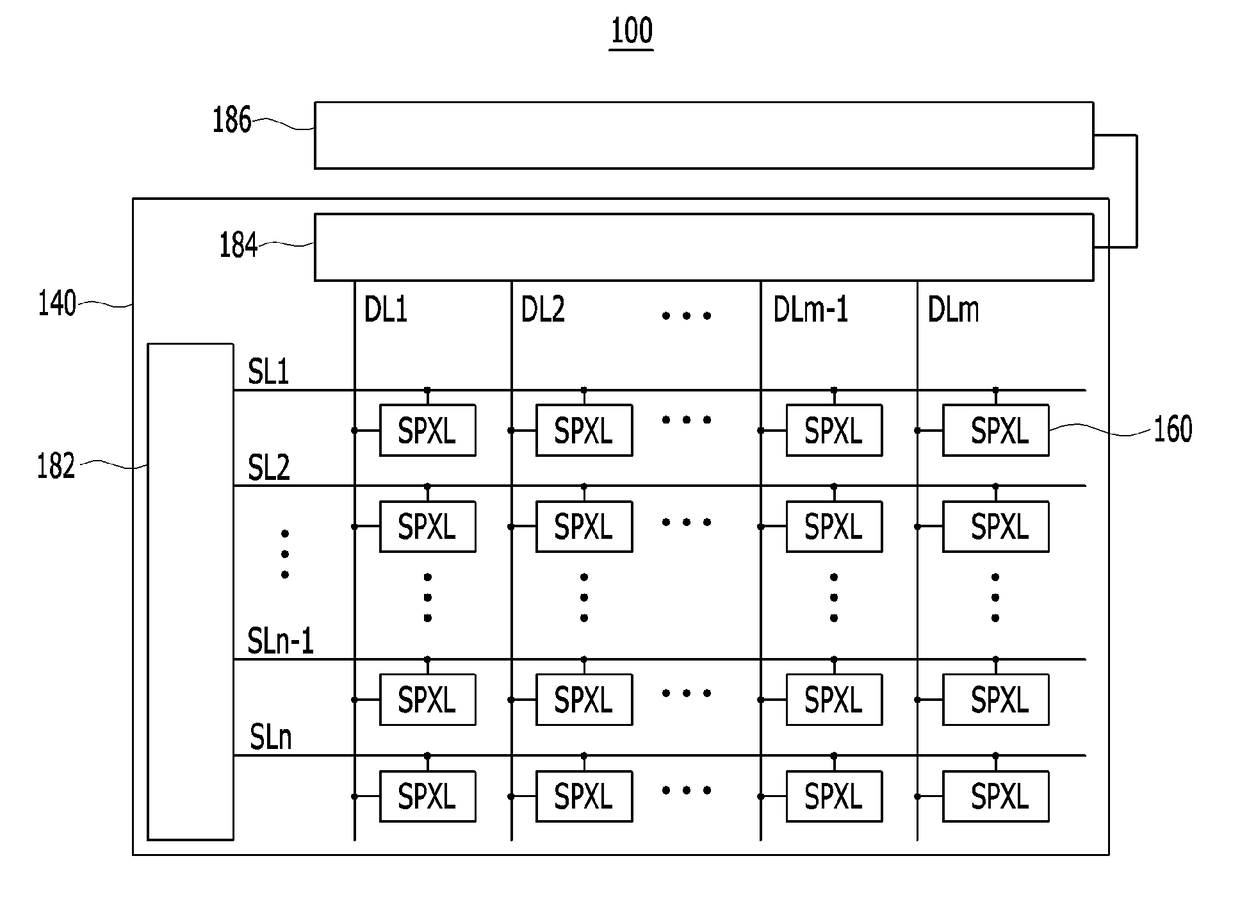

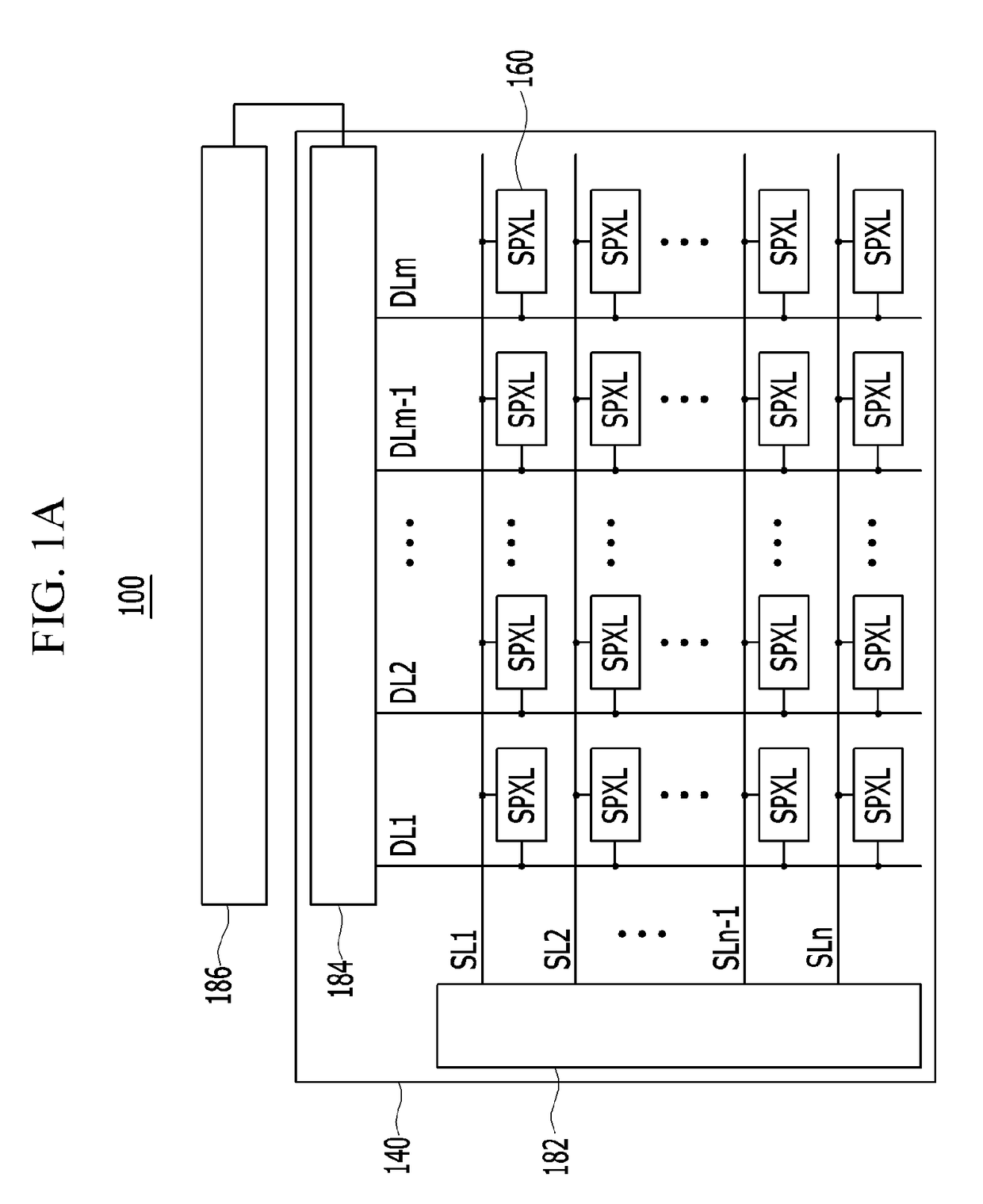

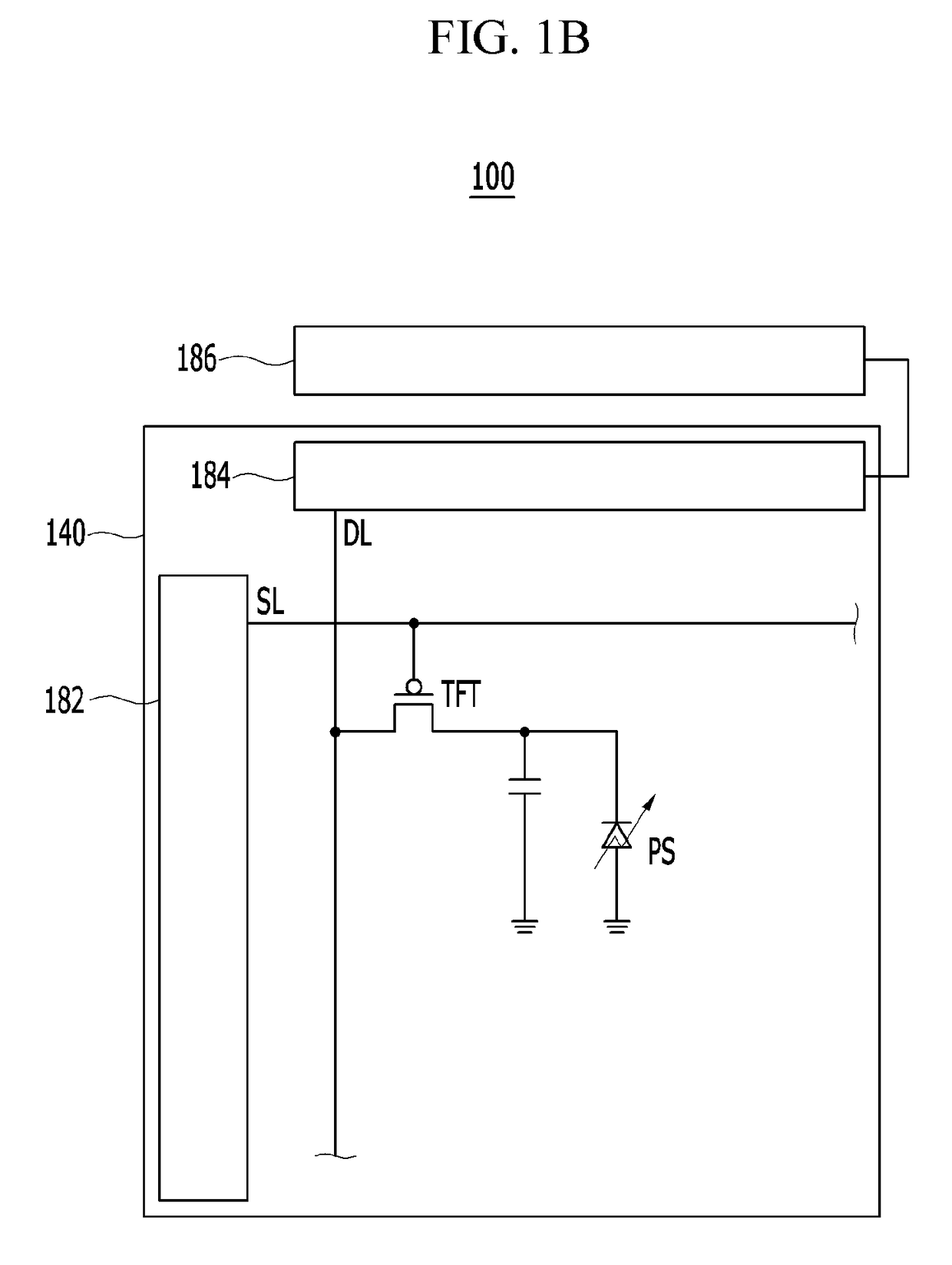

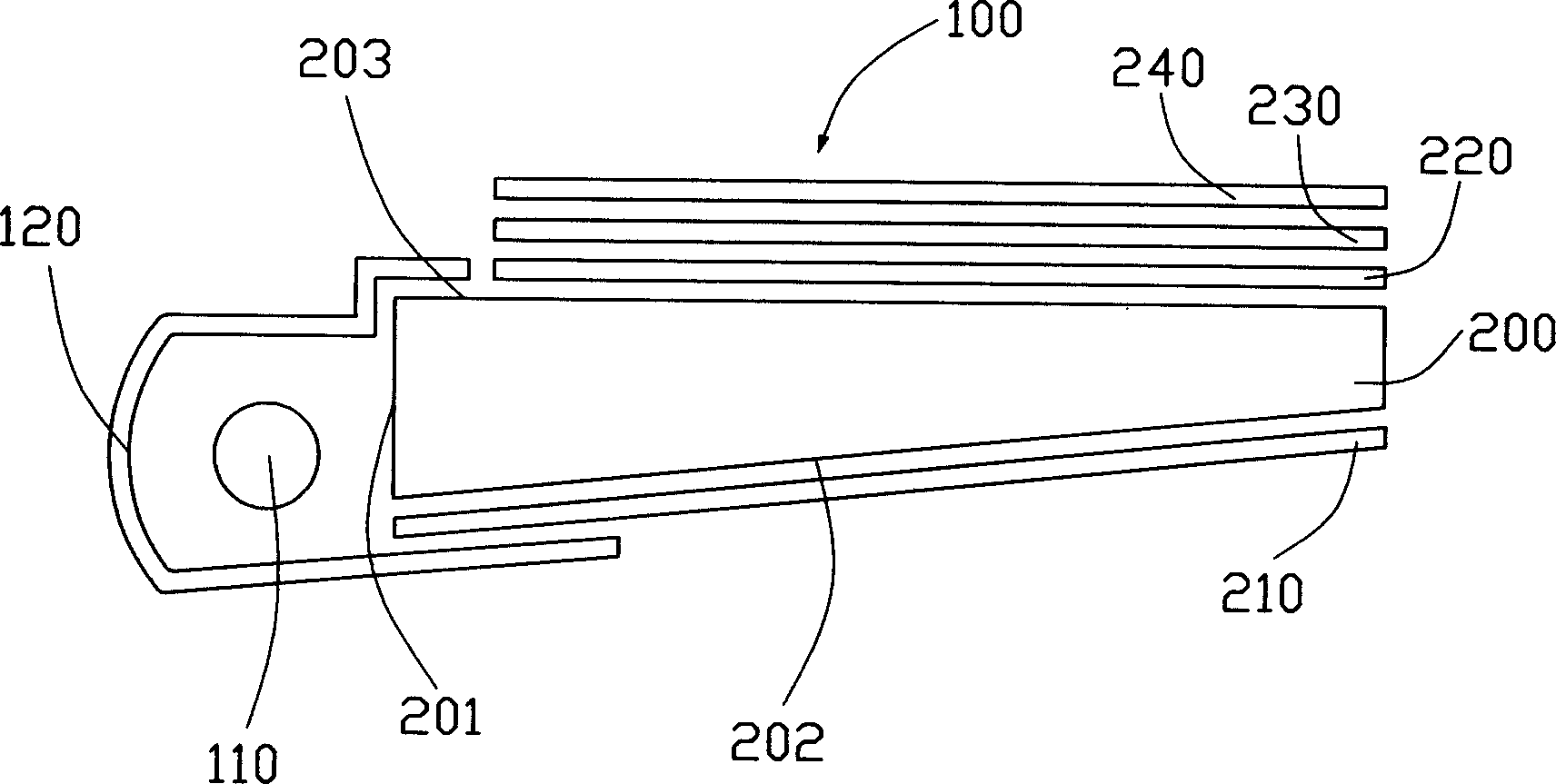

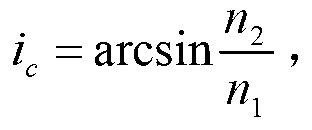

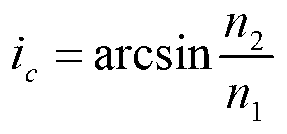

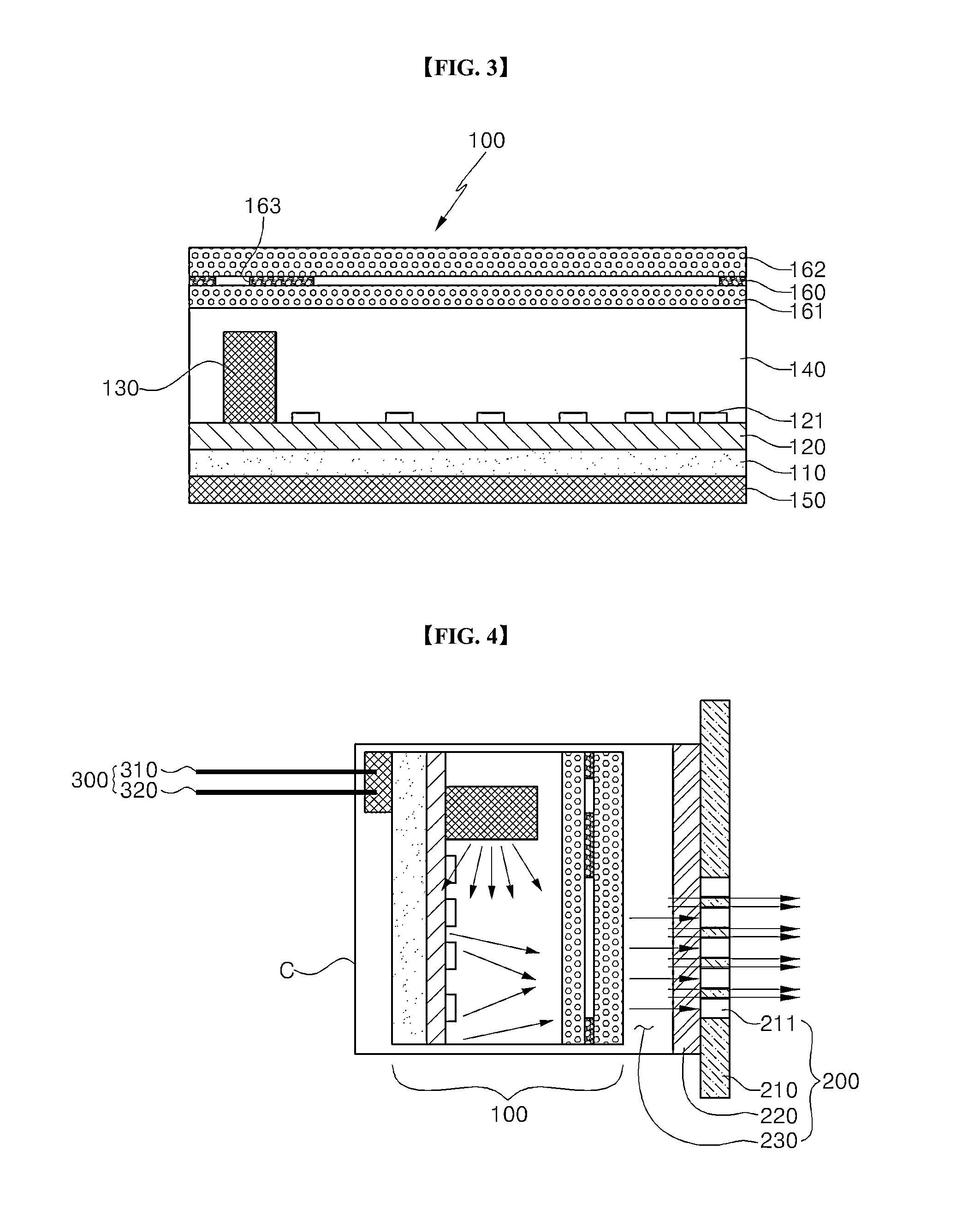

Fingerprint recognition sensor and portable display device having the same

Disclosed are a fingerprint recognition sensor including: a light source positioned while being spaced apart on one surface of the substrate and irradiating light toward the substrate; and a light direction switching layer positioned between the substrate and the light source, having a thickness-direction cross-section having a right-angled triangular shape, and including multiple protrusions constituted by a first surface in which the light irradiated from the light source is incident and refracted, a second surface contacting the one surface of the substrate, in which the refracted light is transmitted toward the substrate, and a third surface vertical to the one surface of the substrate, and a mobile display device having the same.

Owner:SILICON DISPLAY TECH CO LTD

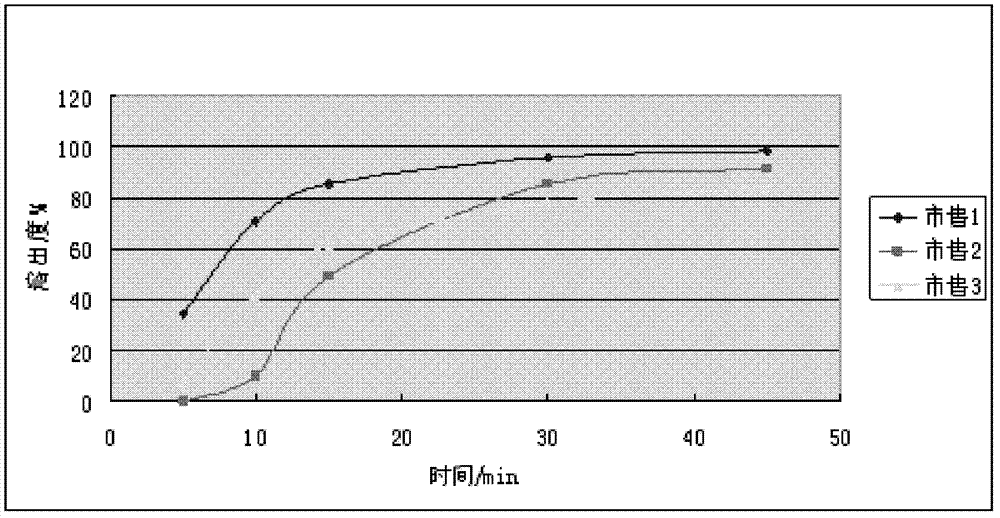

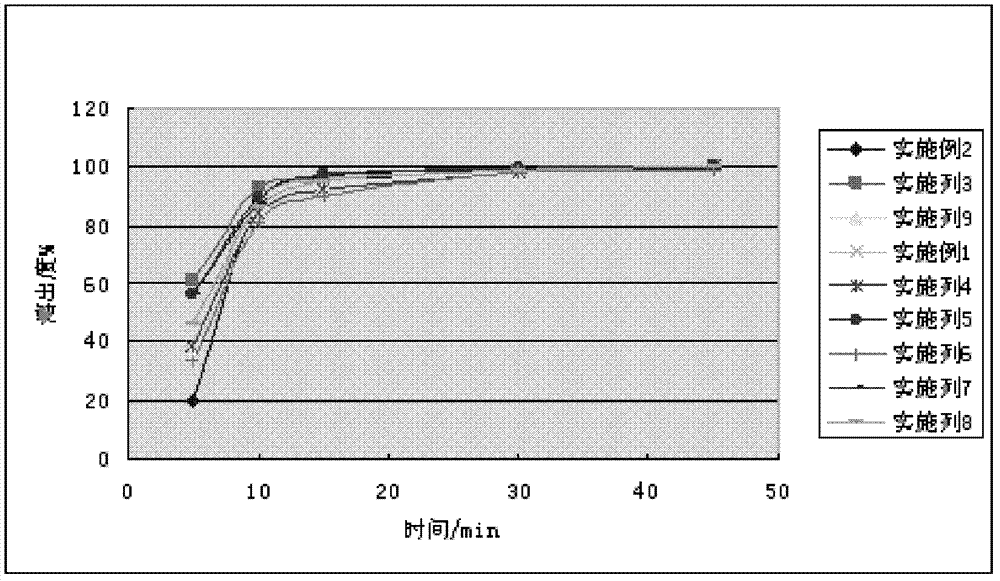

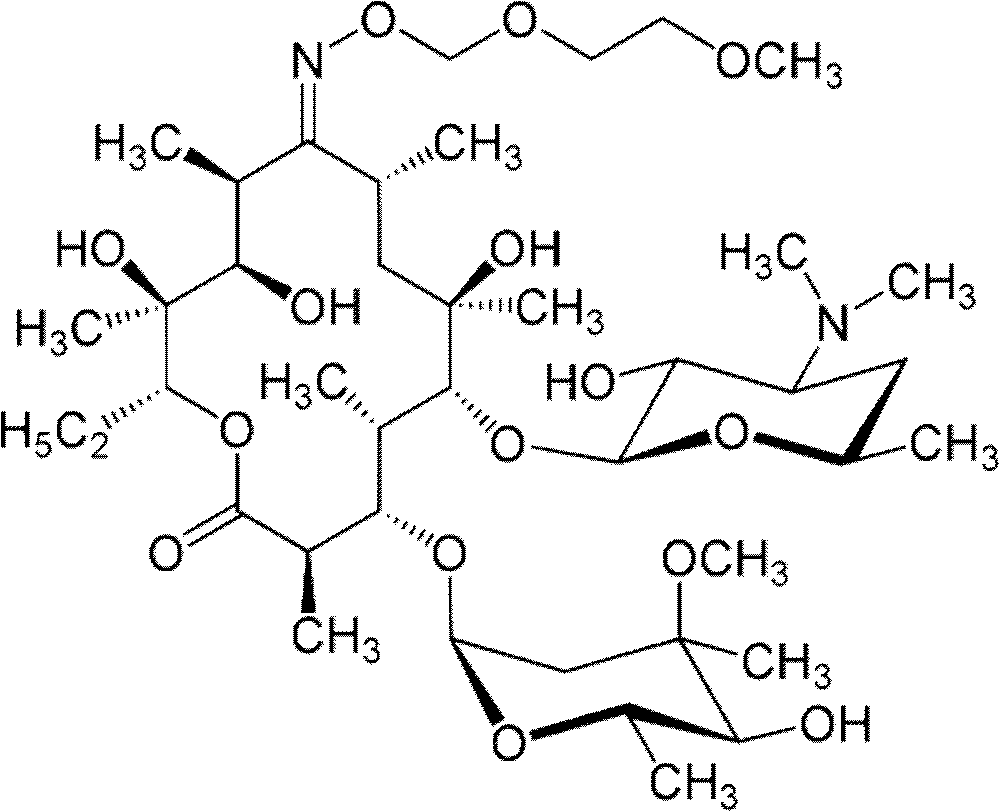

Roxithromycin capsule and preparation method thereof

ActiveCN103083278AImprove the disintegration effectHigh dissolution rateAntibacterial agentsOrganic active ingredientsRoxithromycinDissolution

The invention discloses a roxithromycin capsule and a preparation method thereof. The roxithromycin capsule pharmaceutical composition comprises the roxithromycin, silica powder, a disintegrating agent, a filler, a lubricant, etc. The preparation technology of the roxithromycin capsule comprises a direct filling technology and a wet granulation process. The method can satisfy demands of different equipment and is beneficial for production. The prepared roxithromycin capsule is good in dissolution and small in loading difference, and is a safe, stable and effective product.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

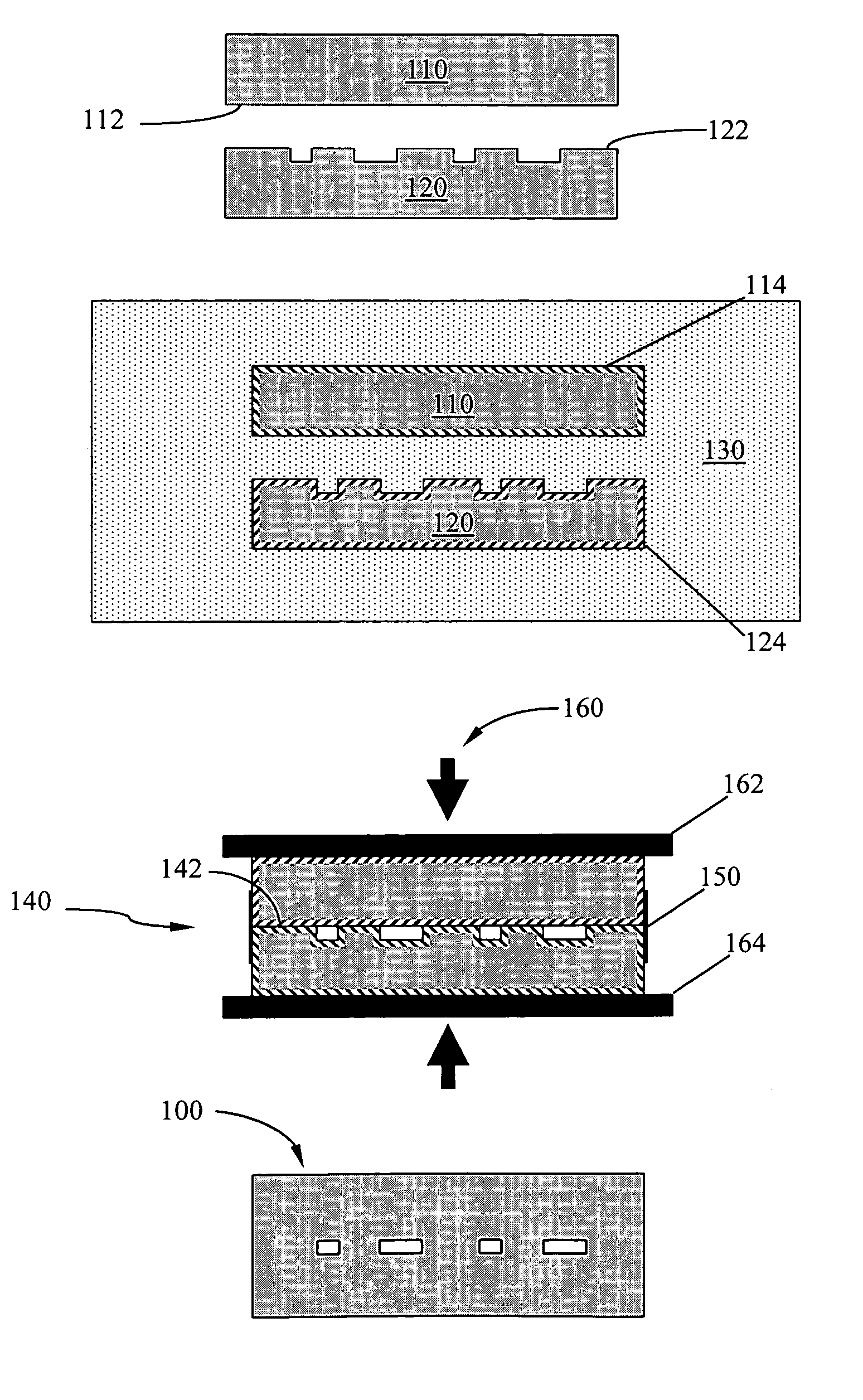

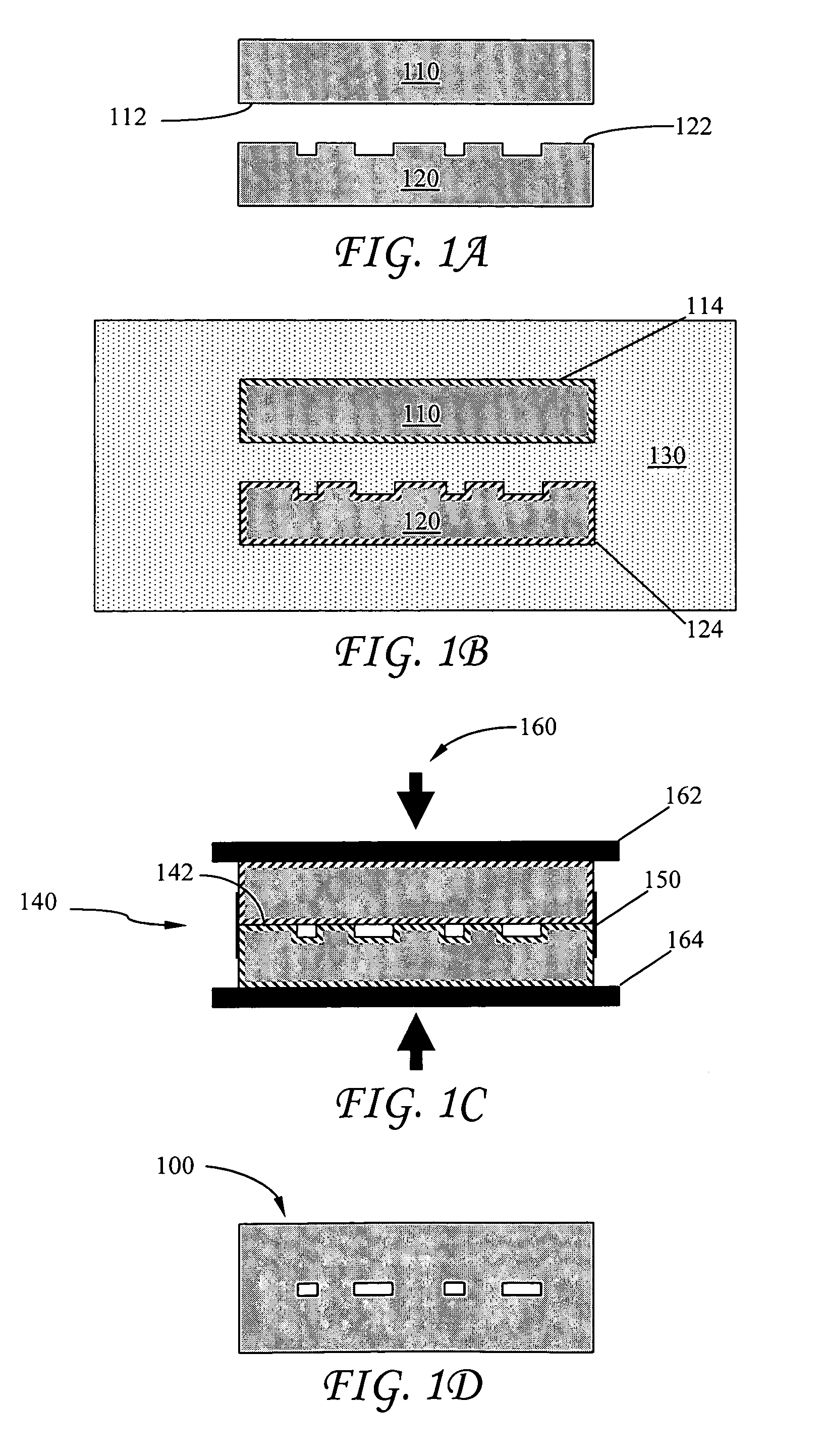

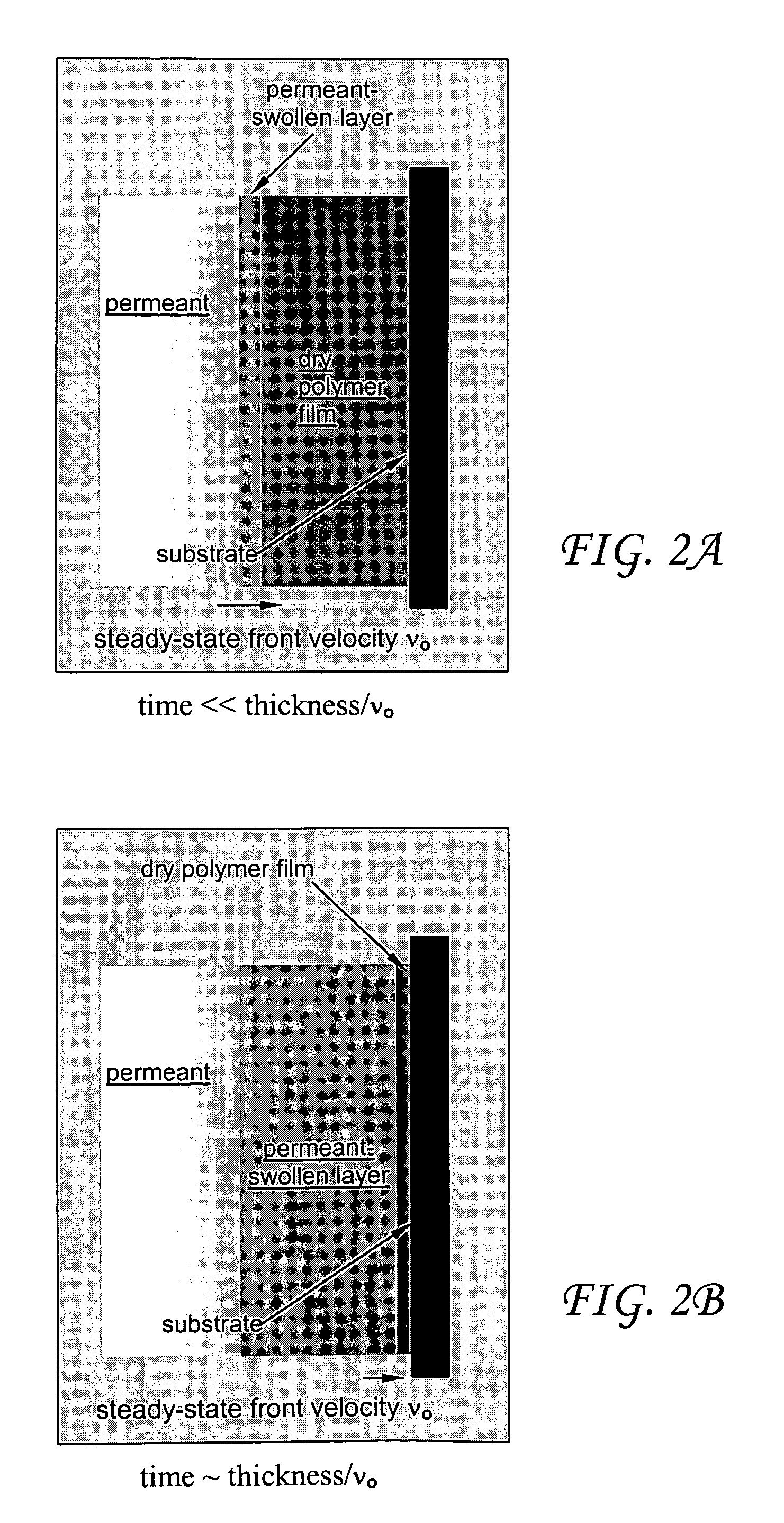

Bonding thermoplastic polymers

InactiveUS7390377B1UniformUniform surface propertiesMechanical working/deformationAdhesive processes with surface pretreatmentMicrometerThermosetting polymer

We demonstrate a new method for joining patterned thermoplastic parts into layered structures. The method takes advantage of case-II permeant diffusion to generate dimensionally controlled, activated bonding layers at the surfaces being joined. It is capable of producing bonds characterized by cohesive failure while preserving the fidelity of patterned features in the bonding surfaces. This approach is uniquely suited to production of microfluidic multilayer structures, as it allows the bond-forming interface between plastic parts to be precisely manipulated at micrometer length scales. The bond enhancing procedure is easily integrated in standard process flows and requires no specialized equipment.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Thermoplastic polyurethane composition and process for producing the same

ActiveUS7084207B2UniformSuppress progressSynthetic resin layered productsThin material handlingChemistryPolyamide

The present invention provides a thermoplastic polyurethane composition which comprises an ethylene-vinyl alcohol copolymer and / or a polyamide, and a thermoplastic polyurethane, in which the retention of melt tension thereof, when kept in a molten state at 220° C. for 1 hour, determined by the following equation (1), is not less than 10%.Retention of melt tension (%)=[Melt tension after being kept in a molten state / Melt tension before being kept in a molten state]×100 (1)The thermoplastic polyurethane composition of the present invention is excellent in production stability of a molded article, and can provide a molded article excellent in appearance because the progress of gelation thereof is suppressed even in a molten state.

Owner:KURARAY CO LTD

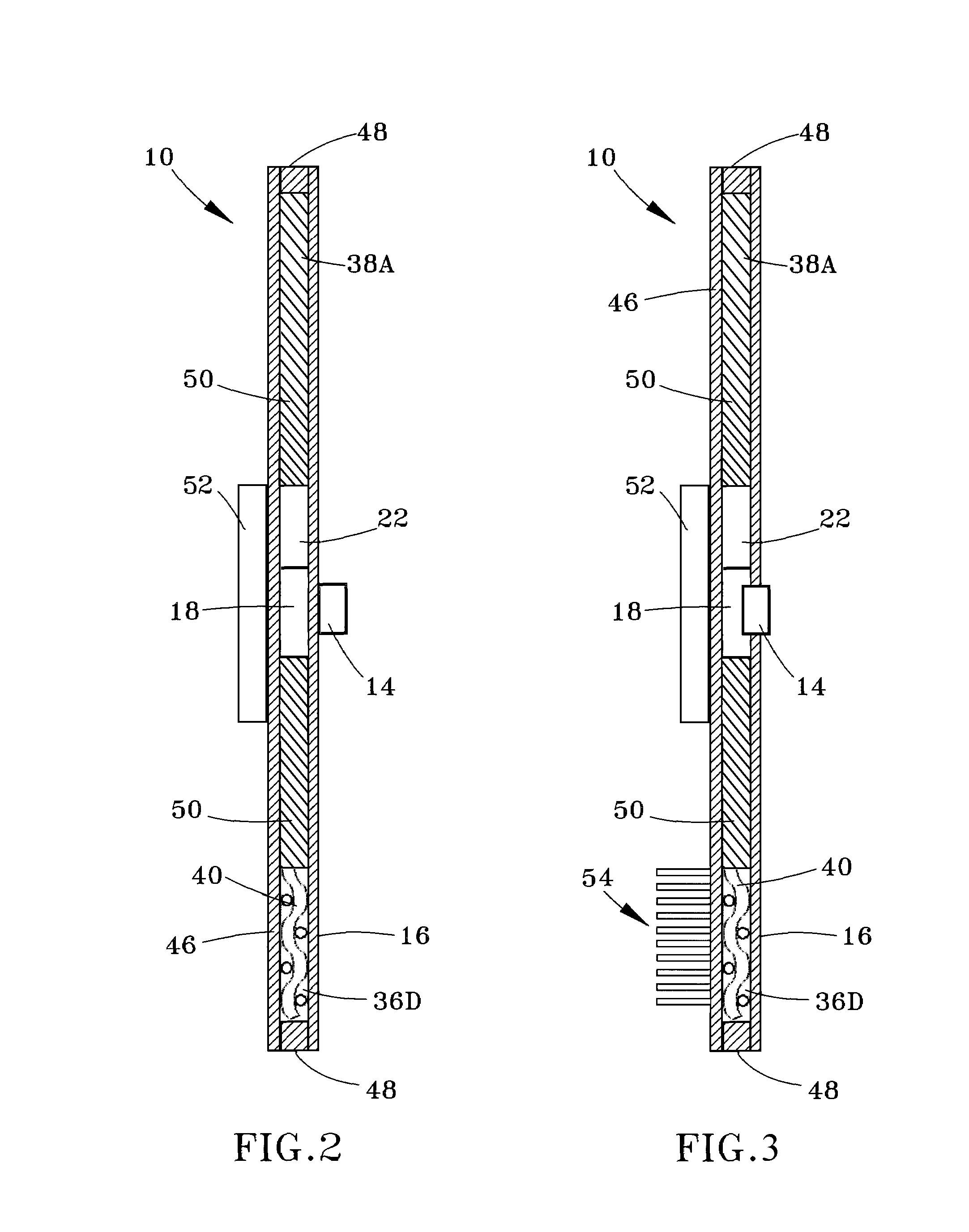

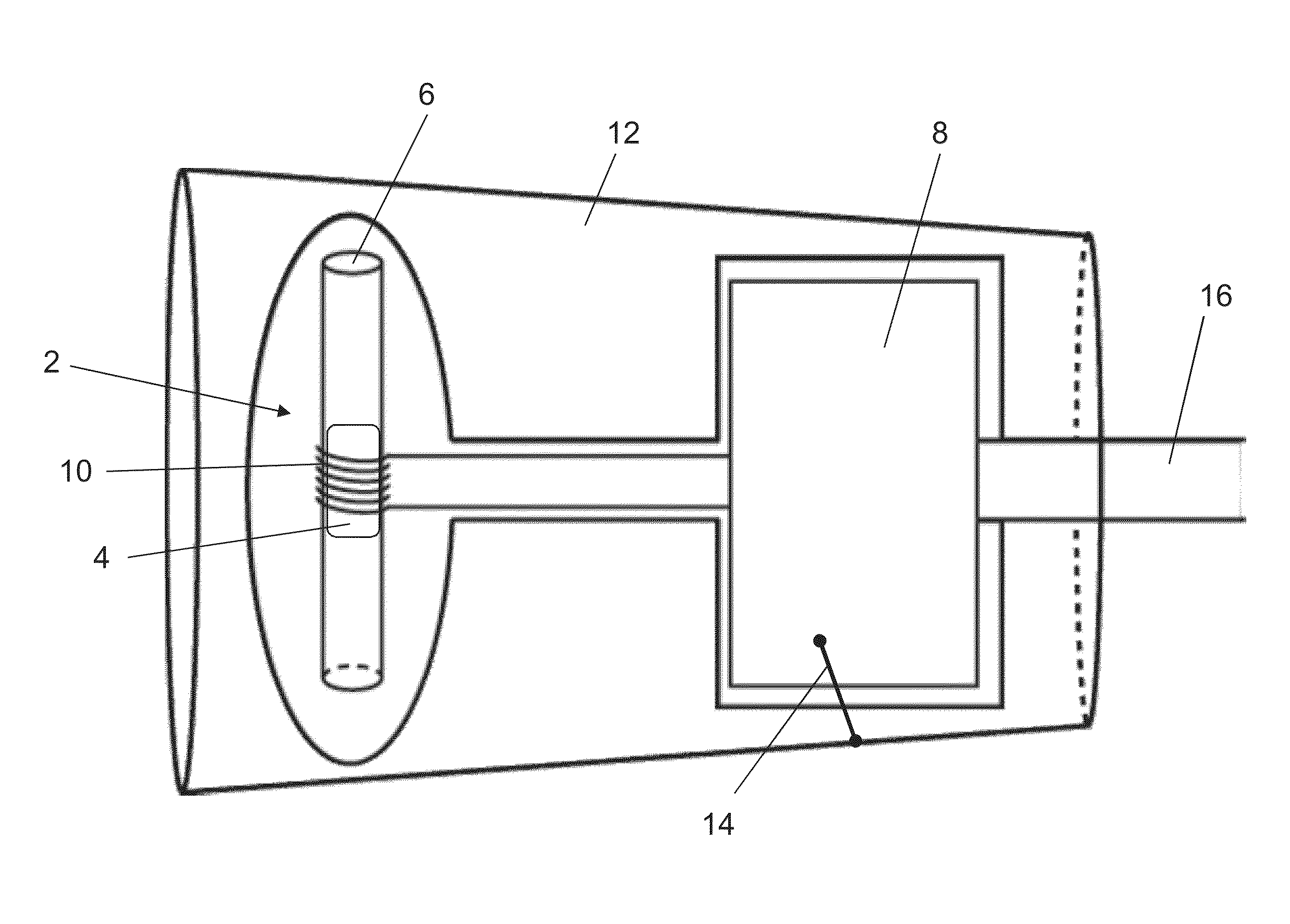

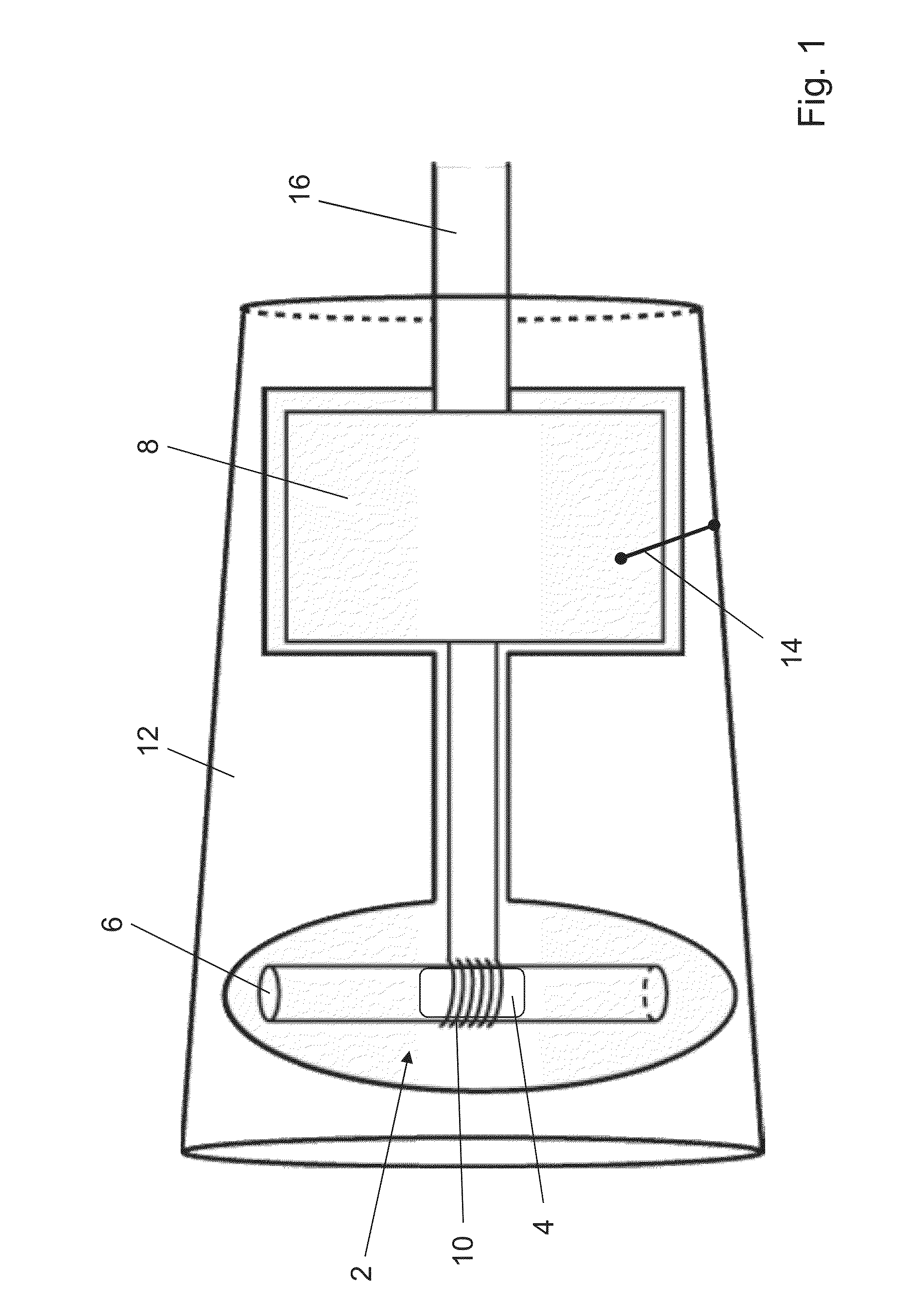

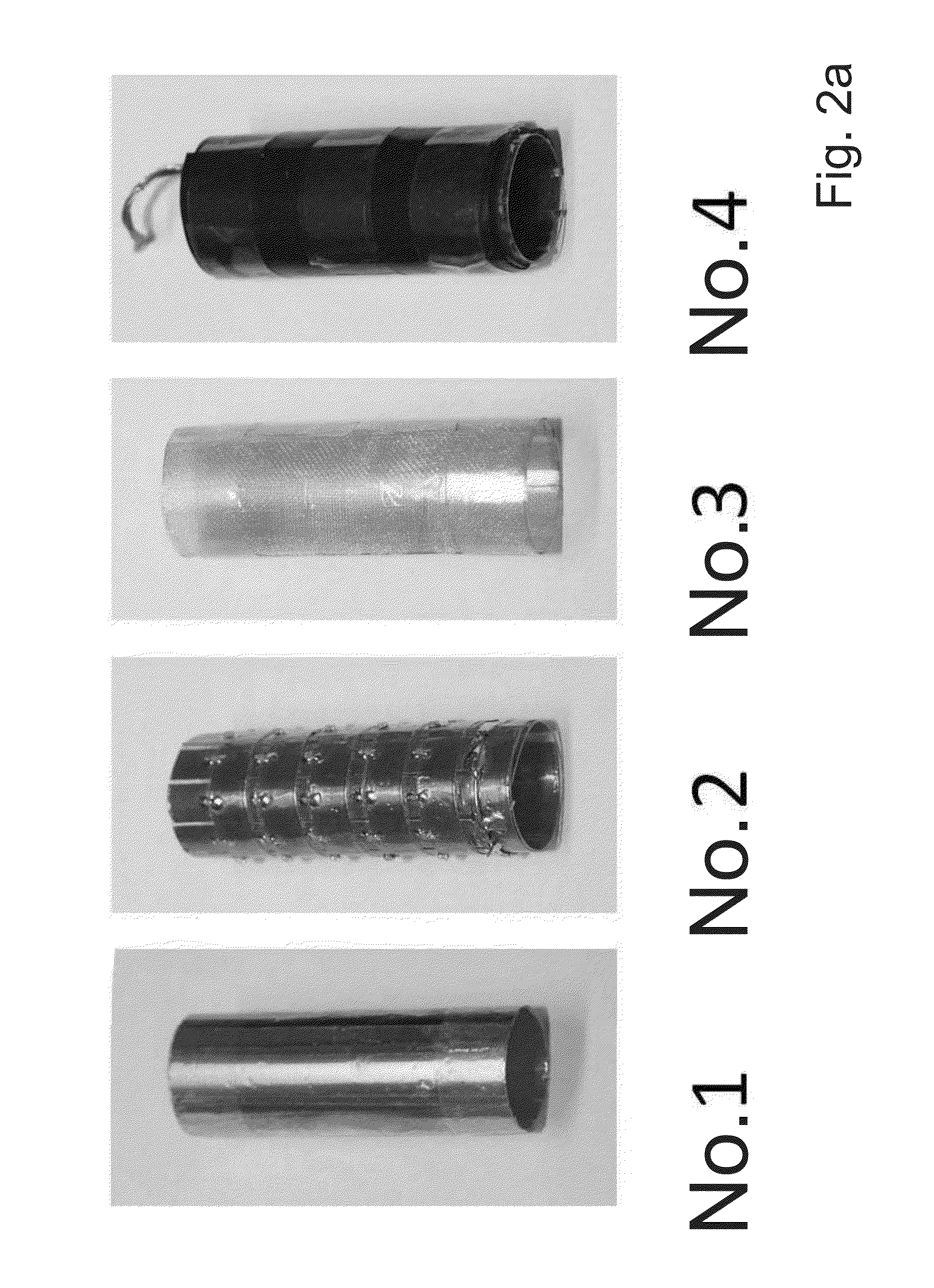

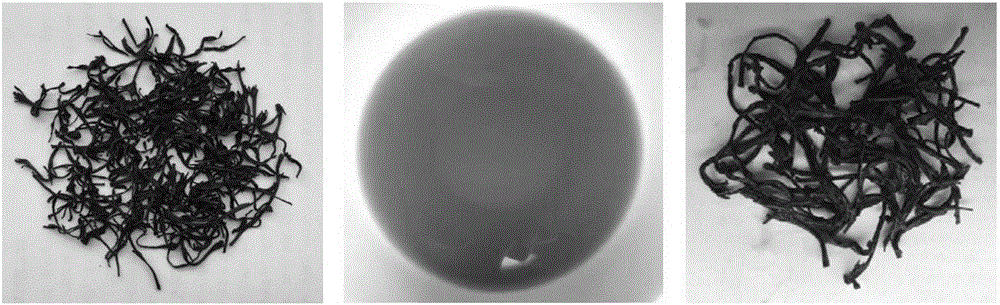

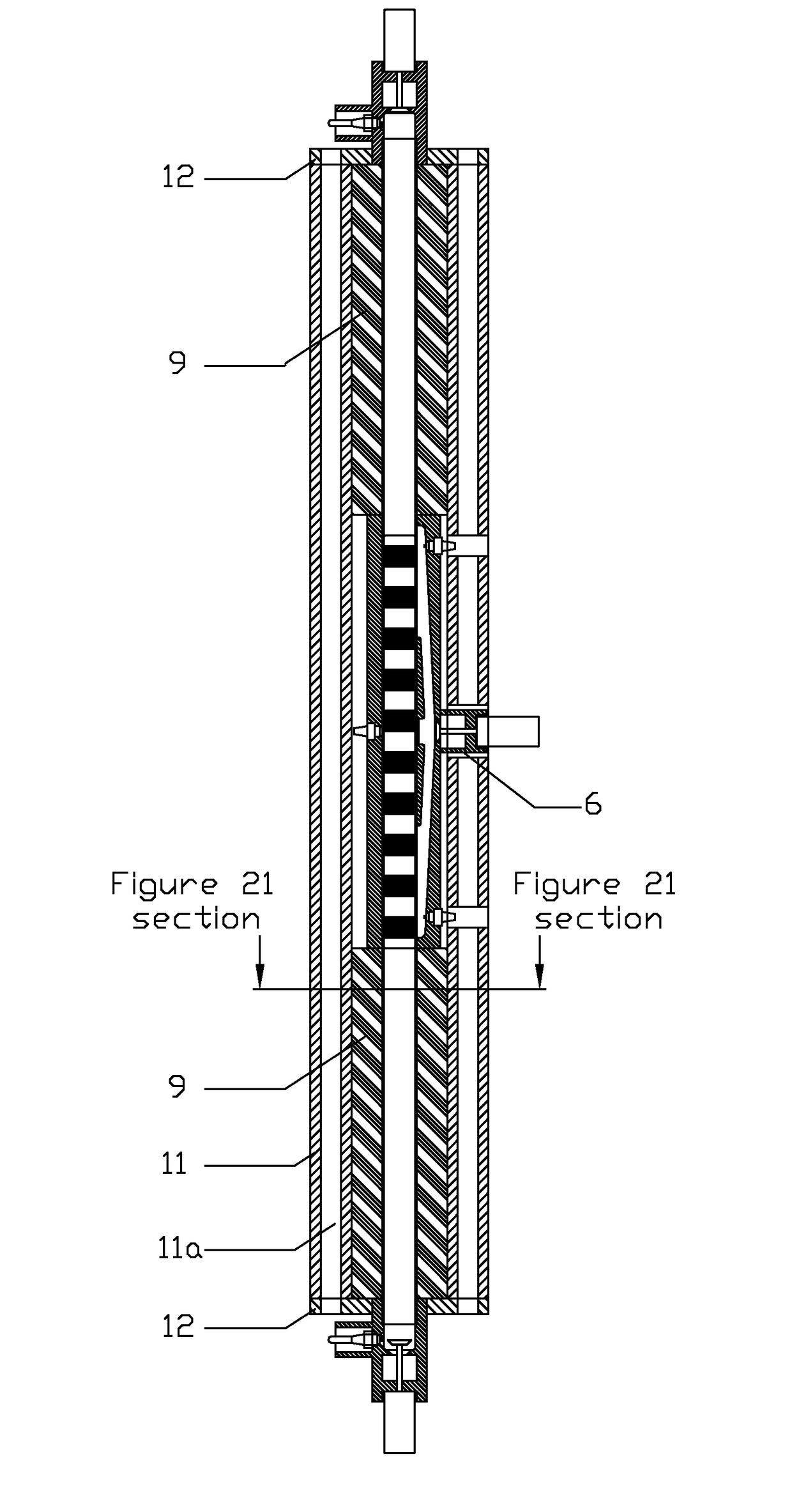

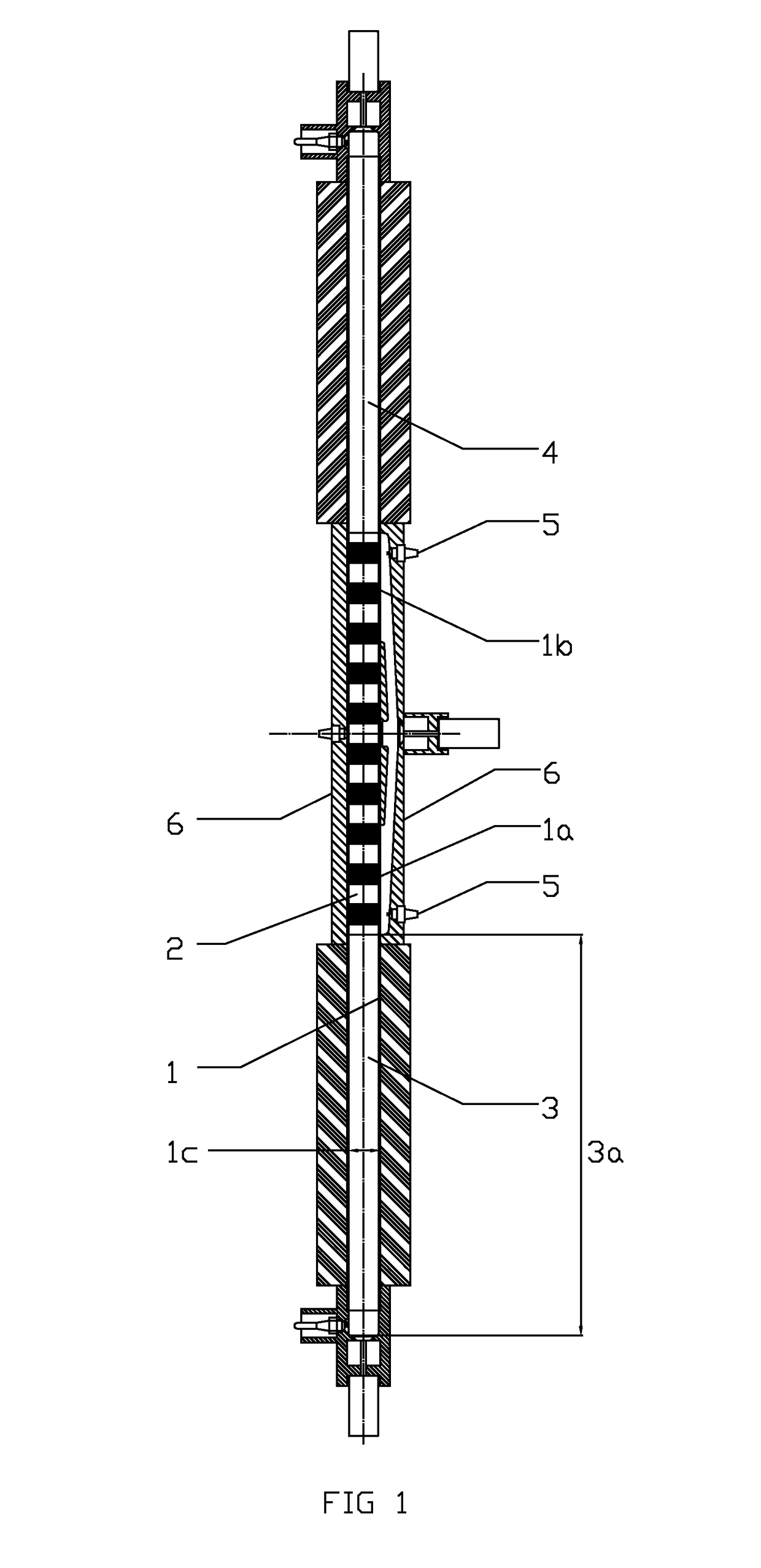

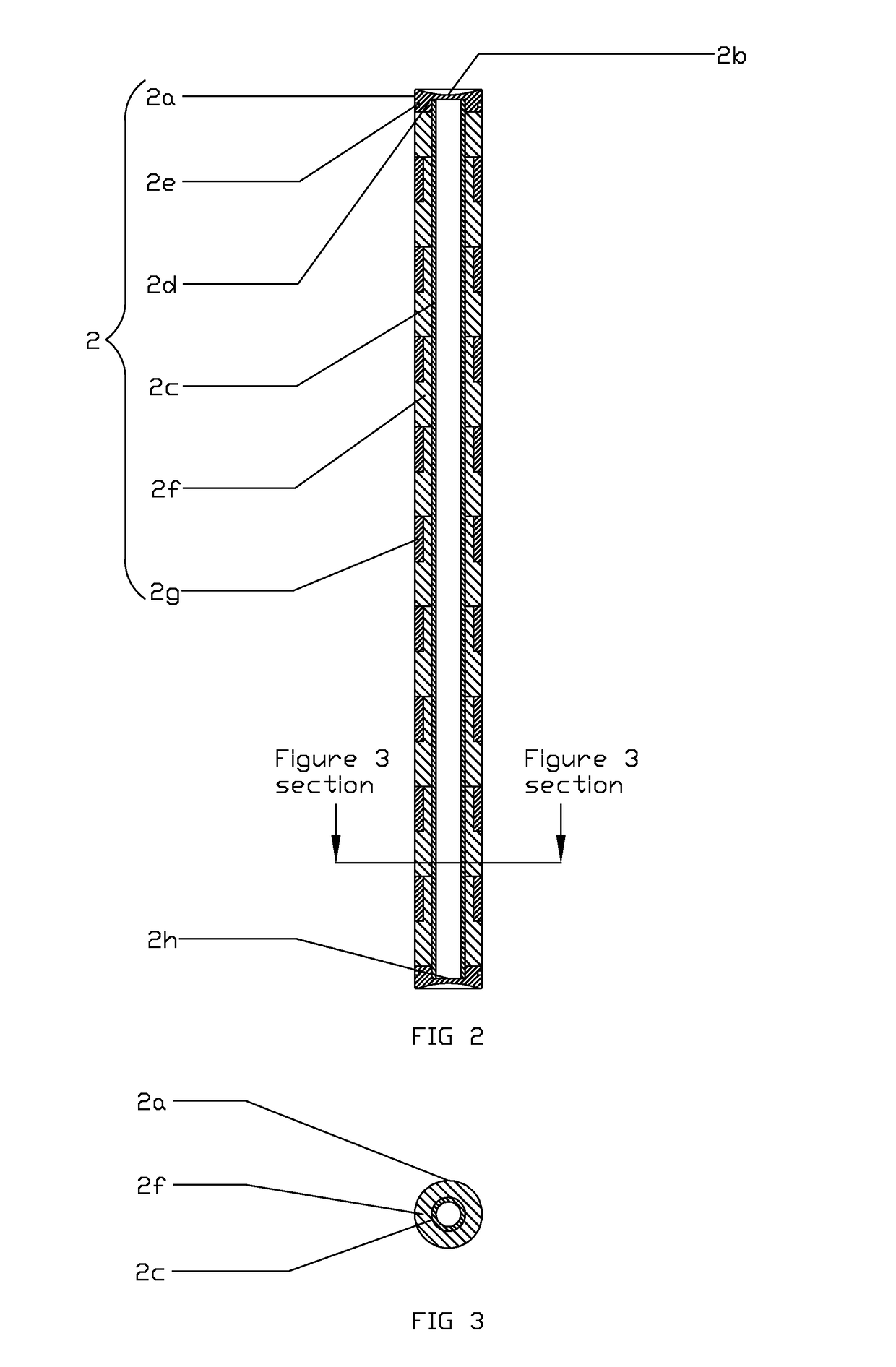

Isolating MR Magnetic Field Probes from External RF Irradiation

ActiveUS20150241530A1Attenuation of signal levelMinimally influenceShielding materialsElectric/magnetic detectionSpectroscopyElectromagnetic field

An arrangement for carrying out dynamic magnetic field measurements in a MR imaging or MR spectroscopy apparatus comprises at least one magnetic field probe (2) comprising a MR active substance (4), means (8, 10) for pulsed MR excitation of said substance and means (8, 10) for receiving an MR signal generated by said substance. The magnetic field probe further comprises a radio frequency shield (12) against external high-frequency electromagnetic field irradiation substantially surrounding the magnetic field probe. The shield is composed of conductive elements embedded in a dielectric material. The conductive elements are electrically conductive filaments and / or electrically conductive platelets.

Owner:SKOPE MAGNETIC RESONANCE TECH

Processing method of orchid-flavored black tea

InactiveCN104171052ATaste sweet and honeyBlack colorPre-extraction tea treatmentTea flavoringNerolidolBlack teas

The invention discloses a processing method of orchid-flavored black tea. The processing method comprises the following steps: (1) picking fresh tea leaves each with one bud and three to four leaves or tea leaves each with buds on a sunny day or in a rainy-to-fine weather; (2) cooling the picked fresh tea leaves, rocking twice and spreading twice; (3) rocking for the second time and spreading for a long time; (4) rocking the fresh tea leaves for the third time in the next day; (5) rocking for the third time and continuously spreading; (6) withering the continuously spread fresh leaves by sunlight, performing fixation, and rolling while the fresh leaves are hot; (7) primarily baking the rolled leaves, spreading, sunning, and performing pile fermentation; (8) fully drying and warehousing. According to the processing method, the orchid aromas in the tea leaves are excited to the maximum extent by controlling the picking time and mastering the fresh leaf maturity, alternatively spreading and rocking for multiple times and withering by sunlight, so that substances such as amino acid and nerolidol influencing the aromas and sweet and fresh tastes of orchids in the tea leaves are brought into play to the maximum extent, and then the black tea prepared by adopting the method has remarkable orchid aromas and is fresh, sweet and honeyed in taste.

Owner:HUNAN TIEXIANG TEA

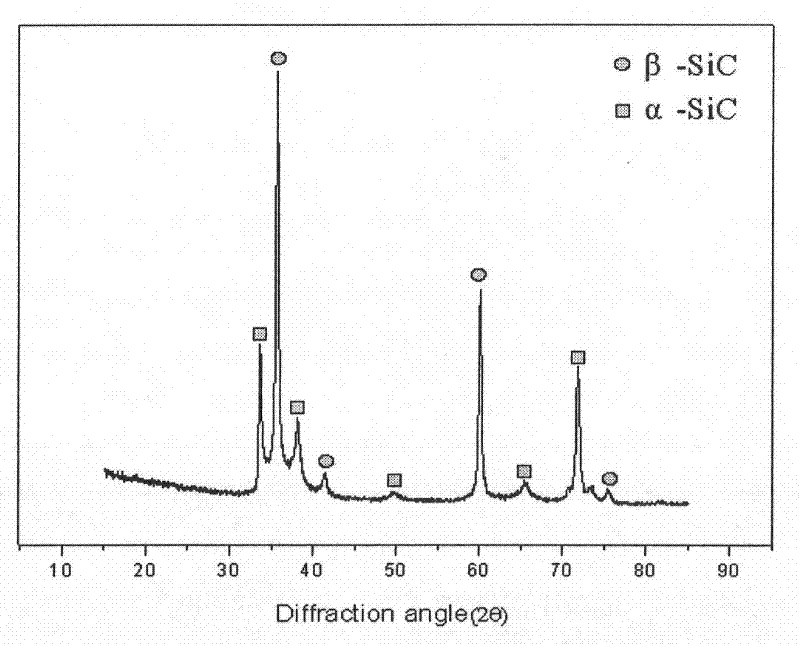

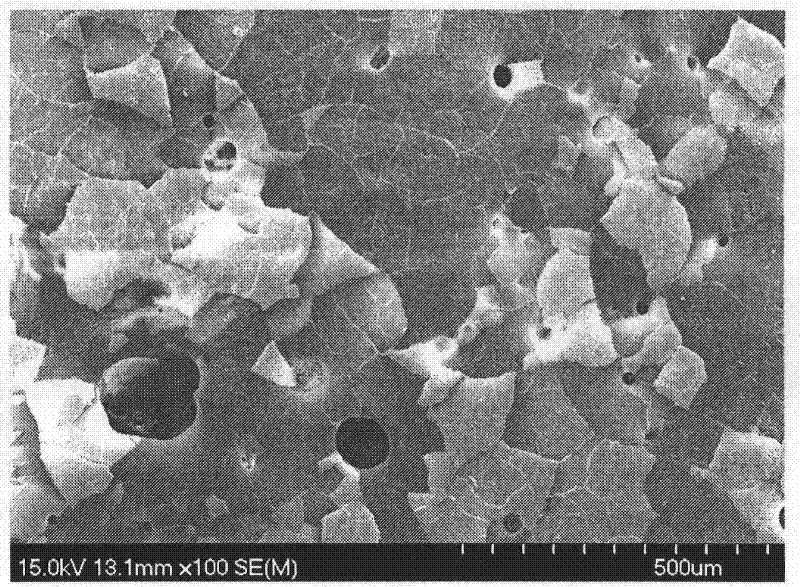

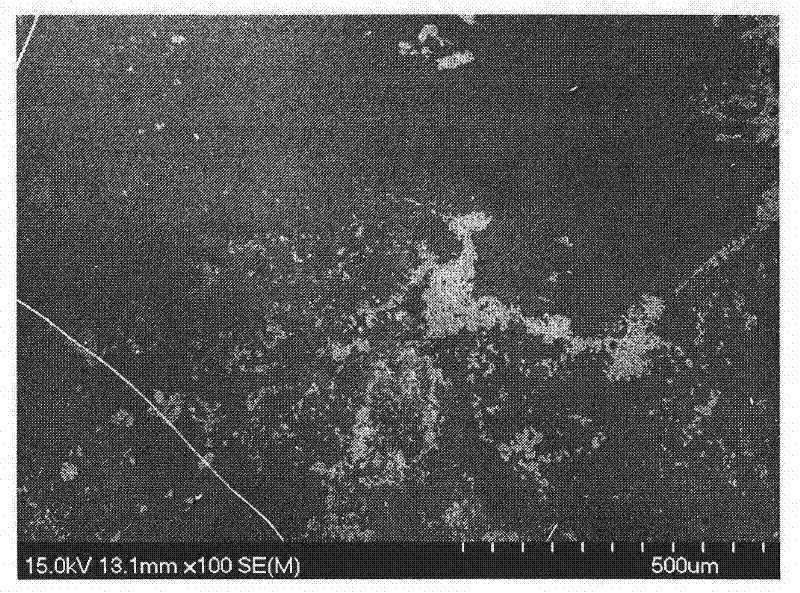

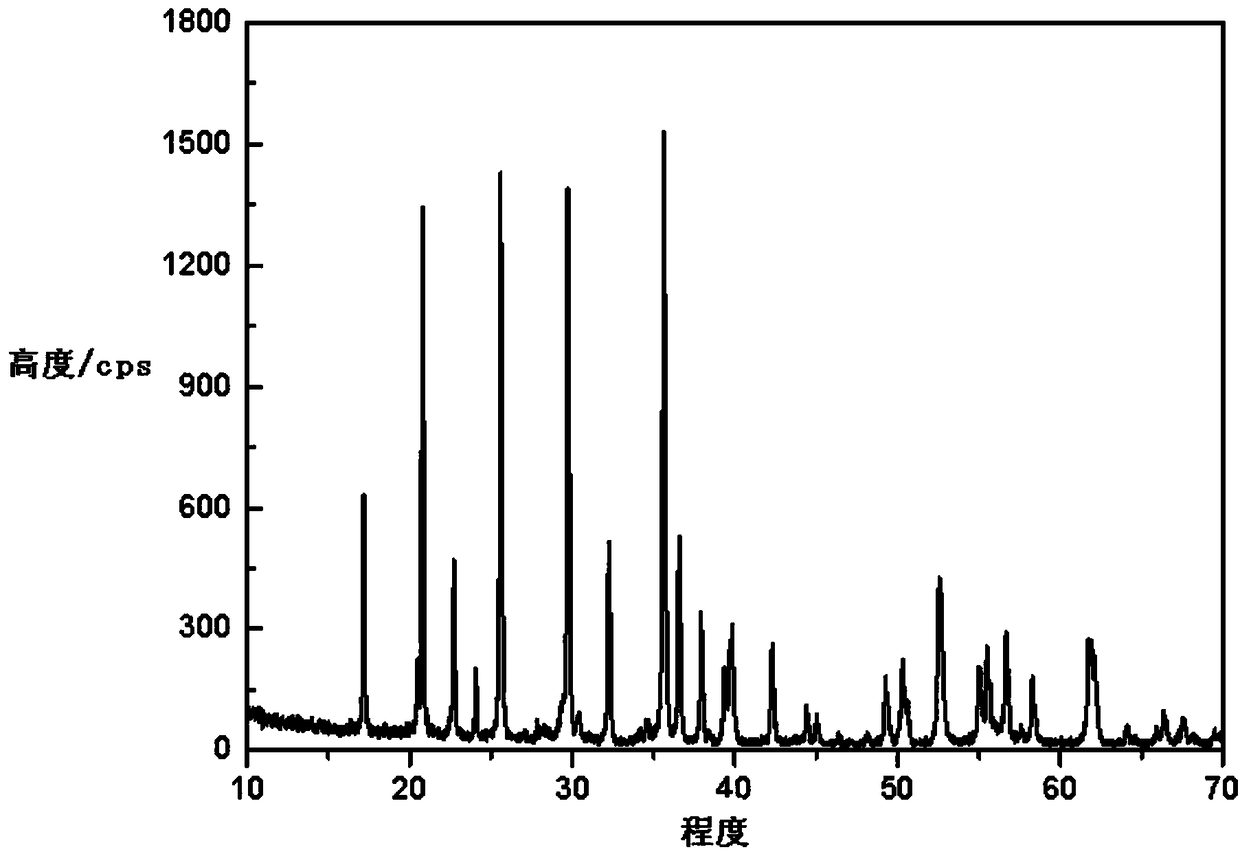

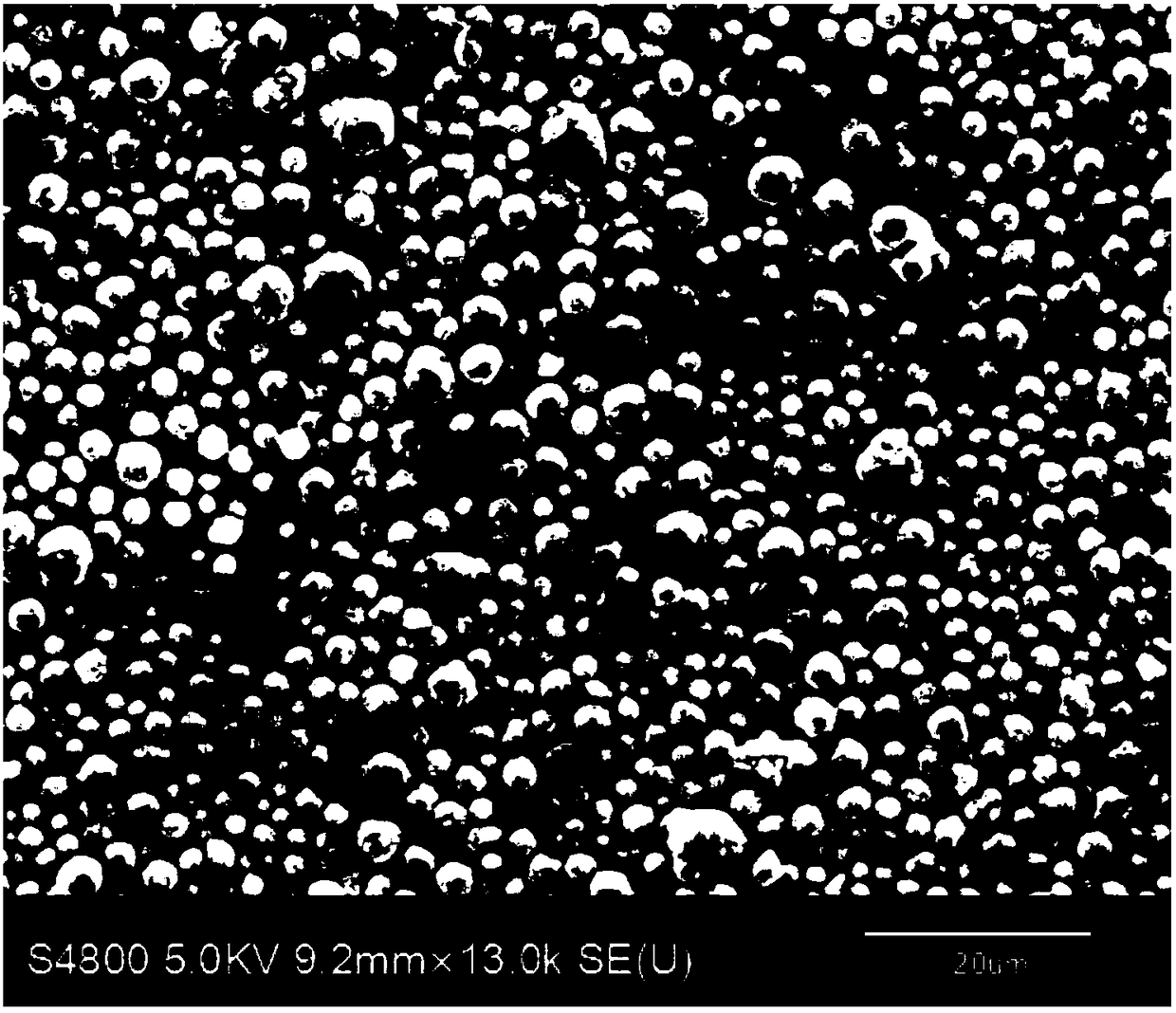

Method for preparing high-temperature resistant silicon carbide

The invention relates to a method for preparing high-temperature resistant silicon carbide. The method is technically characterized by comprising the following steps of: uniformly mixing liquid polycarbosilane and organic metal salt, crosslinking and curing, performing ball-milling, cracking at the temperature of between 900 and 1,100 DEG C, and performing high-heat treatment at the temperature of between 1,600 and 1,850 DEG C to obtain the crystalline silicon carbide containing a trace amount of metal elements. A SiO2 protection membrane which is obtained by performing high-temperature oxidation on the synthesized silicon carbide is SiO2 solid solution containing a trace amount of metal elements. The trace amount of metal elements reduces the activity of SiO2, and increases the conversion temperature of active and passive oxidation of the silicon carbide, so that the use temperature of the silicon carbide is increased. Compared with the prior art, the method has the advantages that: by introducing a trace amount of metal elements into the silicon carbide, the use temperature of the silicon carbide is increased from 1,700 to 1,800-1,850 DEG C, and equipment used by the preparationprocess is simple, safe and reliable, is easy to control and contributes to large-scale production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Warm denim fabric

The invention provides warm denim fabric. The warm denim fabric is formed by weaving warp and weft in a crossed mode; the warp is cotton and tencel blended blend fibers; the weft is wool and polyester blended blend fibers. The warm denim fabric has the advantages of being good in air permeability, high in comfort degree, good in warmth performance and suitable for being worn in spring, autumn and winter.

Owner:TAICANG QIDE GARMENT

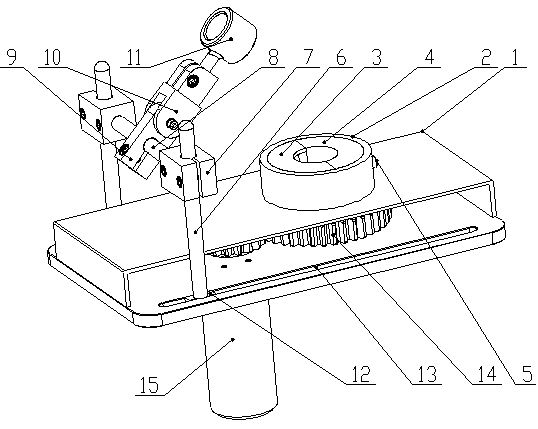

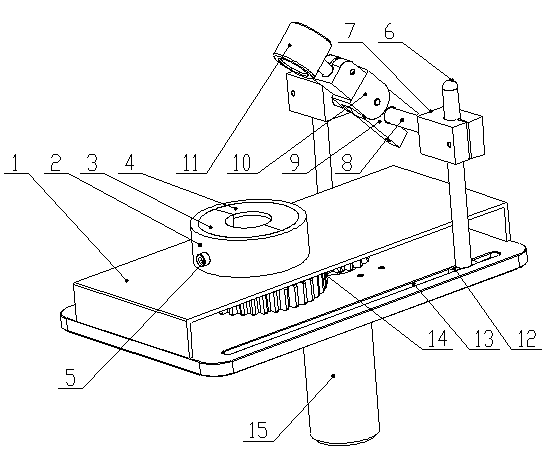

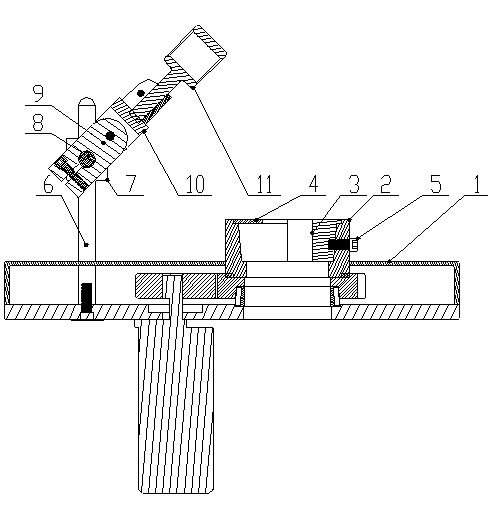

Efficient shape welding machine and using method thereof

InactiveCN103008942AQuick welding jobConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to an efficient shape welding machine and a using method thereof. The efficient shape welding machine comprises a working platform, wherein a rotary barrel is arranged on the working platform; a magnet of which the section is circular-arc-shaped is arranged in the rotary barrel, so that the outer circumferential wall of a welded part is fixed on the inner side arc face of the magnet; and a support frame for fixing a welding gun is arranged beside the rotary barrel. The method comprises the following steps of: I, adsorbing a welded part onto the inner circumferential wall of the magnet to realize fixing of the welded part; II, covering a separation blade for matching the separation blade with the magnet to sleeve the outer circumferential wall of the welded part; III, adjusting relative positions of a vertical rod, a first slide block and a swing stem to make a circular tube reach a corresponding position and position the welding gun erected on the circular tube at a welding position; and IV, starting the welding gun and a driving motor, wherein the driving motor is used for driving the rotary barrel to rotate for driving the welded part to rotate, and the welding gun is used for welding the welded part at the welding position through the driving motor, so that welding work of bent parts can be finished conveniently and rapidly.

Owner:江苏冠赛达工贸有限公司

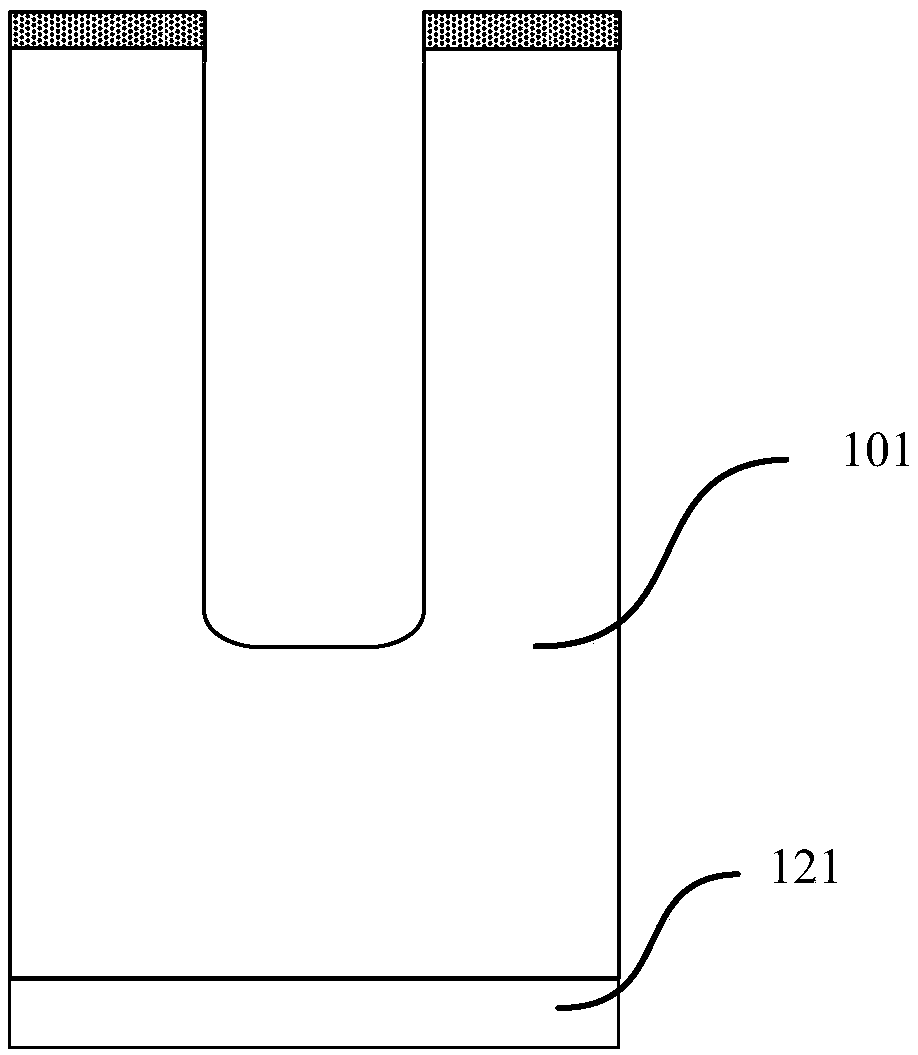

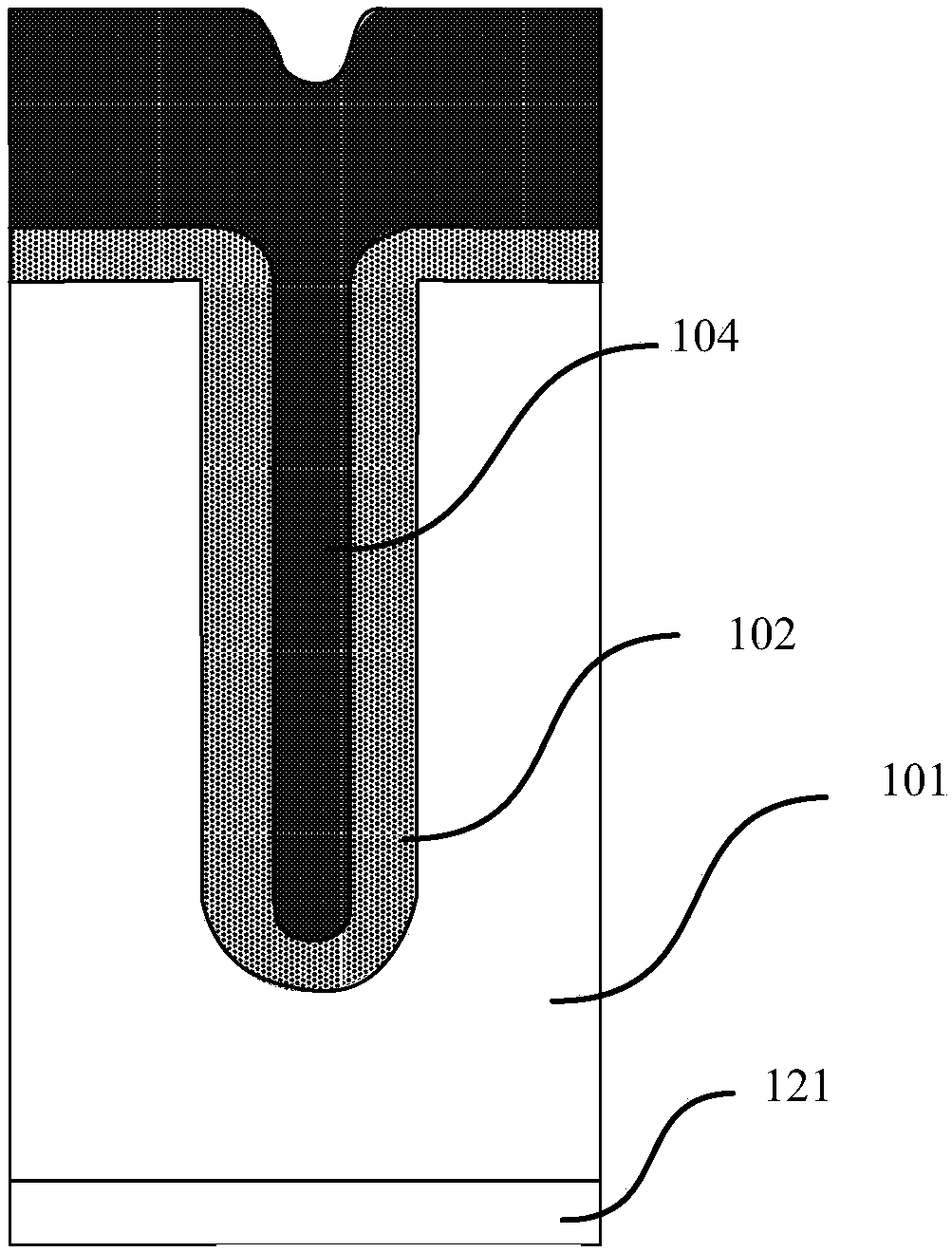

Method for manufacturing trench MOSFET

ActiveCN107871787AThe process steps are simpleIncrease productivitySemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetElectrical conductor

The invention discloses a method for manufacturing a trench MOSFET. The method comprises the steps of forming an epitaxial semiconductor layer on a semiconductor substrate; forming a trench, which extends from the first surface to the interior of the epitaxial semiconductor layer, in the epitaxial semiconductor layer; forming a first insulating layer and a shielding conductor on the lower part ofthe trench; and forming a body region, a source region and a drain electrode, wherein in a step of forming a second insulating layer, the second insulating layer is patterned by a hard mask which at least partially fills the upper part of the trench; and the step of forming the second insulating layer comprises the steps of forming a conformal second insulating layer on the upper part of the trench, wherein the second insulating layer covers the upper part side wall of the trench and the top of the shielding conductor; filling the upper part of the trench with a polysilicon layer; by taking the polysilicon layer as the hard mask, performing etching to remove the part, positioned on the upper part side wall of the trench, of the second insulating layer; and removing the polysilicon layer. The technological steps for forming the trench MOSFET in the prior art are simplified, so that production cost is lowered.

Owner:HANGZHOU SILICON-MAGIC SEMICON TECH CO LTD

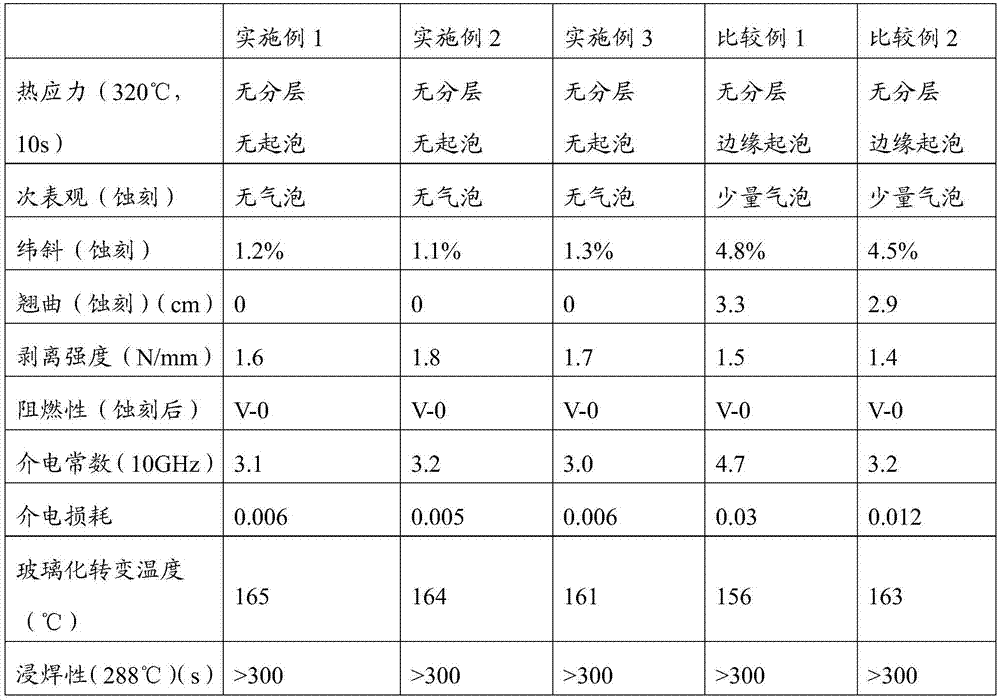

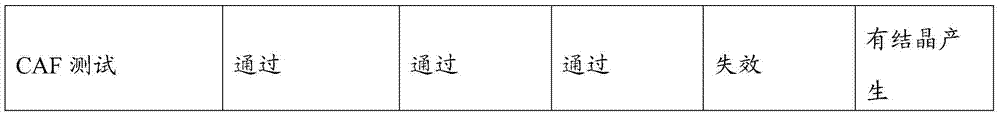

Ultrathin copper clad laminate and production method thereof

ActiveCN105437668ASmall sizeDimensionally stableLamination ancillary operationsSynthetic resin layered productsCross-linkDielectric loss

The invention relates to the technical field of copper clad laminates and particularly relates to an ultrathin copper clad laminate suitable for high-frequency and high-speed transmission. The ultrathin copper clad laminate comprises a copper foil, a piece of setting cloth and an insulating layer which is arranged between the copper foil and the setting cloth, wherein the insulating layer is formed by curing resin glue liquid which comprises the following components in parts by weight: 50-100 parts of first epoxy resin, 0-50 parts of second epoxy resin, 1-35 parts of a cross-linking curing agent, 0-5 parts of a cross-linking curing accelerator and 0-100 parts of filler; the first epoxy resin is dicyclopentadienephenol epoxy resin and / or biphenyl epoxy resin; and the second epoxy resin is bisphenol A epoxy resin and / or AF epoxy resin. According to the invention, by adopting the setting cloth, the defects such as warping and instable size frequently occurring in an ultrathin copper clad laminate are solved; the copper clad laminate is produced by pressing the setting cloth and the copper foil coated with the resin glue liquid and has relatively low dielectric constant and causes relatively low dielectric loss; and the invention also relates to a production method of the ultrathin copper clad laminate.

Owner:GUANGDONG SHENGYI SCI TECH

Water filtration system and its use

InactiveUS20070056890A1Prevent floodingUniformWater cleaningTreatment using aerobic processesWater channelFiltration

The present invention relates to a filtration system for purifying water, in particular aquaculture water. Furthermore, the invention relates to a method of purifying water wherein water is supplied to a filtration system, comprising filtration medium for filtering water and a grid for preventing water channeling within the filter wherein said grid comprises means for allowing passage of said filtration medium through the grid, and a water recirculation system for purifying contaminated water from aquaculture and recirculating purified water to the aquaculture.

Owner:HOLDER TIMMONS ENG

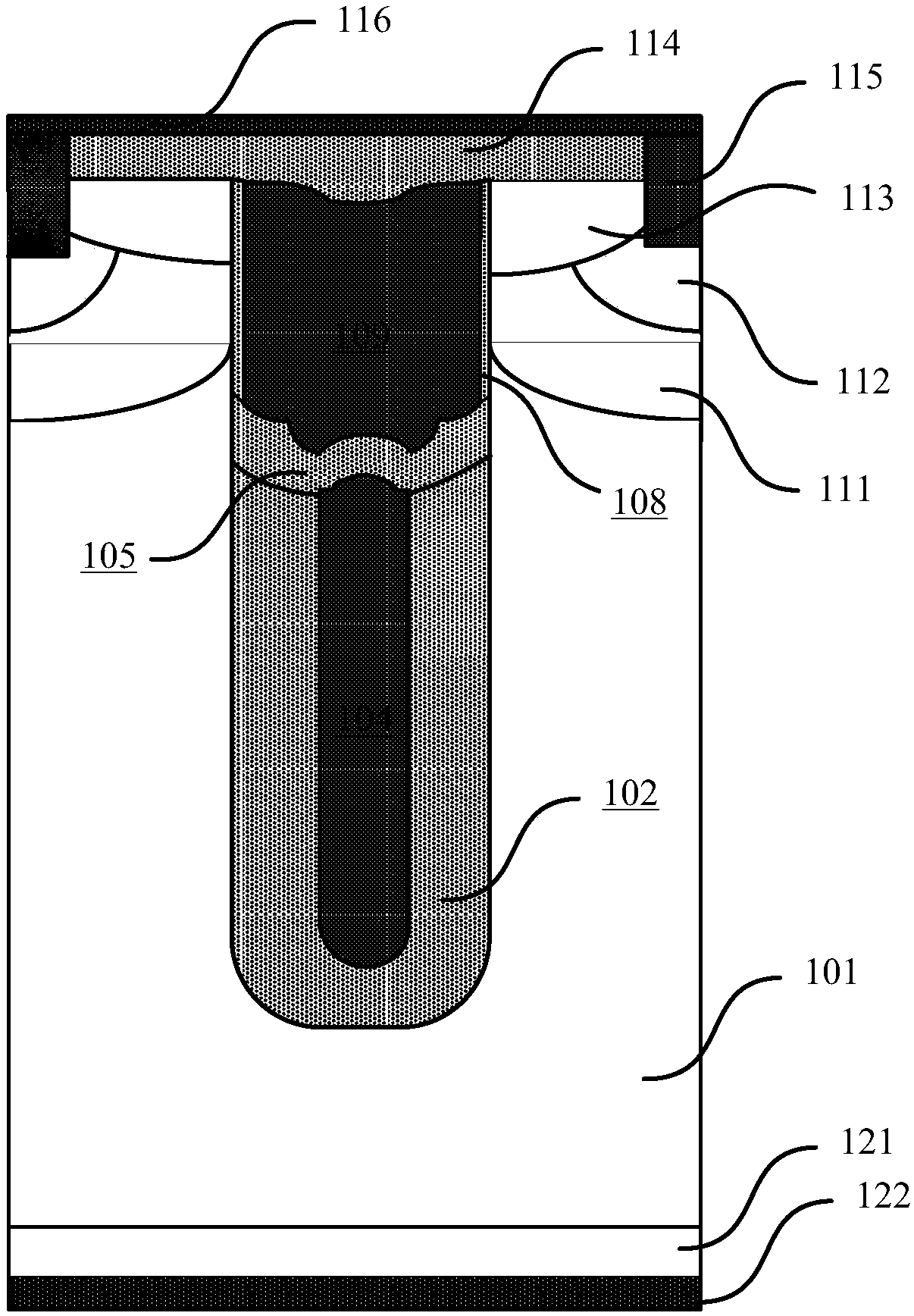

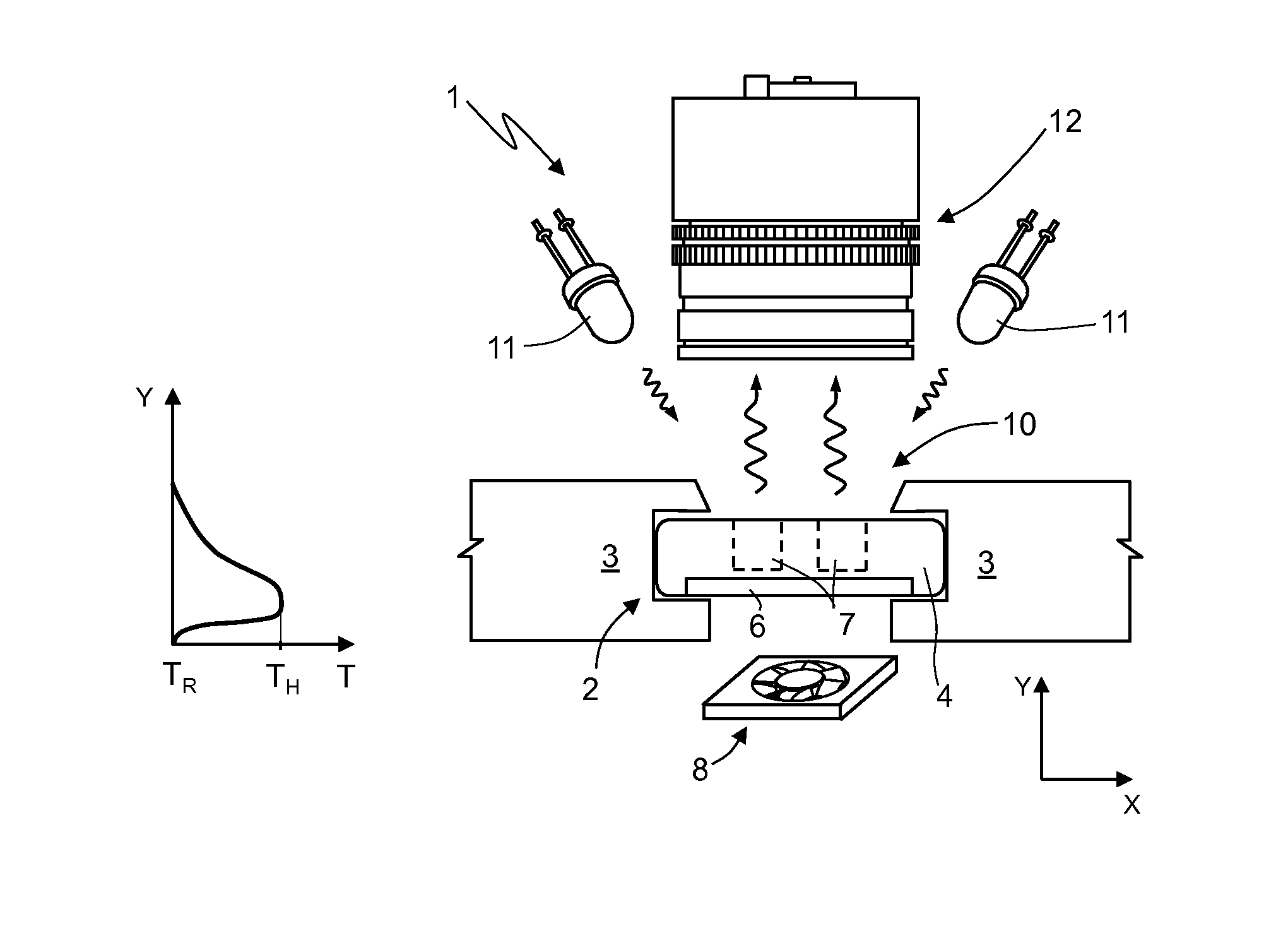

Rt-pcr chip with optical detection

InactiveUS20130102064A1UniformReduce temperature differentialBioreactor/fermenter combinationsHeating or cooling apparatusPhysicsRadiation

An apparatus (100) for performing thermal cycles has a frame (131-134, 137, 147) enclosing a thermal chamber (110) laterally delimited by delimitation walls (103, 154a, 154b) and configured so as to be delimited at the bottom by a reaction holder (104) carrying a plurality of reaction chambers (107) designed to receive chemical reaction substances. A lid (105), of transparent material, is fixed to the frame and delimits the thermal chamber at the top. A source of light radiation (165) is arranged outside the thermal chamber (110) facing the lid (115) and is configured to generate an excitation light radiation. A detector of light radiation (166) is arranged outside the thermal chamber facing the lid and is configured to collect a light radiation emitted in use by the reaction chambers (107). A processor (171) is connected to the detector of light radiation (166) and is configured to detect, in use, a feature of the light radiation emitted.

Owner:STMICROELECTRONICS SRL

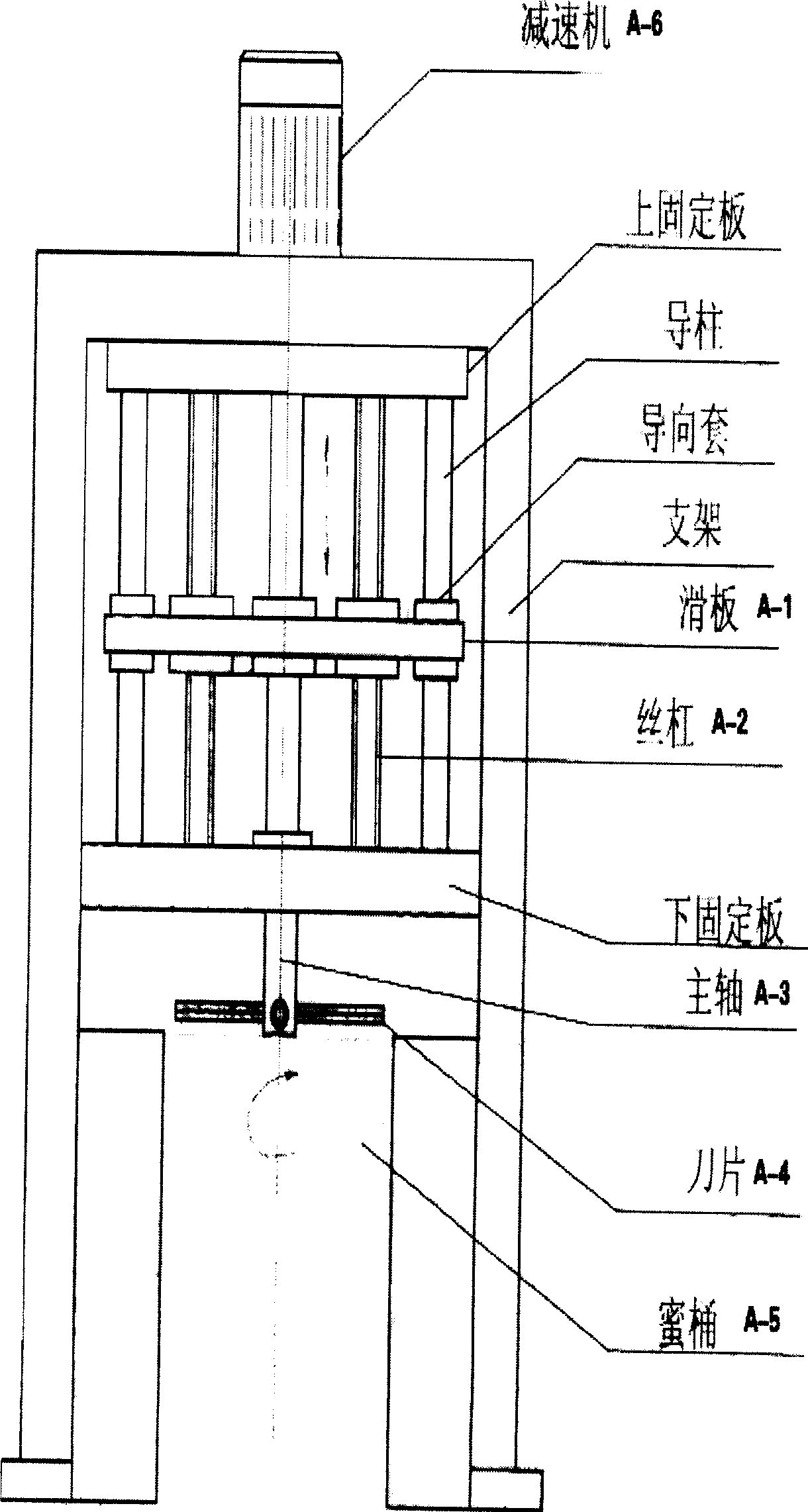

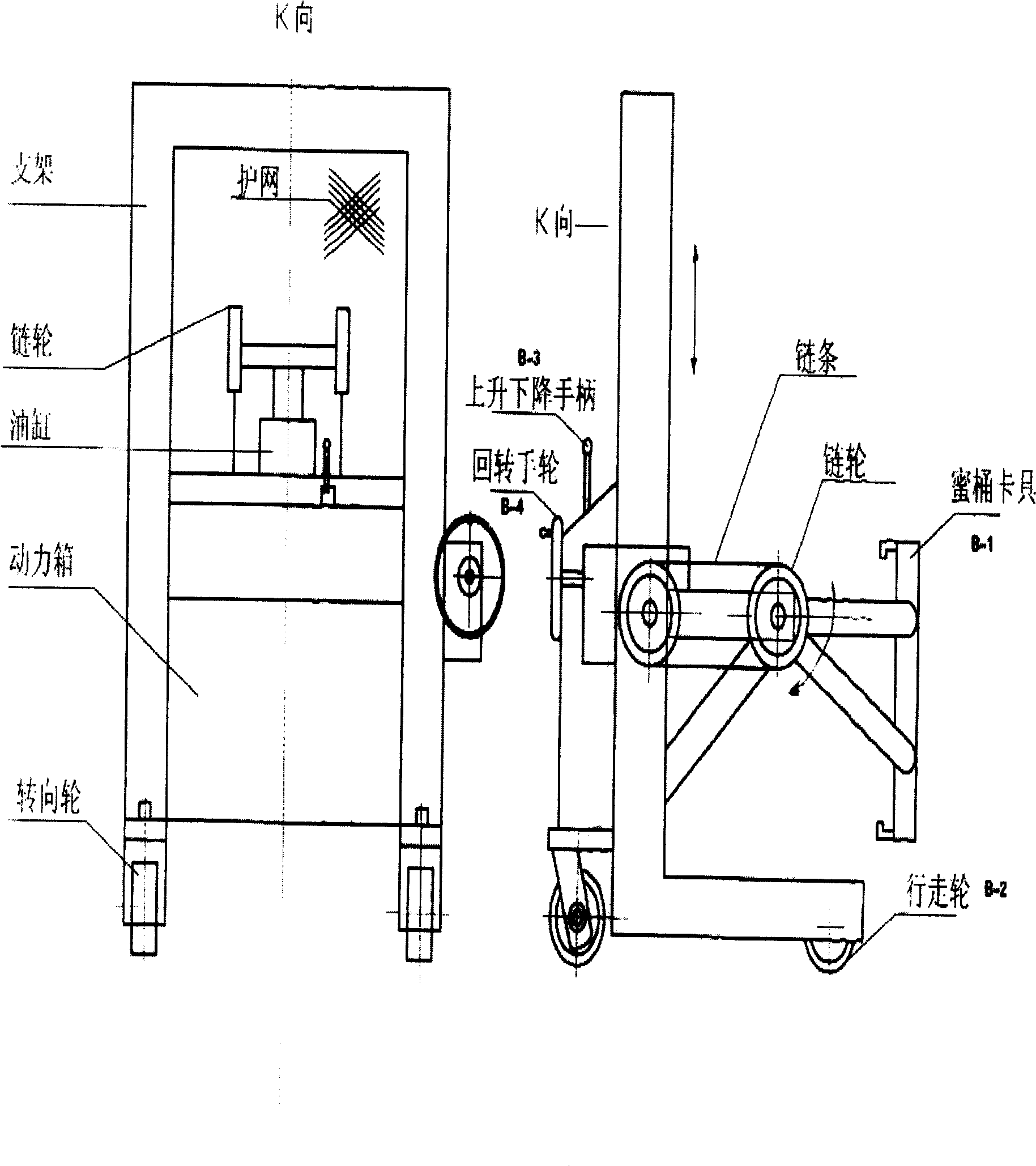

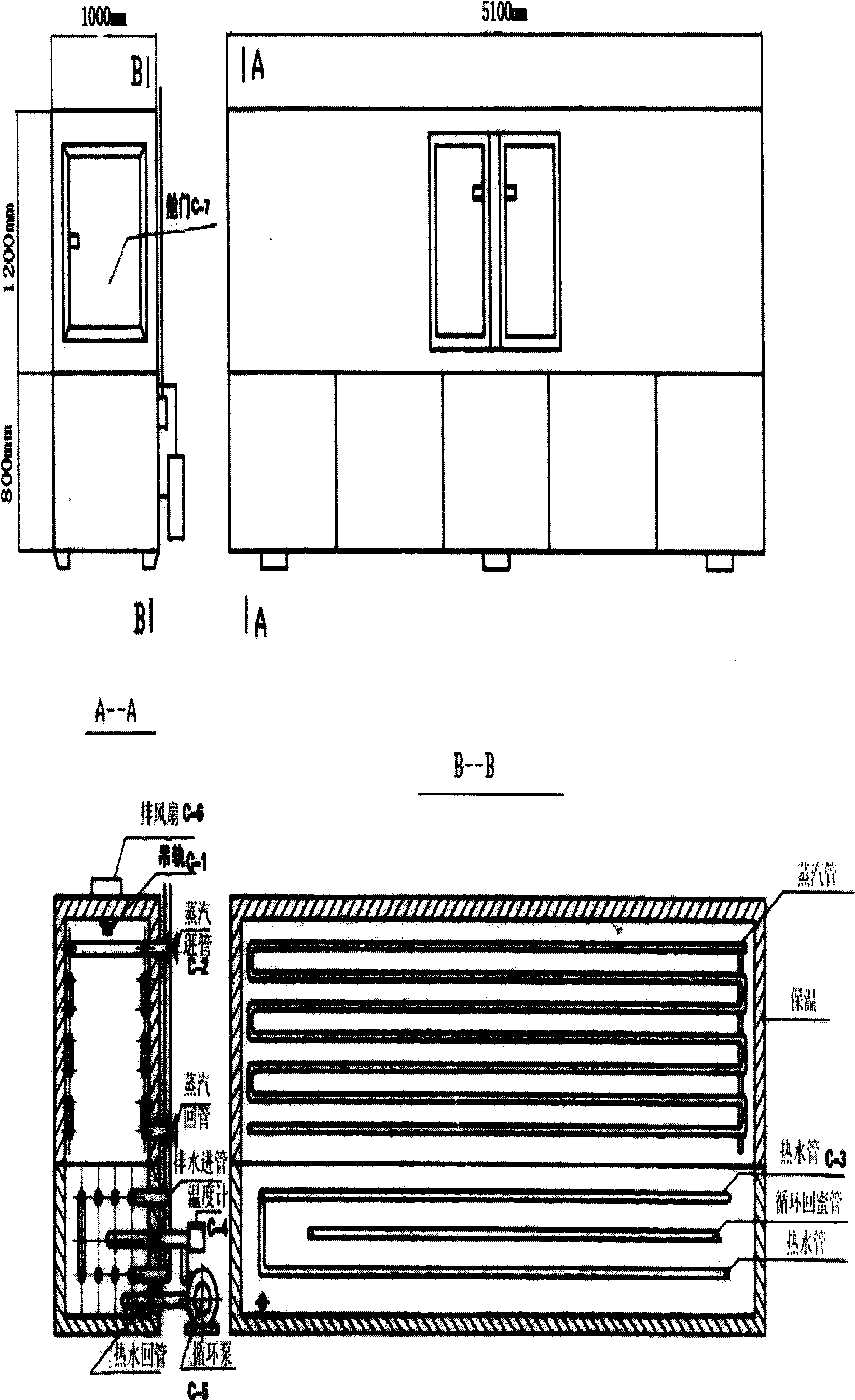

Technique for melting honey with hot air

The invention relates to an improved pretreatment technology in honey production and processing process, which is used for crystallized honey decrystallization and honey pasteurization process. Honey is decrystallized and pasteurized in a water bath heating way in a poor working environment with low production efficiency, easy generation of secondary pollution, unfavorable food security, low energy efficiency, sewage discharge increase and environment pollution. Before being pretreated, honey is heated, repeatedly decrystallized and pasteurized in a closed stainless steel box body so as to have high thermal efficiency, uniformly heated raw materials, easily controlled temperature and high working efficiency, improve the processing environment and accord with the environmental protection. The independently researched and developed equipment has simple structure, is convenient to operate, is safe and sanitary, saves energy resources and has favorable comprehensive benefits for improving the quality of honey products and decreasing the cost.

Owner:北京百花蜂业科技发展有限公司

Method for processing Duyun tippy tea

InactiveCN103798422AStable tasteUniform dehydrationPre-extraction tea treatmentCooling downFood processing

The invention relates to a method for processing Duyun tippy tea, and belongs to the technical field of food processing. The method comprises the following steps: a, spreading fresh leaves for cooling down; b, performing fixation; c, rolling; d, twisting the leaves into pellets; and e, highlighting the vellus. The method has the beneficial effects that the Duyun tippy tea processed by using the method is compact, fine and curly in appearance, uniform and tidy in vellus, green and smooth, yellow green and bright in soup color, uniform and tidy in leaf bottom, and vivid and light green in color.

Owner:DUYUN JIANJIANG TEA

Honey wine fermented with pure honey

The invention discloses a honey wine fermented with pure honey. The method comprises the steps that 1, a pure honey raw material is pretreated, the honey which is approximately colorless or yellowish and pale yellow, pure in aroma and elegant in fragrance is selected, five times of warm water is added and fully stirred, and diluted honey is obtained; 2, the diluted honey is heated to 68 DEG C, the temperature condition is maintained, heating is continuously conducted for 1 hour, and stirring is constantly conducted, the temperature is reduced by natural cooling to normal temperature, filtration is conducted, and honey juice is obtained; 3, dry yeast and water with a mass ratio of 1 to (15-20) are mixed to obtain a yeast solution, the yeast solution is placed in a constant-temperature box of which the temperature is 30 DEG C, activation is conducted for 45 minutes, and activated yeast is obtained; 4, the honey juice and the activated yeast are fermented for 30-45 days under the condition that the temperature is 10-15 DEG C, during the fermentation, density and sugar content are measured daily, and fermented wine is obtained; 5, aging is conducted on the fermented wine, the aging temperature is 18 DEG C, and the aging time is 6 months; 6, aged wine is filtered by a screen of which a filter mesh is 20 mesh or above, then filtration is conducted by diatomite, and the honey wine is obtained.

Owner:青川县川申农特产开发有限公司

Ligh conducting plate

InactiveCN1506699AIncrease lighting brightnessUniformDiffusing elementsNon-linear opticsLight guideLight beam

The light conducting plate is used in guiding the transmission direction of light from light source to raise the brightness and homogeneity of emergent light. The light conducting plate includes incident plane for accepting light beam, emergent plane for guiding light beam and bottom plane opposite to the emergent plane, and the incident plane and the emergent plane intersect. The bottom plane has several distributed lugs to constitute curved surface in special shape and the curved surface can converge the light beams the lugs scatter to raise the emergent light brightness of the light conducting plate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

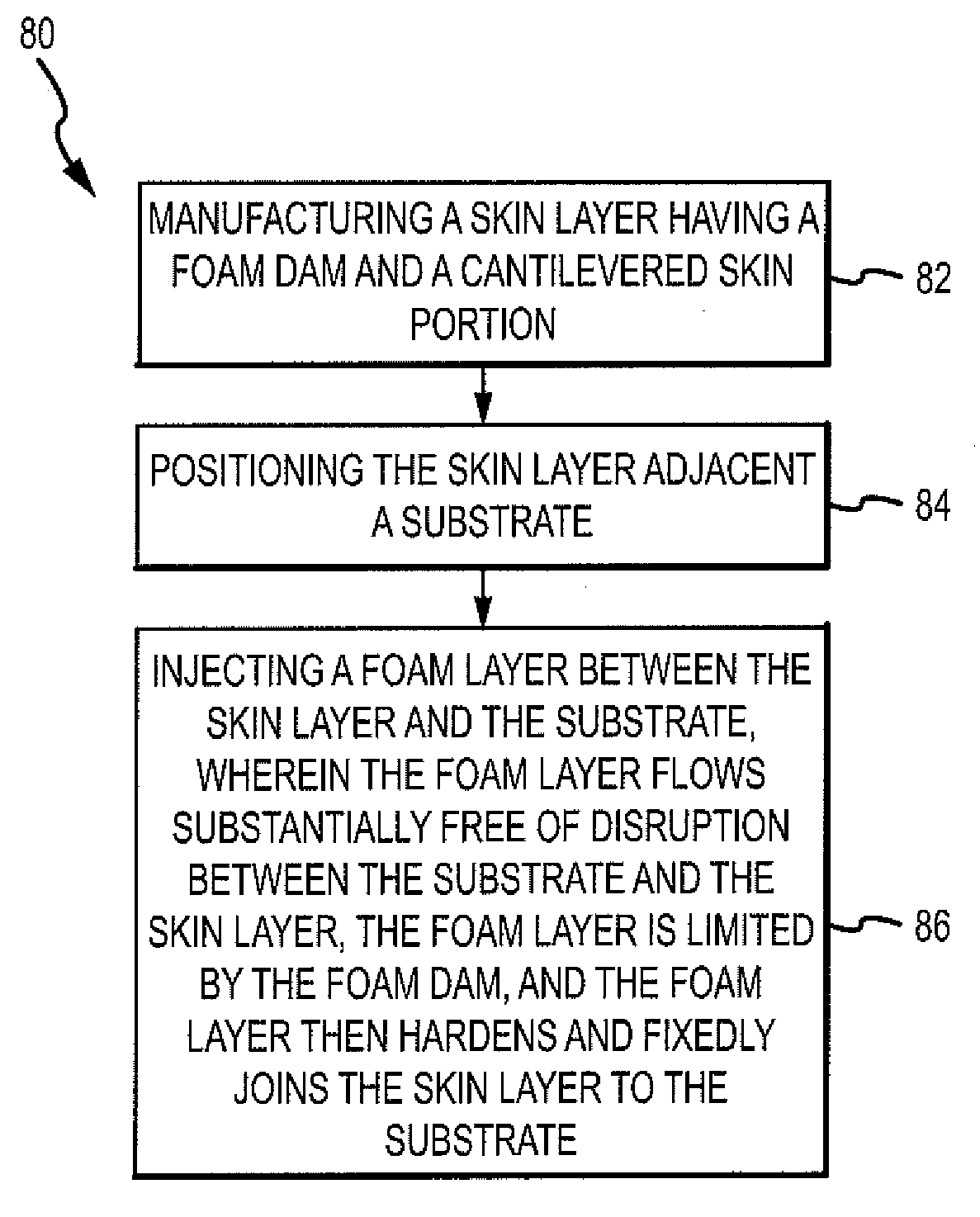

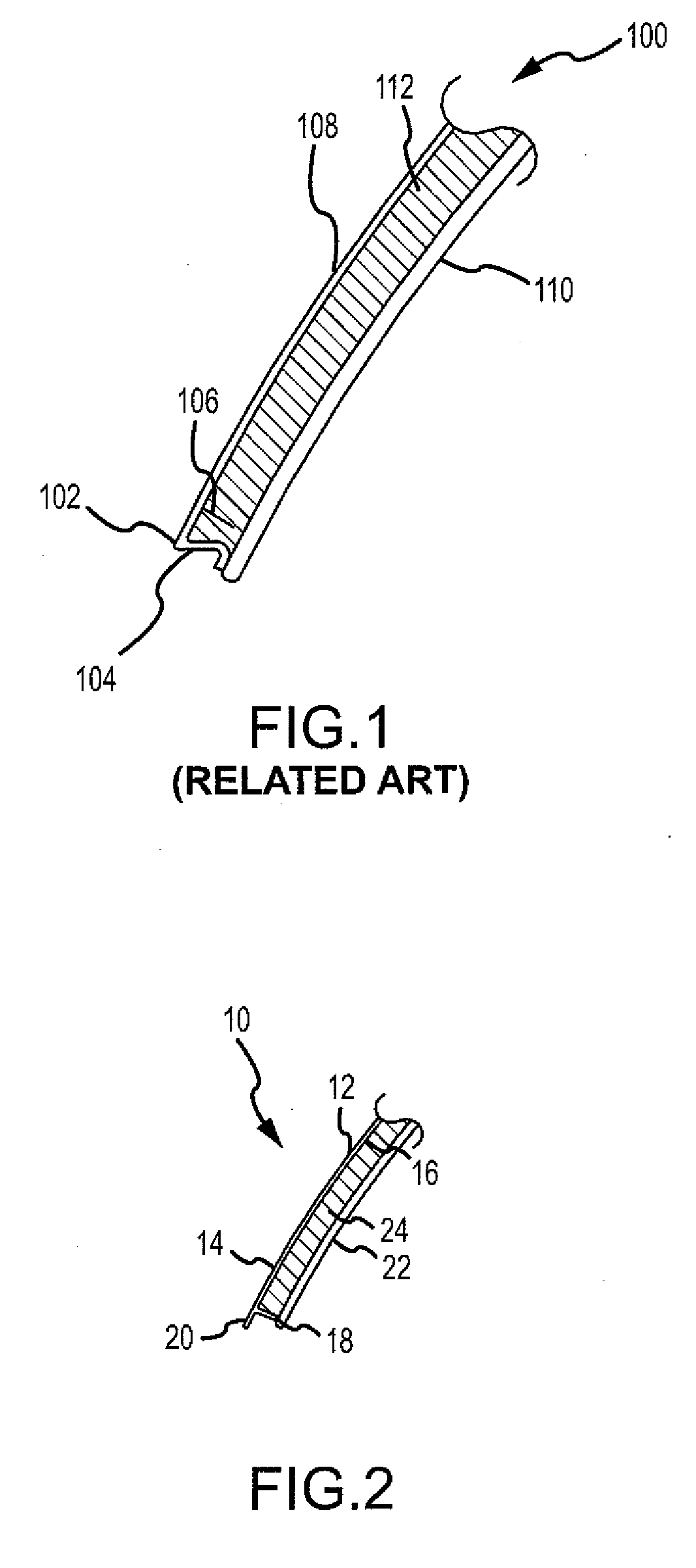

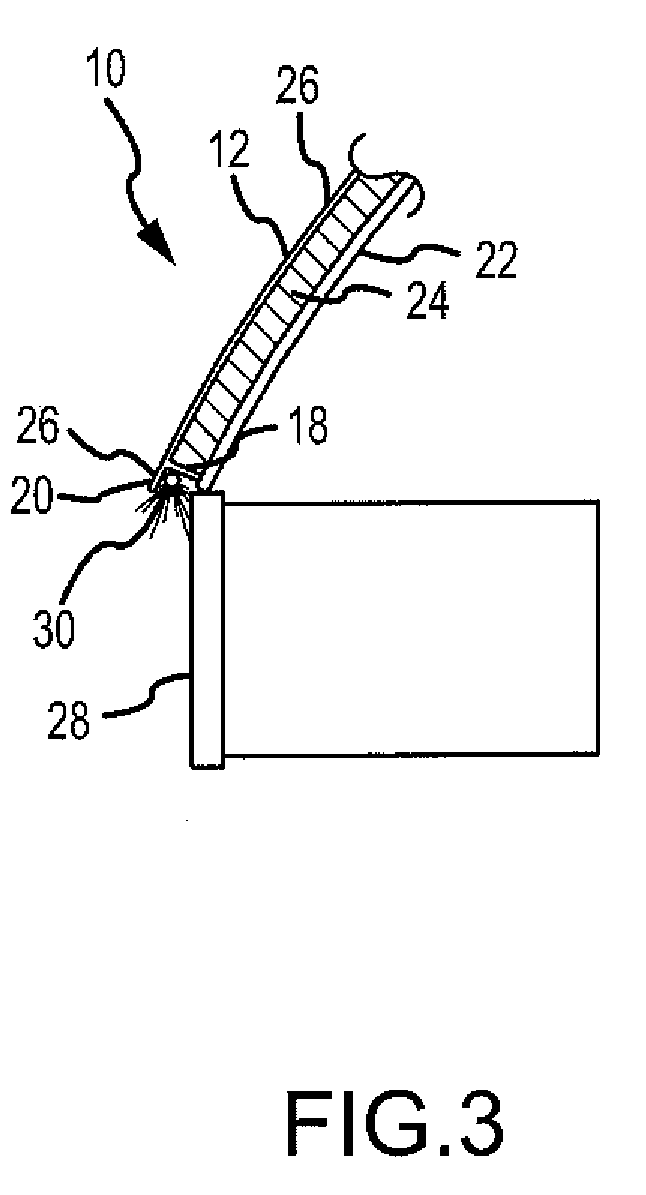

Automotive interior component with cantilevered skin portion and method of making the same

InactiveUS20090246505A1UniformHigh trafficSynthetic resin layered productsDashboard lighting devicesEngineeringTissue skin

The invention provides for a multi-layer automotive interior component and method of making the same. The multi-layer automotive interior component comprises a skin layer having an exterior portion and an underside portion, where the exterior portion is visible. The multi-layer automotive interior component further comprises a foam dam formed on the underside portion of the skin layer, a cantilevered skin portion extending from the foam dam, a substrate disposed opposite the underside portion of the skin layer, and a foam layer between the substrate and the underside portion of the skin layer. The foam layer is limited by the foam dam, and the foam layer is substantially uniform.

Owner:INTERTEC SYST

Making method of pomegranate tea product

The invention relates to the field of preparation of tea and aims to provide a making method of a pomegranate tea product with beautiful appearance and excellent taste by the utilization of mature leaves of young pomegranate shoots and Congou black tea. The making method of the pomegranate tea product comprises the following steps: picking mature leaves of young pomegranate shoots, withering, rolling, fermenting, and drying to obtain pomegranate Congou black tea; and blending the obtained pomegranate Congou black tea and Congou black tea according to a certain mass ratio so as to obtain different pomegranate tea products. The prepared pomegranate tea product belongs to a completely fermented tea type, and the defect of astringent taste due to high polyphenol content of pomegranate leaf tea is solved. The prepared pomegranate tea product is moist in appearance, is tightly tired and uniform, has sweet and mellow smell, is yellowish red and bright, has strong and refreshing taste, and has uniform red and yellow bright color at the leaf bottom. As the main raw material is the mature leaves of young pomegranate shoots, utilization efficiency of the pomegranate leaf resource can be remarkably raised, and wastes can be changed into valuable things.

Owner:四川会理恒格茶叶有限公司

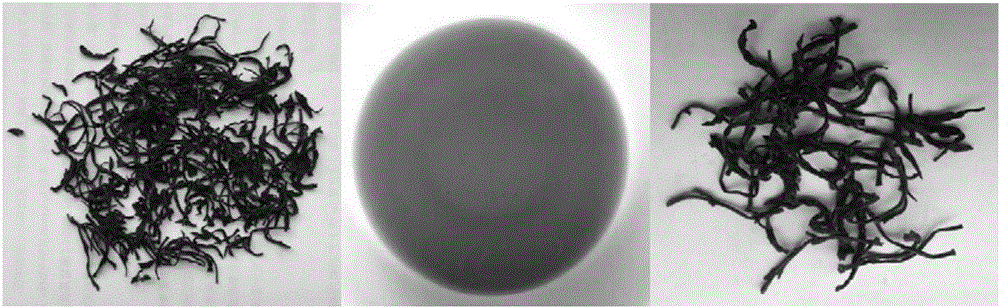

Lubricating grease and preparation method thereof

The invention discloses lubricating grease and a preparation method thereof, and belongs to the technical field of lubricating grease and preparation thereof. The lubricating grease consists of the following raw materials: 95-99 parts of basic lubricating grease and 1-5 parts of additives. The additives are ZIF-71 materials with RHO topological structures. The preparation method of the lubricating grease is simple, convenient and practical, and the performance of the lubricating grease is stable. By the lubricating grease, surfaces of friction pairs can be prevented from being in contact with each other directly, friction is reduced, and the extreme pressure resistance of the lubricating grease is improved.

Owner:TAIYUAN UNIV OF TECH

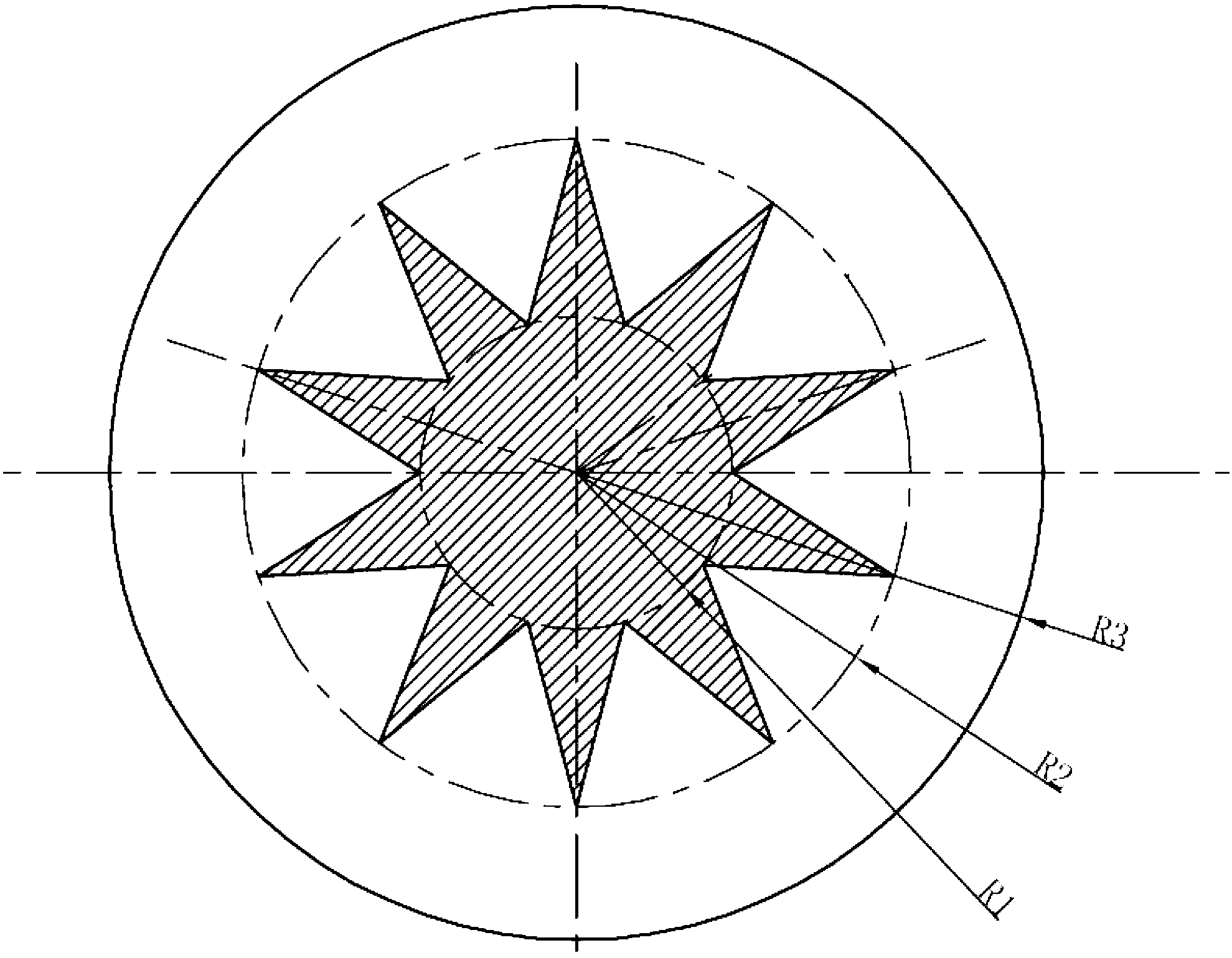

Skin-core structure light-reflecting composite fiber and preparation method thereof

InactiveCN103215675AReduce usageAchieve reflective effectFilament/thread formingConjugated synthetic polymer artificial filamentsRefractive indexFire safety

The invention relates to a skin-core structure light-reflecting composite fiber and a preparation method thereof, in particular to a two-component skin-core structure light-reflecting composite fiber with different refractive indexes and the preparation method thereof. The skin-core structure two-component composite fiber with light-reflecting effect is prepared by utilizing composite spinning technology. The shape of a skin layer in the cross section of the light-reflecting composite fiber is round. A core layer is of a regular polygon star shape. A skin-layer fiber makes close contact with a core-layer fiber. The light-reflecting composite fiber has the advantages of being strong in light-reflecting property, simple in process, low in cost, good in durability, and smooth in mechanical property and the like. After being knitted, the fiber is suitable for safety warning of traffic coordination, fire safety, salvage, down-mine operation and the like, has the advantages of being attractive, safe and the like, and is wide in market application prospect.

Owner:DONGHUA UNIV

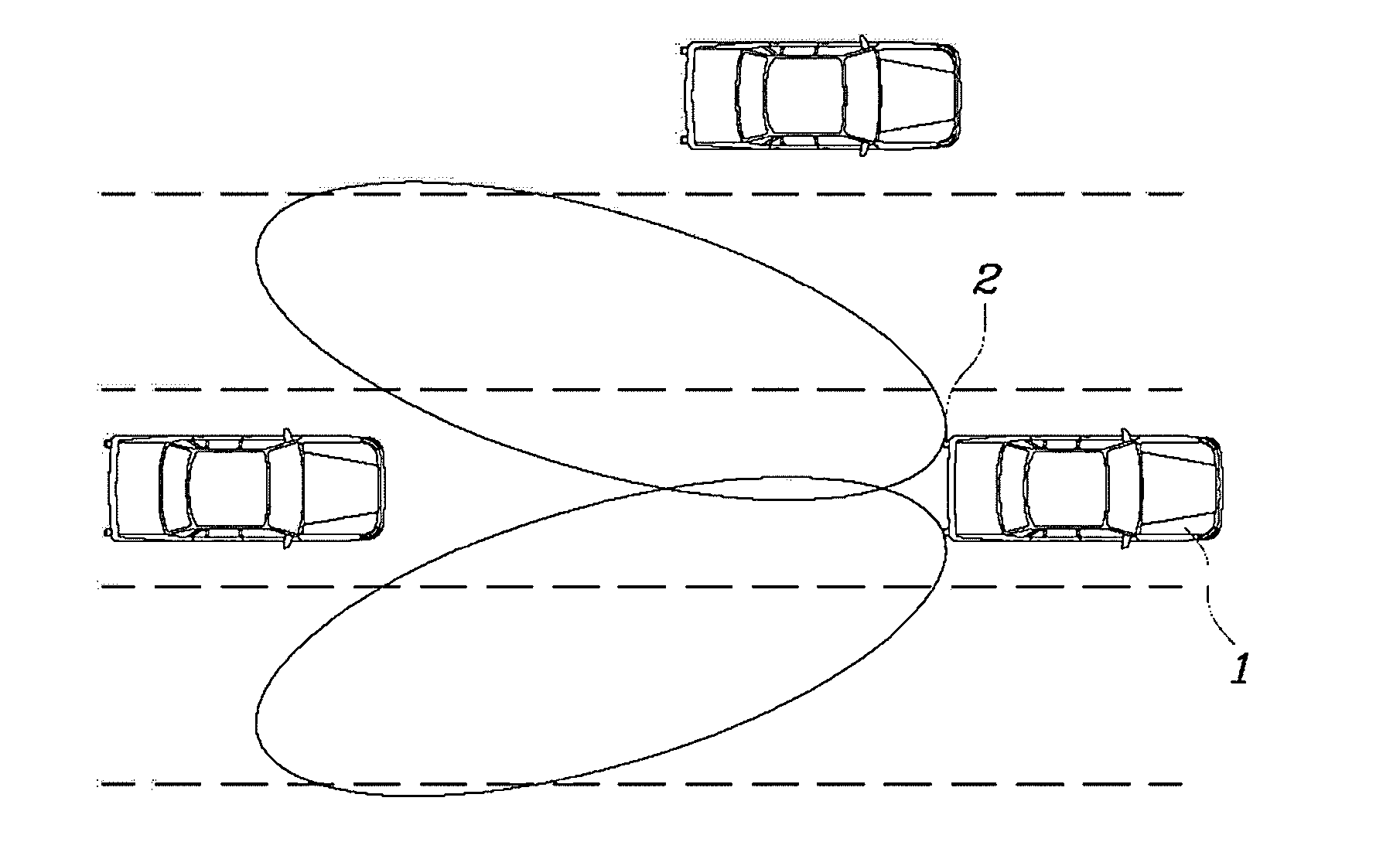

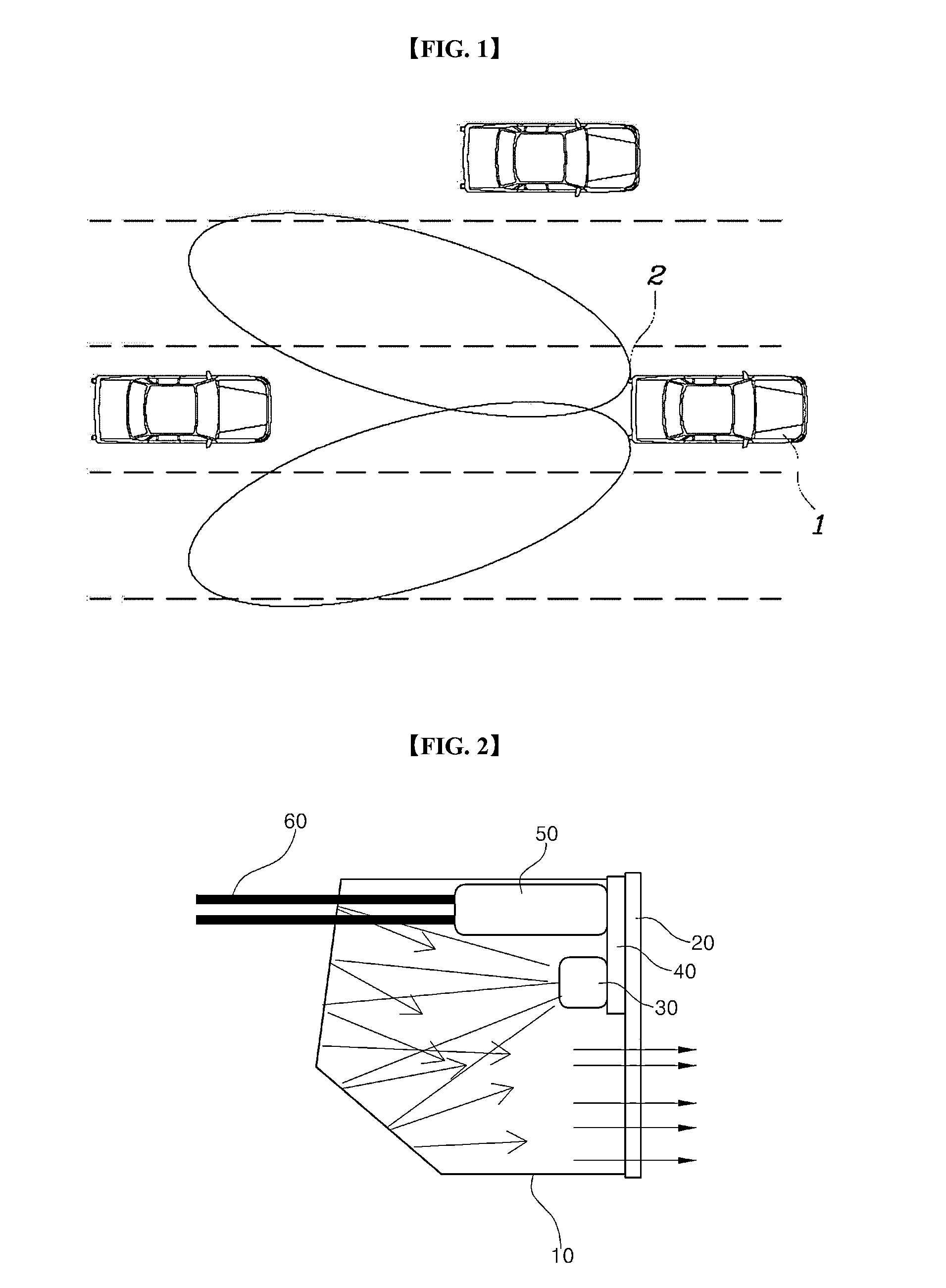

Blind spot detection module

ActiveUS20150329047A1Maximize light efficiencyHigh light efficiencyOptical signallingRoad vehiclesLight guideComputer module

Provided is a blind spot detection module, including: a light source module linked with a sensor signal for detection of an object in an area behind a vehicle to emit light; and a reflector module including a warning optical pattern for transmitting light emitted from the light source module, wherein the light source module comprises a light guide member adopted to receive a light emitting element and to guide light to the reflector module.

Owner:LG INNOTEK CO LTD

Secondary fermentation process of blueberry fruit wine

ActiveCN107304395AReduce higher alcohol contentImprove typicalityAlcoholic beverage preparationMicroorganism based processesFruit wineBiotechnology

The invention relates to a secondary fermentation process of blueberry fruit wine. The secondary fermentation process comprises the following steps: raw material sorting, crushing, and pulping; enzymolysis; juice squeezing; freezing concentration; ice yeast main fermentation and fruit wine yeast secondary fermentation; pot pouring, clarification and filtration; ageing; sterilization, cooling and filtration; and storage, filtration and encapsulation. By utilizing a ice yeast main fermentation-fruit wine yeast secondary fermentation technique, the concentration of a dry extract of the blueberry fruit wine is increased, the generation amount of grain oil in a fermentation process is reduced, and the typicality of the finished wine is improved.

Owner:天津市农业科学院

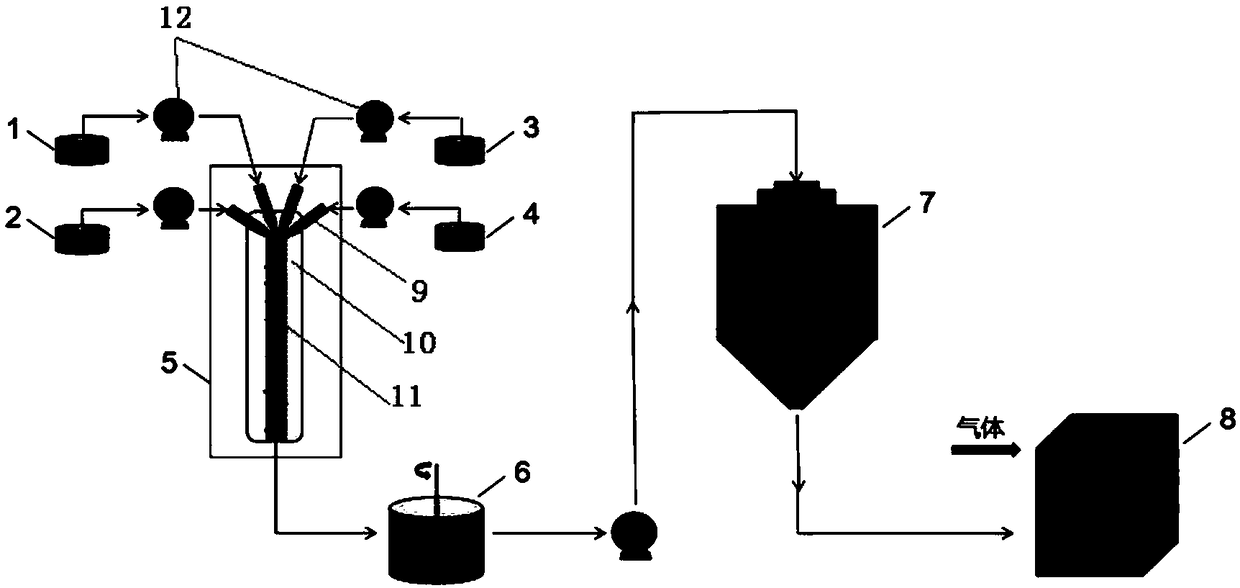

Energy-saving and environment-friendly device for preparing lithium iron phosphate and preparation method

PendingCN108408710AGood for collision mixingAdequate responseChemical industryPhosphorus compoundsContinuous reactorLithium iron phosphate

The invention discloses an energy-saving and environment-friendly device for preparing lithium iron phosphate. The device comprises a tubular continuous reactor, an ultrasonic stirring tank, a spray drying tower and an atmosphere sintering furnace, wherein the ultrasonic stirring tank is communicated with the feeding pipeline of the spray drying tower through a material delivery pipeline, the discharge hole of the tubular continuous reactor is communicated with the feeding pipeline of the ultrasonic stirring tank through a discharge pipeline, and the tubular continuous reactor is provided withat least two feeding holes. The invention also discloses a method for preparing lithium iron phosphate by adopting the device. The whole preparation technology only comprises dissolution, mixed reaction, spray drying and calcination processes, so that the method has the advantages of short processes, simple operation and high controllability. The product discharged from the tubular continuous reactor does not need to be washed and filtered and directly enters the spray drying tower to be dried and granulated, so that the shape size of the material is controllable, the preparation process is further continuous, and the material has better uniformity and stability.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Loquat tea and preparation method thereof

The invention discloses loquat tea and a preparation method thereof and belongs to the technical field of teas. The loquat tea is mainly prepared from the following raw materials in parts by weight: 60-90 parts of loquat leaves, 3-15 parts of loquat flowers, 2-6 parts of honeysuckle, 1-5 parts of Chinese angelica, 2-7 parts of lily, 1-3 parts of radix bupleuri, 1-3 parts of liquorice, 1-2 parts of lotus leaves and 1-4 parts of salviae miltiorrhizae. The loquat tea has the advantages that active ingredients supplement each other and have positive synergistic effect, so that efficacy of the loquat tea is enhanced on the basis of the original lung heat cleaning function; the loquat tea has no side effect, has the curative effects of moistening five internal organs, benefiting lung qi as well as clearing away heat and nourishing nerves, has tonifying effect on human body and is beneficial to improving immunity of the human body and regulating sub health. The loquat tea is obtained by virtue of working procedures such as fermenting, frying and perfuming, so that ingredients of all the raw materials are fully fused, loss of nutrient substances of the raw materials cannot be caused, and the obtained loquat tea is excellent in colour, fragrance and taste.

Owner:贵州省兴仁县佳文生态农业开发有限公司

Linear electrical machine/generator with segmented stator for free piston engine generator

ActiveUS10072567B2Improve efficiencyEfficient Power ConversionMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsFree-piston engineCombustion

A linear electrical machine comprising a movable piston, an axially segmented cylinder having least one magnetically permeable segment and a bore configured to allow the piston to move within the cylinder, a cylinder housing having a bore for receiving the segmented cylinder, and means for securing the segmented cylinder in place within the cylinder housing. This arrangement permits the construction of it free piston engine linear with improved piston position control, more consistent combustion and improved electrical conversion efficiency.

Owner:LIBERTINE FPE

Marinating method of black chicken eggs

The invention provides a marinating method of black chicken eggs. The method comprises the following steps of a marinating seasoning making process and a marinating process, through the adoption of the method, the marinated black chicken eggs are moistening and bright in oil, magenta in color, moderate in soft and hard degrees, uniform in saline and tasteless degrees, fresh, fragrant and palatable, easy to preserve, and convenient to eat and carry. In the marinating process, some traditional Chinese medicine materials are added, so that the medical value of the black chicken eggs is increased, and eaters can preserve the health after eating the eggs.

Owner:旌德县庙首镇再军家庭农场

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com